Patents

Literature

65 results about "Bromamine acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

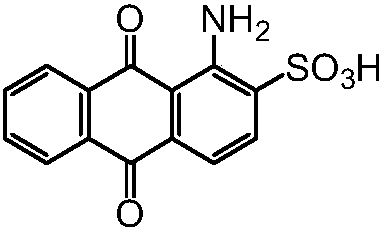

Method for treatng wastewater of producing reactive dyes in class of bromamine acid, and for reclaiming resources

InactiveCN1562774ACombustible gas purificationWater/sewage treatment by sorptionHigh densityWastewater

The processing steps are: water water passes through three kinds of adsorption towers in proper order in temp. 5-50 deg.C and flow quantity 0.5-3 B v / h, each absorption tower is filled by a kind of resin, alkali solution, carbinol and water are used as deadsorption agent to deadsorb and regenerate the resin absorbed organic substances, the deadsorption temp. is 10-60 deg.C, the flow quantity of deadsorption agent is 0.5-3 Bv / h. High density euent generated by deadsorption can be distilled to recover dye and other organic substances, low density eluent can be used to next deadsorption operation. By this invention, waste water producing bromamine acid dye CODcr can be reduced less than 100 mg / L and chromaticness is less than 10 times after being processed by resin.

Owner:NANJING UNIV

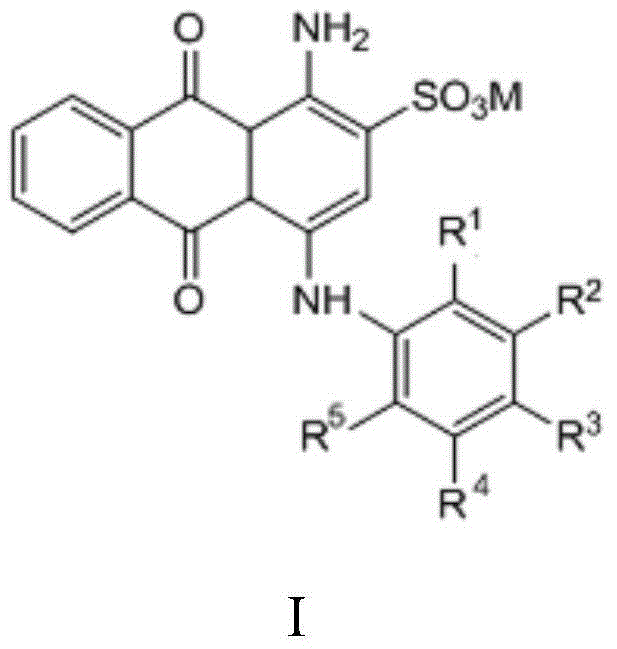

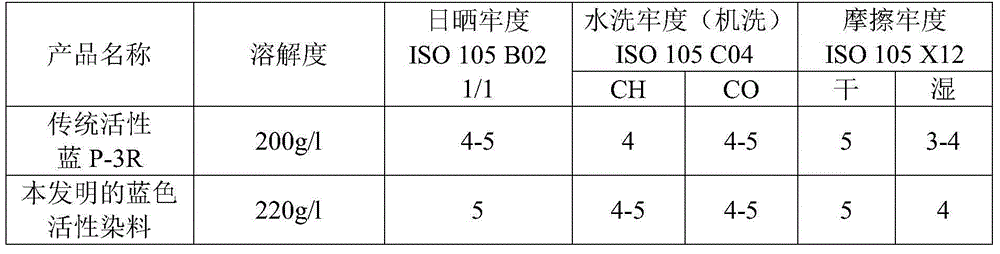

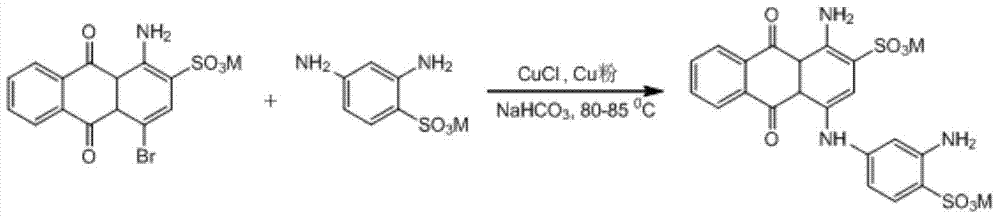

Method for synthesizing anthraquinone type dye or chromophore by aromatic amination of bromamine acid

ActiveCN104312193AReduce usageReduce heavy metal contentAnthraquinone-azo dyesReactive dyesWastewaterSolvent

The invention provides a method for synthesizing anthraquinone type dye or chromophore by aromatic amination of bromamine acid. The method comprises the following steps: catalyzing a condensation reaction of bromamine and arylamine in a solvent by adopting a catalyst system containing cuprous complex. According to the method, the cuprous complex is used as the catalyst system, nearly 100% conversion of the bromaine acid can be realize, no bromamine acid hydrolyzed (purple byproduct) or debrominated byproduct is generated, generation of by products is remarkably reduced, the yield of condensation products is remarkably increased, emission of acid-containing wastewater with deep chromaticity is reduced; and copper powder is not used, the usage of catalyst can be reduced, the content of heavy metals in the condensation products can be reduced, the content of heavy metals in wastewater can be reduced, environmental pollution can be reduced, and production cost can be reduced.

Owner:DALIAN UNIV OF TECH

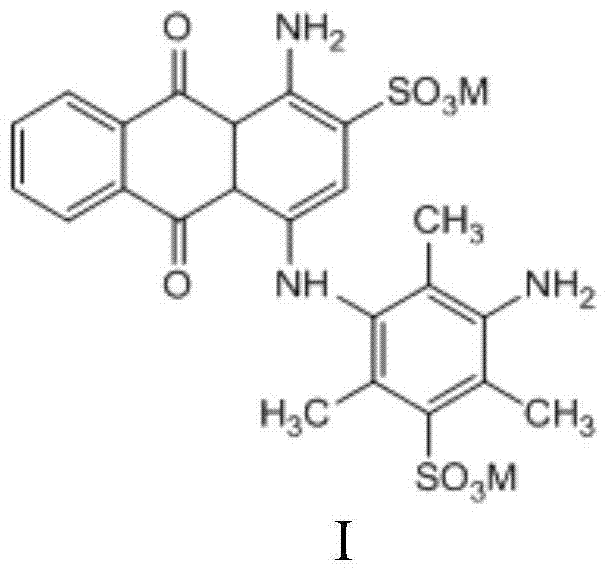

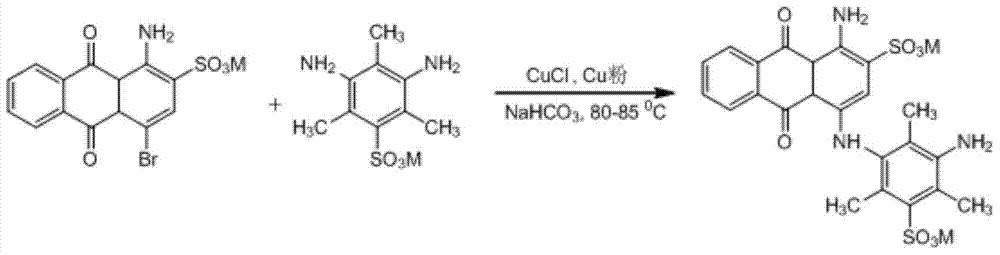

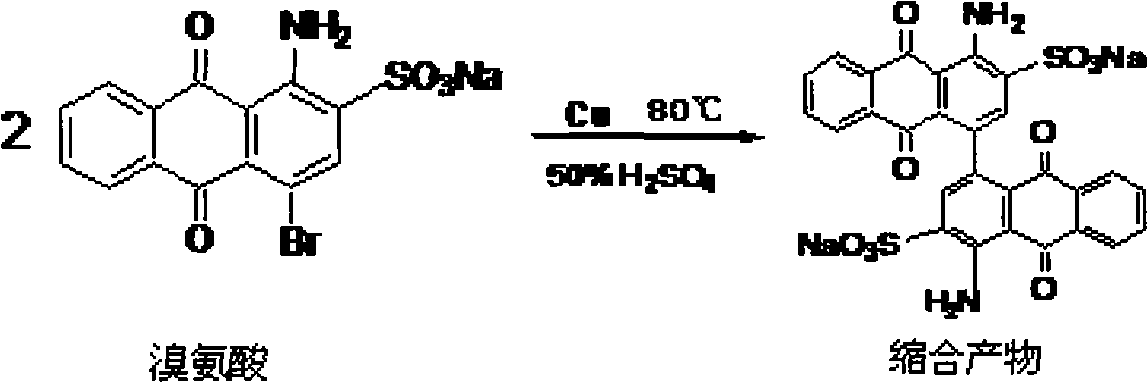

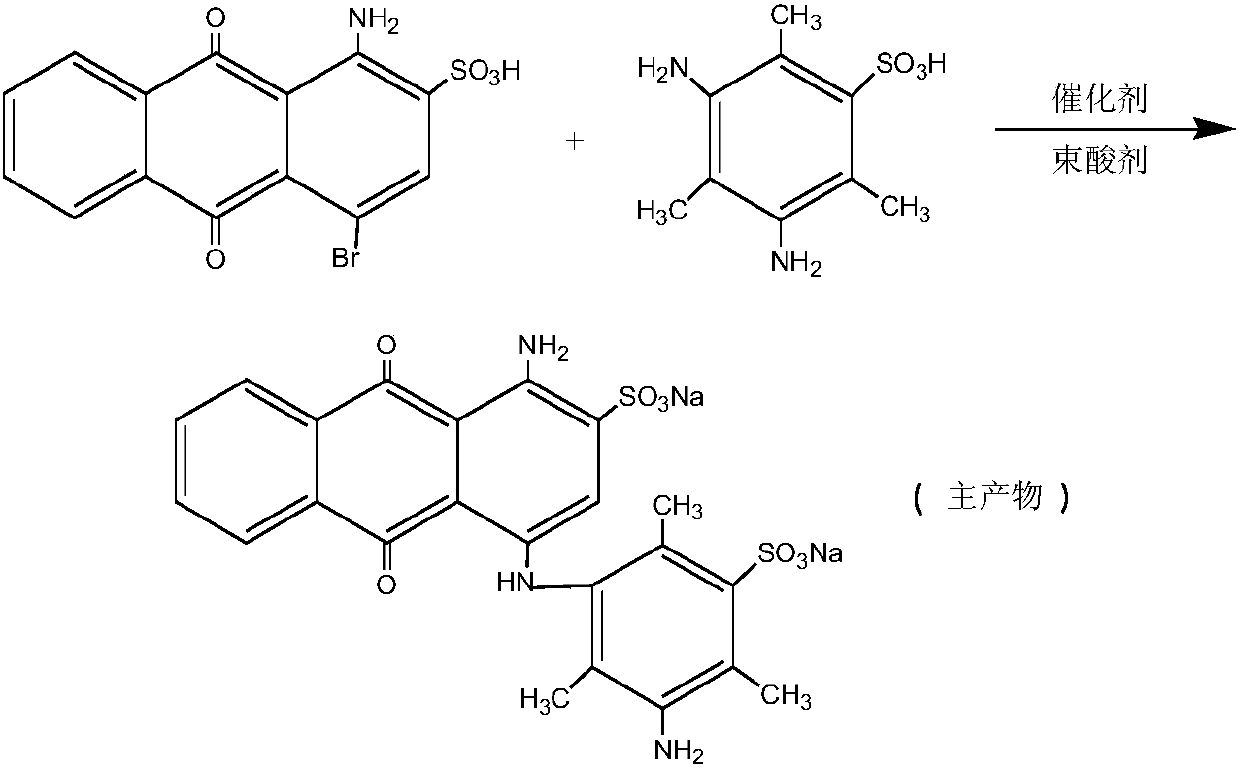

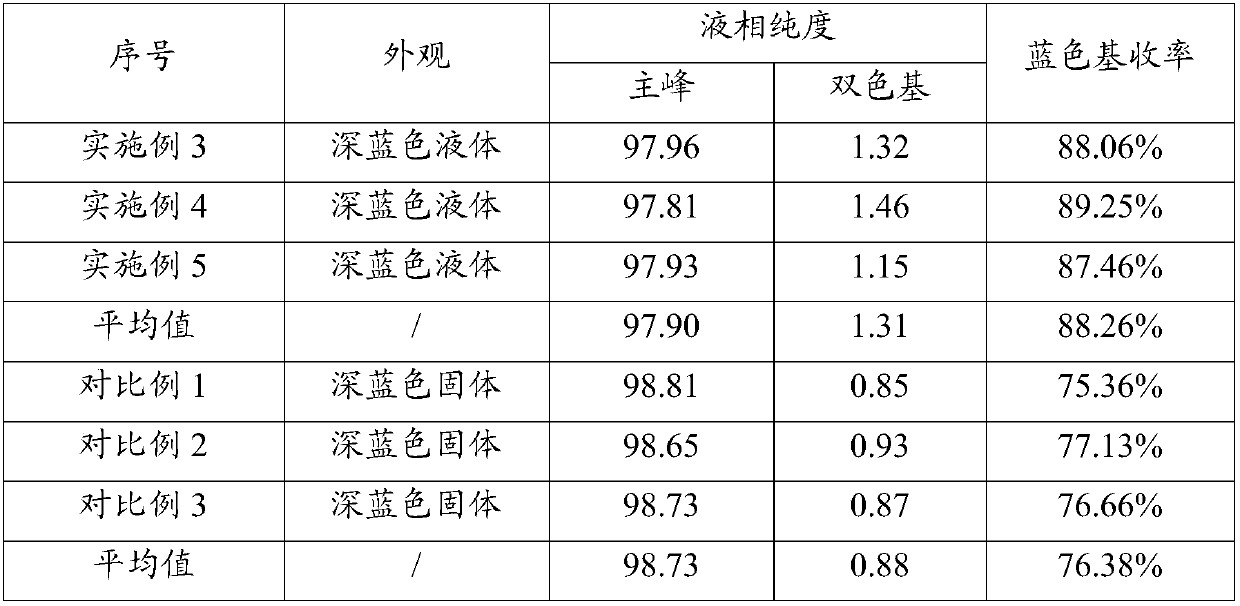

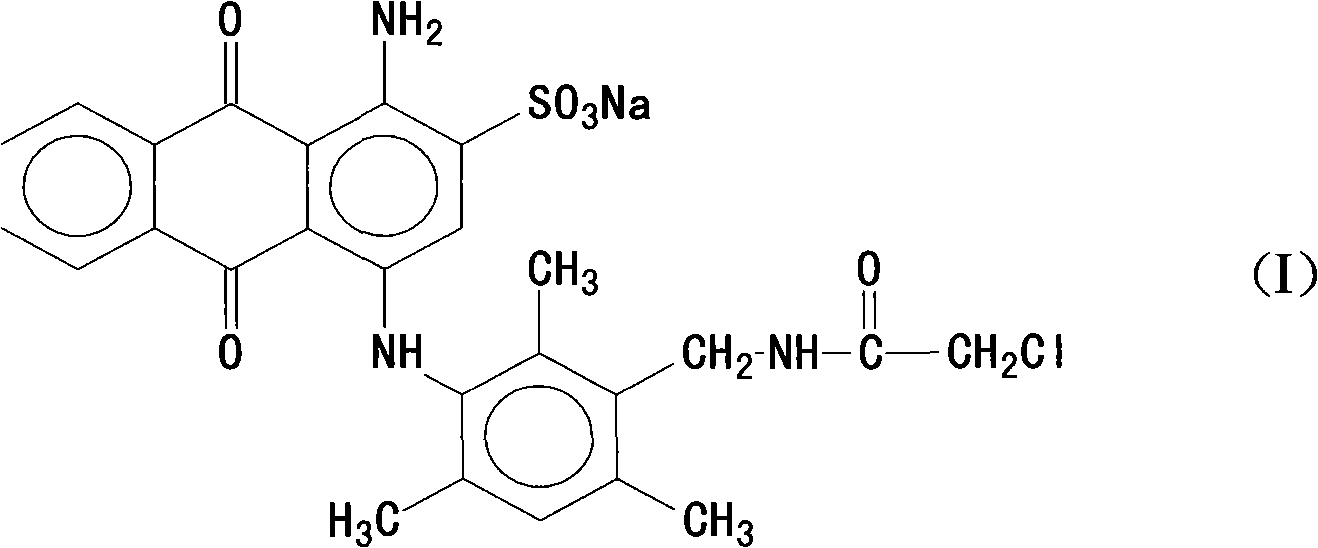

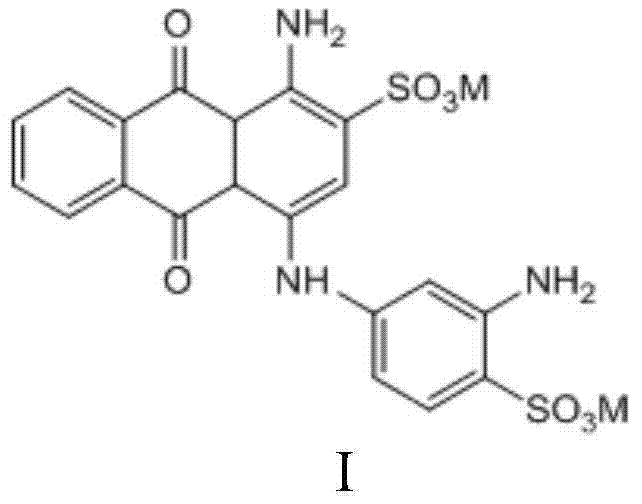

Preparation method of bromine ammonia blue

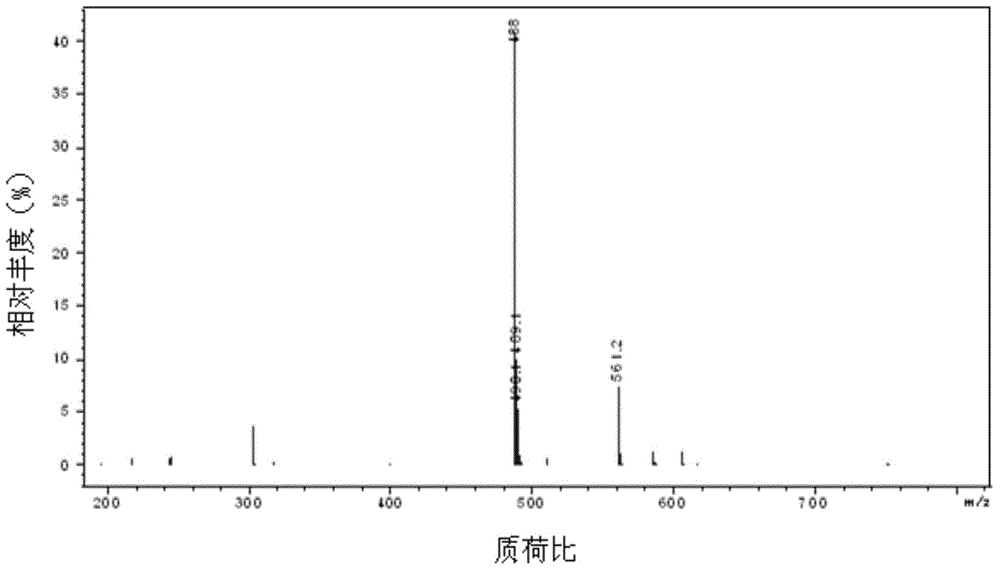

ActiveCN104327532AHigh yieldReduce generationOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acids salts preparationSolventCuprous chloride

The invention provides a preparation method of bromine ammonia blue. The preparation method comprises following steps: carrying out a condensation reaction between bromamine acid and 2,4,6-trimethyl-3,5-diaminobenzenesulfonic acid with a catalyst system containing a cuprous complex for catalyzing the reaction and then performing seperation to obtain the product bromine ammonia blue (sodium 1-amino-4-((3-amino-2,4,6-trimethyl-5-sulfonylphenyl)amino)-anthraquinone-2-sulfonate) after the reaction finished. By means of utilization of the catalyst system containing the cuprous complex, usage amounts of cuprous chloride and copper powder can be effectively reduced, thereby reducing the content of heavy metals in a dye product, reducing the content of heavy metals in waste water and reducing environmental pollution and production cost. In addition, the preparation method can avoid generation of a hydrolyzed by-product (a purple by-product) of the bromamine acid, can greatly reduce the generation of a debromination by-product, can significantly reduce the generation of a double-condensation substance, can increase yields of the condensation reaction and the dye product and can reduce discharge amount of waste water containing acids and being high in chroma.

Owner:DALIAN UNIV OF TECH

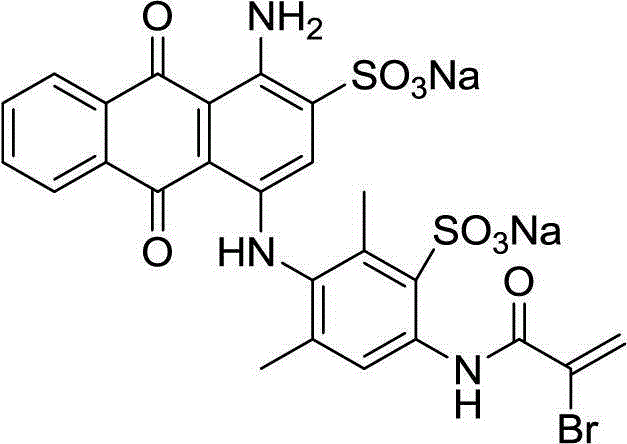

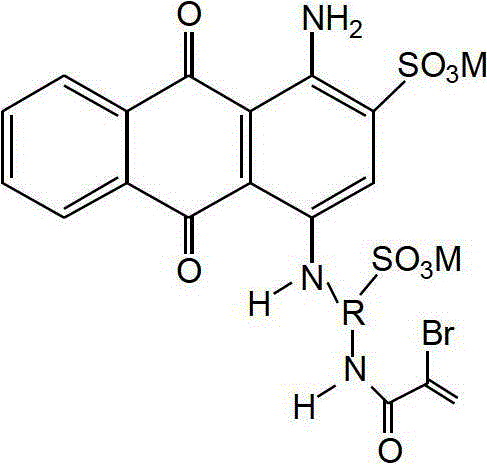

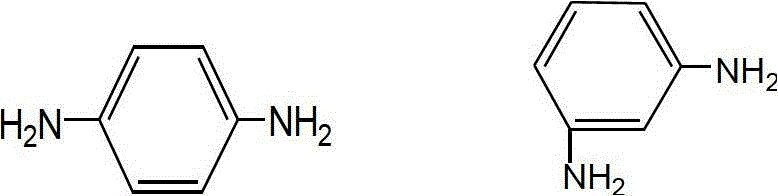

Method for preparing active dye for blue wool

ActiveCN102863815ASolve the problem of large amount of sewageHigh fixation rateReactive dyesDyeing processBromineLight pollution

The invention discloses a method for preparing active dye for blue wool. The preparation method comprises the following steps of: performing first condensation reaction on bromamine acid which serves as a raw material and phenylene diamine, and performing acid refining, sulfonation, second condensation reaction and aftertreatment to obtain the active dye. The method is advanced and low in cost and causes light pollution to the environment. The dye prepared by the method has bromo-acrylamide groups, and under a slightly acidic condition, by being used together with Sibagol B, the active dye has a high reactivity with wool and a high fixation rate and meets the 'machine washable' high fastness requirement of International Wool Secretariat, so the active dye is quite high in market competitiveness.

Owner:HUBEI HUALI DYESTUFF INDAL

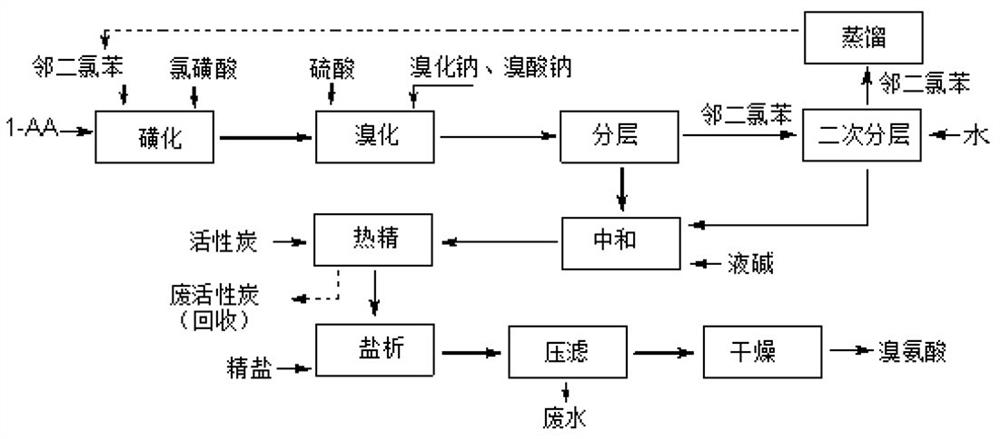

Method for recovering o-dichlorobenzene through sulfonation process of bromamine acid produced by solvent method

InactiveCN102516025AHalogenated hydrocarbon separation/purificationChlorosulfuric acidOrganic solvent

The invention relates to a method for recovering o-dichlorobenzene through a sulfonation process of bromamine acid produced by a solvent method, which comprises the following steps of: after 1-amino-anthraquinone is sulfonated by the chlorosulfonic acid in an o-dichlorobenzene solvent, adding 93-96 percent of sulfuric acid to extract 1-amino-anthraquinone-2-sulfonic acid from an o-dichlorobenzene layer; and carrying out distilling under reduced pressure on sulfuric acid solution to recover the o-dichlorobenzene. The sulfuric acid solution recovering the o-dichlorobenzene can be directly bromized. The method has the beneficial effects that the recovery rate of the o-dichlorobenzene reaches above 98 percent, the recovery rate of the solvent o-dichlorobenzene is greatly improved, the emission of an organic solvent is reduced, the environment is protected, and meanwhile, the energy consumption is low.

Owner:YANCHENG OUHUA CHEM IND

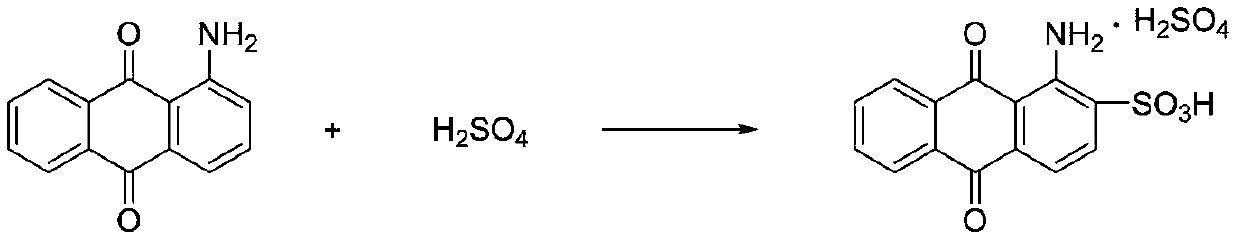

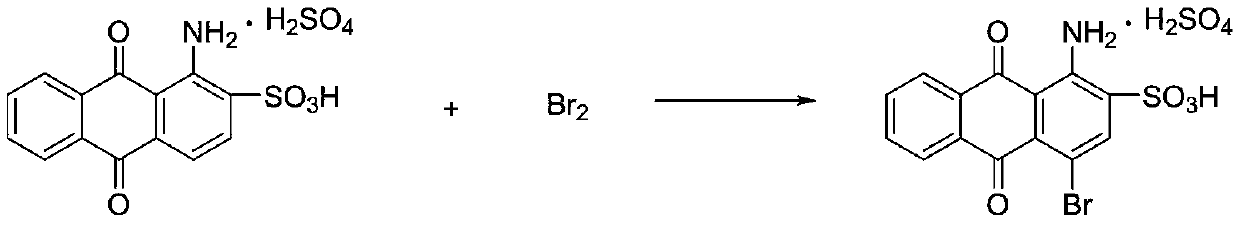

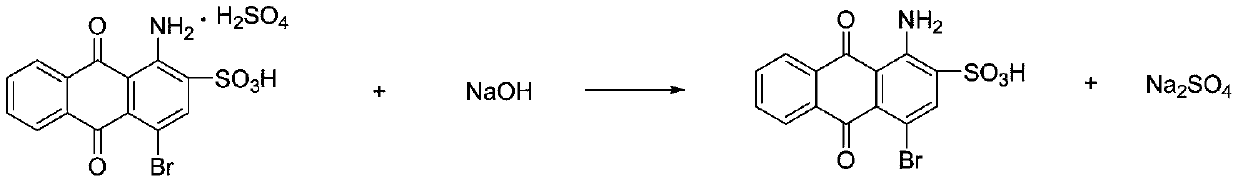

Preparation process of bromamine acid

InactiveCN106748913ALess side effectsReasonable designOrganic compound preparationSulfonic acid preparationBromineNitration

The invention discloses a preparation process of bromamine acid. The preparation process is characterized by comprising the following steps of carrying out nitration reaction, reduction reaction, sulfonation reaction and bromination reaction and finally refining to prepare the bromamine acid from anthraquinone; reaction conditions and a process step of adding materials are reasonably designed, so that the generated bromamine acid has high purity and the yield is relatively high.

Owner:TAIZHOU DONGFENG CHEM CO LTD

Preparation method of bromaminic acid sodium salt and intermediate of bromaminic acid sodium salt and solvent recovery method

InactiveCN106565547ALow costReduce lossesOrganic compound preparationSulfonic acids salts preparationRecovery methodChlorosulfuric acid

The invention discloses a preparation method of bromaminic acid sodium salt and an intermediate of the bromaminic acid sodium salt and a solvent recovery method. The preparation method of 1-aminoanthraquinone-2-sulfonic acid comprises the following steps that (1) in an inert solvent, a sulfonation reaction is conducted on 1-aminoanthraquinone and chlorosulfonic acid; (2) secondly, after the sulfonation reaction in the step (1) is ended, layered extraction is conducted with concentrated sulfuric acid, the upper layer is a solvent organic phase layer, and the lower layer is a material layer containing the 1-aminoanthraquinone-2-sulfonic acid and sulfuric acid. By the adoption of the preparation method of the 1-aminoanthraquinone-2-sulfonic acid, the extraction layering is complete, and the yield of the 1-aminoanthraquinone-2-sulfonic acid is high. Meanwhile, a method of recycling the solvent with water is adopted, the recycled solvent can be directly used for preparation of bromamine acid and sodium slat of the bromamine acid, and the bromamine acid is high in yield.

Owner:YANTAI ANOKY FINE CHEM CO LTD +2

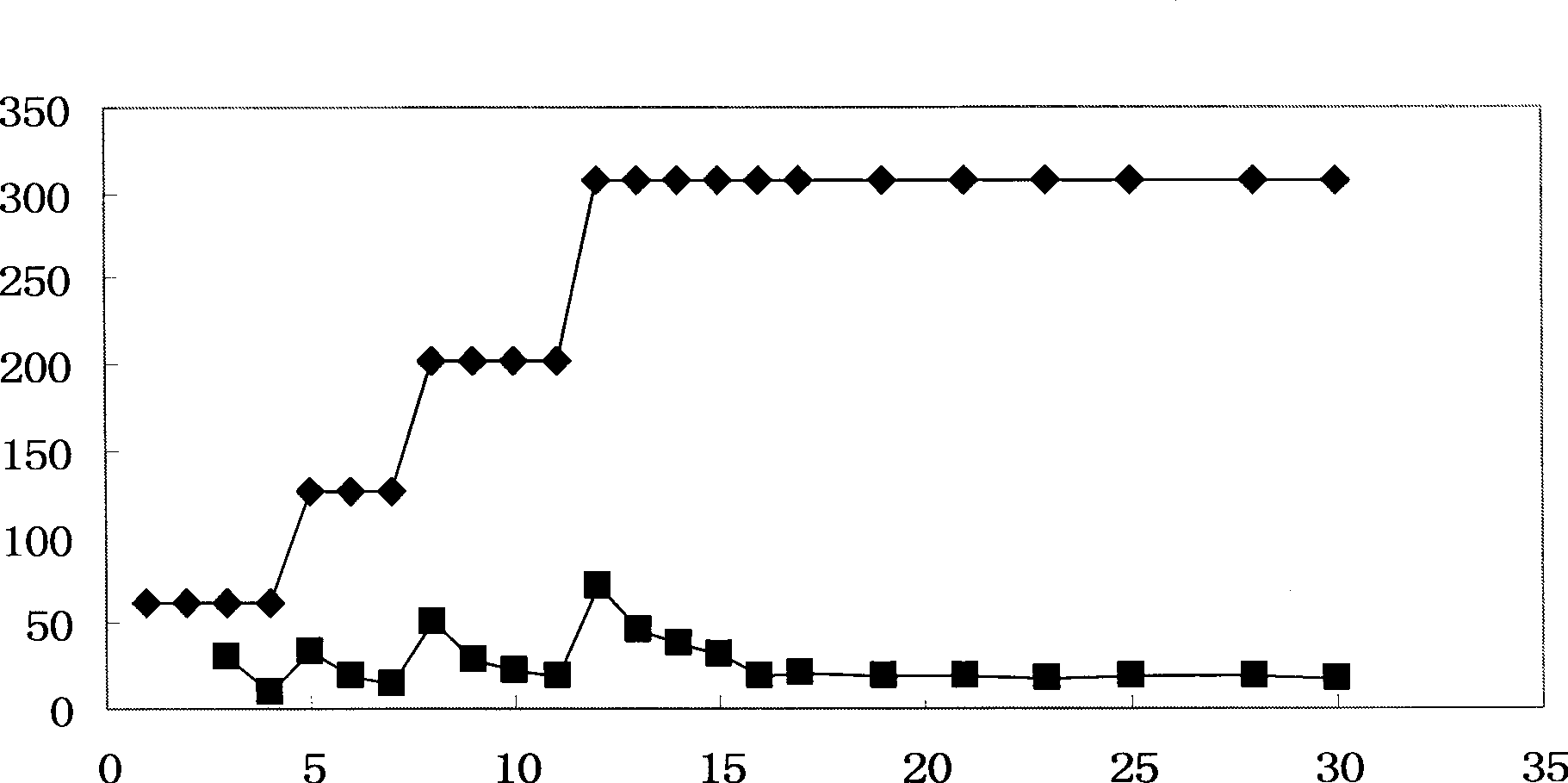

Integrated method for catalyzing condensation reaction of bromamine acid by using solid acid and degrading waste water produced by condensation reaction

InactiveCN101792611AEasy to prepareHigh catalytic activityWater/sewage treatment by irradiationChemical recyclingWater useSolid acid

The invention provides an integrated method for catalyzing the condensation reaction of bromamine acid by using solid acid and degrading waste water produced by the condensation reaction. The method comprises the following steps of: preparing a solid acid catalyst SO42- / TiO2, forming a catalytic system of the condensation reaction of bromamine acid, forming an integrated system used for the catalysis of the condensation reaction of bromamine acid by using the solid acid catalyst SO42- / TiO2 and photocatalytic degradation of the waste water produced by the condensation reaction, and recycling the solid acid catalyst SO42- / TiO2. The integrated method has the advantages that: the method for preparing the solid acid catalyst SO42- / TiO2 is simple, the catalytic activity is high, the solid acid catalyst SO42- / TiO2 can be used for catalyzing the condensation reaction of bromamine acid for reducing a temperature needed for the reaction system, increasing a reaction yield, avoiding the use of solution H2SO4 and lowering difficulty in processing the production waste water in following steps, and the solid acid catalyst SO42- / TiO2 can be recycled after the reaction; and simultaneously, the production waste water used for the condensation reaction of bromamine acid is subjected to photocatalytic degradation, the decoloring rate of the production waste water is over 85 to 96.22 percent, the removal rate of TOC is 51 to 86 percent, the environmental pollution is lowered, and the integration of the solid acid catalysis reaction and the processing of the production waste water is realized.

Owner:TIANJIN URBAN CONSTR COLLEGE

Preparation method of 1-amino-4(ethylamino) anthraquinone-2-carbonitrile

ActiveCN107501124AImprove shadingImprove dyeing effectCarboxylic acid nitrile preparationOrganic compound preparationDistillationFiltration

The invention provides a preparation method of 1-amino-4(ethylamino) anthraquinone-2-carbonitrile. The method comprises steps as follows: purified bromamine acid, copper sulfate, ethylamine and sodium carbonate in a certain ratio are subjected to a reaction at the temperature of about 60-90 DEG C for 4-10 h, a 1-amino-4 ethylamino-anthraquinone-2-sodium sulfonate solution is obtained, excessive ethylamine is recovered through distillation, water and activated carbon are added, bromine-containing impurities are adsorbed with a rare earth adsorbent, and a filtrate containing 1-amino-4 ethylamino-anthraquinone-2-sodium sulfonate is pumped into a cyaniding kettle. In the cyaniding kettle provided with a tail gas absorption device, sodium carbonate with a certain proportion and a sodium cyanide water solution with the mass percentage concentration being 20%-40% are subjected to a reaction at the temperature of 85-105 DEG C for 4-10 hours, filtration, washing and drying are performed, and 1-amino-4(ethylamino) anthraquinone-2-carbonitrile is obtained.

Owner:宁波德欣科技有限公司

Bacteriostatic acid dye

The invention discloses bacteriostatic acid dye. The bacteriostatic acid dye is prepared from resorcinol, bromamine acid, sodium poly[(naphthaleneformaldehyde)sulfonate], sodium silicate, triphenylphosphine-3,3',3''-trisulfonic acid trisodium salt, pyrazolone, chitosan, nano-copper particles, nano-cuprous oxide particles, deionized water, a defoaming agent and an auxiliary. According to the bacteriostatic acid dye, the stability is high, and use is convenient; by optimizing the dye components and cooperatively using the home-made auxiliary, the coloring power of the dye is enhanced, the problem that the color fixing effect of traditional acid dye on a chinlon fabric dyed by the acid dye is not ideal is solved, and the effect of the wet treatment fastness is greatly improved; in the preparing process of the acid dye, the components are divided into two parts to be processed through mixing separately and then processed through total mixing, and by cooperating with the added auxiliary, the dye components can be greatly homogenized, and the coloring effect and the coloring quality of the dye are improved; the dye has the very good antibacterial property on escherichia coli, staphylococcus aureus and candida albicans.

Owner:安徽宜民服饰股份有限公司

Preparation method of copper powder carrier catalyst for bromamine acid Ullman condensation reaction

ActiveCN103506138AInhibit aggregationEliminate complex preprocessingPhysical/chemical process catalystsSulfonic acid preparationPre treatmentCopper sulfate

The invention provides a preparation method of a copper powder carrier catalyst for a bromamine acid Ullman condensation reaction. By using powder-shaped sepiolite as a carrier of copper powder, the copper powder is loaded on the sepiolite which is treated by sulfuric acid. The powder-shaped sepiolite is dispersed in water and stirred, and is slowly added with the sulfuric acid to adjust the pH value to 3 until no bubble is discharged from the mixture; the final pH value is controlled to be 3 to obtain a sepiolite-water mixture treated by the sulfuric acid; copper sulfate is dissolved in the sepiolite-water mixture, and then is added with a complexing agent to complex for 30-60 minutes; then, formaldehyde is added to reduce for 30-60 minutes at the temperature of 45-60 DEG C to obtain the catalyst loaded with the copper powder on the surface of the sepiolite for the bromamine acid Ullman condensation. The catalyst is prepared in site, and is used for the bromamine acid Ullman condensation reaction in site, so that the catalytic activity is higher, and the complex pre-treatment to the copper powder is avoided; the yield of Ullman condensation products being 93% above is higher.

Owner:宇虹颜料股份有限公司 +1

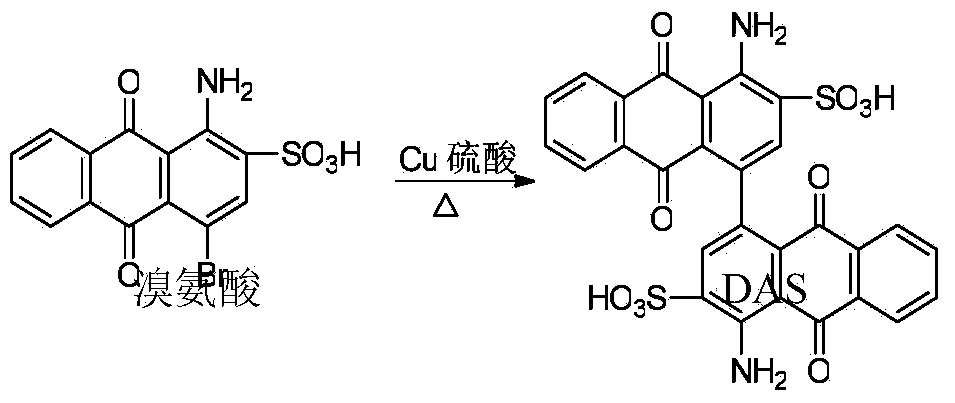

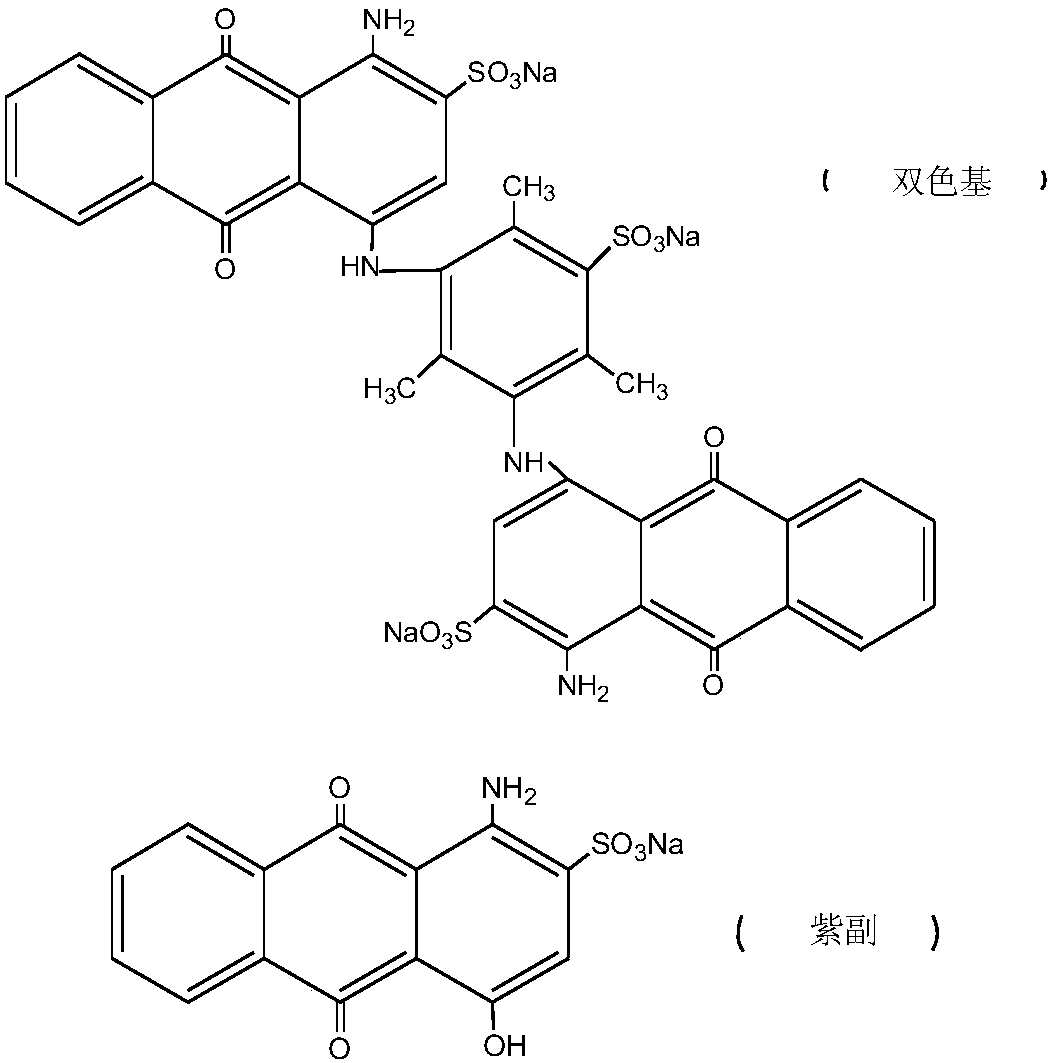

Method for preparing blue reactive dyes

ActiveCN104559309AOvercome the defect of large amount of sewageShorten the reaction cycleReactive dyesChlorideSewage

The invention discloses a method for preparing blue reactive dyes. The method comprises the following steps: (1) primary condensation reaction, to be specific, taking copper sulfate pentahydrate, ferrous chloride or a mixture of copper sulfate pentahydrate and ferrous chloride as a catalyst, and enabling bromamine acid and M acid to be subjected to the condensation reaction; (2) refining, to be specific, refining all primary condensation compounds; (3) secondary condensation reaction, to be specific, enabling the refined compound and cyanuric chloride to react to obtain secondary condensation compounds; (4) ternary condensation reaction, to be specific, enabling the obtained secondary condensation compounds and aminobenzene sulfonic acid to react to obtain ternary condensation compounds, filtering, spray drying and packaging, so as to obtain the product. The method can synthesize a new blue reactive dye and has the advantages that the cycle of reaction is shortened, the reaction yield is increased, the reaction is more thorough, the reaction process is clean and environmentally-friendly, the sewage quantity is less, and the prepared product has bright colors.

Owner:HUBEI HUALI DYESTUFF INDAL

Compound orally disintegrating tablet containing loratadine and ambroxol and preparation process thereof

InactiveCN1994304AImprove bioavailabilityIncrease blood concentrationOrganic active ingredientsPill deliveryOrally disintegrating tabletLoratadine

The invention relates to a luleitadingmione oral calving tablet which can treat allergic rhinitis, etc. wherein, it has quick adsorption, high biological utilization, and simple intake method without water. It uses Loratadine and bromamine acid as materials, with some findings.

Owner:BEIJING RUNDEKANG MEDICAL TECH CO LTD

Preparation method of water-soluble blue printing dye

ActiveCN108017926AImprove conversion rateImprove efficiencyPhysical/chemical process catalystsAnthracene dyesSulfanilic acidSalting out

The invention relates to a preparation method of a water-soluble blue printing dye. The method includes the following steps of 1, dissolving M acid in water, adding bromamine acid, controlling pH to main within 8.0-8.5, raising the temperature to 70-80 DEG C for conducting a first condensation reaction, and adding a solid-supported catalyst in batches during the condensation reaction, wherein themolar ratio of M acid to bromamine acid is (1.8-2.2):1; 2, after the first condensation reaction is completed, adding water and diatomaceous earth and conducting stirring and filtering, adjusting thepH of the filtrate to 1.5-2.0, conducting filtering again, and adjusting the pH of the filtrate to neutrality to obtain a blue-based intermediate liquid; 3, after cyanuric chloride is subjected to icebath, beating and dispersion, adding the blue-based intermediate liquid, controlling the temperature to main within 3-8 DEG C and the pH to more than 6.0, and conducting a second condensation reaction; 4, after the second condensation reaction is completed, adding a mixture of m-aminobenzenesulfonic acid and p-aminobenzenesulfonic acid, raising the temperature to 40-45 DEG C, maintaining the pH within 6.0-7.0, and conducting a third condensation reaction to obtain raw pulp of the blue dye. The method can solve the problem that a large amount of high-COD high-salt colored wastewater is produced by traditional salting-out refining methods.

Owner:ZHEJIANG JINGGUANG IND

Bromamine acid sodium salt bromination process

InactiveCN111116425AReduce generationEasy to handleSulfonic acids salts preparationSulfonic acid preparationAnthraquinonesChlorosulfuric acid

The invention relates to the technical field of dyes, in particular to a bromamine acid sodium salt bromination process which comprises the following steps: carrying out sulfonation reaction on 1-aminoanthraquinone and chlorosulfonic acid in an inert solvent to obtain 1-aminoanthraquinone-2-sulfonic acid; after the sulfonation reaction is finished, diluting the liquid with water, performing standing treatment for layering to remove an inert solvent layer, and recycling the solvent by a distillation kettle; pumping an aqueous solution of the sulfonation liquid into a bromination kettle to be subjected to bromination reaction with hydrobromic acid and an oxidizing agent; and alkalizing, filtering and refining the bromination reaction product to obtain the high-quality bromaminic acid sodiumsalt. The invention provides the bromination reaction process of bromamine acid sodium salt, wherein the hydrobromic acid and an oxidizing agent which are low in price and easy to obtain are selected;the reaction temperature is controlled at 30-35 DEG C, the brominated product is filtered and refined to obtain high-quality bromamine acid sodium salt, the generation of byproduct sodium chloramineis reduced, the purity is improved by 0.1-0.3% and reaches 99.6% or above compared with the prior art, and the generated wastewater is also easy to treat. The method is a new safe, green and environment-friendly production process.

Owner:JIANGSU YABANG DYE

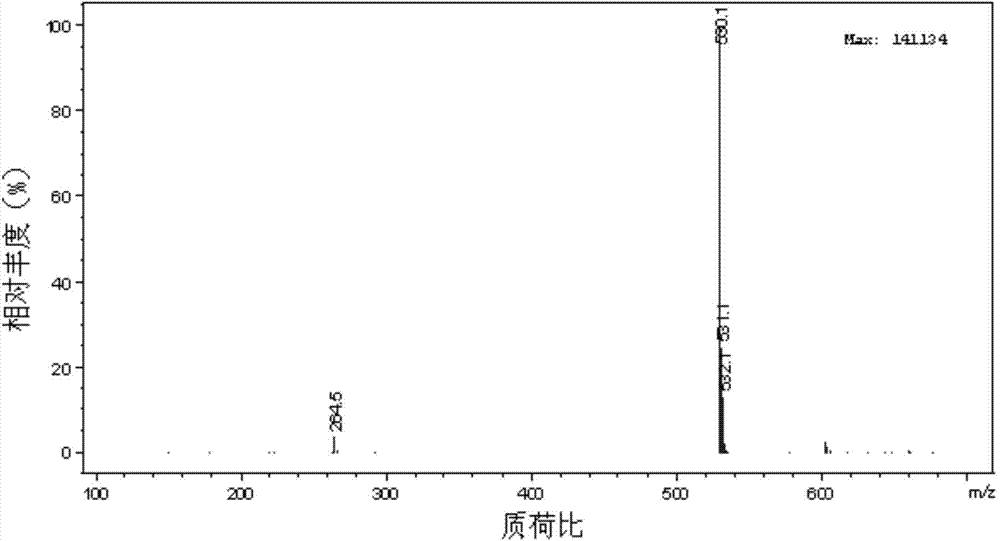

Method for preparing acid blue 260

The invention provides a method for preparing acid blue 260, which comprises the following steps: condensing bromamine acid and trimethylaniline, removing auxiliary lac dyes, refining for three times, activating, icing, neutralizing, refining again, drying, adjusting the color and the strength and packaging finished products. The method for preparing acid blue 260 consumes less raw material consumption, has high dye rate, generates less auxiliary lac dyes, improves the yield of the dyes and plays a promotion role in environmental protection.

Owner:TIANJIN DEK CHEM

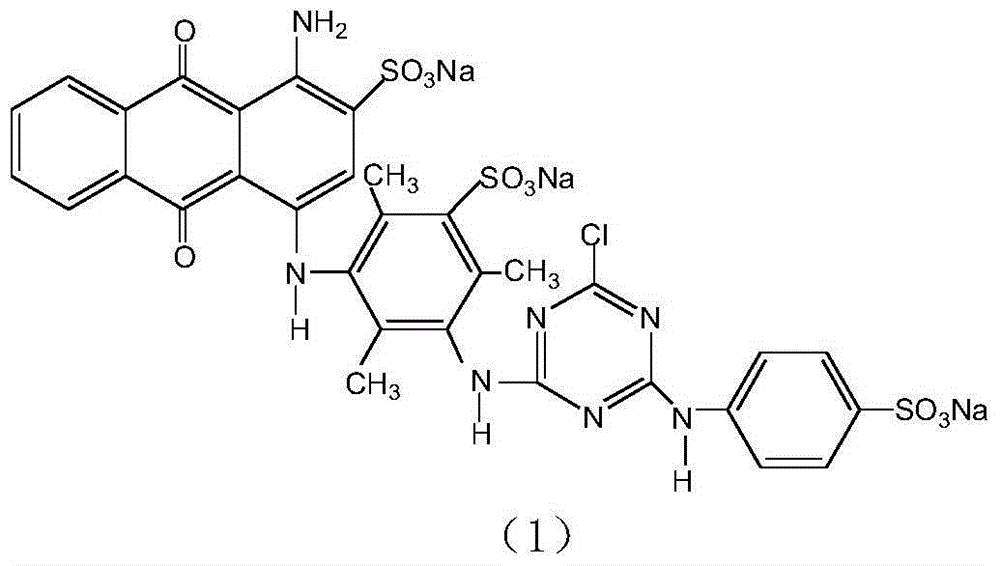

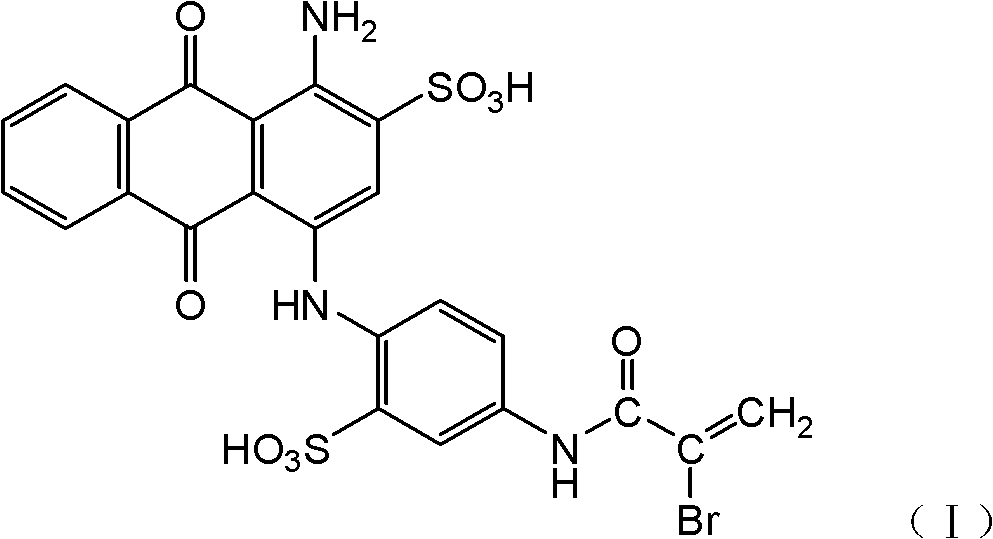

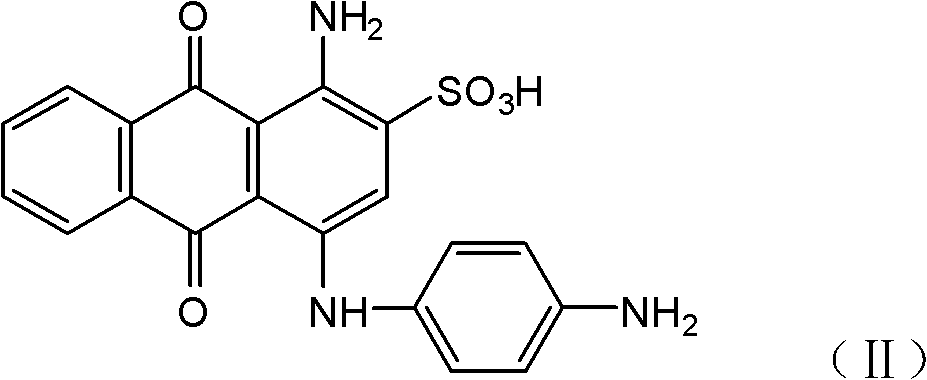

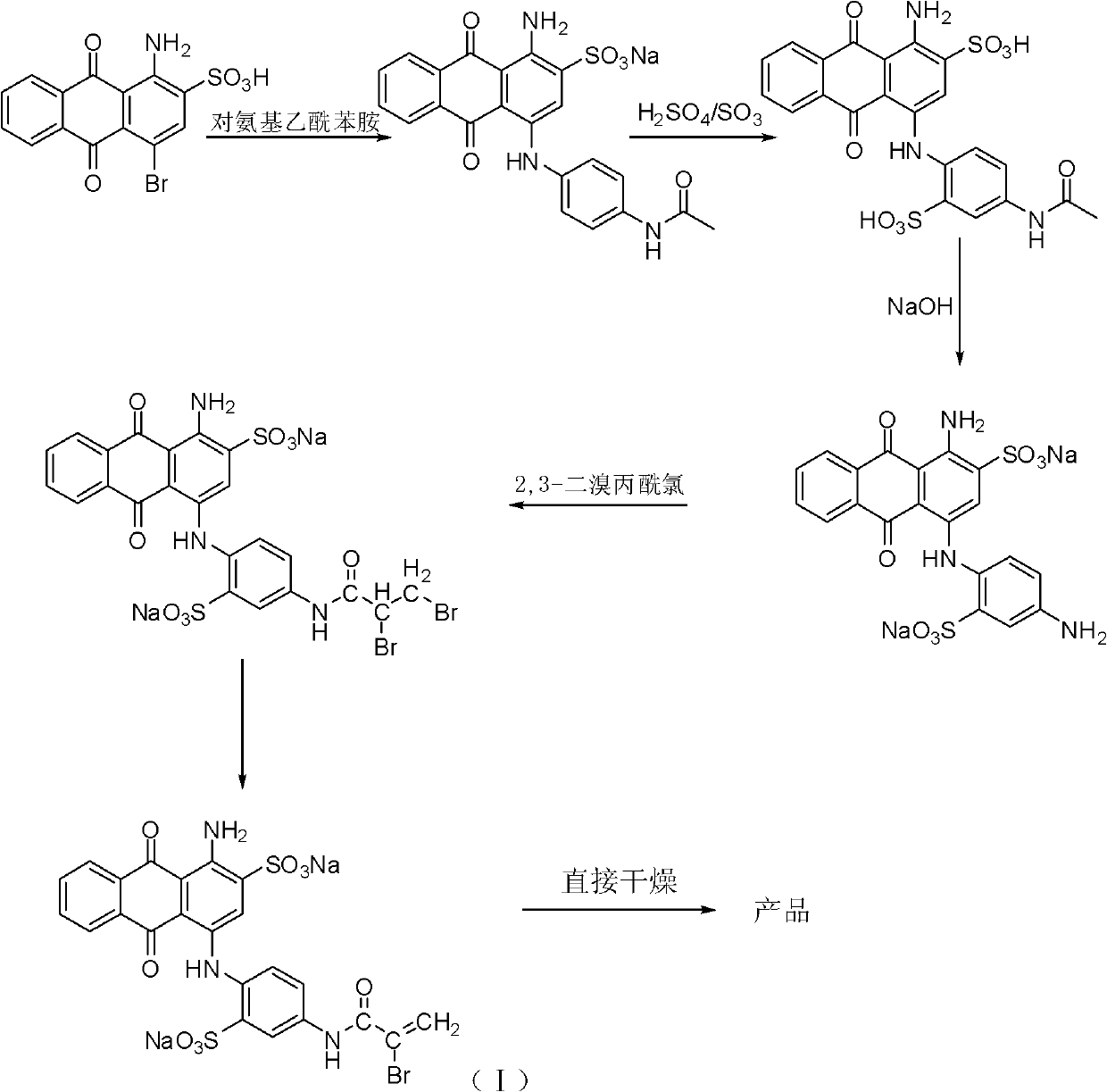

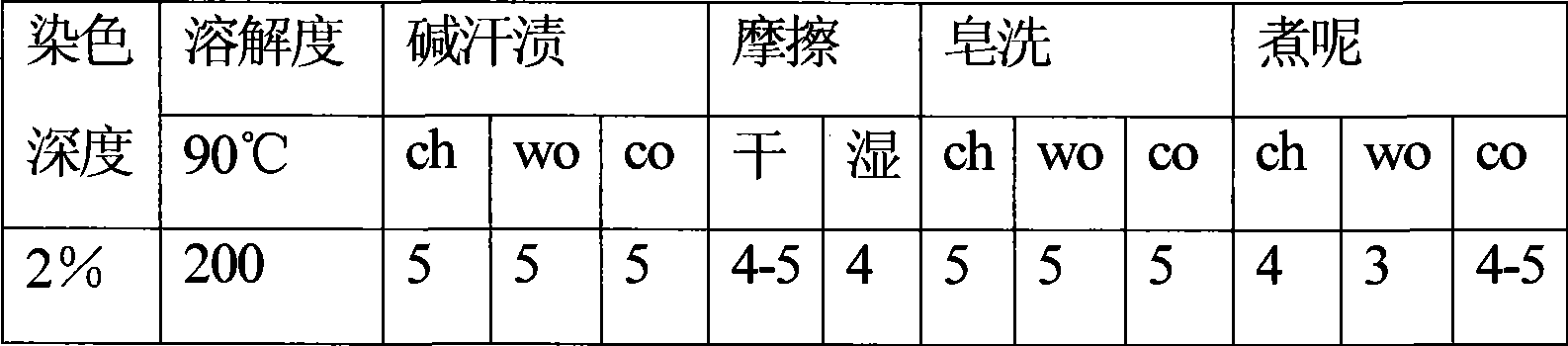

Method for preparing reactive brilliant blue 3G for wool

ActiveCN103289431AEasy to operateBroad prospects for commercializationReactive dyesDyeing processPropionyl chloridePerformance index

The invention provides a method for preparing reactive brilliant blue 3G for wool. The method comprises the following steps of: (1) condensing bromamine acid and p-amine acetanilide under the action of a catalyst, and acidifying to obtain a condensation product; (2) sulfonating the condensation product by using fuming sulfuric acid, and performing basic hydrolysis to remove acetyl; and (3) condensing a hydrolysis product with 2,3-dibromo propionyl chloride, and performing debromination to prepare a reactive brilliant blue 3G dye. The preparation method provided by the invention is low in cost, energy consumption and pollution, and is suitable for industrial large-scale production. Various application performance indexes of the reactive brilliant blue 3G for wool, which is obtained by the preparation method provided by the invention, reach or exceed those of products of foreign companies.

Owner:中国中化股份有限公司 +1

Modified attapulgite used for immobilizing polycyclic aromatic hydrocarbon degrading bacteria, and preparation method thereof

InactiveCN106591279AHigh mechanical strengthEnhanced mass transferAluminium silicatesOn/in inorganic carrierSodium bicarbonateMethyl salicylate

The invention discloses a modified attapulgite used for immobilizing polycyclic aromatic hydrocarbon degrading bacteria. A preparation method of the modified attapulgite comprises the following steps: modifying attapulgite with a mixed solution prepared from sodium bicarbonate, cinnamaldehyde, 3-oxacyclobutanone, dibromobenzoquinone, methyl salicylate, anisole and laurene to prepare a substance B; modifying the substance B with a mixed solution prepared from isobutyl mercaptan, hexyl sulfide, o-chlorocinnamic acid and 3-methylthiophene to prepare a substance D; modifying the substance D with a mixed solution prepared from N-acetyl-DL-phenylalanine, 5-hydroxytryptophan and 3.3 g of D-homophenylalanine to prepare a substance F; and modifying the substance F with a mixed solution prepared from hydroxy propyl cellulose, galacturonic acid and bromamine acid to prepare a substance which is the modified attapulgite used for immobilizing polycyclic aromatic hydrocarbon degrading bacteria.

Owner:光合强化(北京)生物科技有限公司

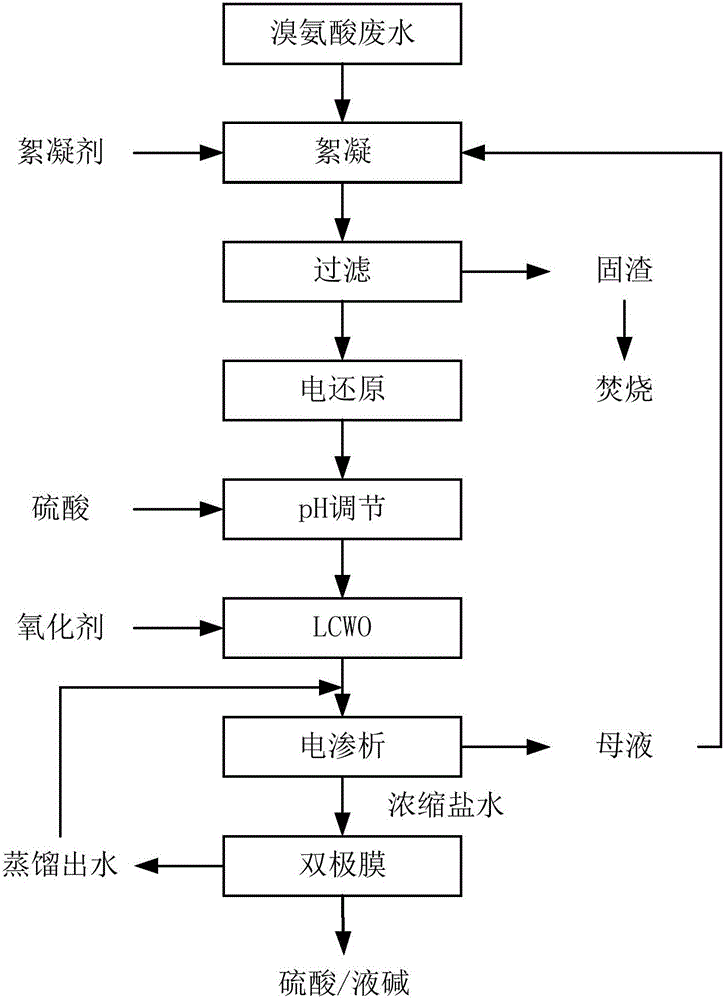

Treatment method of bromamine acid wastewater

ActiveCN106315936ASimple processEasy to operateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFlocculationBromine

The invention discloses a treatment process of bromamine acid neutralizing wastewater. The treatment process mainly includes flocculation, electroreduction, low-temperature wet oxidation, electrodialysis and bipolar membrane dialysis. The treatment process using 'flocculation-electroreduction-LCWO-electrodialysis and bipolar membrane dialysis' as the main line has the advantages that the treatment process specially aims at the alkaline wastewater generated during the production of bromamine acid dye, the residual organic matter in the wastewater is gradually separated in a targeted manner, the COD and color in the wastewater are removed, acid and alkali of certain concentration are produced, and the treatment process is continuous and automatic in process flow, mild in reaction condition, simple to operate and evident in effect and has certain economic benefits.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

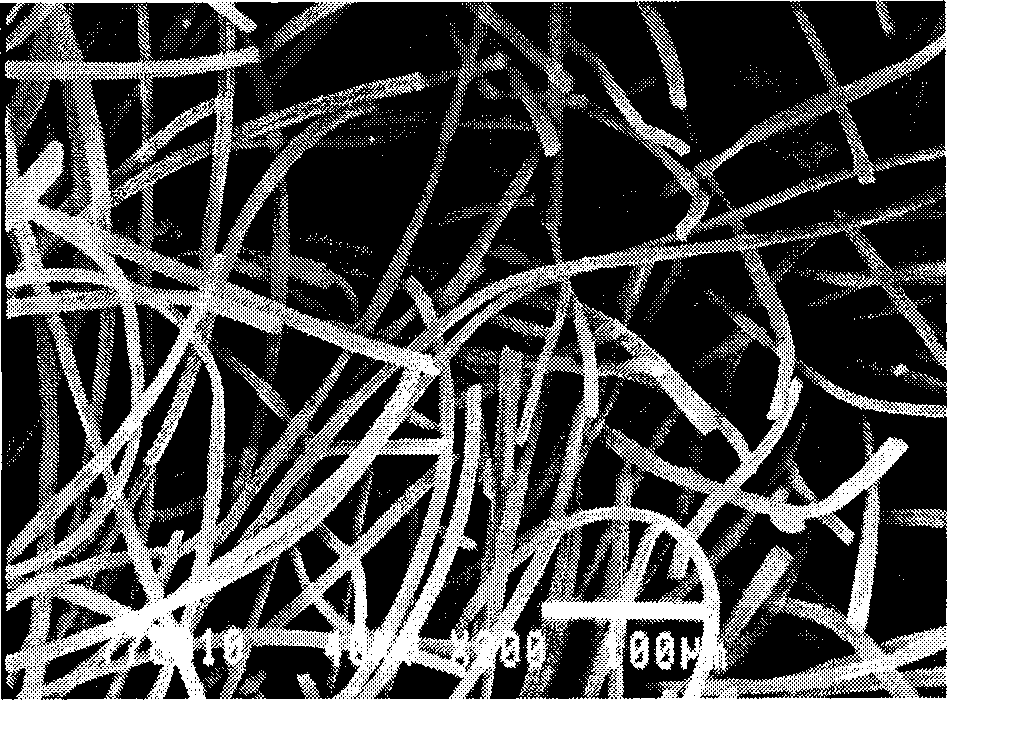

Aerobic biomineralization method of bromamine acid

InactiveCN101391856AWide variety of sourcesEasy to operateMultistage water/sewage treatmentSustainable biological treatmentMicroorganismWastewater

The invention relates to a method of mineralization of aerobiont of bromamine acid, belonging to the technical field of water treatment of environmental engineering. The method is characterized in that high-efficiency absorbing material is added into an aerobiont reactor, and not only can be used as carrier fixed microorganism but also can be used as decolorizing products so as to lead the decolorizing products in liquid phase to keep lower concentration; and in the regeneration process of in-situ or of the absorbing material, the degradation rate of the decolorizing products is larger than the autooxidation rate thereof, thus effectively avoiding the autooxidation of the decolorizing products and leading the bromamine acid to be mineralized completely. The method of mineralization of aerobiont of bromamine acid has the effects and benefits that the used high-efficiency absorbing material has wide source and simple and convenient technological operation, effectively solves the problem that the complete biodegradation is blocked by autooxidation products hard to degrade formed in the decolorization of the aerobiont of the bromamine acid, provides an aerobic mineralization of the bromamine acid technology being economic and high efficiency and has wide application prospect in the treatment of the waste water of anthraquinone dye and intermediates thereof.

Owner:DALIAN UNIV OF TECH

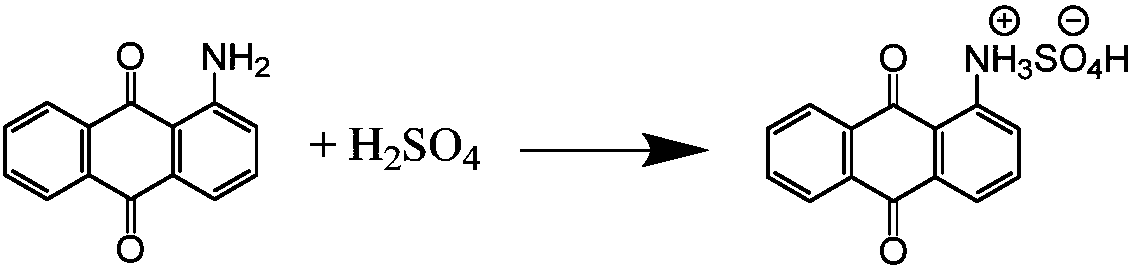

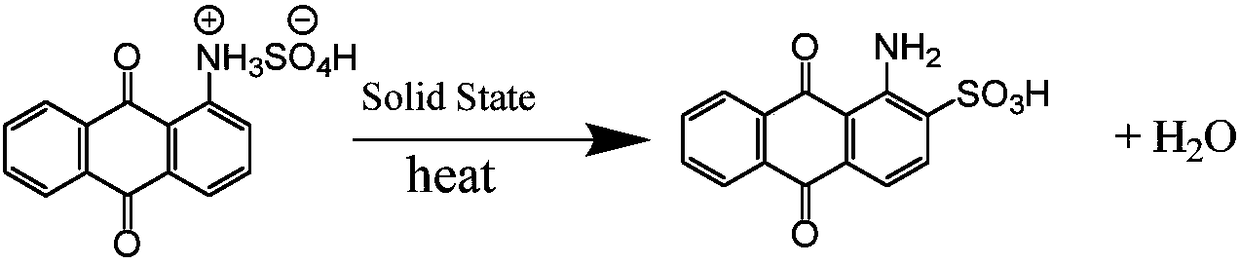

Process for synthesizing 1-amino-anthraquinone-2-sulfonic acid through solid-phase method

InactiveCN108129363ALow impurity contentImprove product qualityOrganic compound preparationSulfonic acid preparationOleumSulfate

The invention provides a method for synthesizing 1-amino-anthraquinone-2-sulfonic acid from 1-amino-anthraquinone. The method comprises the following steps: generating a sulfate solid of 1-amino-anthraquinone through reaction of the 1-amino-anthraquinone and sulfuric acid, and then performing transposition on the sulfate solid of the 1-amino-anthraquinone to generate the 1-amino-anthraquinone-2-sulfonic acid. A process of synthesizing the 1-amino-anthraquinone-2-sulfonic acid by a sulfuric acid method is fundamentally improved; the sulfate of the 1-amino-anthraquinone is efficiently subjectedto transposition reaction under a solid-phase condition without a solvent after generated water is removed, so that the reaction yield is high, and no side effects are caused; furthermore, no 1-amino-4-chloroant-2-sulfonic acid is generated, and no wastewater, waste gas and waste residues are generated; an obtained product is further synthesized into bromamine acid, and the purity of the obtainedbromamine acid is close to 100 percent; the quality and the yield of the bromamine acid are both higher than the quality and the yield of bromamine acid synthesized by a chlorosulfonic acid method, afuming sulfuric acid method and a conventional sulfuric acid method.

Owner:DALIAN HEPTACHROMA SOLAR TECH CO LTD

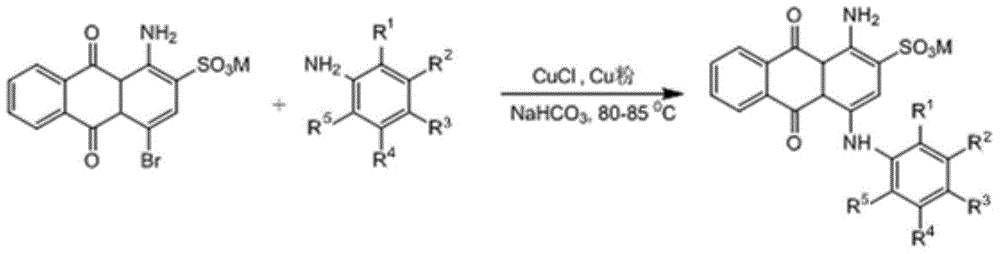

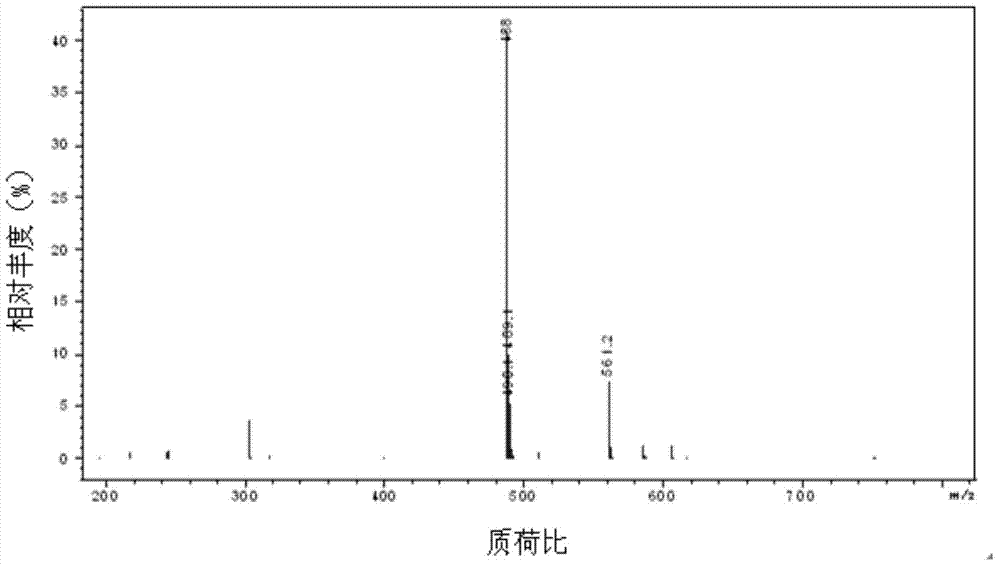

Preparation method of reactive brilliant blue K-GR intermediate

ActiveCN104326947AHigh yieldReduce contentOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acids salts preparationSulfonateBromine

The invention provides a preparation method of a reactive brilliant blue K-GR intermediate. The preparation method comprises following steps: carrying out a condensation reaction between bromamine acid and 2,4-diaminobenzene sulfonic acid or sodium 2,4-diaminobenzene sulfonate with a catalyst system containing a cuprous complex for catalyzing the reaction to obtain the reactive brilliant blue K-GR intermediate (sodium 1-amino-4-((4-amino-3-sulfonylphenyl)amino)-anthraquinone-2-sulfonate). By means of the preparation method of the reactive brilliant blue K-GR intermediate, usage amounts of cuprous chloride and copper powder can be effectively reduced, thereby reducing the content of heavy metals in a dye product, reducing the content of heavy metals in waste water and reducing environmental pollution and production cost. In addition, the preparation method can avoid generation of a hydrolyzed by-product (a purple by-product) of the bromamine acid, can greatly reduce the generation of a debromination by-product, can significantly reduce the generation of a double-condensation substance, can increase yields of the condensation reaction and the dye product and can reduce discharge amount of waste water containing acids and being high in chroma.

Owner:DALIAN UNIV OF TECH

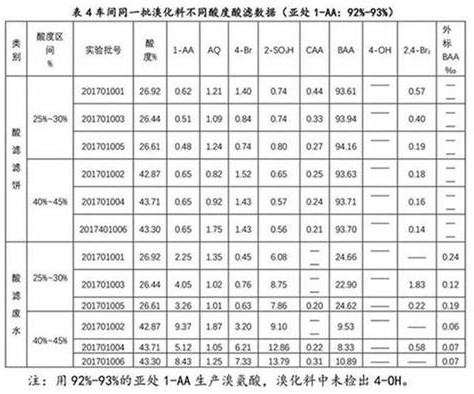

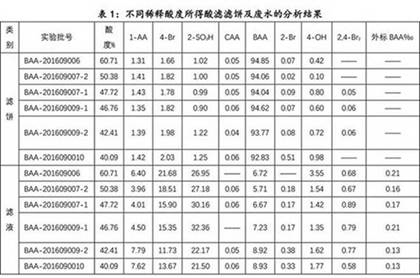

Clean production method of bromamine acid

InactiveCN112645851AImprove production efficiencyLess quantityOrganic compound preparationWater contaminantsAnthraquinonesActivated carbon

The invention relates to a clean production method of bromamine acid. The method comprises the following steps: preparing 1-amino anthraquinone-2-sulfonic acid; preparing a sulfuric acid solution of 1-amino anthraquinone-2-sulfonic acid; adjusting the acidity of a sulfuric acid solution of 1-amino anthraquinone-2-sulfonic acid to a preset value, and adding a brominated material to prepare a bromamine acid crude product; standing a bromamine acid crude product to remove redundant o-dichlorobenzene solution; carrying out thermal refining on the bromamine acid solution, and adsorbing organic matters in the solution by using activated carbon after thermal refining; salting out the solution to obtain a solution containing bromamine acid crystals, compressing the solution, and drying the filter cake to obtain bromamine acid. By adjusting the acidity of the sulfuric acid solution of 1-amino anthraquinone-2-sulfonic acid in the BAA preparation process, the isomer 1-amino-4-hydroxy anthraquinone which is difficult to remove can be effectively reduced, the amount of acid chloride wastewater generated in the subsequent process is effectively reduced, and the content of BAA in the prepared BAA filter cake is effectively increased; therefore, the preparation efficiency of the BAA prepared by the method provided by the invention is effectively improved.

Owner:YANCHENG OUHUA CHEM IND

Preparation method for bromamine acid

InactiveCN109734631AThe reaction steps are simpleReduce manufacturing costSulfonic acid preparationFiltrationDistillation

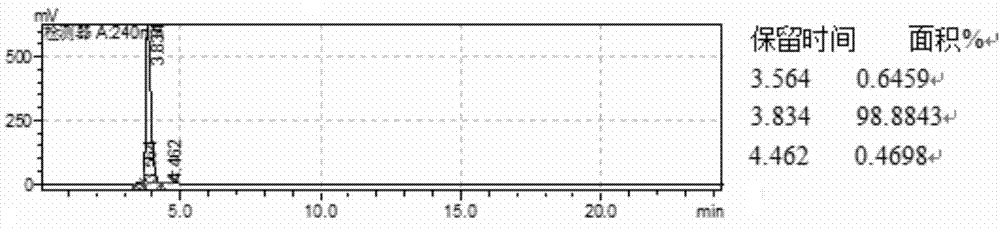

The invention discloses a preparation method for bromamine acid. The preparation method comprises the following steps: 1) taking 1-amino anthraquinone as a raw material and reacting with fuming sulfuric acid and sodium sulfate in a solvent, thereby acquiring a reaction liquor containing sulfonating products, wherein temperature of sulfonating reaction is at 100-150 DEG C and reaction time is 3-10h; 2) cooling the reaction liquor to 60-80 DEG C, adding iodine and anti-foaming agent, slowly dropwise adding bromine for 5-8h, and keeping temperature for 2-3h after the ending of dropwise adding; 3)ending bromination reaction, removing excessive bromine through reduced pressure distillation, adding a certain amount of water, cooling to 50-60 DEG C and filtering, thereby acquiring bromamine acidsulfate; 4) placing bromamine acid sulfate into a large amount of water, heating to 70-90 DEG C, adding sodium hydroxide for regulating pH to 8-9, cooling to 20-30 DEG C and performing suction filtration, thereby acquiring the product bromamine acid. The yield of product is 91% and the purity detected through liquid chromatogram is 99%.

Owner:MAANSHAN DEHONG BIOTECH

Method of preparing 1,4-diaminoanthraquinone-2-sulfonic acid

ActiveCN104447431AReduce the temperatureReduce energy consumptionSulfonic acid preparationBromineAmmonia

The invention discloses a method of preparing 1,4-diaminoanthraquinone-2-sulfonic acid. According to the method, bromamine acid is taken as a raw material and ammoniated in an ammonia water medium to directly obtain 1,4-diaminoanthraquinone-2-sulfonic acid. The method specifically comprises the following steps: uniformly mixing diluted ammonia water, bromamine acid and sodium carbonate in a pressure container in a mass ratio of (4 to 10):1:(0.1 to 0.3), heating while stirring, heating to 70-110 DEG C within 1-2 hours, insulating for 2-4 hours, cooling to 50-60 DEG C after the reaction is concluded, heating to distill off ammonia water occupying 30-40% of the volume of the mother liquor, then cooling to 50-70 DEG C, adjusting the pH value to 1-1.5 by hydrochloric acid or sulphuric acid, and filtering to obtain a 1,4-diaminoanthraquinone-2-sulfonic acid filter cake. According to the method disclosed by the invention, because the purity of the bromamine acid raw material is high, the contents of industrial products are generally greater than 99%, and moreover, obvious by-products are not generated during the reaction process, and high-purity 1,4-diaminoanthraquinone-2-sulfonic acid can be obtained during production.

Owner:JIANGSU HUAER CHEM

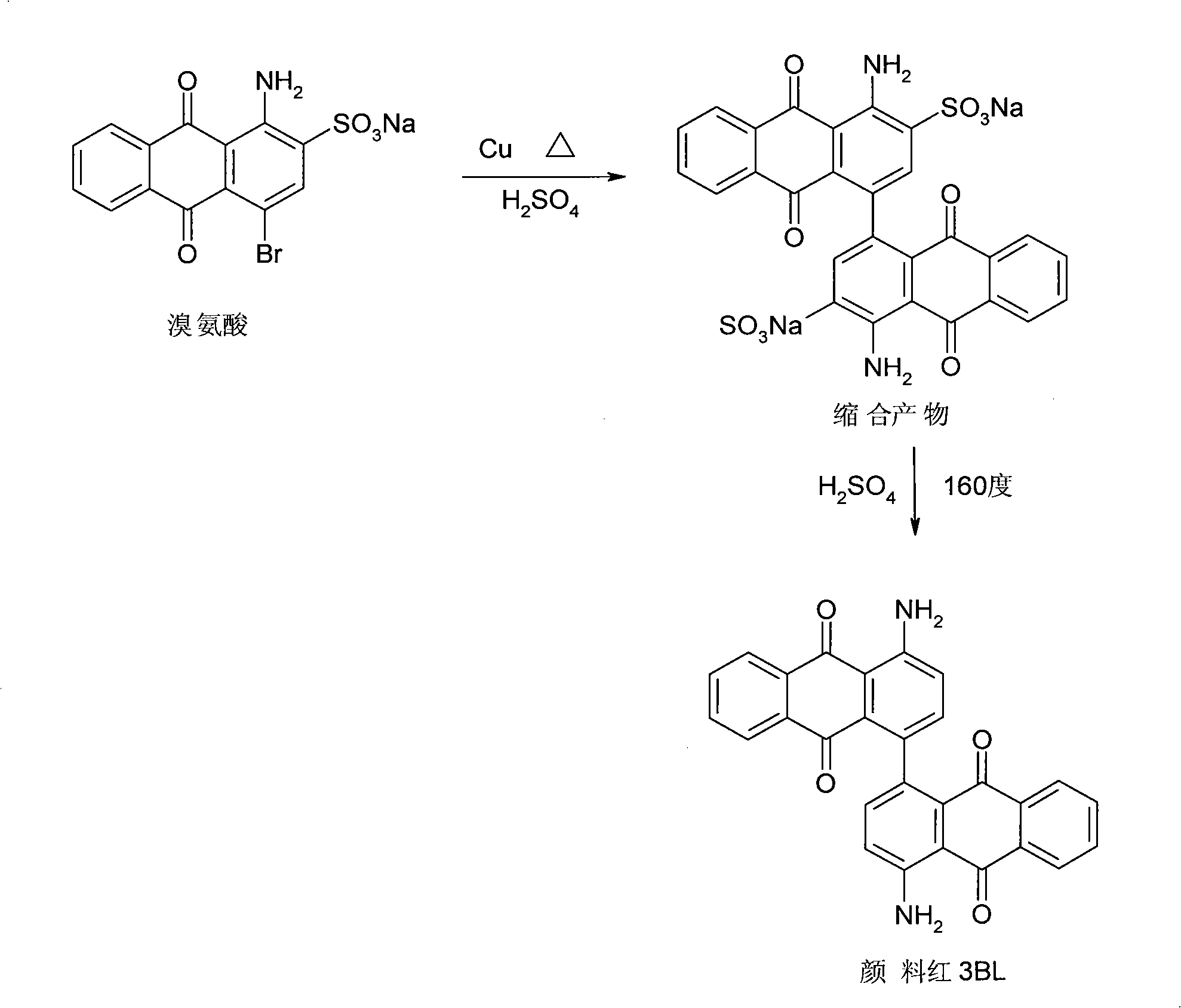

Method for manufacturing pigment red 3BL condensation intermediate

ActiveCN101830836AAchieving zero emissionsHigh activitySulfonic acids salts preparationSurface-active agentsBottle

The invention relates to a method for manufacturing a pigment red 3BL condensation intermediate, which is characterized by comprising the following steps of: adding 25 parts by weight of bromamine acid and 280 to 450 parts by weight of catalysts consisting of an organic solvent, a surface active agent and copper powder into to a 500-mL four-neck bottle provided with a thermometer, a stirrer and a reflux condensing tube; stirring the mixture for reacting for 150 min at 68-72 DEG C, filtering when the mixture is hot , moving the filtrate to a distilling bottle for distilling and recycling the organic solvent; after the organic solvent is distilled, adding 300 to 350 parts by weight of hot water, heating to boiling, adding 50 parts by weight of sodium chloride at 70 to 80 DEG C, salting out and filtering; washing a filter cake washed by 10% sodium chloride solution, and then, drying the washed filter cake in a drying box to obtain the pigment red 3BL condensation intermediate. The invention has the advantages of having high activity and good chemical stability, improving the reaction speed and productivity, having no corrosion to equipment and low cost, and realizing zero discharge of acid containing waste water.

Owner:南通市埃唯卡新材料有限公司

Method for synthesizing 2,4-dinitro-6-bromoaniline by using bromamine acid product wastewater

PendingCN112851523ATo achieve the purpose of comprehensive utilization of resourcesSimple processOrganic compound preparationAmino compound preparationDisperse dyeSodium cyanide

The invention relates to the technical field of chemistry and chemical engineering, and discloses a method for synthesizing 2,4-dinitro-6-bromoaniline by using bromamine acid product wastewater. The method comprises the steps of 1, adding sodium cyanide for reaction, synthesizing a disperse dye from byproducts in mother liquor and separated trace main products, filtering, and washing a filter cake with hot water to obtain the disperse dye; 2, adding an oxidizing agent into the filtrate and the washing liquid to oxidize and remove sodium cyanide, then reacting with 2,4-dinitroaniline, pulping in a sulfuric acid medium, dropwise adding sodium chlorate, reacting at the temperature of 35-75 DEG C, filtering the reaction liquid after bromination, washing a filter cake until the pH value is 6-7, and drying to obtain the product 2,4-dinitro-6-bromoaniline; and 3, decolorizing the mother liquor with activated carbon, performing membrane treatment, concentration and separation, recycling low-concentration salt water, and spraying high-concentration salt to be dry to serve as industrial salt (or serving as an active or acid dye assistant for internal digestion of a company). The problems of high COD and high-salt mother liquor wastewater of bromamine acid dye products in the prior art are solved.

Owner:ZHEJIANG YIDE CHEM

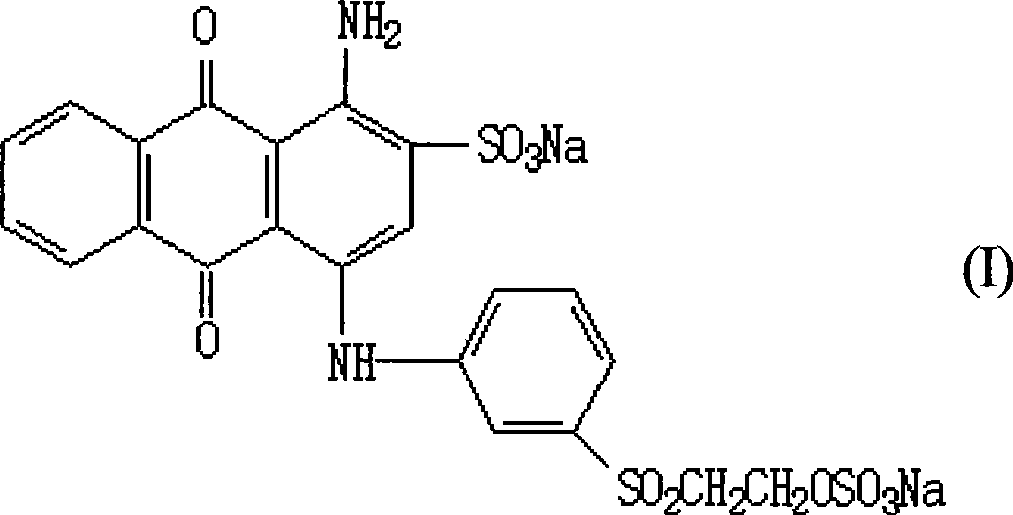

Method for catalytically synthesizing bromamine acid condensation product by using heterogeneous system

The invention discloses a novel method for catalytically synthesizing a bromamine acid condensation product by using a heterogeneous system. A strong-acidic ion exchange resin-mixed solvent-copper powder catalytic system is used for substituting a traditional thick sulfuric acid-water-copper powder catalytic system to perform the bromamine condensation reaction, and by utilizing the difference of solubility of the reaction raw material bromamine acid and the reaction condensation product in a mixed solvent in the reaction, and by selecting an organic solvent type in the mixed solvent, adjusting a volume ratio of the organic solvent and water and controlling the total consumption of the mixed solvent, a condensation product is separated from the reaction solution into a solid mixture of the heterogeneous system, so that the separation of the condensation product from a byproduct copper bromide can be realized, and a condensation product with higher purity and yield can be prepared. Under the condition that the consumption of the bromamine acid raw material is 1mol, by controlling the volume ratio of the organic solvent (methanol or ethanol) in the mixed solvent to the water to be (10 to 1) to (9 to 2) and the consumption of the mixed solvent to be 110 to 200 mL, the yield of the prepared condensation product can reach 95 percent above, and the spectral (HPLC) purity is 95.50 percent to 98.88 percent.

Owner:TIANJIN CHENGJIAN UNIV

Method for treatng wastewater of producing reactive dyes in class of bromamine acid, and for reclaiming resources

InactiveCN1280206CCombustible gas purificationWater/sewage treatment by sorptionHigh concentrationPresent method

Owner:NANJING UNIV

Preparation of dye brilliant blue KN-R

InactiveCN101481535AGood coloring rateGood color fixation rateReactive dyesPhotochemistryReactive dye

The invention relates to a method for preparing an improved reactive dye brilliant blue KN-R. The preparation method improves color radicle esterification rate, quality, color fixing rate and hoisting rate. Specifically, the invention provides a method for preparing a reactive dye brilliant blue KN-R used for fur, the method comprises condensation, refining, esterification and dilution of bromamine acid and metaposition oil and is characterized in that in esterification, 100% sulphuric acid is adopted, so that chromophore esterification is more complete.

Owner:TIANJIN DEK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com