Production method of diethanolisopropanolamine

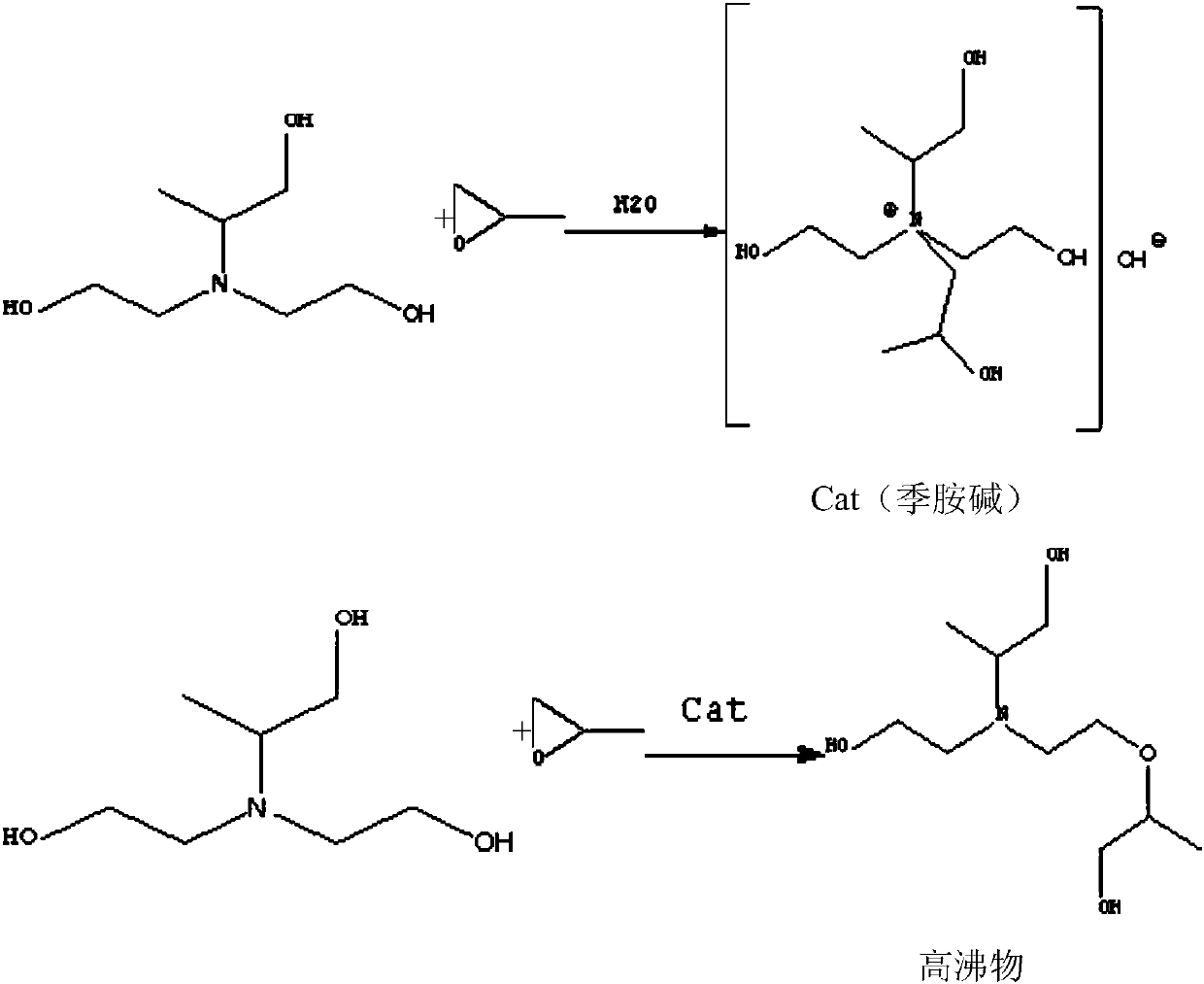

A monoisopropanolamine and production method technology, applied in the field of chemical building materials, can solve the problems of increasing energy consumption and process, not easy to improve economic benefits, and cumbersomeness, so as to reduce the generation of high boiling substances and inhibit the production of quaternary ammonium bases generation, to avoid the effect of reducing the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

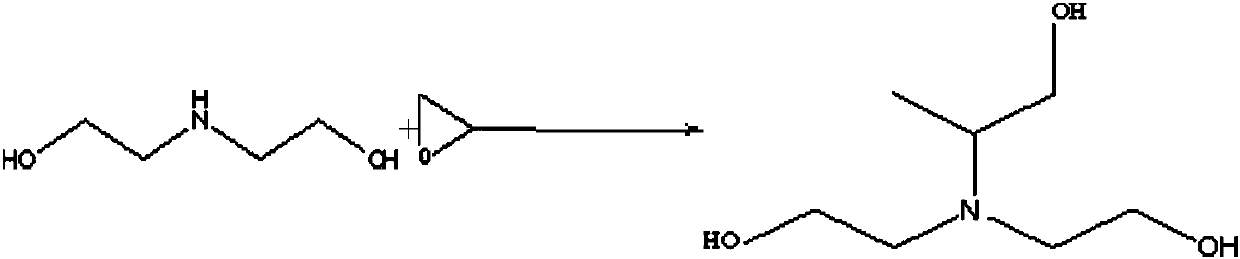

Method used

Image

Examples

Embodiment 1

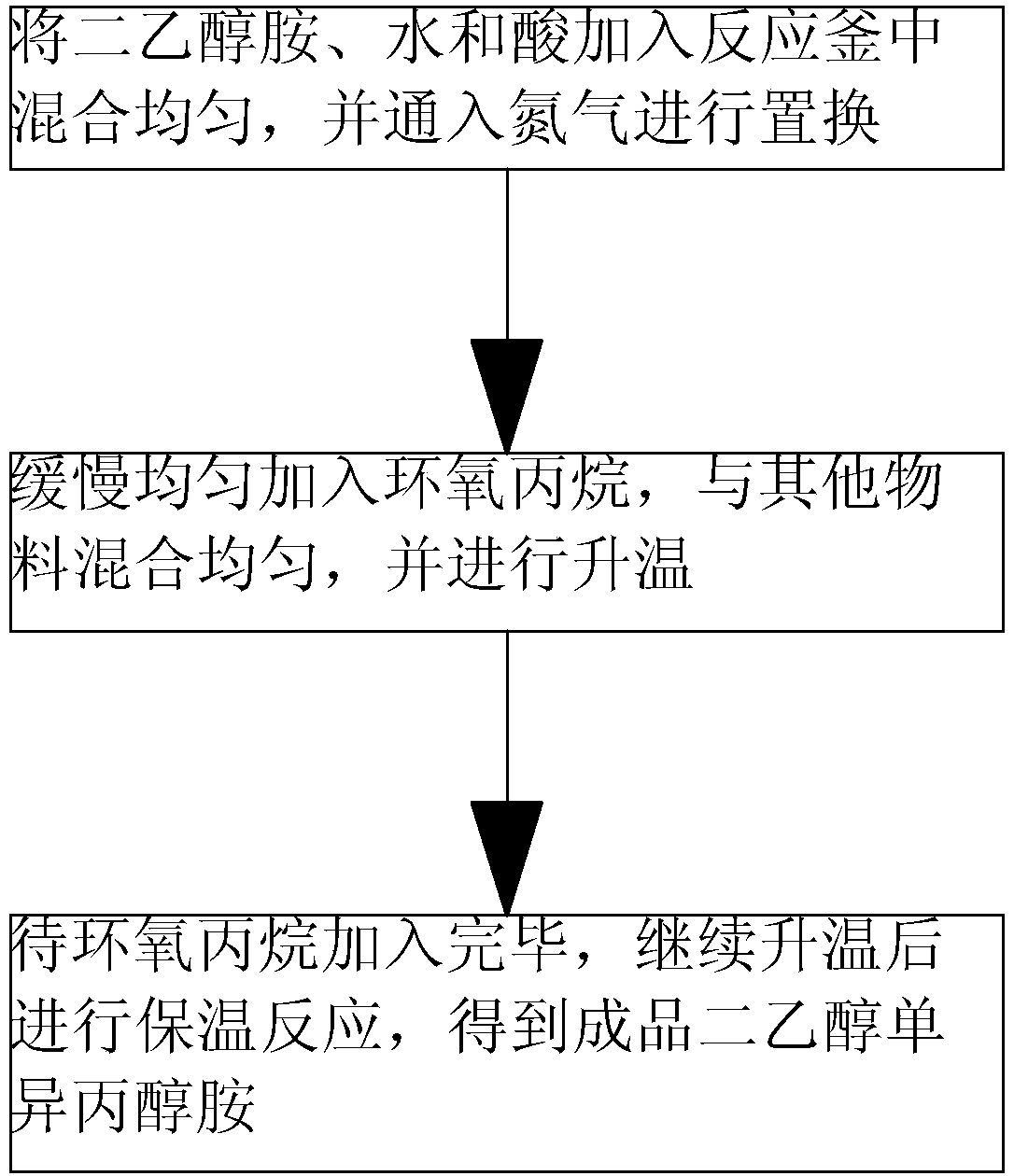

[0033] Step 1: Add 10046Kg diethanolamine, 2050Kg water and 31Kg glacial acetic acid into the reaction kettle, then feed nitrogen into the reaction kettle to repeat the replacement three times, exhaust the air inside the reaction kettle, open the stirring paddle for stirring, and mix the materials Fully mix evenly, the rotating speed of the stirring paddle is 500rpm;

[0034] Step 2: In the case of room temperature, slowly and evenly add propylene oxide, the amount of propylene oxide added is 5272Kg, and the speed of adding is controlled at about 1171.6Kg / h, and the temperature of the reactor is gradually raised to 30°C;

[0035] Step 3: After the propylene oxide is added, the temperature of the reactor is raised to 60° C. within 30 minutes, and the temperature is maintained for 30 minutes to obtain the finished product diethanol monoisopropanolamine.

[0036] Wherein, the acid used here can also be various acids that can ionize protons, and can be various organic acids or in...

Embodiment 2

[0038] Step 1: Add 10046Kg diethanolamine, 700Kg water and 127Kg concentrated sulfuric acid into the reaction kettle, then feed nitrogen into the reaction kettle for three times of replacement, exhaust the air inside the reaction kettle, turn on the stirring paddle for stirring, and mix the materials Fully mix evenly, the rotating speed of the stirring paddle is 500rpm;

[0039] Step 2: At room temperature, slowly and evenly add propylene oxide, the amount of propylene oxide added is 5827Kg, and the adding speed is controlled at 1295Kg / h, and the temperature of the reactor is gradually raised to 80°C within 30 minutes ;

[0040] Step 3: After adding the propylene oxide, keep the temperature for another 30 minutes to obtain the finished product diethanol monoisopropanolamine.

Embodiment 3

[0042] Step 1: Add 10046Kg diethanolamine, 1010Kg water, 52Kg glacial acetic acid and 26Kg concentrated sulfuric acid into the reaction kettle, then feed nitrogen into the reaction kettle to repeat the replacement three times, exhaust the air inside the reaction kettle, and turn on the stirring paddle to carry out Stir, fully mix the materials evenly, the rotating speed of the stirring paddle is 500rpm;

[0043]Step 2: At room temperature, slowly and evenly add propylene oxide, the amount of propylene oxide added is 5549Kg, and the adding speed is controlled at 1233Kg / h, and the temperature of the reactor is gradually raised to 55°C within 30 minutes ;

[0044] Step 3: After the propylene oxide is added, the temperature of the reactor is raised to 70° C. within 30 minutes, and the temperature is maintained for 30 minutes to obtain the finished product diethanol monoisopropanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com