Modified graphene oxide/hyperbranched polymer composite film as well as preparation method and application thereof

A technology of hyperbranched polymer and oxide stone, applied in the field of membrane separation, can solve the problem of less membrane separation process, and achieve the effects of improving compatibility, improving film-forming efficiency, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

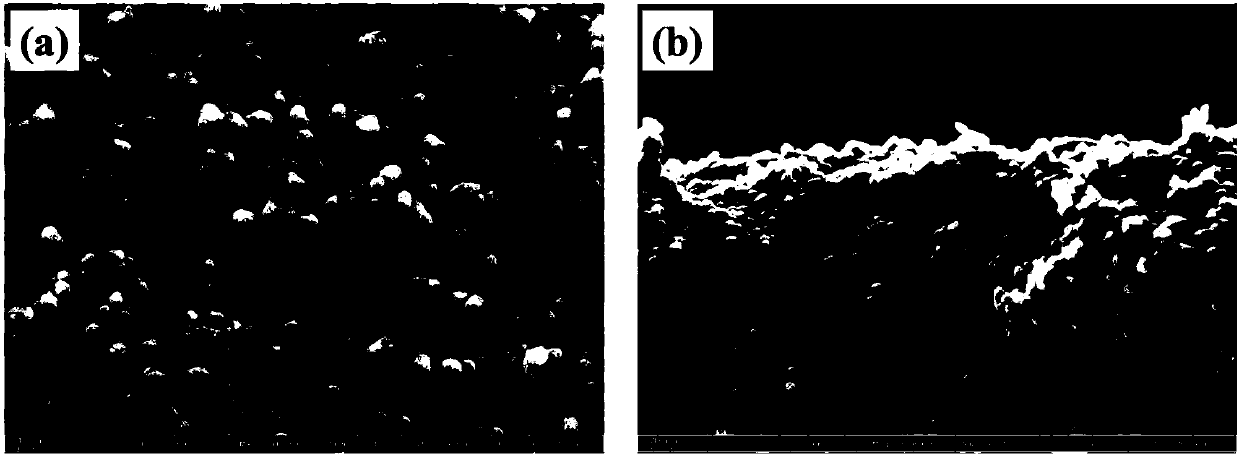

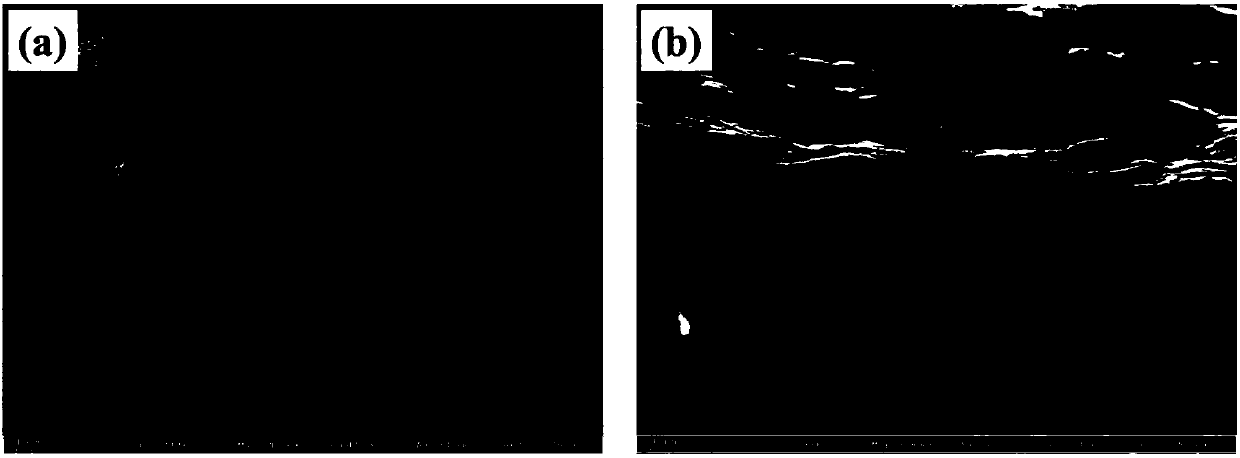

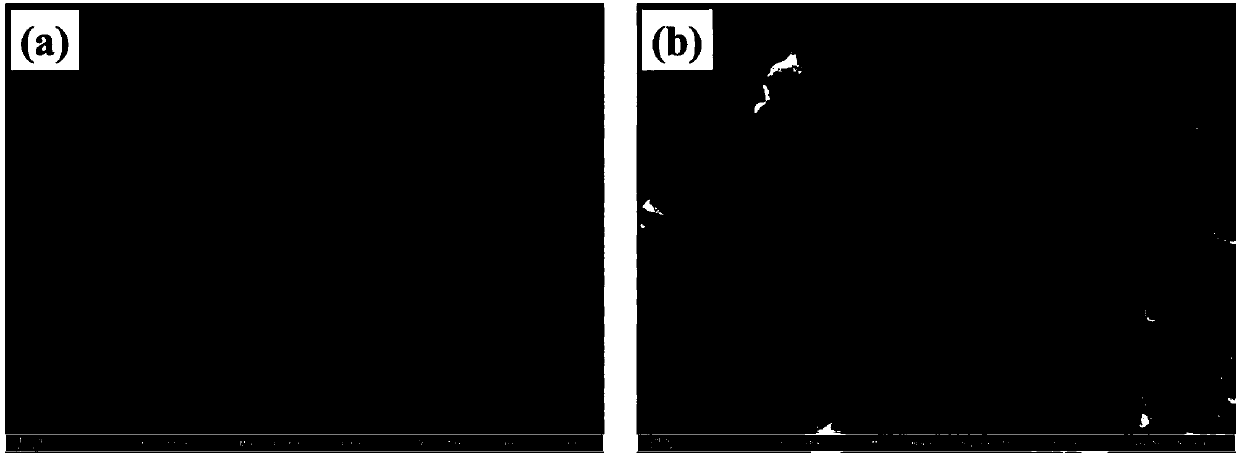

Image

Examples

Embodiment 1

[0028] The specific method for the preparation of hyperbranched polymer modified graphene oxide composite membrane is as follows:

[0029] (1) Take 30 mg of graphene oxide powder, add 30 mL of deionized water, and ultrasonically obtain a 1 mg / mL graphene oxide dispersion that is stably dispersed for 4 hours, take 1 mL of the dispersion and add deionized water to dilute to 30 mL;

[0030] (2) Add 2.584g 1-(2-aminoethyl)piperazine to the dispersion prepared in step (1), and stir at 30°C for 24 hours;

[0031] (3) Add 3.083g of N,N-methylenebisacrylamide to the reaction system in step (2), and continue stirring at a constant temperature of 30°C for 48 hours to obtain hyperbranched polymer / hyperbranched polymer modified graphene oxide The mixed solution, diluted to 500mL, wherein the concentration of graphene oxide is 2mg / mL;

[0032] (4) Pretreatment of the inorganic tubular membrane: immerse the inorganic membrane in 0.8wt% 3-amino-triethoxysilane ethanol solution for 2 hours, ...

Embodiment 2

[0038] The specific method for the preparation of hyperbranched polymer modified graphene oxide composite membrane is as follows:

[0039] (1) Take 30 mg of graphene oxide powder, add 30 mL of deionized water, and ultrasonically obtain a 1 mg / mL graphene oxide dispersion that is stably dispersed for 4 hours, take 10 mL of the dispersion and add deionized water to dilute to 30 mL;

[0040] (2) Add 2.584g 1-(2-aminoethyl)piperazine to the dispersion prepared in step (1), and stir at 30°C for 24 hours;

[0041] (3) Add 3.083g of N,N-methylenebisacrylamide to the reaction system in step (2), and continue stirring at a constant temperature of 30°C for 48 hours to obtain hyperbranched polymer / hyperbranched polymer modified graphene oxide The mixed solution, diluted to 500mL, wherein the concentration of graphene oxide is 20mg / mL;

[0042](4) Pretreatment of the inorganic tubular membrane: immerse the inorganic membrane in 0.8wt% 3-amino-triethoxysilane ethanol solution for 2 hours,...

Embodiment 3

[0048] The specific method for the preparation of hyperbranched polymer modified graphene oxide composite membrane is as follows:

[0049] (1) Take 30 mg of graphene oxide powder, add 30 mL of deionized water, and ultrasonically obtain a 1 mg / mL graphene oxide dispersion that is stably dispersed for 4 hours, take 1 mL of the dispersion and add deionized water to dilute to 30 mL;

[0050] (2) Add 2.584g 1-(2-aminoethyl)piperazine to the dispersion prepared in step (1), and stir at 30°C for 24 hours;

[0051] (3) Add 3.083g of N,N-methylenebisacrylamide to the reaction system in step (2), and continue stirring at a constant temperature of 30°C for 60 hours to obtain hyperbranched polymer / hyperbranched polymer modified graphene oxide The mixed solution, diluted to 500mL, wherein the concentration of graphene oxide is 2mg / mL;

[0052] (4) Pretreatment of the inorganic tubular membrane: immerse the inorganic membrane in 0.8wt% 3-amino-triethoxysilane ethanol solution for 2 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com