Composite active black dye

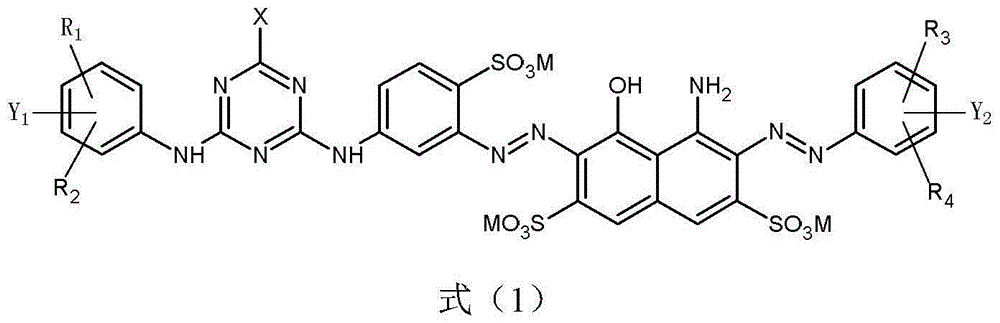

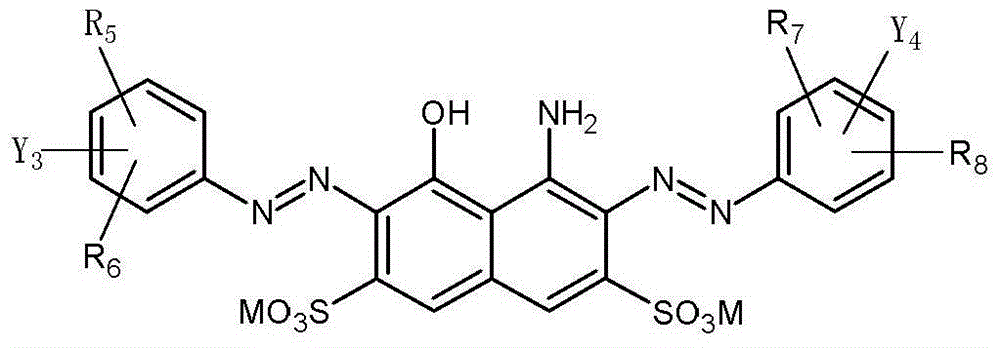

A technology of reactive dyes and reactive black, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of low success rate, rework, modification, high COD of dyeing residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Each reactive dye composition (sample number 1-10) according to the ratio shown in Table 1 was mixed as dry powder in a mixing tank, or spray-dried after dissolving together.

[0061] There are other reactive dye compositions that are not listed one by one, but are included in the present invention.

[0062] Table 1

[0063]

Embodiment 2

[0065] 100g cotton cloth, by the black dyestuff that sample 1-15 obtains in the embodiment 1, by the weight 2% of fabric, in the dyeing bath that contains 60g / l yuan Mingfen, liquor ratio is 20:1, absorbs 30min under 60 ℃, adds Soda ash (amount of 15-20g / l) fixes the color for 45 minutes. The dyed fabric is washed, soaped and dried. The resulting black cotton cloth had a uniform black color and satisfactory light and wet treatment fastness. The specific performance is shown in Table 2.

[0066] Table 2

[0067]

[0068]

[0069] According to a large number of experimental detections, the composite reactive black dye of the present invention has better application performance than the traditional reactive black dye, and the specific comparative data are shown in Table 3.

[0070] table 3

[0071] serial number

[0072] sample 14

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com