Segmented copolymer with fully-saturated soft segment and crystallizable hard segment and preparation method of segmented copolymer

A technology of block copolymer and soft segment, applied in the field of block copolymer and its preparation, can solve the problems of limiting the application range and field of TPE, the destruction of physical cross-linking points, the limited range of Tg increase, etc., and achieve dimensional stability of the material. Improve the physical and mechanical properties, stabilize the physical cross-linking point, and simplify the process and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

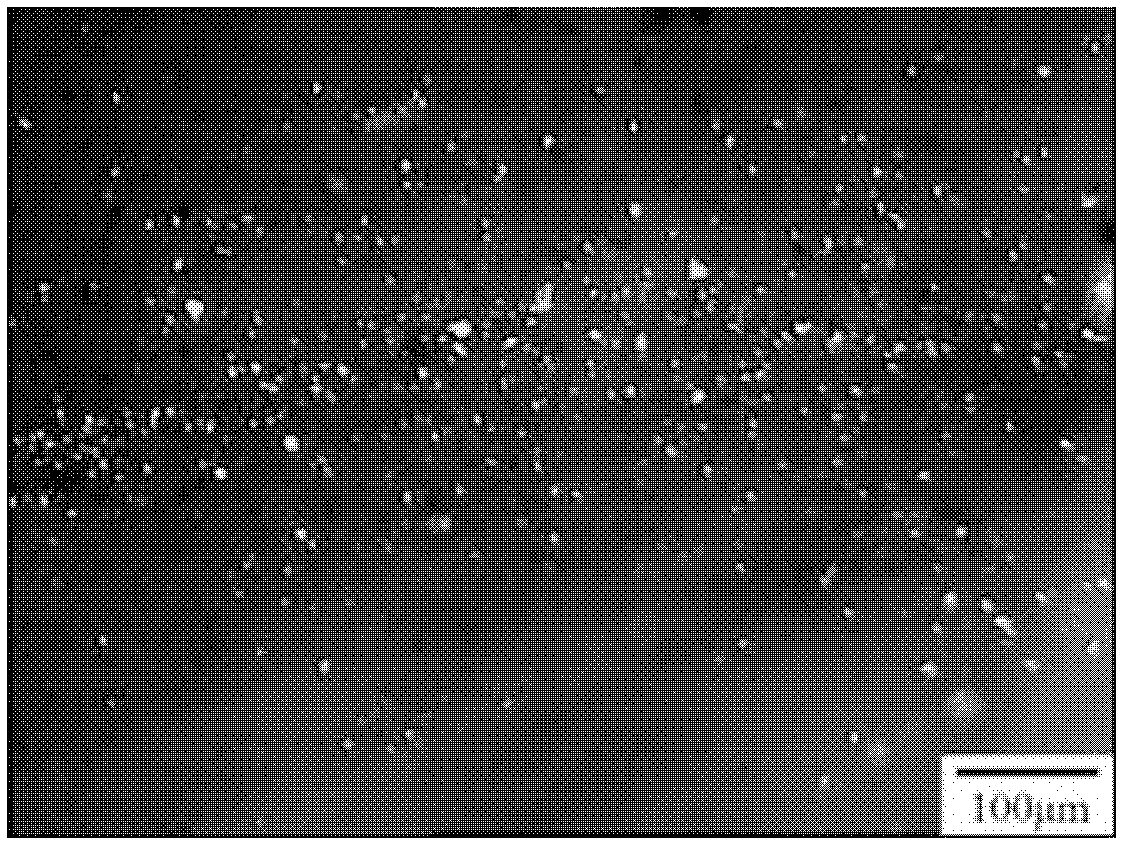

Image

Examples

Embodiment 1

[0034] A. Under the protection of nitrogen at -80°C, add dichloromethane, n-hexane, 2,4,4-trimethyl-2-chloropentane (TMPCl), isobutylene (IB), N , N-dimethylacetamide (DMA) and TiCl 4 , making [IB]=1.8mol / L, TMPCl:TiCl 4 :DMA:IB=1:2:0.47:40 (molar ratio). After 60 minutes of polymerization reaction, add 1wt% NaOH mixed solution of ethanol and water (the volume ratio of ethanol and water is 1:1) to terminate the reaction, purify by dissolving and precipitating, vacuum dry at 40°C to constant weight, and obtain Based polyisobutylene macroinitiator, weight average molecular weight (M w ) is 6.3×10 3 , molecular weight distribution index (M w / M n ) is 2.1;

[0035] B. At -80°C and under the protection of nitrogen, add dichloromethane, n-hexane, triphenylamine (TPA), the above-mentioned 0.08mmol polyisobutylene macroinitiator, styrene (St) and AlCl to the polymerization reactor 3 , making [St]=0.63mol / L, polyisobutylene chain: AlCl 3 :TPA:St=1:1:0.2:150 (molar ratio). Aft...

Embodiment 2

[0037] A, the preparation method of double-ended tertiary chloropolyisobutylene macroinitiator are the same as embodiment 1 step A, just replace TMPC1 with 1,4-bis(2-chloro-2-propyl)benzene (DCC), and [IB ]=1.1mol / L, DCC:TiCl 4 :DMA:IB=1:10.2:1:308 (molar ratio). The M of the prepared double-ended tertiary chloropolyisobutylene macroinitiator w 1.2×10 4 ,M w / M n is 1.5;

[0038] B, the method for preparing block copolymer with above-mentioned polyisobutylene macroinitiator is the same as embodiment 1 step B, just polyisobutylene chain: AlCl 3 :TPA:isoprene:St=1:2:0.24:3:300 (molar ratio). The M of the gained polystyrene-b-polyisobutylene-b-polystyrene triblock copolymer w 2.4×10 5 ,M w / M n It is 5.1, the mass content of polystyrene is 79%, and the crystallization melting temperature range of polystyrene segment is 160°C-187°C.

Embodiment 3

[0040] The preparation method of A, tertiary chloropolyisobutylene macroinitiator is the same as embodiment 1 step 1, just [IB]=1.7mol / L, TMPCl: TiCl 4 :DMA:IB=1:5:0.5:200 (molar ratio). The M of the prepared tertiary chloropolyisobutylene macroinitiator w 2.6×10 4 ,M w / M n is 2.4;

[0041] B, the method for preparing block copolymer is the same as embodiment 1 step B, just replace TPA with triphenylphosphine (TPP), AlCl 3 Replaced by TiCl 4 , and the polyisobutylene chain: TiCl 4 :TPP:St=1:40:16:300 (molar ratio). The M of the gained polyisobutylene-b-polystyrene block copolymer w 4.9×10 4 ,M w / M n It is 1.4, the mass content of polystyrene is 73%, and the melting temperature of polystyrene segment crystallization is in the range of 150°C to 175°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com