Integrated method for catalyzing condensation reaction of bromamine acid by using solid acid and degrading waste water produced by condensation reaction

A technology of solid acid catalysis and solid acid catalyst, applied in chemical instruments and methods, oxidized water/sewage treatment, chemical recovery, etc., can solve the problems of complicated separation process, difficult environmental restoration, environmental impact, etc., and achieve high catalytic activity, The effect of reducing the difficulty of wastewater treatment and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

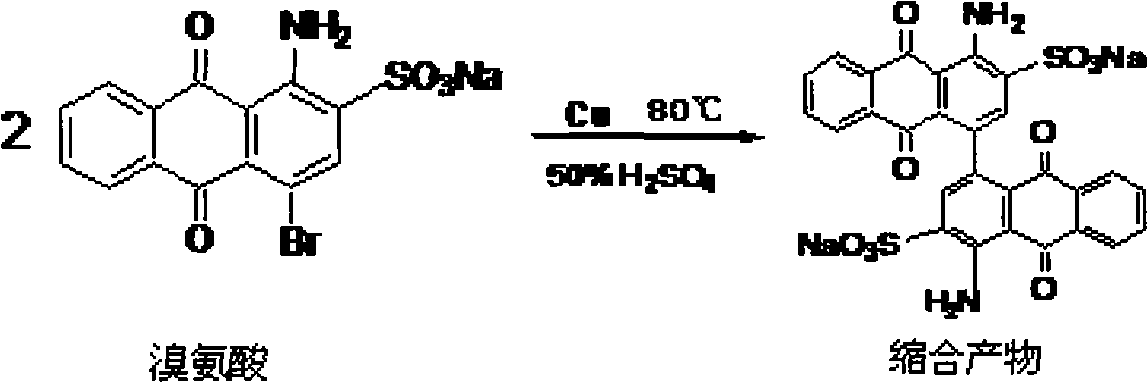

Image

Examples

Embodiment 1

[0037] process 1

[0038] Weigh 1.0g of TiO 2 Powder, immersed in 15mL 0.75mol / L H 2 SO 4 Soak in aqueous solution for 24 hours, dry in a drying oven at 110°C, and calcinate at 500°C for 2 hours to obtain SO 4 2- / TiO 2 solid acid catalyst.

[0039] process 2

[0040] Weigh 10g of copper powder, add 50ml of 70% sulfuric acid solution, heat on the electric heating mantle, continue heating at 80°C for 1 hour after boiling, wash with water until neutral, then add 10ml of acetone to rinse, rinse three times and blow dry with nitrogen Copper powder, put the dry copper powder in a desiccator to prevent oxidation.

[0041] process 3

[0042] In a 250ml four-neck flask equipped with a thermometer, a stirrer, and a reflux condenser, add 2.02g (5mmol) of bromine, 0.95g (15mmol) of copper powder treated in the above process 2, 80.0ml of distilled water, and add SO 4 2- / TiO 2 0.1g, react at a constant temperature at 70°C for 90 minutes, filter out the solid acid catalyst and c...

Embodiment 2

[0044] process 1

[0045] Weigh 1.0g of TiO 2 Powder, immersed in 15mL 0.75mol / L H 2 SO 4 Soak in aqueous solution for 24 hours, dry in a drying oven at 110°C, and calcinate at 400°C for 2 hours to obtain SO 4 2- / TiO 2 solid acid catalyst.

[0046] process 2

[0047] Weigh 10g of copper powder, add 50ml of 70% sulfuric acid solution, heat on the electric heating mantle, continue heating at 80°C for 1 hour after boiling, wash with water until neutral, then add 10ml of acetone to rinse, rinse three times and blow dry with nitrogen Copper powder, put the dry copper powder in a desiccator to prevent oxidation.

[0048] process 3

[0049] In a 250ml four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, add 2.02g (5mmol) of bromine, 0.95g (15mmol) of copper powder treated in process 2, 80.0ml of distilled water, and add a solid acid catalyst SO 4 2- / TiO 2 0.2g, react at a constant temperature at 70°C for 90min, filter out the solid acid catal...

Embodiment 3

[0051] process 1

[0052] Weigh 1.0g of TiO 2 Powder, immersed in 15mL 0.75mol / L H 2 SO 4 Soak in aqueous solution for 24 hours, dry in a drying oven at 110°C, and calcinate at 500°C for 2 hours to obtain SO 4 2- / TiO 2 solid acid catalyst.

[0053] process 2

[0054] Weigh 10g of copper powder, add 50ml of 70% sulfuric acid solution, heat on the electric heating mantle, continue heating at 80°C for 1 hour after boiling, wash with water until neutral, then add 10ml of acetone to rinse, rinse three times and blow dry with nitrogen Copper powder, put the dry copper powder in a desiccator to prevent oxidation.

[0055] process 3

[0056] In a 250ml four-neck flask equipped with a thermometer, a stirrer, and a reflux condenser, add 2.02g (5mmol) of bromine, 0.95g (15mmol) of copper powder treated in process 2, 80.0ml of distilled water, and add SO 4 2- / TiO 2 0.2g, after constant temperature reaction at 60°C for 90min, filter out the solid acid catalyst and copper powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com