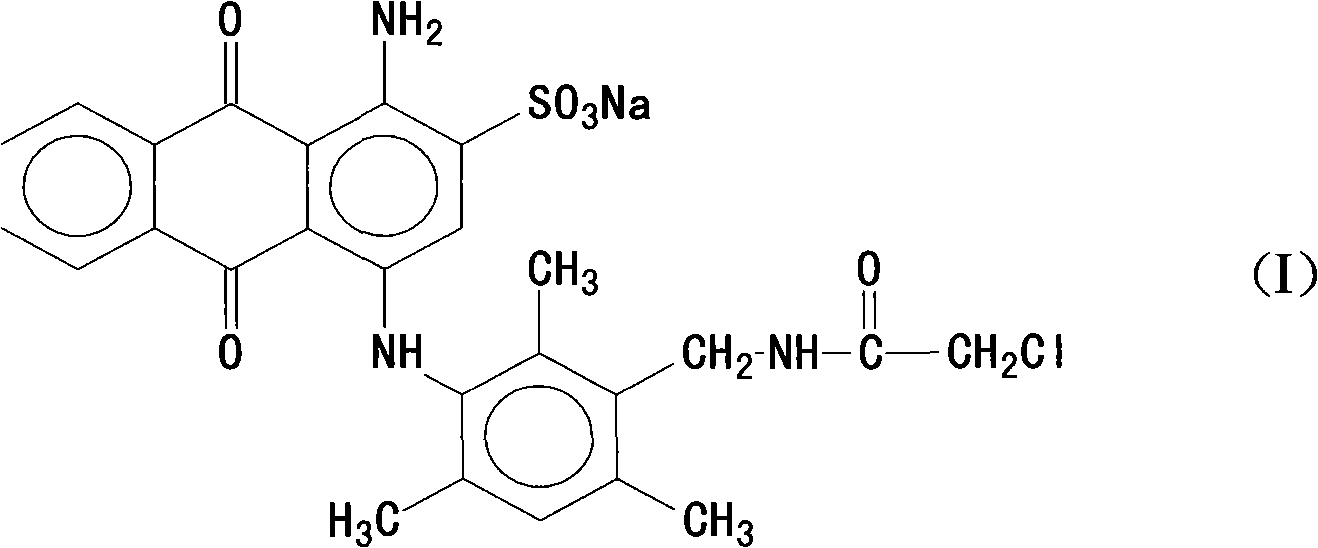

Method for preparing acid blue 260

A technology of acid blue and bromamine acid, applied in chemical instruments and methods, reactive dyes, azo dyes, etc., can solve the problems of many purple sub-dyes, low color yield, large consumption of raw materials, etc., and achieve light fastness Good, increase the conversion rate, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of acid blue 260 dye is described in the following steps:

[0033] a, the dissolution of bromamine acid and mes-trimethylaniline

[0034] to 10m 2 Add 4600 liters of water to the reaction tank, then add 404Kg of bromamine acid and 175.5Kg of mesitidine, stir, heat up to 90-95°C, dissolve the material, clarify, maintain the temperature at 90-95°C, and set aside;

[0035] b. Preparation of catalyst

[0036] Add 9.9Kg of cuprous chloride, 25 liters of water, 42.5 kg of 30% hydrochloric acid into a 200-liter plastic bucket, heat up to 40-42°C, dissolve the material, and set aside;

[0037] c. Condensation reaction

[0038] Add 336Kg of sodium bicarbonate to the bromamine and mesitidine solution prepared in step a, stir and cool down to 70-75°C, add 962Kg of butanol, and then add the catalyst prepared in step b with 5Kg of phosphoric acid Add tributyl ester, stir the reaction, control the reaction temperature at 60-65°C, and use TLC aluminum-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com