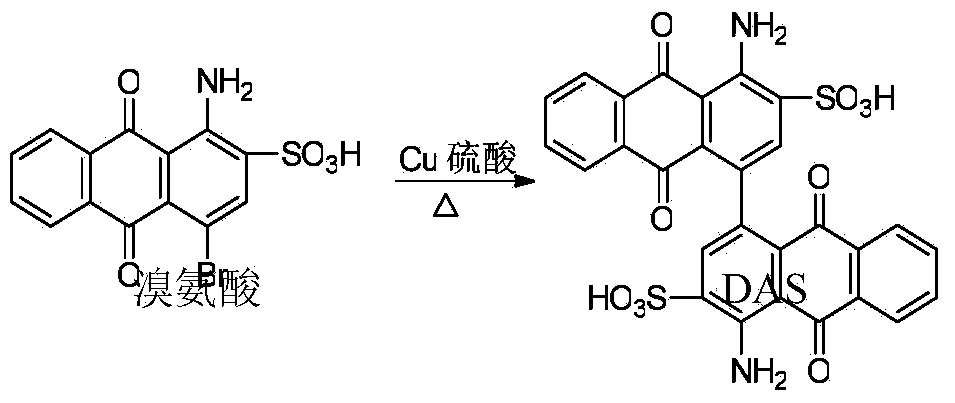

Preparation method of copper powder carrier catalyst for bromamine acid Ullman condensation reaction

A technology of condensation reaction and bromine, which is applied in the direction of sulfonic acid preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of troublesome steps, low catalytic activity, uneven dispersion, etc., and save pretreatment , high catalytic activity and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The process of treating sepiolite with sulfuric acid of the present invention is:

[0021] Stir and disperse 21g of powdered sepiolite (purchased from Hebei Hongli Sepiolite Wool Co., Ltd., but not limited to the products of this company) in 160mL of water, slowly add sulfuric acid, and bubbles are formed. Continuously add sulfuric acid to adjust the pH to 3 until no bubbles are released in the mixture, and control the final pH to 3. The treated sepiolite mixed solution was reserved for the preparation of the following copper supported catalyst.

[0022] Preparation of copper powder carrier catalyst:

[0023] The mass ratio of sepiolite to copper sulfate is 3:1

[0024] The mass ratio of ethylenediaminetetraacetic acid disodium salt and iminodiacetic acid in the two-component complexing agent is 1:1. The ratio of the total mass of EDTA disodium salt and iminodiacetic acid to copper sulfate is 1.1:1.

[0025] The mass ratio of reducing agent formaldehyde (calculated ...

Embodiment 2

[0029] The process of treating sepiolite with sulfuric acid of the present invention is:

[0030] Stir and disperse 14g of powdered sepiolite in 160mL of water, slowly add sulfuric acid, and bubbles will form. Continuously add sulfuric acid to adjust the pH to 3 until no bubbles are released in the mixture, and control the final pH to 3. The treated sepiolite mixed solution was reserved for the preparation of the following copper supported catalyst.

[0031] Preparation of copper powder carrier catalyst:

[0032] The mass ratio of sepiolite to copper sulfate is 2:1

[0033] The mass ratio of ethylenediaminetetraacetic acid disodium salt and iminodiacetic acid in the two-component complexing agent is 1:1. The ratio of the total mass of EDTA disodium salt and iminodiacetic acid to copper sulfate is 1.3:1.

[0034] The mass ratio of reducing agent formaldehyde (calculated as 35% formaldehyde aqueous solution) to copper sulfate is 4:1

[0035] Add 7g of copper sulfate to the ...

Embodiment 3

[0038] The process of treating sepiolite with sulfuric acid of the present invention is:

[0039] Stir and disperse 28g of powdered sepiolite in 160mL of water, slowly add sulfuric acid, and bubbles will form. Continuously add sulfuric acid to adjust the pH to 3 until no bubbles are released in the mixture, and control the final pH to 3. The treated sepiolite mixed solution was reserved for the preparation of the following copper supported catalyst.

[0040] Preparation of copper powder carrier catalyst:

[0041] The mass ratio of sepiolite to copper sulfate is 4:1

[0042] The mass ratio of ethylenediaminetetraacetic acid disodium salt and iminodiacetic acid in the two-component complexing agent is 1:1. The ratio of the total mass of EDTA disodium salt and iminodiacetic acid to copper sulfate is 0.9:1.

[0043] The mass ratio of reducing agent formaldehyde (calculated as 35% formaldehyde aqueous solution) to copper sulfate is 3:1

[0044]Add 7g of copper sulfate to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com