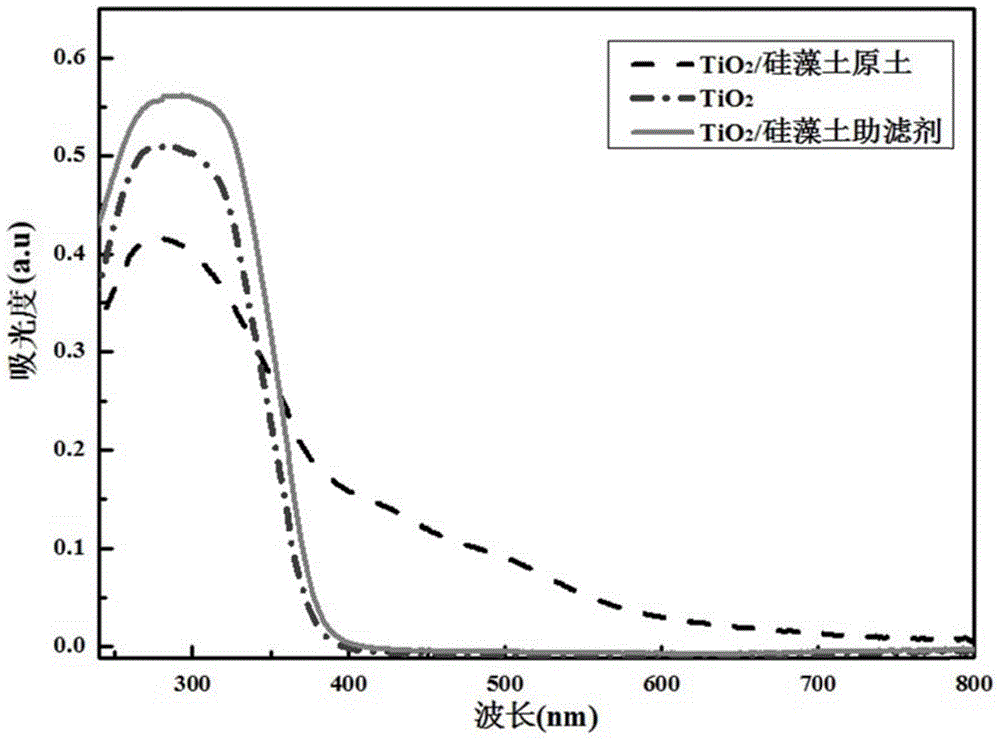

Nano TiO2-diatomite composite photocatalyst and preparation method thereof

A diatomite and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low utilization rate of visible light, low degradation ability of organic pollutants, etc., to improve visible light utilization, avoidance of competing adsorption problems, tight binding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

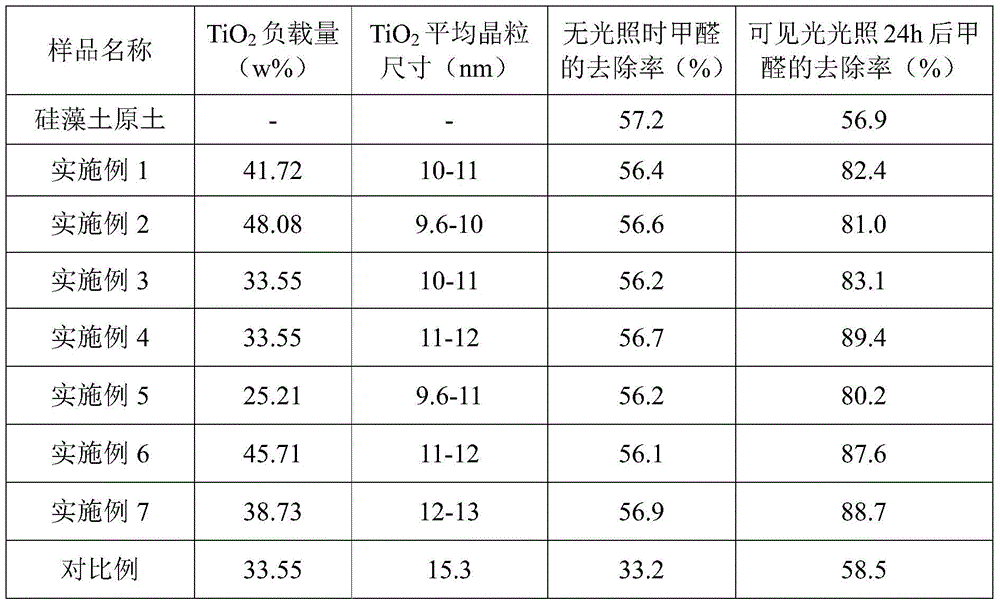

Embodiment 1

[0029] Diatomite raw ore is removed silt and dried, and prepared diatomite raw soil is standby; 17kg titanium tetrachloride is mixed with the titanium tetrachloride solution that mass fraction is 50%, is made into the mass concentration of 5.61kg ammonium sulfate 200g / L ammonium sulfate solution, titanium tetrachloride solution and ammonium sulfate solution are slowly added to 600LpH respectively in the hydrochloric acid solution of 3 and vigorously stirred for 30min to obtain an acidic mixed solution containing titanium tetrachloride and ammonium sulfate, the The pH of the acidic mixed solution is still 3, wherein the mass concentration of titanium tetrachloride is 26.0g / L; 10 kg of diatomite raw soil is added to the acidic mixed solution, and vigorously stirred for 30 minutes to obtain a slurry; Add ammonium carbonate solution with a mass concentration of 100g / L, adjust the pH value of the slurry to 6, and then age the slurry at a temperature of 28°C for 3 hours; filter the a...

Embodiment 2

[0031] Diatomite raw ore is removed silt and dried, and prepared diatomite raw soil is standby; 22kg titanium tetrachloride is mixed with the titanium tetrachloride solution that mass fraction is 50%, is made into the mass concentration of 7.26kg ammonium sulfate 200g / L of ammonium sulfate solution, titanium tetrachloride solution and ammonium sulfate solution are slowly added to 600LpH respectively in the hydrochloric acid solution of 2 and vigorously stirred for 30min to obtain an acidic mixed solution containing titanium tetrachloride and ammonium sulfate. The pH of the acidic mixed solution is still 2, wherein the mass concentration of titanium tetrachloride is 32.8g / L; 10 kg of diatomite raw soil is added to the acidic mixed solution, and vigorously stirred for 30 minutes to obtain a slurry; Add the ammonium carbonate solution whose mass concentration is 250g / L, adjust the pH value of this slurry to 7, then carry out aging, the aging temperature is 20 ℃, and the aging time...

Embodiment 3

[0033] Diatomite raw ore is removed silt and dried, and diatomite raw soil is prepared for subsequent use; 12kg titanium tetrachloride is mixed with the titanium tetrachloride solution that mass fraction is 50%, is made into the mass concentration of 2.64kg ammonium sulfate 200g / L of ammonium sulfate solution, titanium tetrachloride solution and ammonium sulfate solution are slowly added to 600LpH respectively in the hydrochloric acid solution of 2 and vigorously stirred for 30min to obtain an acidic mixed solution containing titanium tetrachloride and ammonium sulfate. The pH of the acidic mixed solution is still 2, wherein the mass concentration of titanium tetrachloride is 19.0g / L; 10 kg of diatomite raw soil is added to the acidic mixed solution, and vigorously stirred for 30 minutes to obtain a slurry; Add ammonium carbonate solution with a mass concentration of 190g / L, adjust the pH value of the slurry to 8, and then age, the aging temperature is 25°C, and the aging time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com