Clean production method of bromamine acid

A clean production, bromo-acid technology, applied in chemical instruments and methods, sulfonic acid preparation, water/sludge/sewage treatment, etc., can solve problems such as low efficiency of BAA preparation from incapable wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

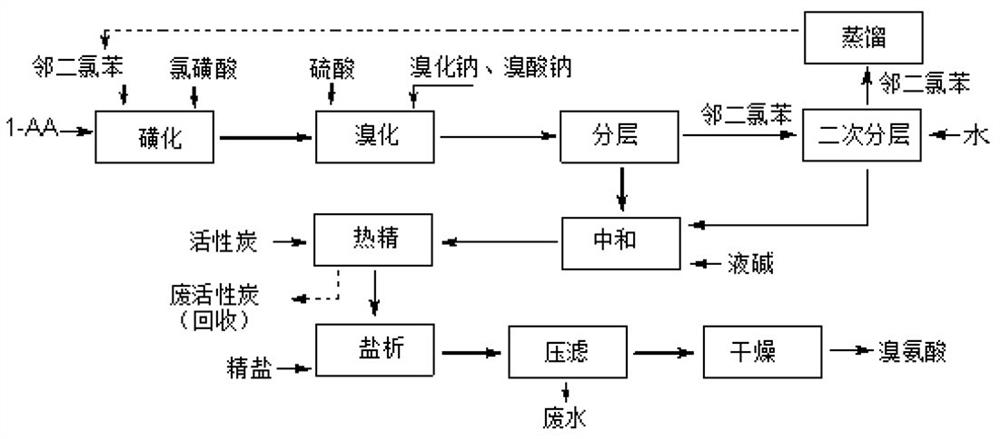

Method used

Image

Examples

Embodiment 1

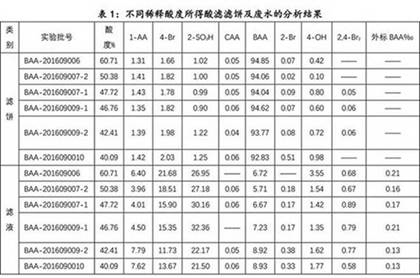

[0123] This embodiment determines the sulfuric acid concentration of brominated material in the BAA preparation process by experiment

[0124] At present, the concentration range of sulfuric acid after dilution of the brominated material in the workshop is 25%-30%. In this embodiment, it is considered to first purify the acid filtration wastewater to remove anthraquinone compounds, and then concentrate dilute sulfuric acid before applying it. For this reason, the diluted acidity should be increased as much as possible to reduce the energy consumption of dilute sulfuric acid concentration. In this embodiment, the quality of the acid filter cake and the composition of the acid filtrate at 30%, 40%, 50%, and 60% diluted acidity are compared successively to determine a reasonable acidity. On the premise of improving the quality of filter cake and reducing the loss of BAA, the diluted acidity should be increased as much as possible.

[0125] Table 1, Table 2, and Table 3 are the ...

Embodiment 2

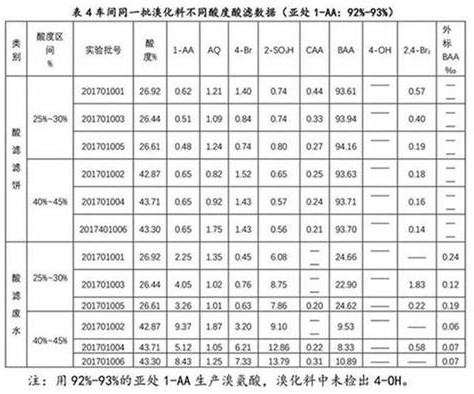

[0137] This embodiment is verified to different dilution acidity

[0138]Comparative experiment: take the same batch of brominated materials in the workshop, and conduct three parallel experiments with diluted acidity of 25%-30% and 40%-45%, respectively, and compare the data of the two diluted acidities. The data are shown in Table 4-Table 5 :

[0139]

[0140] It can be seen from Table 4 that in two different sulfuric acid dilution acidity intervals, the BAA content in the filter cake has little difference, but the BAA content (external standard) in the filtrate has a large difference, and the sulfuric acid acidity is between 25%-30%. The content of BAA in medium (external standard) is 2-4 times of the acidity of sulfuric acid at 40%-45%, so it can be seen that the diluted acidity of sulfuric acid should be controlled between 40%-45%.

[0141]

[0142] As can be seen from Table 5, neutralizing the BAA content in the filter cake, the sulfuric acid diluted acidity betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com