Treatment method of bromamine acid wastewater

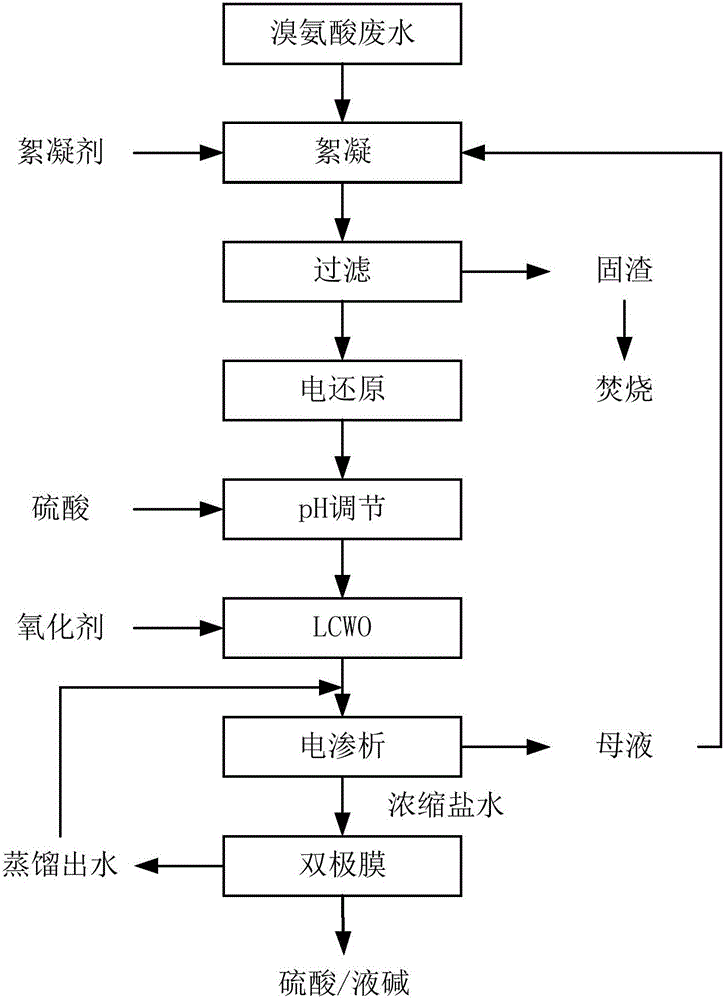

A technology for bromamic acid and waste water, which is applied in the field of bromine acid neutralization wastewater treatment, can solve the problems of difficult comprehensive treatment of bromine acid dye wastewater, difficult automatic control, etc., and achieves mild conditions, simple process and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the neutralized wastewater produced by the production of bromic acid, sodium sulfate was measured: 5.3% (mass fraction), ammonia nitrogen 43.9 mg / L, COD=4214mg / L, pH=11.33.

[0034] (1) Flocculation: add 0.03%wt aluminum chloride PAC to the bromic acid neutralization wastewater, stir for 0.5h at 25°C, let stand for 1h, filter to obtain the filtrate. The filter cake is red, and the filtrate is light red transparent clear liquid. Filtrate COD=2670 mg / L, sodium sulfate 5.3%wt, ammonia nitrogen 112.7 mg / L.

[0035] (2) Electrocatalytic reduction: pass the filtrate after flocculation filtration into the electrocatalytic reaction cell, pass in oxygen, and use Ti / RuO 2As the anode and the graphite electrode as the cathode, the catalyst was catalyzed for 25 min. Solution COD=2550 mg / L.

[0036] (3) Low-temperature wet oxidation (hereinafter referred to as LCWO): use 1 mol / L sulfuric acid to adjust the pH to 7.3, add dropwise H 2 o 2 Catalytic oxidation at 40°C, effluent...

Embodiment 2

[0044] In the neutralized waste water from the production of bromic acid, sodium sulfate was measured: 5.2% (mass fraction), ammonia nitrogen 42.7 mg / L, COD=1998mg / L, pH=11.88.

[0045] (1) Flocculation: add 0.05% wt of polyferric sulfate PFS to the bromic acid neutralization wastewater, stir at 45°C for 1 hour, let stand for 0.5 hours, and filter to obtain the filtrate. The filter cake is red, and the filtrate is light red transparent clear liquid. Filtrate COD=670 mg / L, sodium sulfate 5.3%wt, ammonia nitrogen 3 mg / L.

[0046] (2) Electrocatalytic reduction: The filtrate after flocculation and filtration was passed into the electrocatalytic reaction cell, and oxygen was introduced, and the Pt / Ti electrode was used as the anode, and the metal Cu electrode was used as the cathode, and the catalyst was catalyzed for 10 min. Solution COD=530 mg / L.

[0047] (3) LCWO: Use 1 mol / L sulfuric acid to adjust the pH to 7.5, add H 2 o 2 Catalytic oxidation at 60°C, effluent COD<10 mg / ...

Embodiment 3

[0053] In the neutralized waste water from the production of bromic acid, sodium sulfate was measured: 5.4% (mass fraction), ammonia nitrogen 44.9 mg / L, COD=2274mg / L, pH=10.73.

[0054] (1) Flocculation: add 0.03%wt aluminum chloride PAC and 0.01%wt polyacrylamide PAM to bromic acid neutralization wastewater, stir for 2h at 35°C, let stand for 1.5h, filter to obtain filtrate. The filter cake is red, and the filtrate is light red transparent clear liquid. Filtrate COD=490 mg / L, sodium sulfate 5.4%wt, ammonia nitrogen 2.5 mg / L.

[0055] (2) Electrocatalytic reduction: pass the filtrate after flocculation filtration into the electrocatalytic reaction cell, pass in oxygen, and use Ti / SnO 2 -Sb electrode as anode, graphite electrode as cathode, catalysis for 15 min. Solution COD=450 mg / L.

[0056] (3) LCWO: Use 1 mol / L sulfuric acid to adjust the pH to 7.1, add ClO dropwise 2 Catalytic oxidation at 60°C, effluent COD<10 mg / L.

[0057] (4) Electrodialysis: Electrodialysis is pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com