Method for catalytically synthesizing bromamine acid condensation product by using heterogeneous system

A technology of condensation product, bromo-acid, applied in the direction of organic chemistry, sulfonate preparation, etc., can solve problems such as influence, difficult separation of condensation product and by-product copper bromide, etc., and achieve the effect of high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] At room temperature, according to the solid-to-liquid ratio (w / v) of 1:4, the strongly acidic ion exchange resin was stirred and soaked for 5 hours with 0.5mol / L NaOH solution and 0.5mol / L HCl solution in turn, and then suction filtered. The filter cake was washed with water until it was neutral, and then air-dried at 75°C to obtain a pretreated strong acidic ion exchange resin, ready for use;

[0031] At room temperature, according to the solid-to-liquid ratio (w / v) of 1:3, use 0.5mol / L HCl solution to stir and soak the copper powder for 4 hours, then filter with suction, wash the filter cake with water until neutral, and dry it in vacuum at 50°C , cross 200 mesh sieves to obtain pretreated copper powder, stand-by;

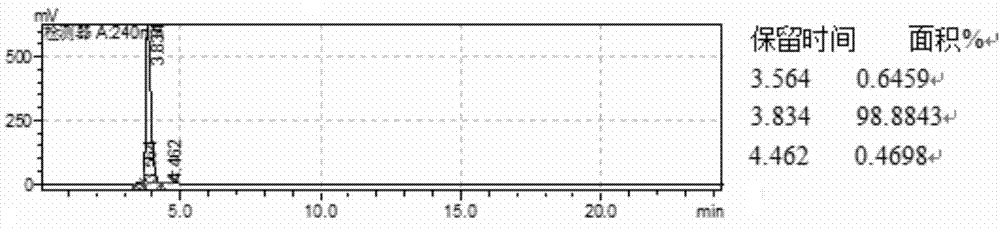

[0032] Weigh 1mol of bromine and add it to a reaction flask equipped with a thermometer, a stirrer and a reflux condenser, then add 50mL of mixed solvent (methanol:water=10:1, V / V) to soak for 30min, and then pour Continue to add 60mL of mixed solvent, an...

Embodiment 2

[0034] The mixed solvent in Example 1 was replaced with ethanol:water=10:1 (V / V), the reaction temperature was increased to 75° C., and other reaction conditions remained unchanged. The yield of the condensation product calculated by weighing was 96.24%, and its purity was found to be 95.50% by high performance liquid chromatography (HPLC).

Embodiment 3

[0036] Adopt 50mL mixed solvent (methanol:water=9:1, V / V) to carry out immersion treatment to bromic acid raw material as embodiment example 1, other reaction conditions remain unchanged. The yield of the condensation product calculated by weighing was 96.19%, and its purity was found to be 97.62% by high performance liquid chromatography (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com