Method for preparing active dye for blue wool

A reactive dye for wool and reactive dye technology, applied in the field of reactive dye for blue wool and its preparation, can solve the problems affecting the reaction effect and repeatability, the low efficiency of copper catalyst utilization, and non-compliance with green chemistry, etc., to achieve Bright and beautiful color light, simple and easy preparation process, high fiber-dye bond stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

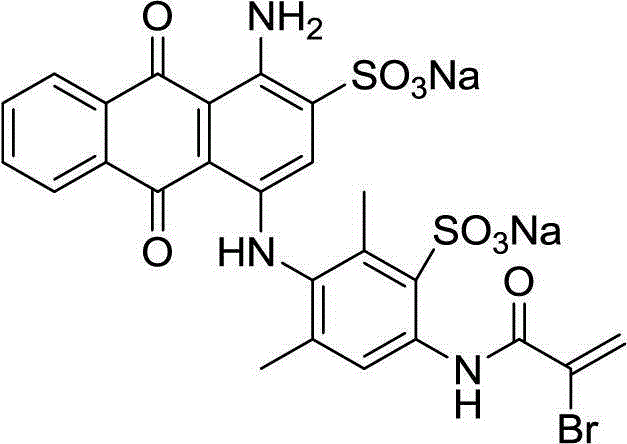

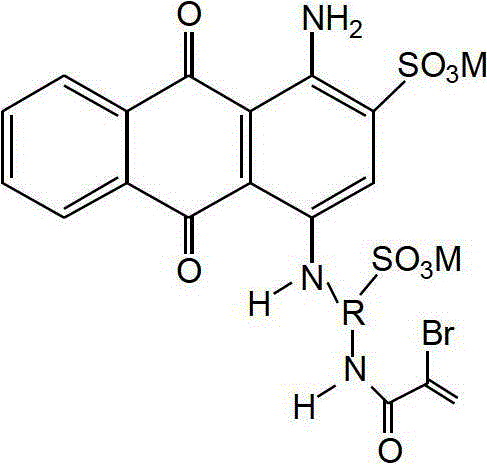

[0045] Embodiment 1 prepares blue reactive dye 1, operates according to the following steps:

[0046] a, a condensation reaction:

[0047] ①Put 1500L of bottom water into the primary condensation reaction pot, raise the temperature to 80°C, and put in 100kg of bromic acid to dissolve it;

[0048] ②Add 60kg of sodium carbonate and 16.5kg of sodium sulfite and stir for 1 hour to dissolve completely;

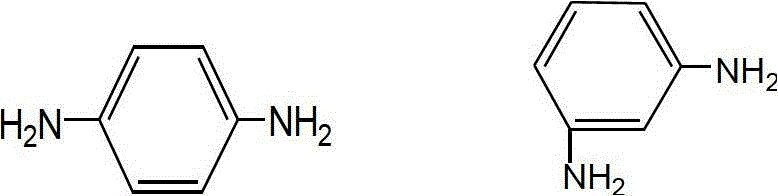

[0049] ③Put in 35kg of powdered p-phenylenediamine, stir and react for 1 hour, then add 5kg of cuprous chloride in two equal parts, maintain the temperature at 35-36°C, and react for 5 hours until the raw materials disappear. This reaction must be well stirred, and no reactants are allowed to sink to the bottom of the reactor during the reaction, otherwise the reaction will be incomplete. Finally, TLC chromatographic monitoring was performed to confirm the disappearance of the raw materials to terminate the reaction.

[0050] b. Acid refining:

[0051] ①Put 1500L of bottom wate...

Embodiment 2

[0062] Embodiment 2 Prepare blue reactive dye 2, operate according to the following steps:

[0063] a, a condensation reaction:

[0064] ①Put 2500L of bottom water into the primary condensation reaction pot, raise the temperature to 80°C, and put in 200kg of bromic acid to dissolve it;

[0065] ②Add 130kg of sodium carbonate and 33kg of sodium sulfite and stir for 1 hour to dissolve completely;

[0066] ③Put in 80kg of powdered m-phenylenediamine, stir for half an hour, then add 8kg of cuprous iodide in two equal parts, maintain the temperature at 35-38°C, and react for 5 hours until the raw materials disappear. During the reaction, no reactants were allowed to settle at the bottom of the reactor, and finally TLC was performed to confirm the end point.

[0067] b. Acid refining:

[0068] ①Put 3000L of bottom water in the refining pot, add 50kg of sodium sulfite, stir for 3 hours to completely dissolve it, and then cool down to 9-10°C.

[0069] ②The primary condensation rea...

Embodiment 3

[0079] Embodiment 3 Prepare blue reactive dye 1, operate according to the following steps:

[0080] a, a condensation reaction:

[0081] ①Put 1500L of bottom water into the primary condensation reaction pot, raise the temperature to 70°C, and put 100kg of bromic acid to dissolve it;

[0082] ②Add 60kg of sodium carbonate and 16.5kg of sodium sulfite and stir for 1 hour to dissolve completely;

[0083] ③Put in 35kg of powdered p-phenylenediamine, stir and react for 1 hour, then add 5kg of cuprous chloride in two equal parts, maintain the temperature at 35-36°C, and react for 5 hours until the raw materials disappear. This reaction must be well stirred, and no reactants are allowed to sink to the bottom of the reactor during the reaction, otherwise the reaction will be incomplete. Finally, TLC monitoring was performed to confirm that the raw materials disappeared and the reaction was terminated.

[0084] b. Acid refining:

[0085] ①Put 1500L of bottom water in the refining p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com