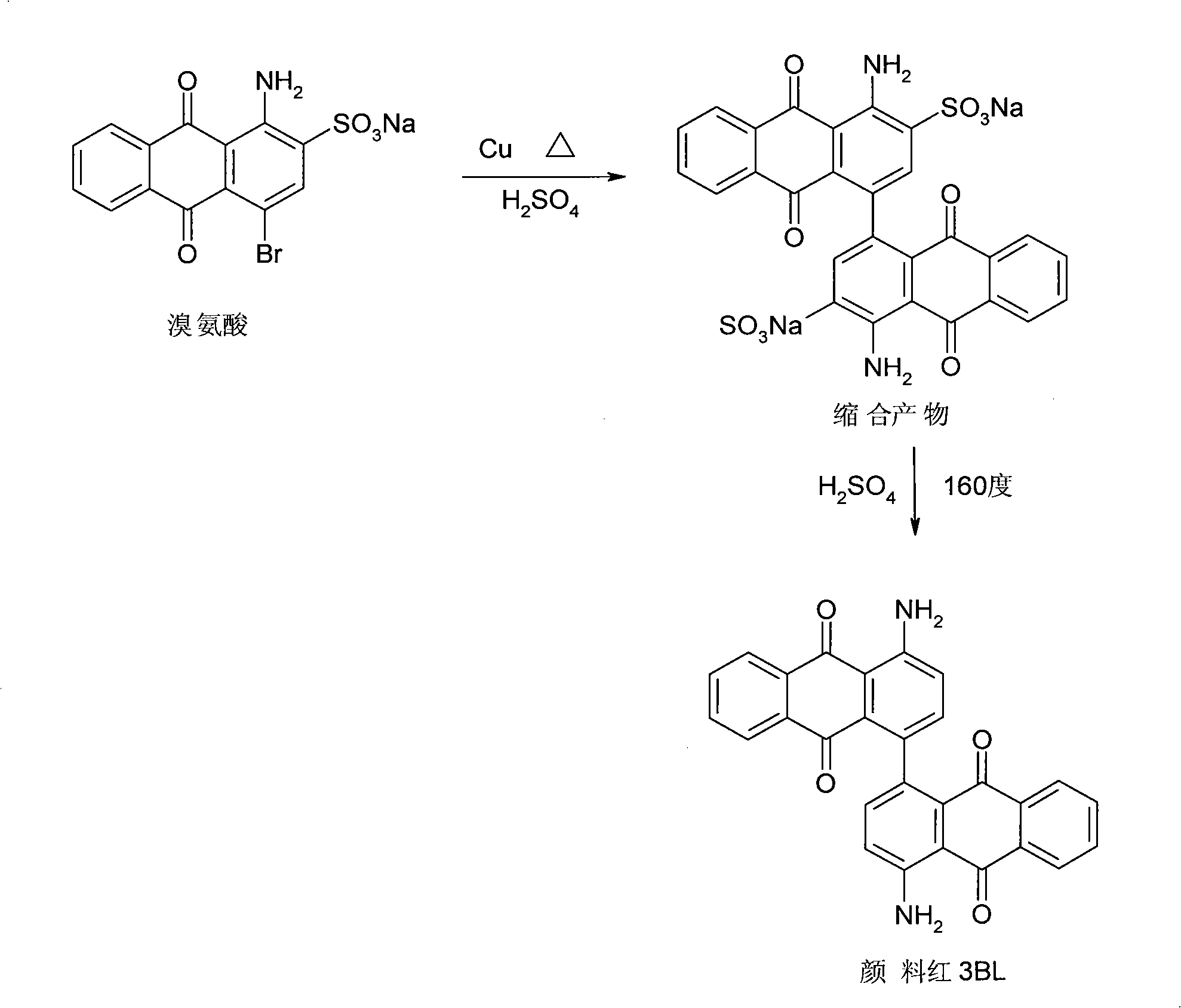

Method for manufacturing pigment red 3BL condensation intermediate

A production method and intermediate technology, applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of large energy consumption, environmental pollution, high processing cost, etc., and achieve faster reaction speed, good chemical stability, and no corrosion of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of production method of pigment red 3BL condensation intermediate, in the 500mL four-necked bottle that thermometer, agitator and reflux condenser are equipped with, add bromine 25g, copper powder 13g, diethylene glycol ethyl ether 350mL and laurylamine 1.5g , stirred and reacted at 68-72°C for 150 minutes, then filtered while it was hot, transferred the filtrate to a distillation flask to distill and recover diethylene glycol ethyl ether, after the distillation of diethylene glycol ethyl ether was completed, add 320ml of hot water and heat to boiling, then Add 50g of sodium chloride at 70-80°C for salting out and filter, wash the filter cake with 10% sodium chloride solution, and then dry it in a drying oven to obtain the pigment red 3BL condensation intermediate. The yield can reach 67.2%.

Embodiment 2

[0019] A kind of production method of pigment red 3BL condensation intermediate, in the 500mL four-neck bottle that is equipped with thermometer, agitator and reflux condenser tube, add 25g of bromine, 12.5g of copper powder, 380mL of N,N~dimethylformamide and octadecylamine 1.7g, stirred and reacted at 68-72°C for 150min, then filtered while hot, transferred the filtrate to a distillation flask to recover N,N-dimethylformamide, and waited for N,N-dimethylformamide After the distillation is completed, add 300ml of hot water and heat to boiling, add 50g of sodium chloride at 70-80°C for salting out and filter, wash the filter cake with 10% sodium chloride solution, and then place it in a drying oven to dry to obtain Pigment Red 3BL condensation intermediate. The yield can reach 73.2%.

Embodiment 3

[0021] A kind of production method of pigment red 3BL condensation intermediate, in the 500mL four-necked bottle that thermometer, stirrer and reflux condenser tube are housed, add bromine 25g, copper powder 13.2g, propylene glycol ether 380mL and stearylamine 1.7g, Stir and react at 68-72°C for 150 minutes, then filter while it is hot, transfer the filtrate to a distillation flask to recover propylene glycol ether, and after the distillation of propylene glycol ether is completed, add 350ml of hot water and heat to boiling, then add 50g at 70-80°C Sodium chloride was salted out and filtered, the filter cake was washed with 10% sodium chloride solution, and then dried in a drying oven to obtain the pigment red 3BL condensation intermediate. The yield can reach 73.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com