Patents

Literature

50results about How to "Fully neutralized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

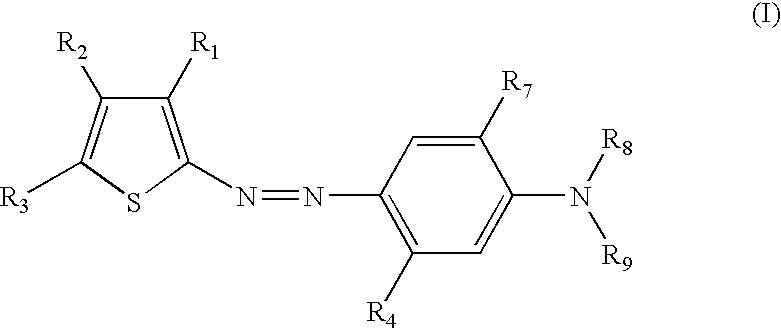

Novel single compound toners for use in polyesters

InactiveUS20030212172A1Low extractionExcellent resultOrganic dyesMixingPolyesterMethods of production

Individual compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such an individual compound is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive single bluing agent compound thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

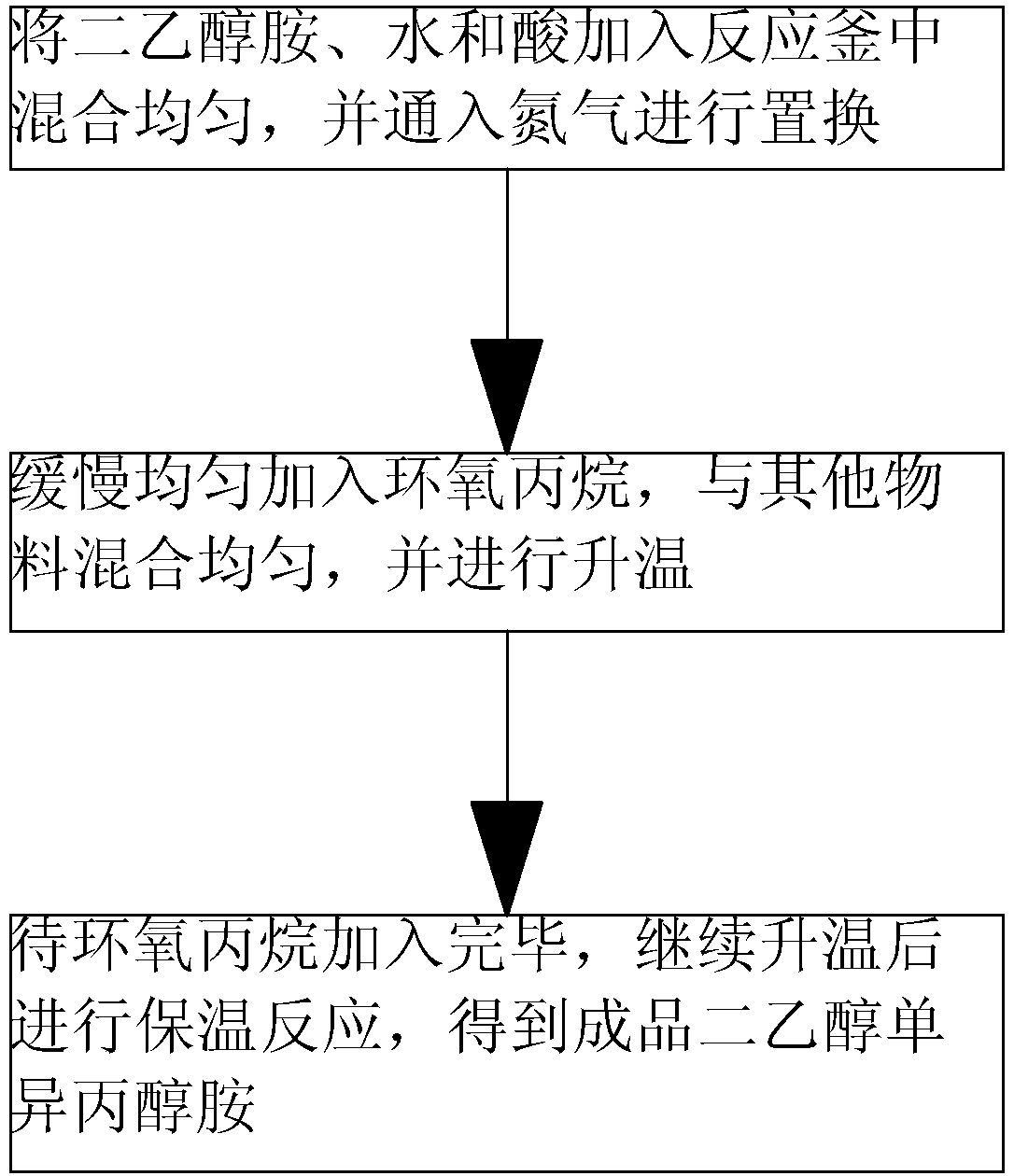

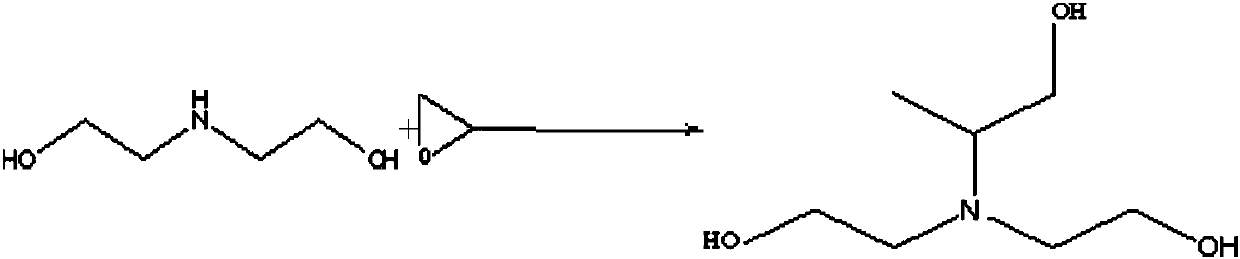

Production method of diethanolisopropanolamine

InactiveCN107556205AInhibits the formation of quaternary amine basesReduce the formation of high boilersOrganic compound preparationAmino-hyroxy compound preparationChemistryQuaternary amine

The invention provides a production method of diethanolisopropanolamine. The method comprises the following steps of S1, adding diethanol amine, water and acid into a reaction kettle; starting a stirring paddle for uniformly mixing each material; S2, in room temperature state, slowly adding epoxy propane; performing continuous stirring so that the epoxy propane and other materials can be uniformlymixed; raising the reaction temperature to 30 to 80 DEG C; S3, after all of the epoxy propane is added, performing heat insulation reaction on the reaction kettle for 30min to obtain a finished product of diethanolisopropanolamine. The diethanolisopropanolamine produced through the reaction of the diethanol amine and the epoxy propane can partially react with the epoxy propane under the water existence condition to produce quaternary amine alkali; the quaternary amine alkali is a strongly basic catalyst and can be used for catalyzing hydroxyls on the diethanolisopropanolamine to continuouslyreact with the epoxy propane to form ester. The acid can fast and effectively achieve the neutralization effect on the quaternary amine alkali in the reaction process; the reaction of the diethanolisopropanolamine in the direction of byproducts of eater is reduced.

Owner:NINGBO YUANLI CHEM

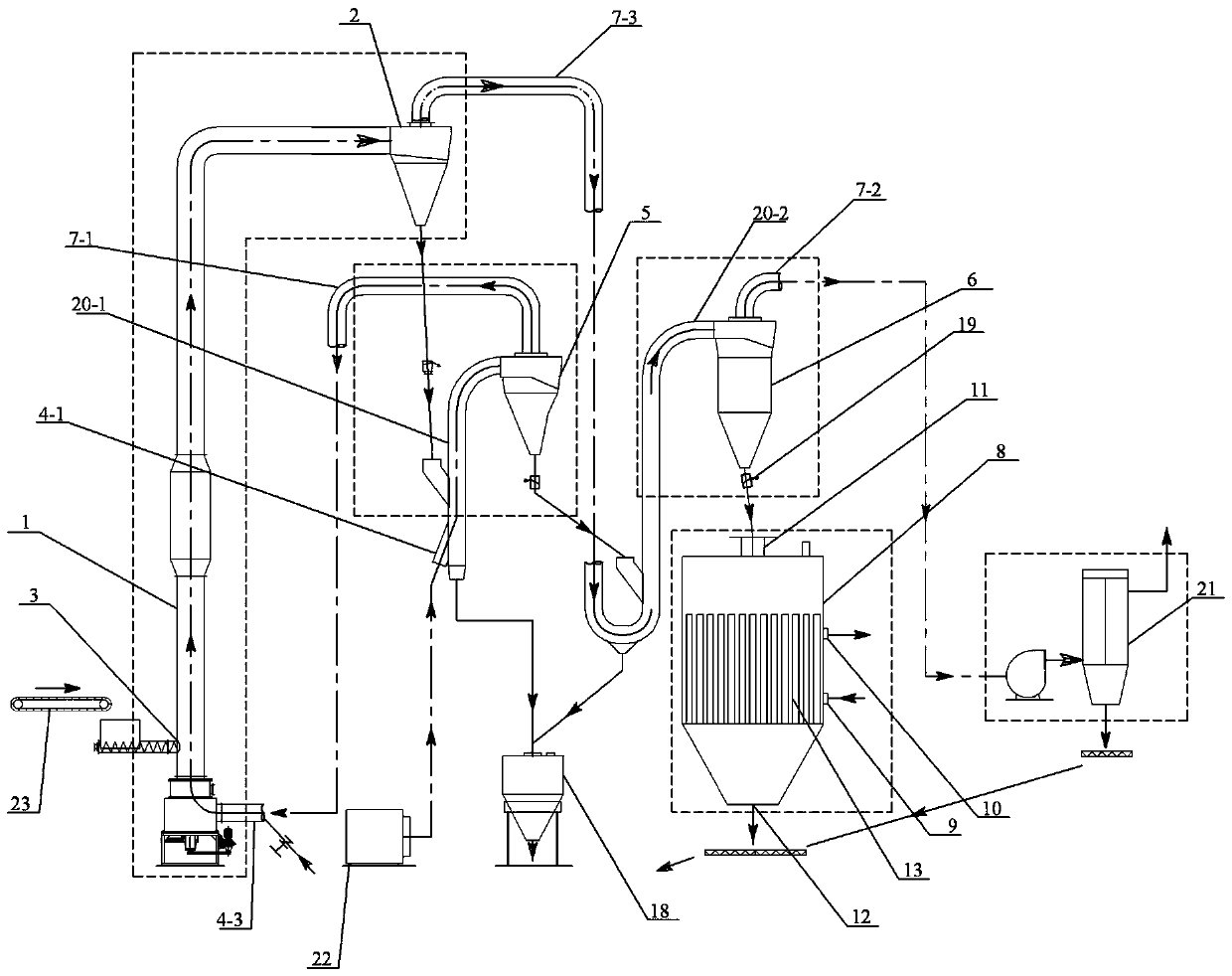

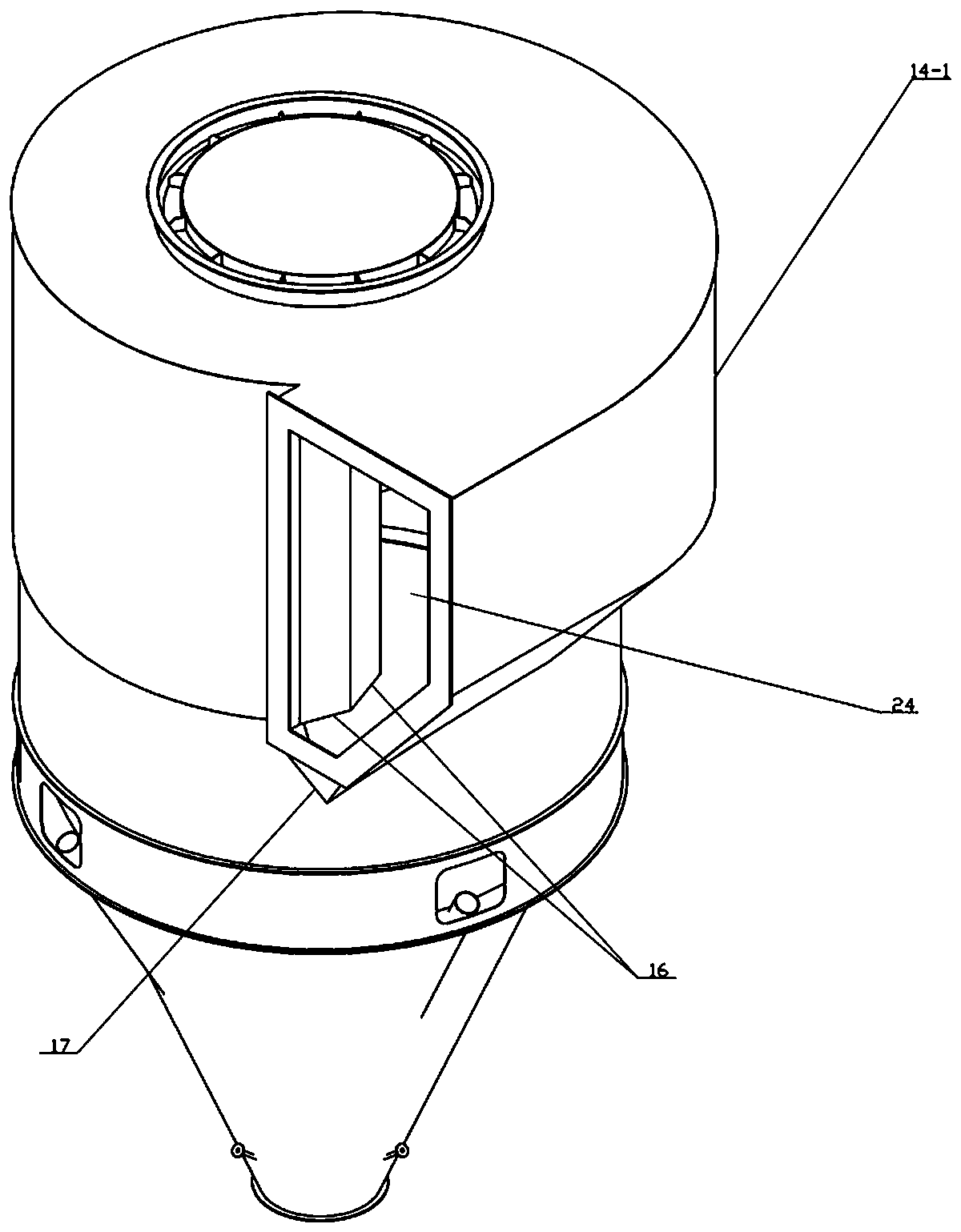

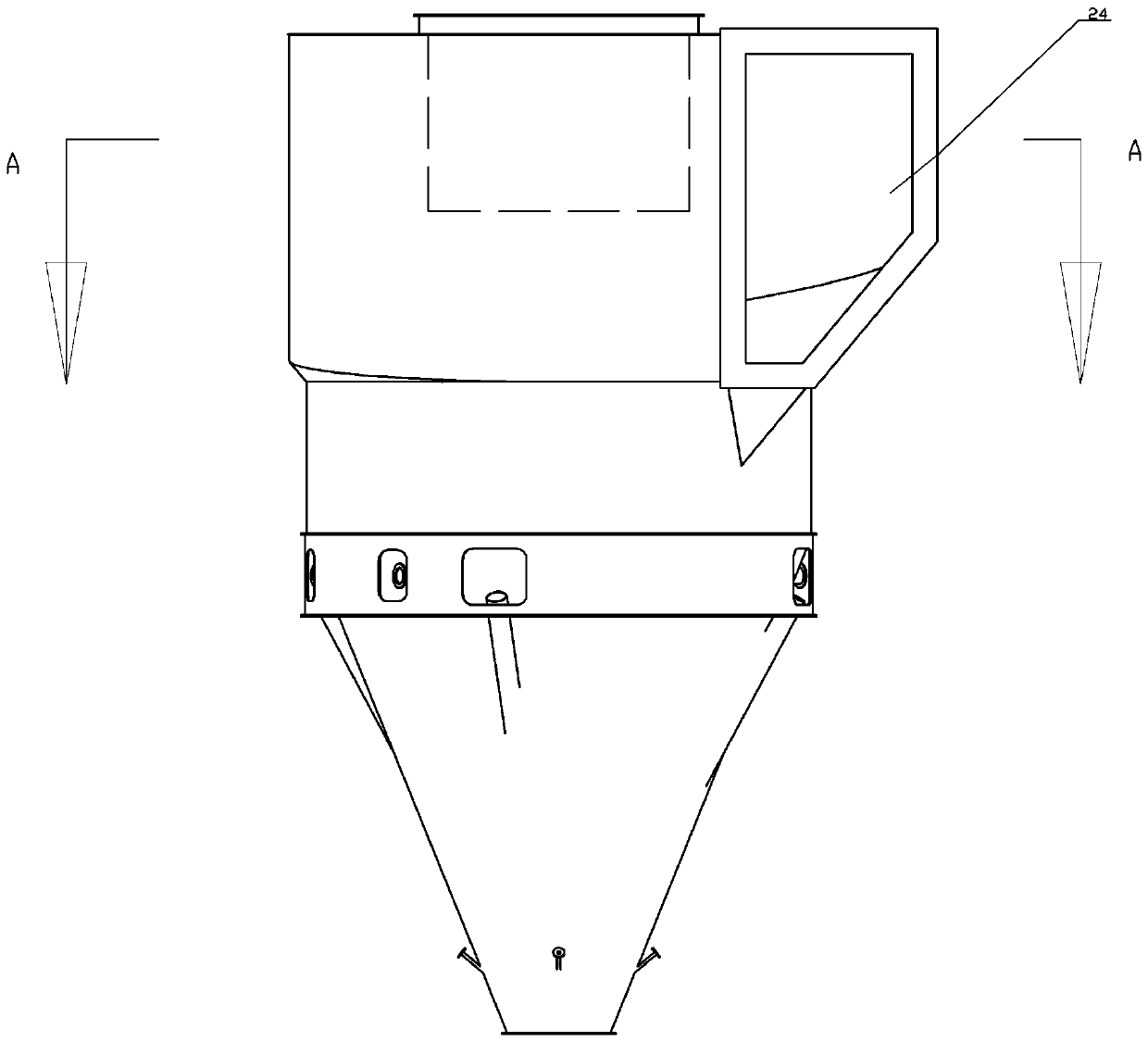

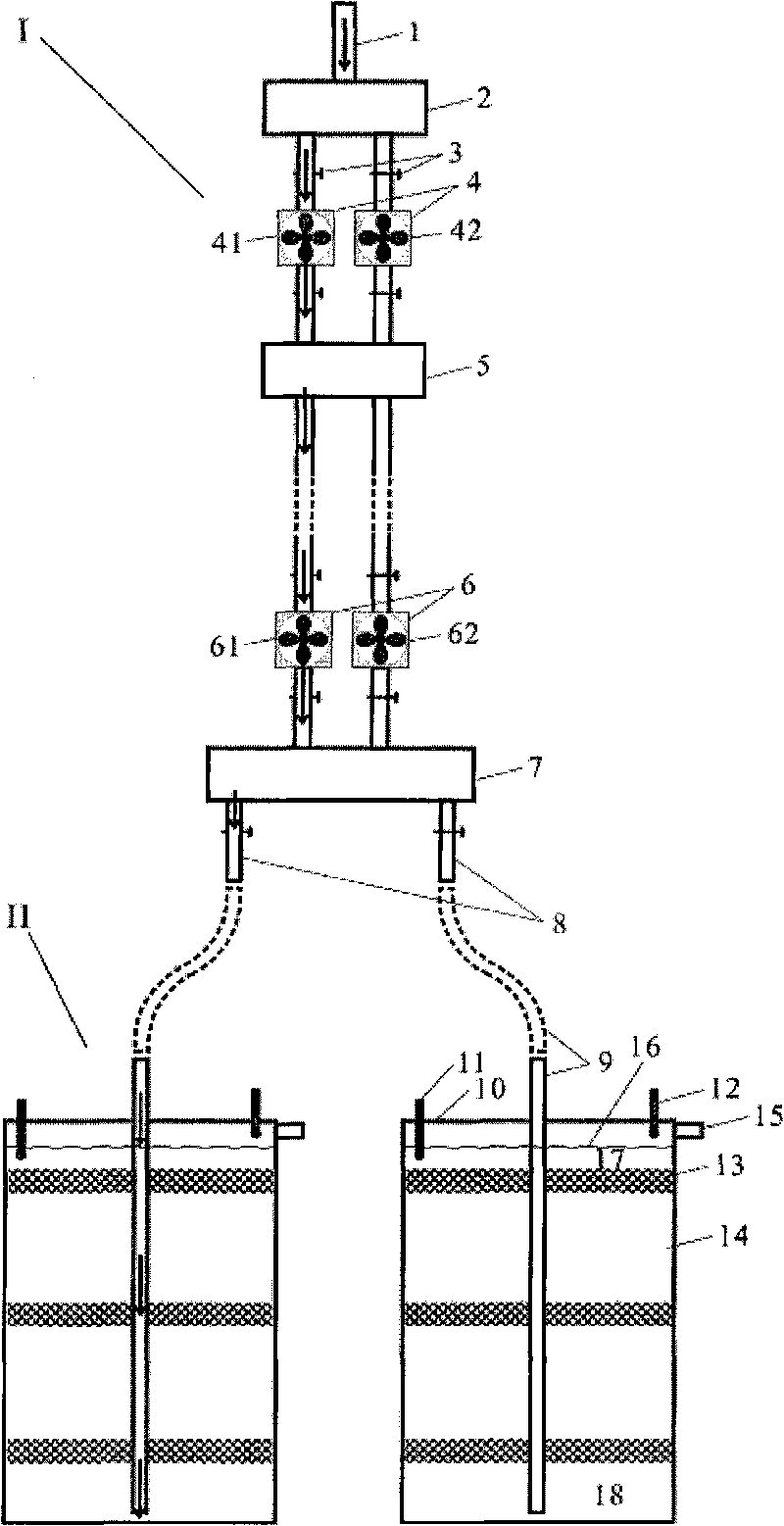

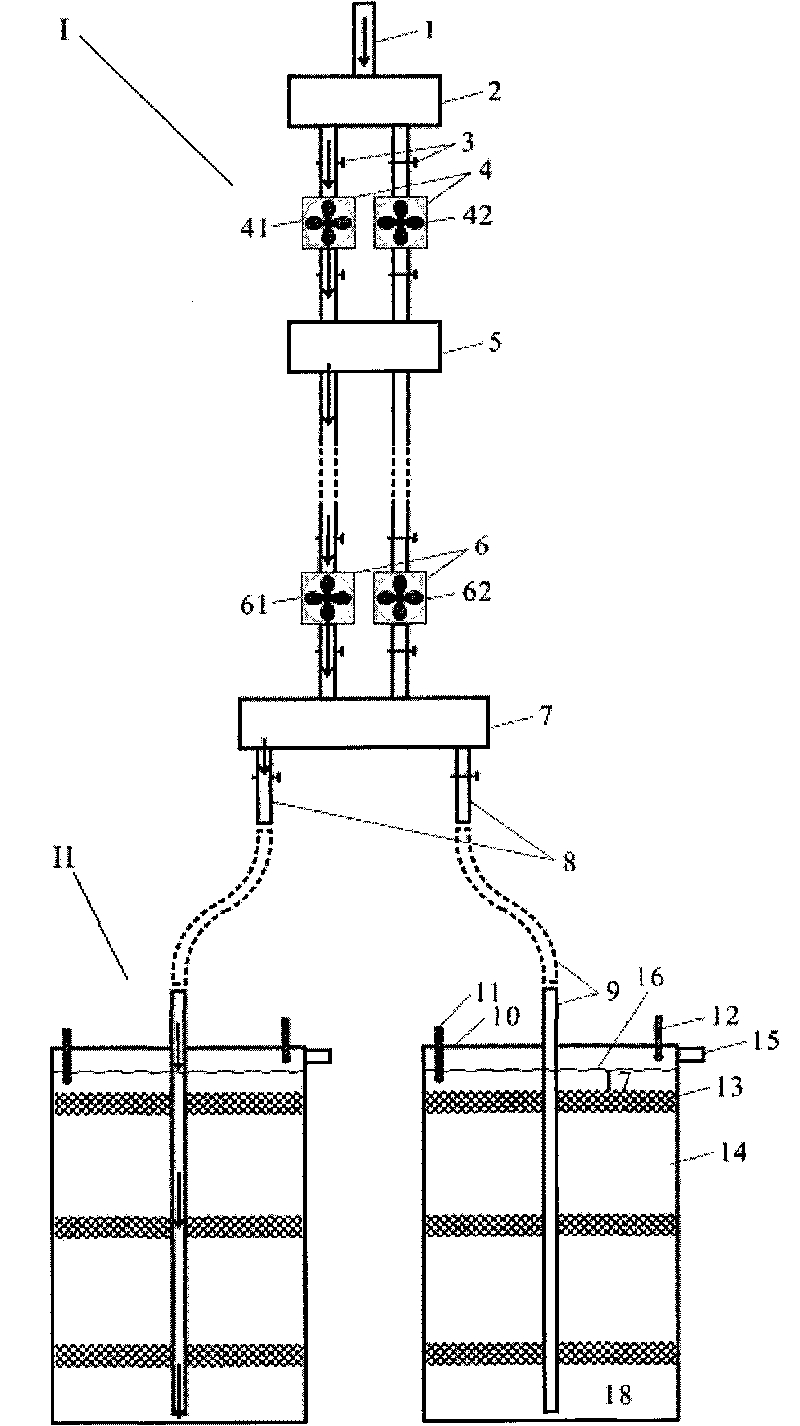

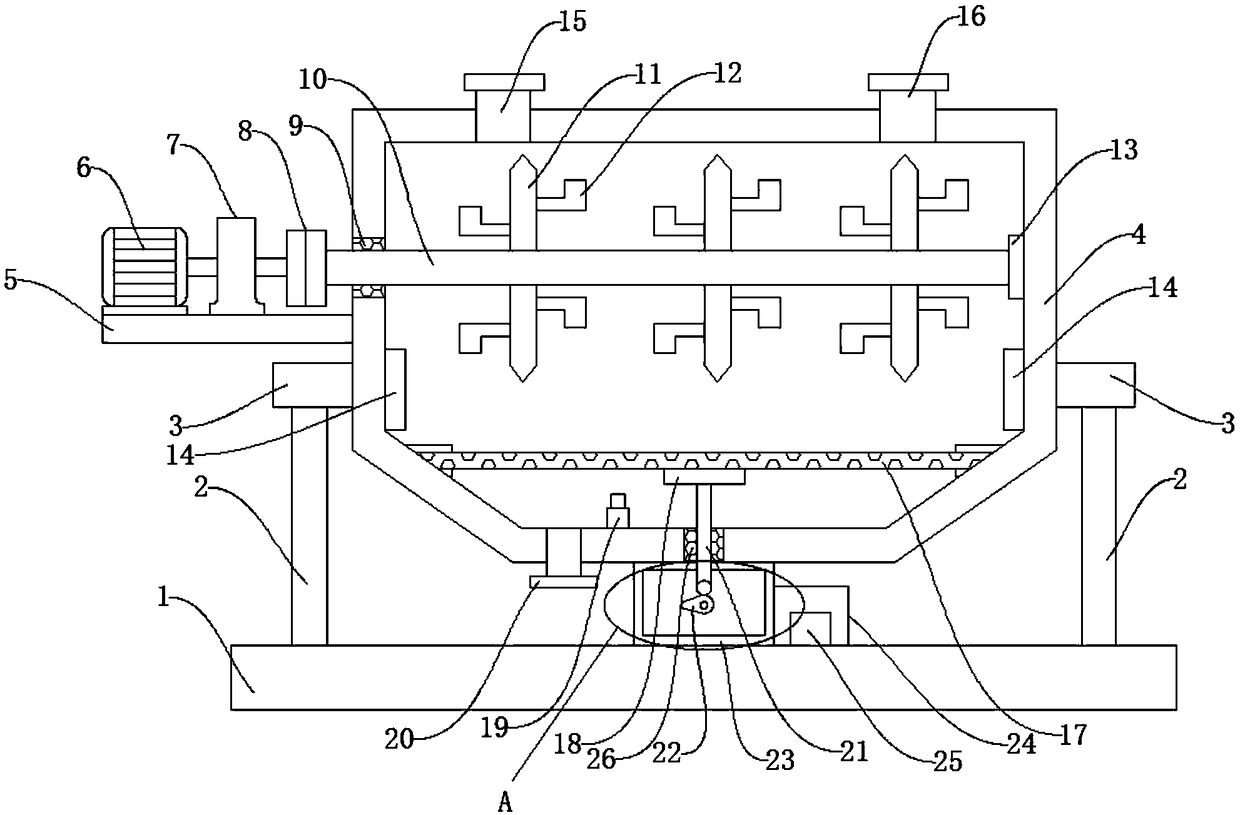

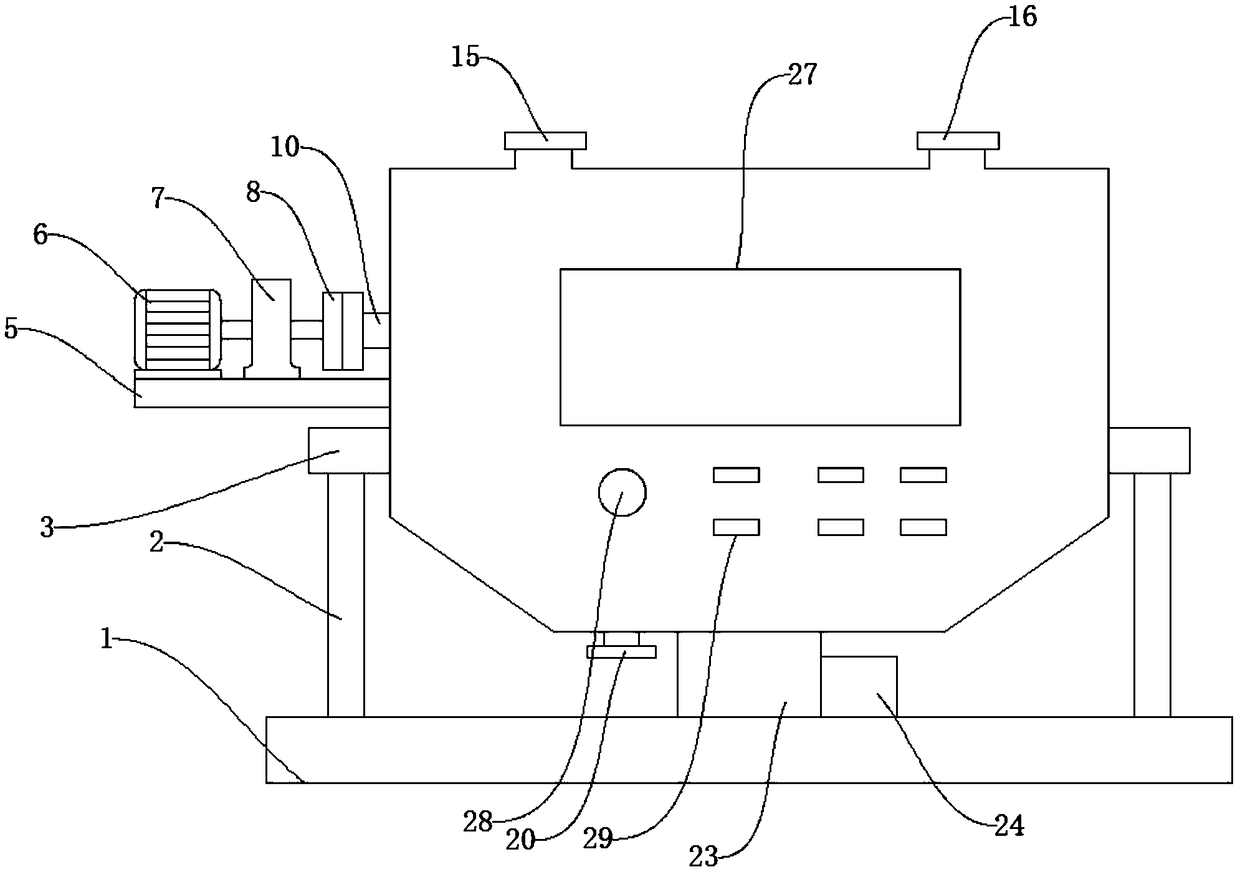

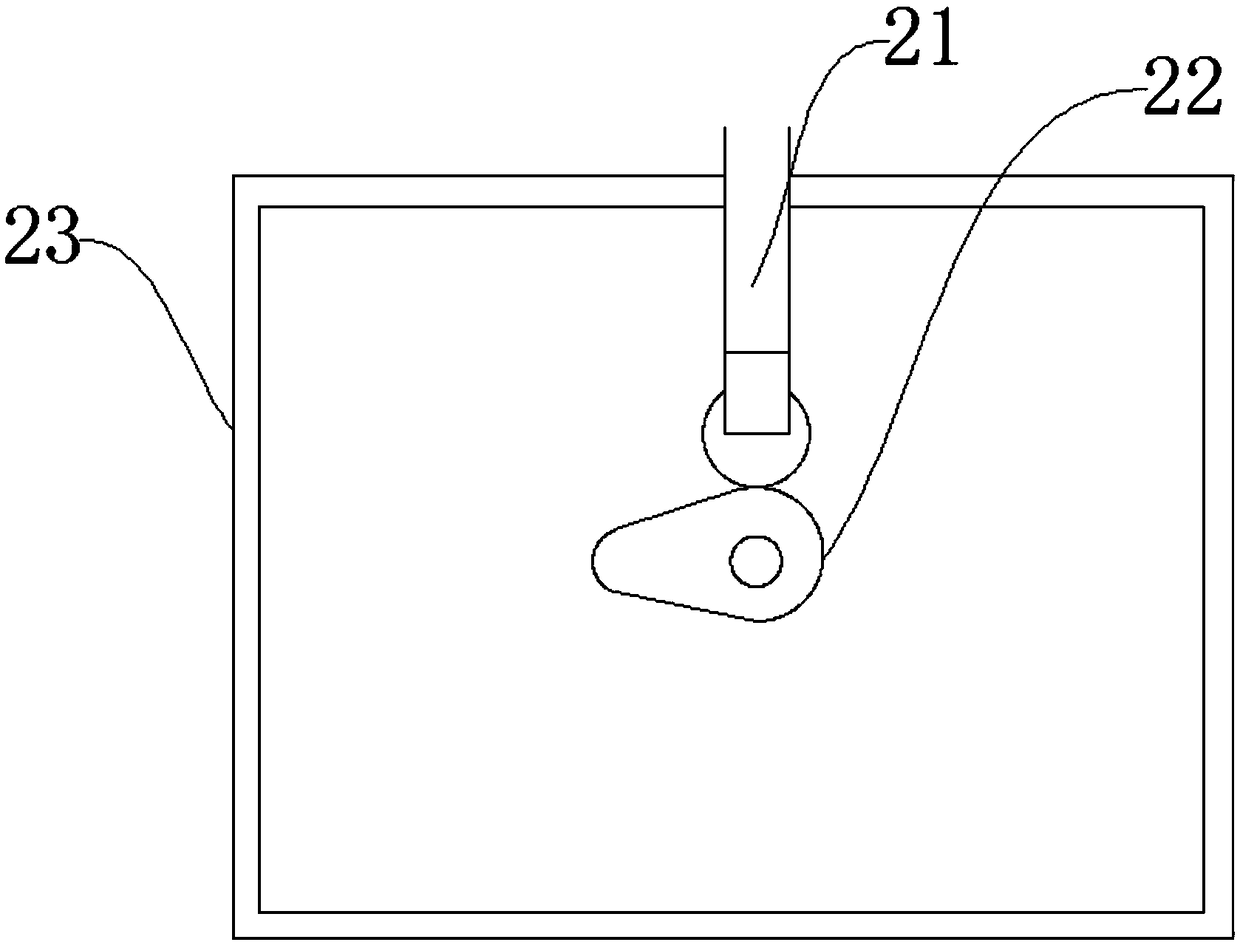

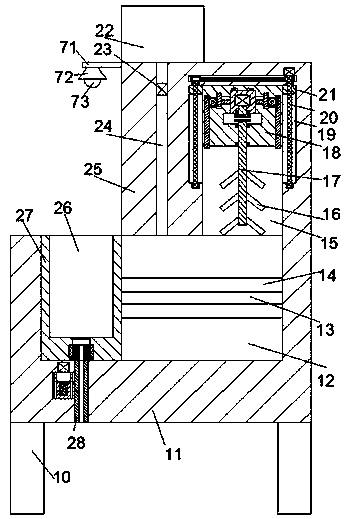

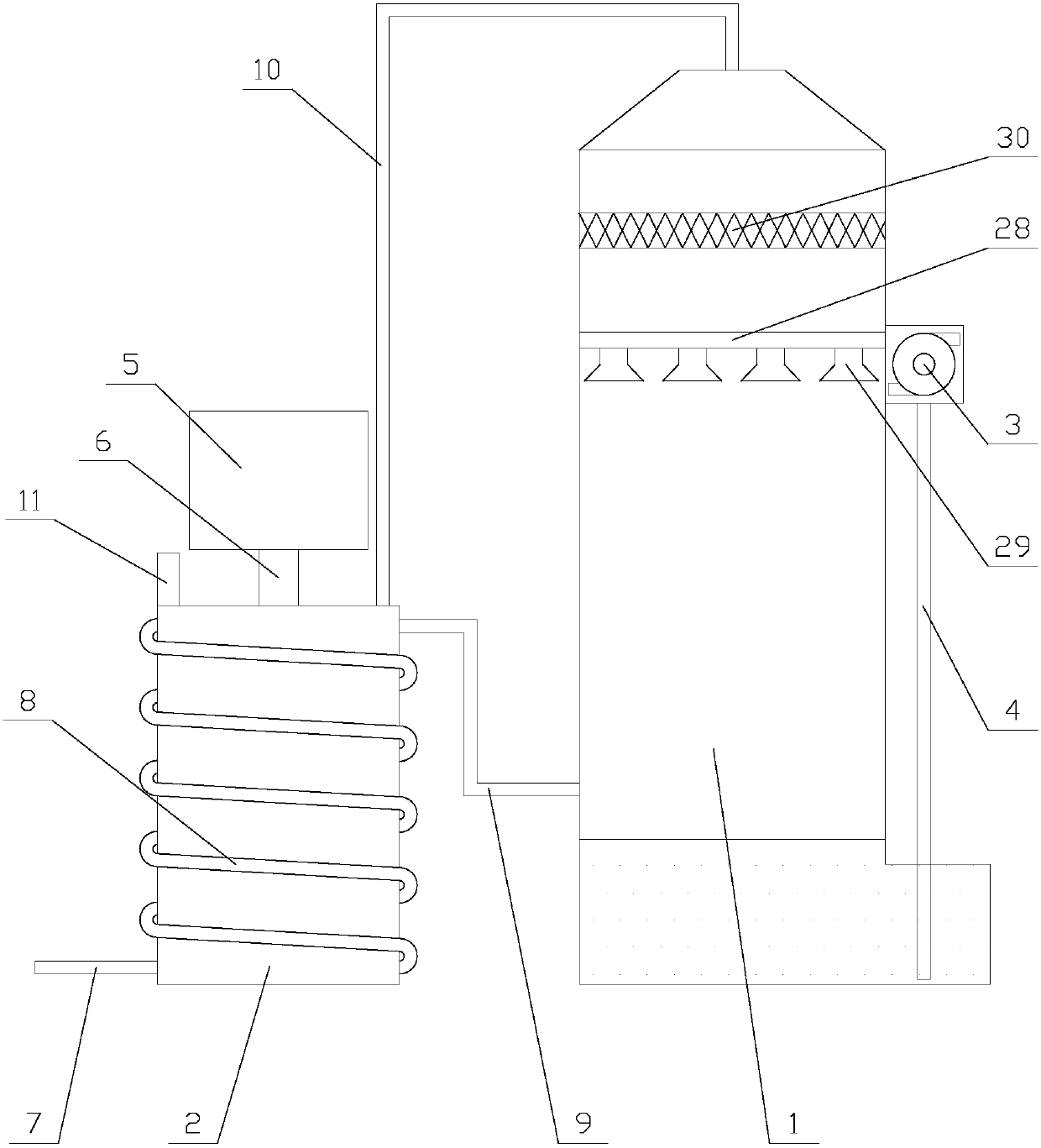

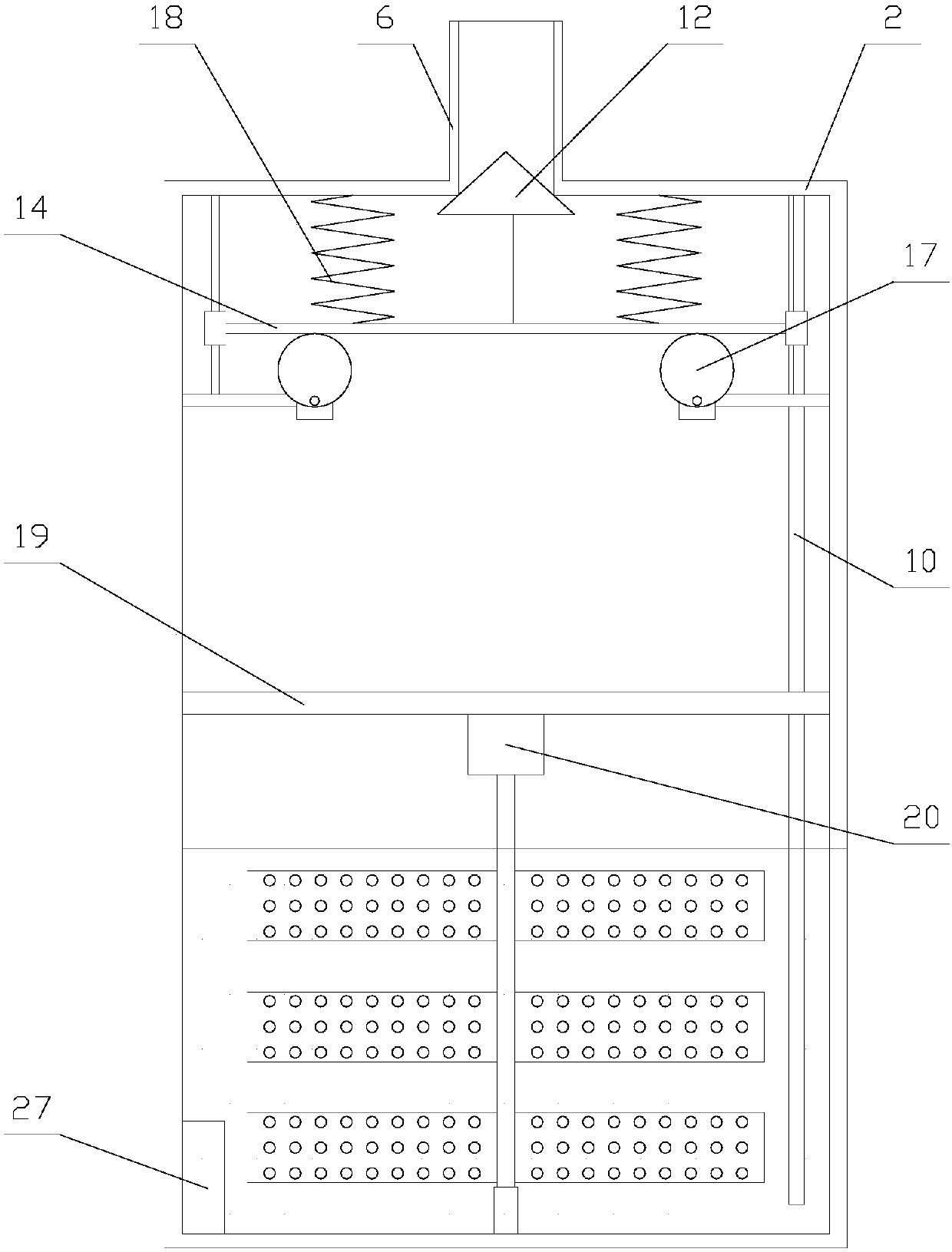

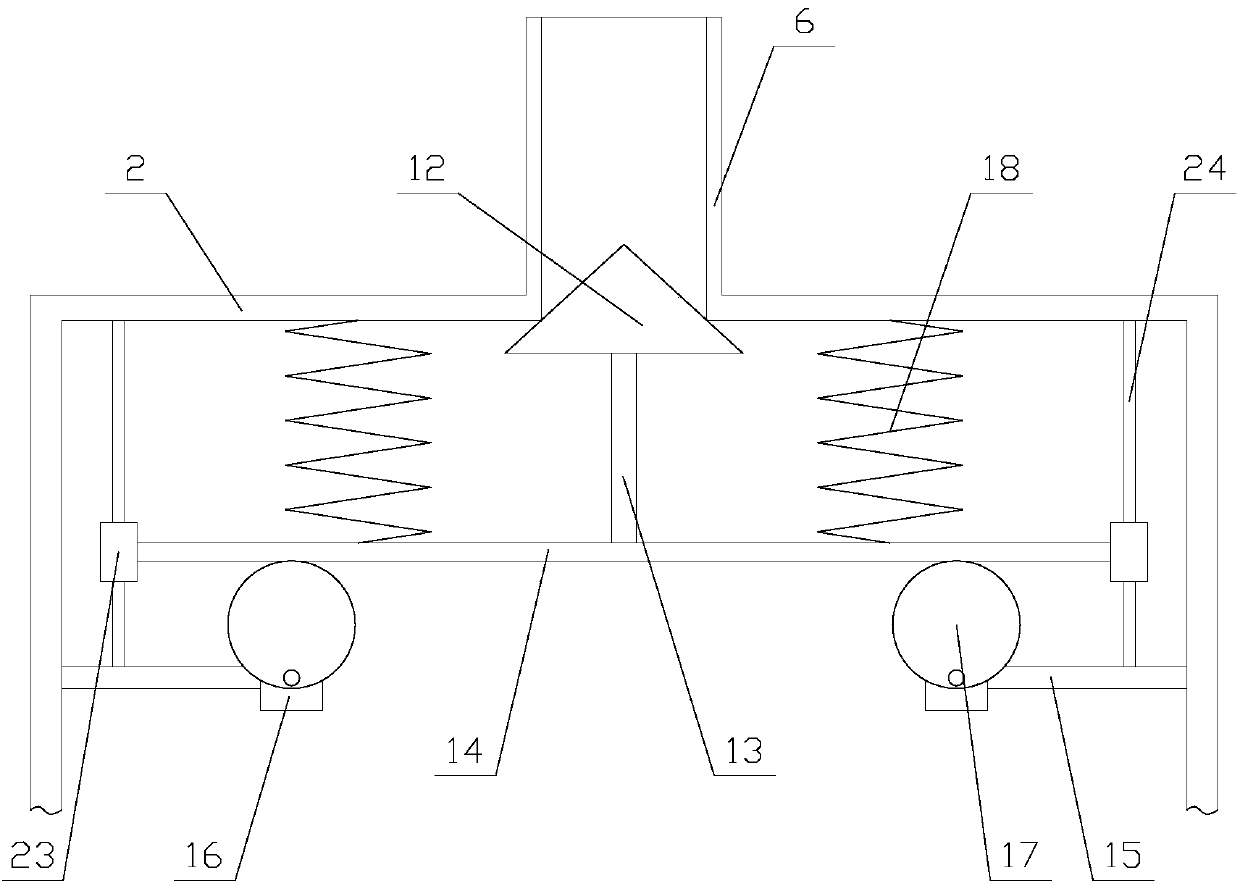

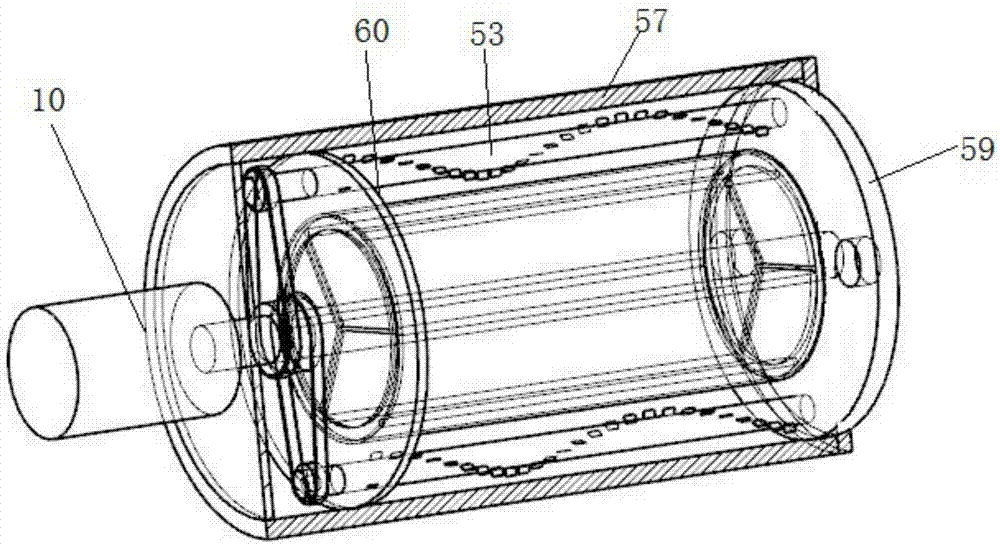

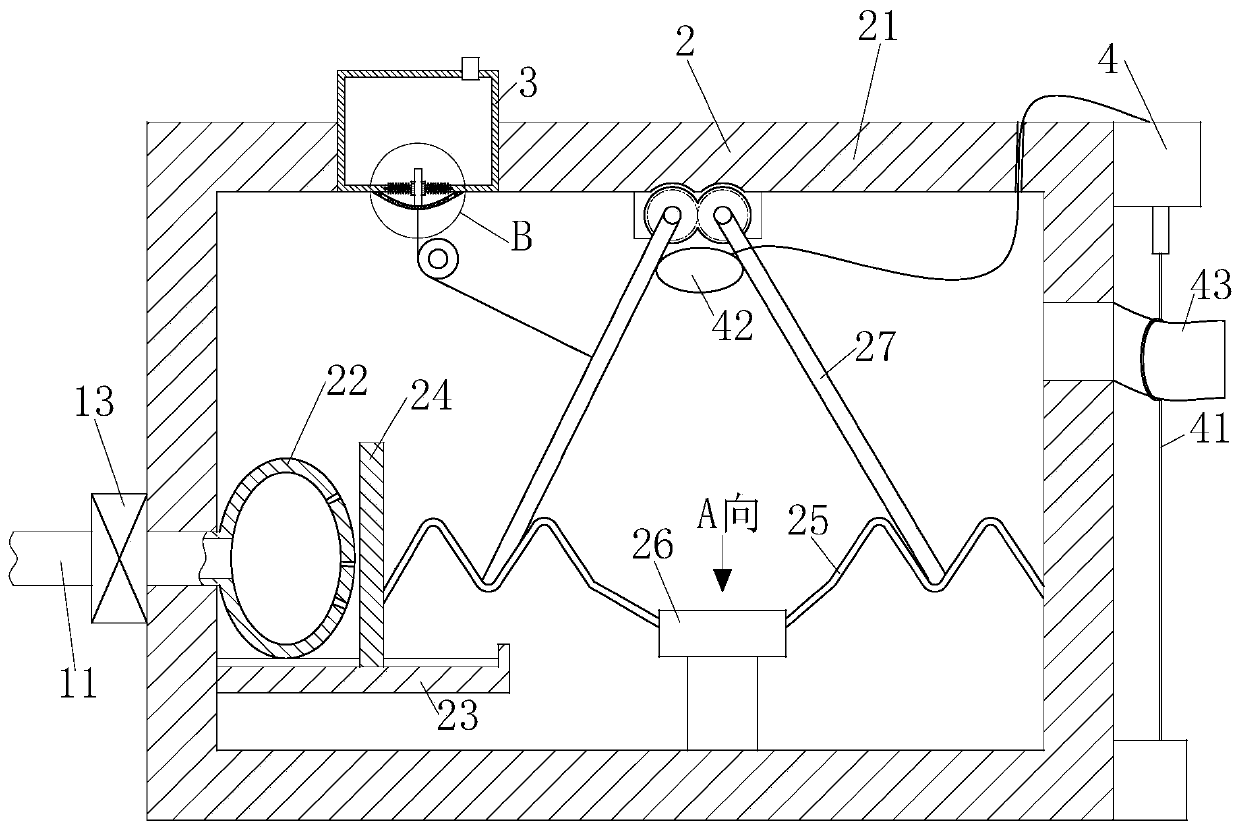

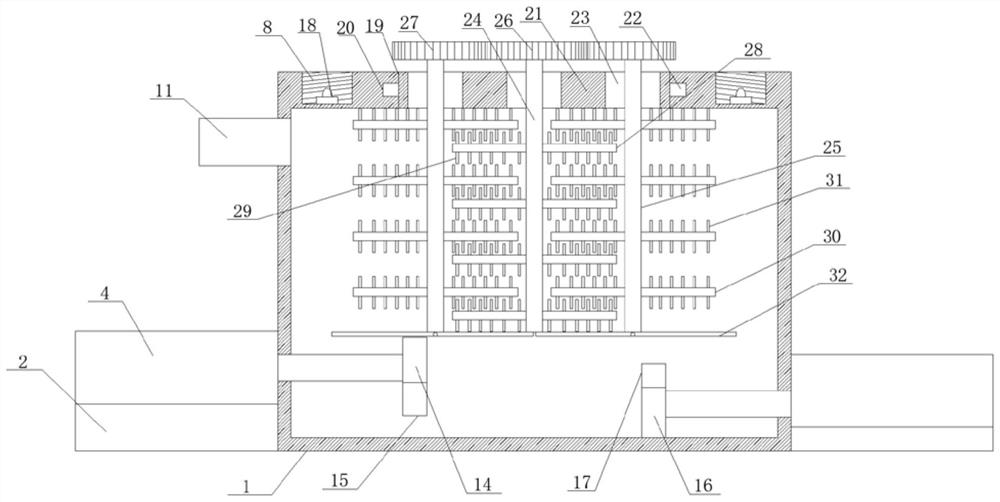

Suspension air flow type ardealite integrated treatment device and method

The invention discloses a suspension air flow type ardealite integrated treatment device and belongs to the technical field of industrial gypsum producing and processing. The suspension air flow typeardealite integrated treatment device comprises a drying unit, a high-temperature decontaminating unit, a roasting unit and a cooling unit which are sequentially connected, wherein the a first main heat exchange pipe is connected to one side of the upper part of the high-temperature decontaminating unit; the high-temperature decontaminating unit comprises a decontaminating furnace, the first mainheat exchange pipe and a first discharging system, the first main heat exchange pipe and the first discharging system are connected to the decontaminating furnace, and a first feeding system and a first hot air inlet are connected to the first main heat exchange pipe; the roasting unit comprises a phase change furnace, a second main heat exchange pipe and a second discharging system, the second main heat exchange pipe and the second discharging system are connected to the phase change furnace, a second feeding system is connected to the second main heat exchange pipe, the first discharging system is connected into the second feeding system, and the second discharging system is connected into the cooling unit. Meanwhile, the invention provides a processing method of the suspension air flowtype ardealite integrated treatment device. According to the suspension air flow type ardealite integrated treatment device disclosed by the invention, technologies of drying ardealite, modifying anddecontaminating the ardealite, roasting the ardealite, cooling the ardealite and the like are integrated; thus, the suspension air flow type ardealite integrated treatment device can meet a requirement of processing different physical properties of ardealite into a qualified beta type hemihydrates gypsum cementing material.

Owner:河南建筑材料研究设计院有限责任公司

Device for neutralizing treatment of chlorine-containing gas

InactiveCN101732969AIncrease contact areaGood effectDispersed particle separationExhaust gasProduct gas

The invention relates to a device of neutralizing treatment of chlorine-containing gas, which is simple and economic, and can be used for the neutralizing treatment of the chlorine-containing gas in small flow rate(less than or equal to 1 m3 / h). The device comprises conveying equipment and neutralizing treatment equipment, wherein a gas output end of the conveying equipment is connected to the neutralizing treatment equipment; and the neutralizing treatment equipment comprises a container and a gas conveying tube, one end of the gas conveying tube is connected with the gas output end of the conveying equipment, the other end of the gas conveying tube is inserted to the bottom part of the container, the gas conveying tube is in sealed connection with the container, the middle part of the container is provided with sponge-shaped dividing plates by which the container is divided into an upper part and a lower part. The device has the advantages that: the neutralizing treatment of the chlorine-containing gas in small flow rate can be safely and continuously performed; the neutral reaction is performed more fully, and the effect is better; and after the chlorine-containing gas in small flow rate is treated by the device, the content of C12 in exhaust gases is less than 1mg / m3 or 0.3mmp, and the emission meets the standard.

Owner:NANJING UNIV

Composition for protecting and nourishing fruit tree

InactiveCN101270006AWill not cause secondary pollutionAppropriate proportionFertilizer mixturesFruit treeNormal growth

The present invention discloses a compound that is used for protecting and providing nutrition for fruit trees. The compound is aqueous solution of KNO3, Ca(NO3)2, MgSO4.7H2O, MnCl2.4H2O, H3B3O3, CuSO4.5H2O, Zn(NO3)2.6H2O, Fe(NO3)3.9H2O, KH2PO4, Na2HPO4.12H2O, NH4Cl, and (NH4)6Mo7O24.4H2O. The compound provides thirteen mineral elements that are required for the normal growth and development of the fruit trees and has excellent effects on the growth and development of the fruit trees, the flowering rate, the productivity of fruits and the quality of the fruits. And the compound can completely prevent the influence of acid rain and soil acidification on the growth and development of the fruit trees.

Owner:GUANGDONG PHARMA UNIV

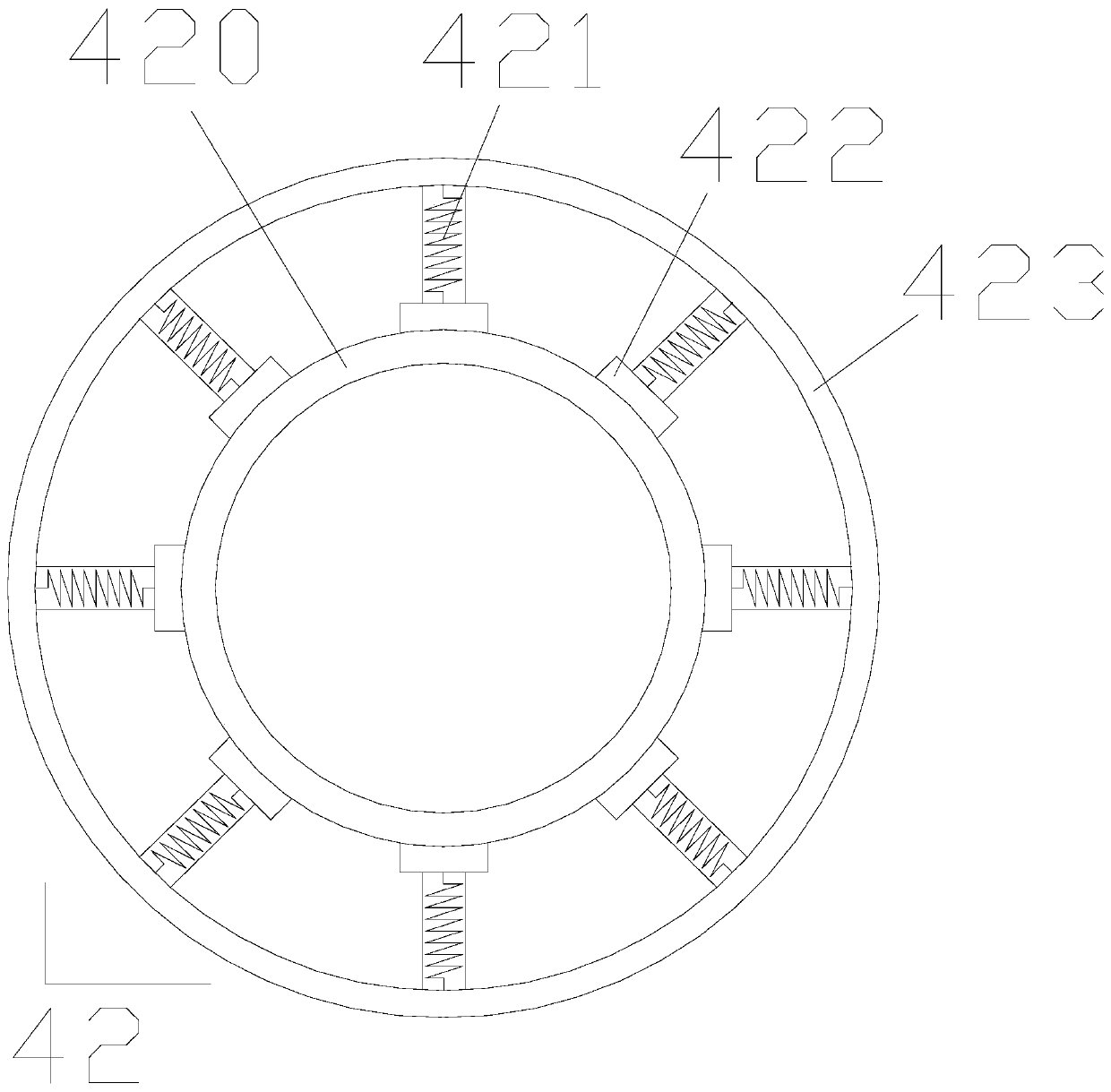

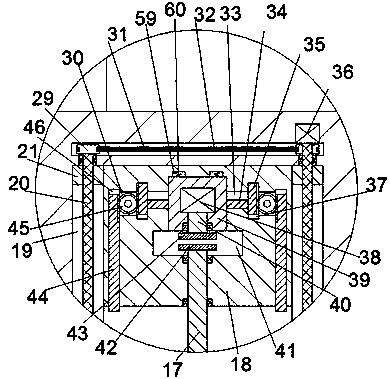

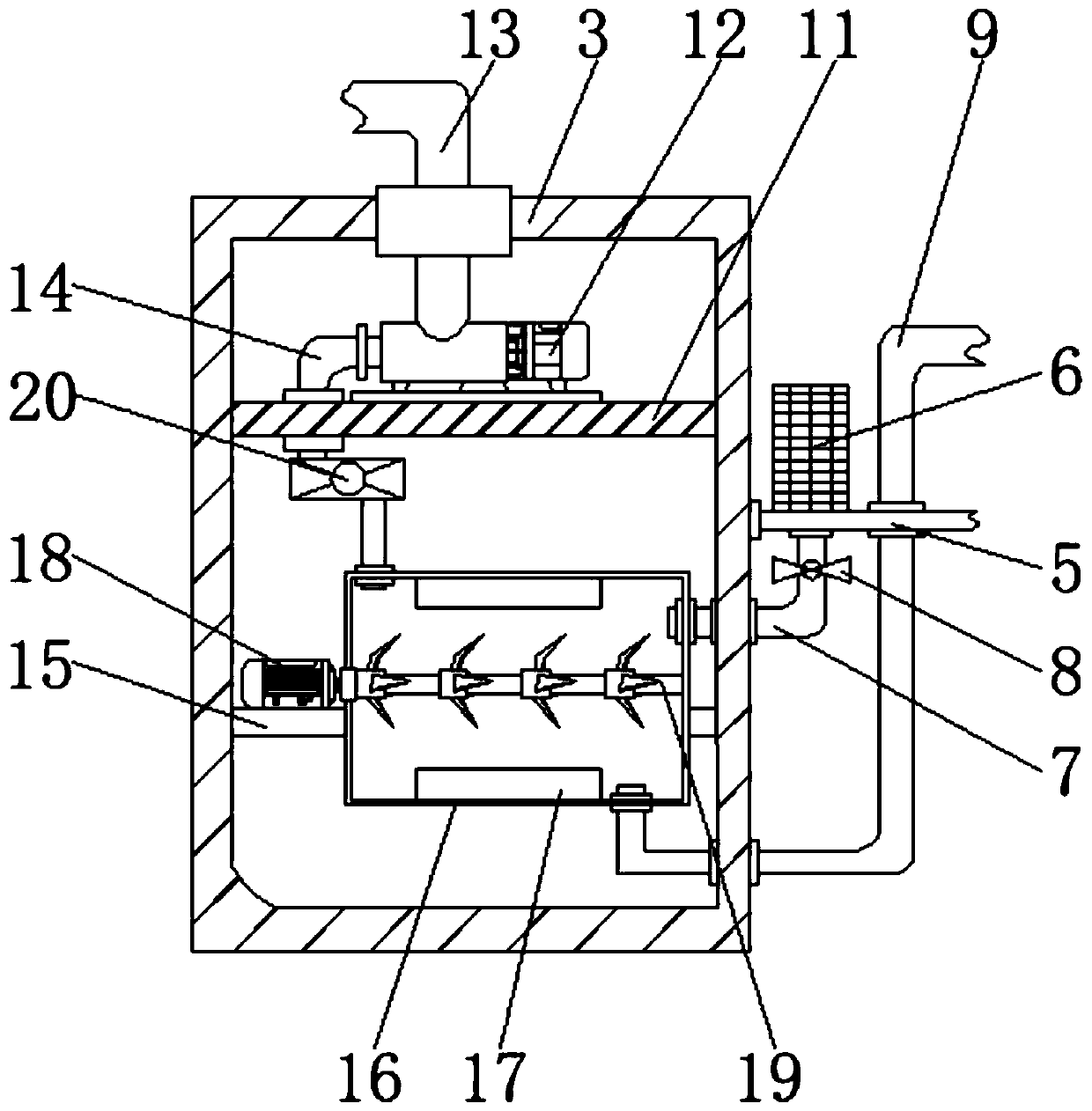

Aeration-type treatment equipment utilizing centrifugal force to swing and expand and contract for domestic wastewater

InactiveCN109970220AFully neutralizedImprove the aeration effectSpecific water treatment objectivesWater aerationActivated sludgeSewage

The invention discloses aeration-type treatment equipment utilizing centrifugal force to swing and expand and contract for domestic wastewater. A structure of the equipment comprises a sewage funnel,a filter box, a sludge storage tank and an aeration device. According to the equipment provided by the invention, aeration check devices together with stirring blades rotate quickly by using a stirring rod as a center to stir the sewage and activated sludge, at the time, the tops of air ejecting pipes are connected with an air storage space, an airflow enters the interiors of the aeration check devices through the air ejecting pipes, after the air ejecting pipes are ventilated, the aeration check devices directly perform aeration treatment from the center to the periphery, so that the aerationeffect is greatly improved, the sludge and the sewage can be fully neutralized, and the sewage blowing effect can be improved; when a movable ball is thrown out by the centrifugal force, the movableball is located in the position of a through opening of a straight-through pipe, so that the splashed sludge can be prevented from entering directly; and if the sludge is splashed into an opening expending ring under stirring and drops to the movable ball, guide blocks are tilted along with the centrifugal force to slide the sludge out, so that sludge residues in movable ball can be avoided, and the aeration device is prevented from being clogged.

Owner:郭剑庭

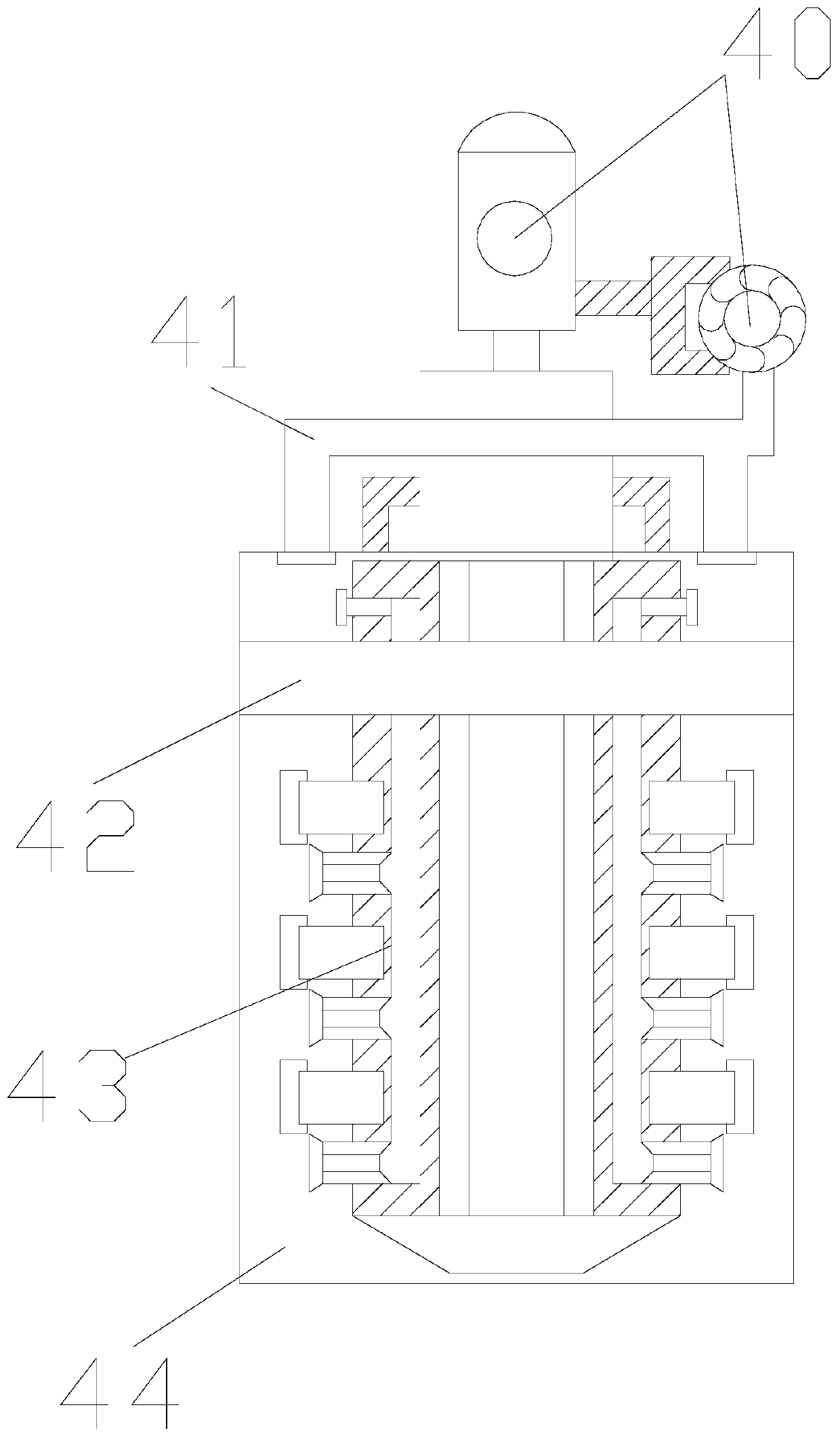

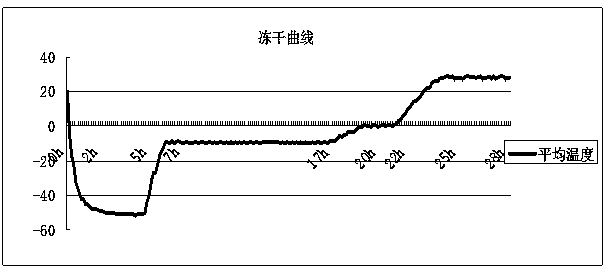

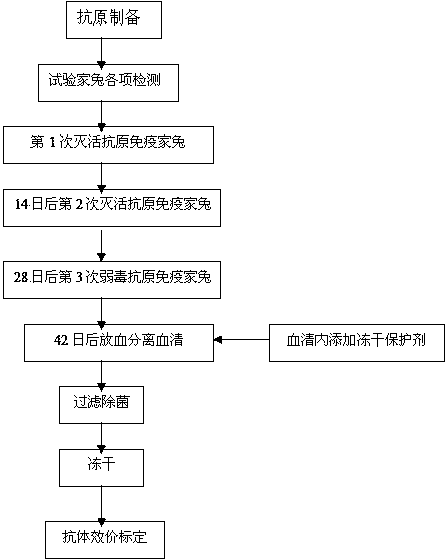

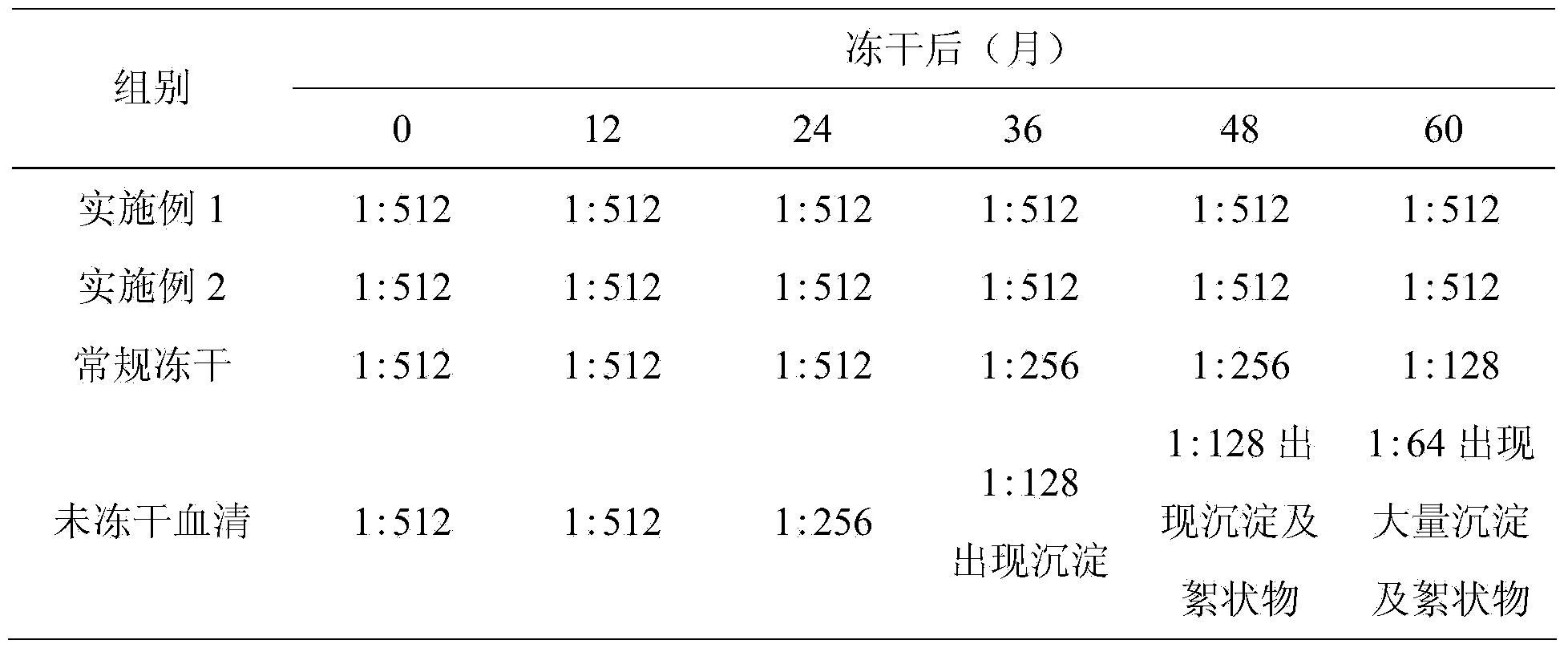

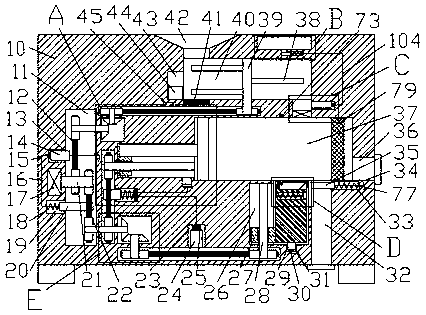

Preparation and freeze-dried storage method of pseudorabies standard positive serum

ActiveCN103864931AFully neutralizedLong storage timeSerum immunoglobulinsImmunoglobulins against animals/humansMonosodium glutamateFreeze-drying

The invention discloses a preparation and freeze-dried storage method of pseudorabies standard positive serum. The preparation comprises the following steps: immunizing a rabbit twice with an inactivated PRV (pseudorabies virus) solution, then, immunizing the rabbit once with the inactivated PRV solution, and collecting the serum; adding a protective agent sodium chloride, trehalose, monosodium glutamate and L-arginine into the serum, fully dissolving, filtering to remove bacteria, and subpackaging; adding the subpackaged serum into a freeze dryer box, and performing freeze-drying according to a freeze-drying curve shown as fig.1 described in the specification to obtain the pseudorabies standard positive serum. For the pseudorabies standard positive serum obtained by the method disclosed by the invention, PRV neutralizing antibody titer is more than 1:512, the antibody titer remains unchanged after the pseudorabies standard positive serum is stored for 60 months at 2-8 DEG C, so that the pseudorabies standard positive serum has good stability, can fully neutralize pseudorabies virus in vaccine exogenous virus and specificity detection, and provides a good technical support for quality inspection of pseudorabies virus vaccines.

Owner:WUHAN CHOPPER BIOLOGY

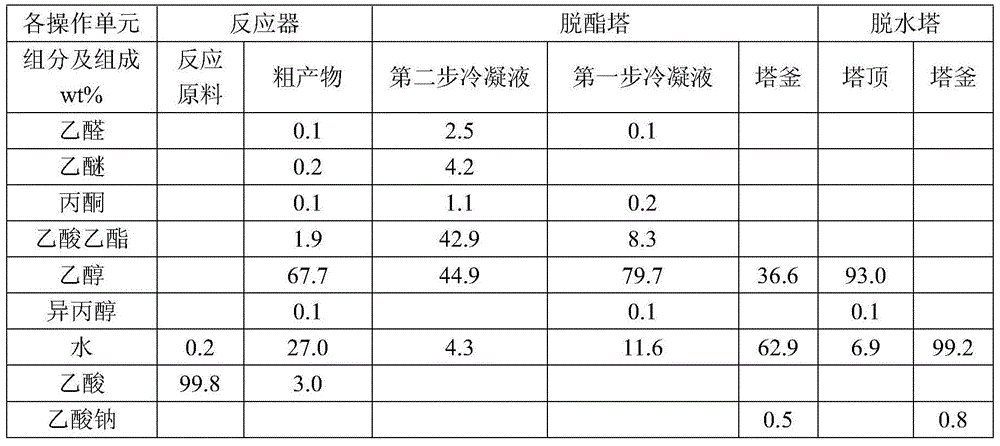

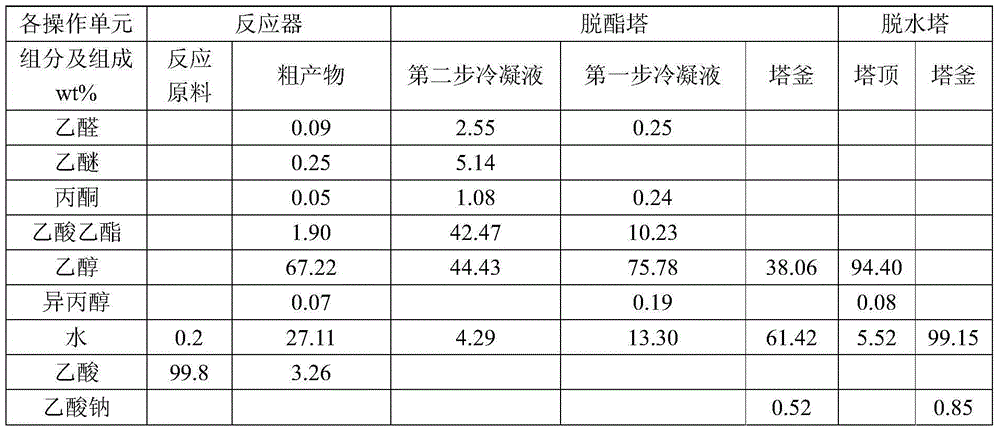

Method for low-energy consumption acetic acid hydrogenation production of ethanol

InactiveCN105198704AImprove qualityEasy to separateOrganic compound preparationHydroxy compound separation/purificationAcetic acidHydrogenation reaction

The invention discloses a method for producing ethanol by acetic acid hydrogenation and belongs to the technical field of alcohol substance production. The method overcomes defects of the existing ethanol purification process and improves ethanol product quality. Through deep and careful research, the inventor provides the method comprising that acetic acid undergoes a direct hydrogenation reaction to produce a crude ethanol product and the crude ethanol product is orderly subjected to ethyl acetate separation and acetic acid removal degreasing and dehydration processes so that an ethanol product is obtained. The method effectively separate ketones and acetaldehyde produced by acetic acid hydrogenation, is conducive to improvement of distillation column separating effects, effectively reduces impurities in a product and improves final ethanol product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-physical-state incineration technology for industrial hazardous wastes

InactiveCN104819477AReduce concentrationFully neutralizedLighting and heating apparatusDispersed particle separationSlagHousehold hazardous waste

The invention discloses a multi-physical-state incineration technology for industrial hazardous wastes, and refers to the technical field of a purifying treatment of the industrial hazardous wastes. The incineration technology comprises the following steps: performing denitration treatment on industrial hazardous wastes after burning twice, and then cooling smoke gas and neutralizing with Ca (OH)2; neutralizing and absorbing smoke gas after reaction by slaked lime, and then discharging it after removing dust by a bag type dust collector; centralizing slag fluid discharged in above steps and then solidifying. According to different physical states, the hazardous wastes can be subdivided into solid hazardous wastes, liquid hazardous wastes and semisolid hazardous wastes, and so on. The multi-physical-state incineration technology selects the incineration method, and is well-adapted to incineration wastes, mature in technology, reliable in running, and relative simple in running and operation; besides, the multi-physical-state incineration technology can well satisfy requirements of various hazardous incinerations on feeding, slag discharging, complete burning and the like.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Chemical nitric acid wastewater treatment device

InactiveCN108911099AFully neutralizedPrevent precipitationWater contaminantsTreatment involving filtrationCompound (substance)Engineering

The invention discloses a chemical nitric acid wastewater treatment device, which comprises a bottom plate, a device main body, a stirring rotation shaft, a PH sensor and a controller, wherein a support plate is arranged above the bottom plate; a fixing seat is arranged above the support plate; the device main body is arranged between the fixing seats; a fixing plate is arranged above the fixing seat; a first motor is arranged above the fixing plate; a speed reducer is arranged at the lateral surface of the first motor; a shaft coupler is arranged at one side, far away from first motor, of thespeed reducer. The chemical nitric acid wastewater treatment device has the beneficial effects that sewage can be strongly stirred through the arrangement of the stirring rotation shaft and the stirring blade, so that the neutralization reaction is fully performed; through the arrangement of a cam, a filtering net can vertically move; neutralization reaction products can be prevented from precipitation; through the arrangement of a heater, the sewage can be heated; further, the neutralization reaction can be more full, so that the discharged water can reach the discharging standard; the environment pollution is avoided.

Owner:协建(江苏)智能装备有限公司

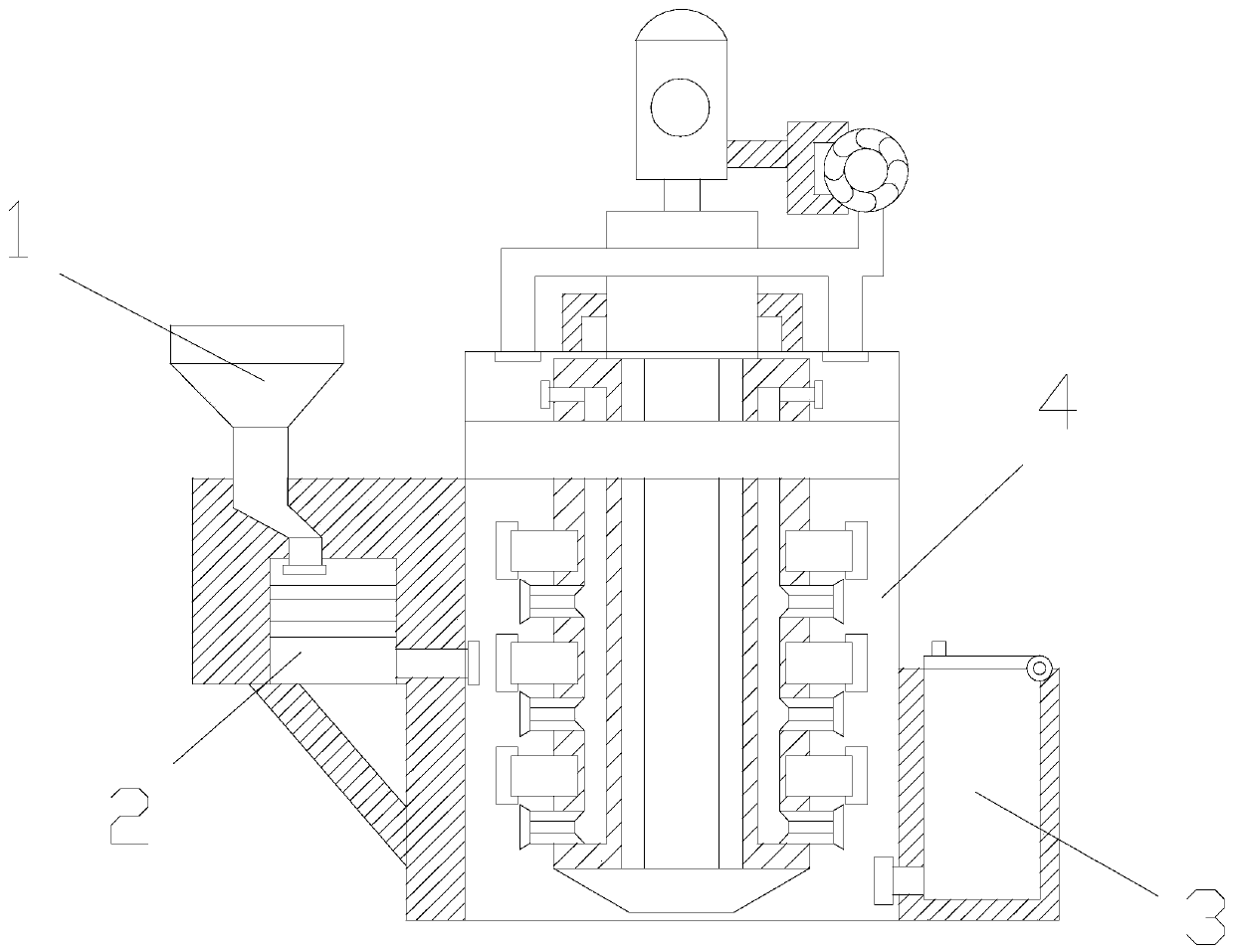

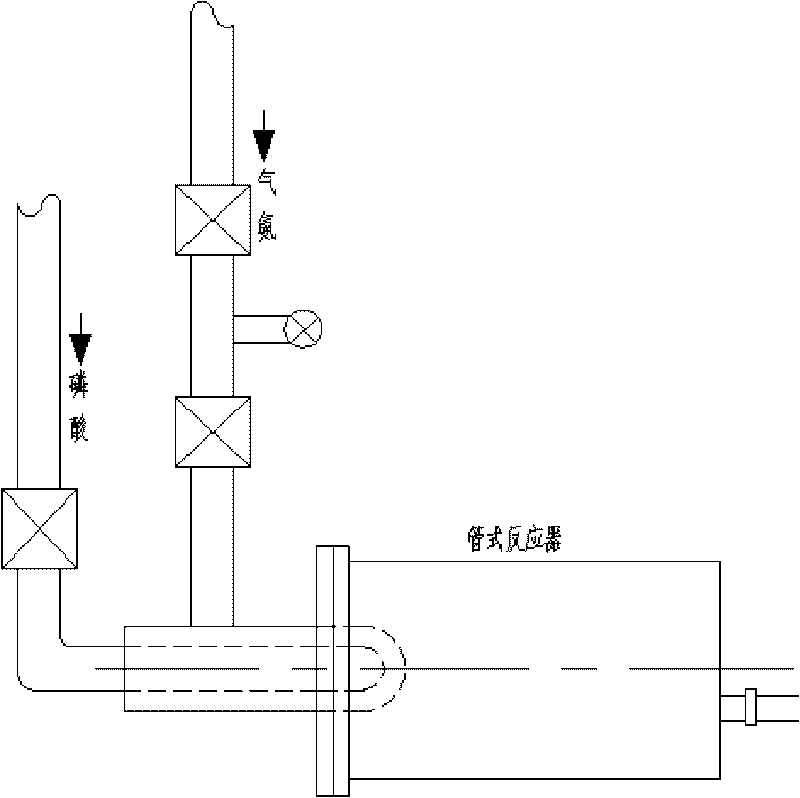

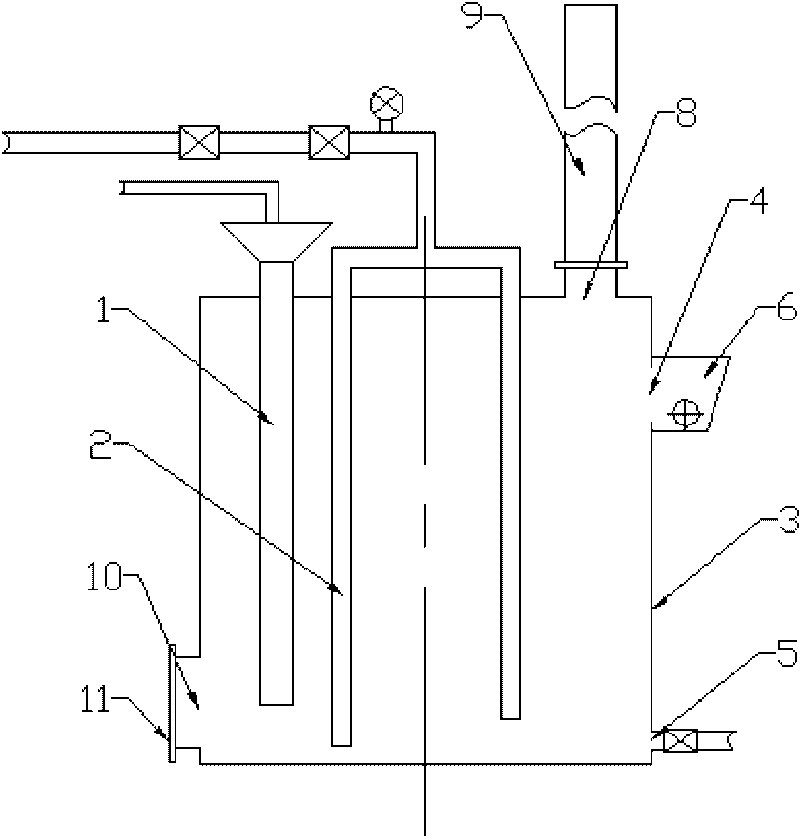

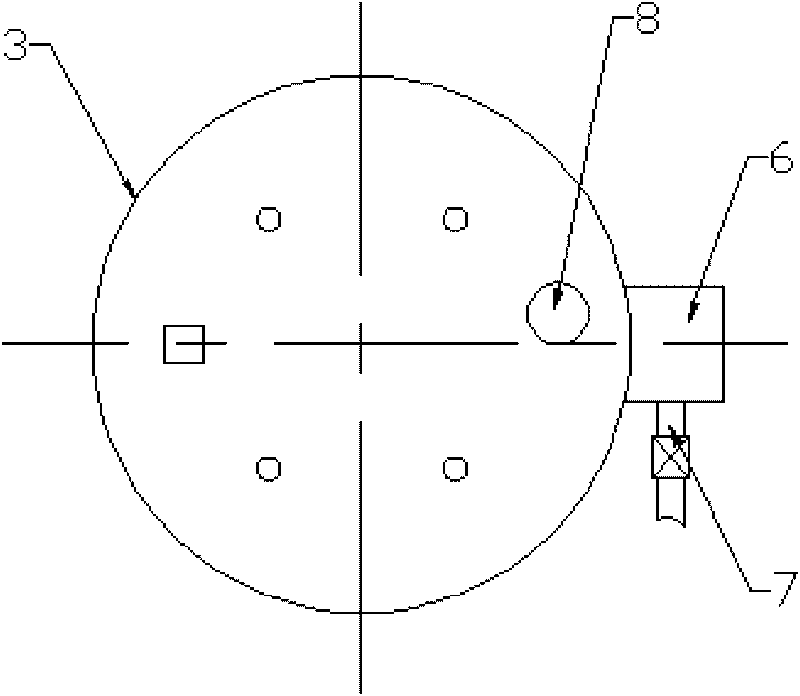

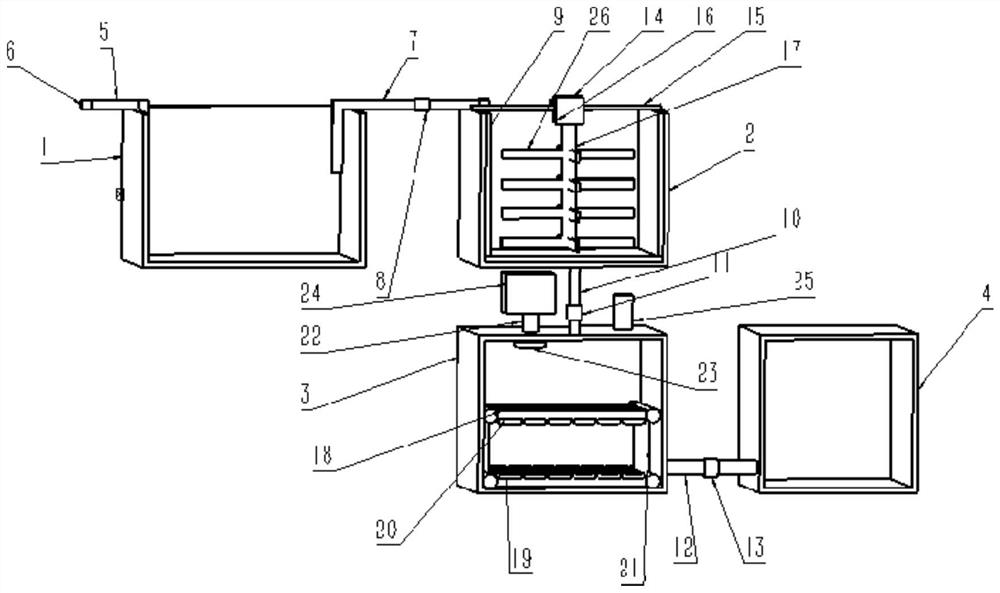

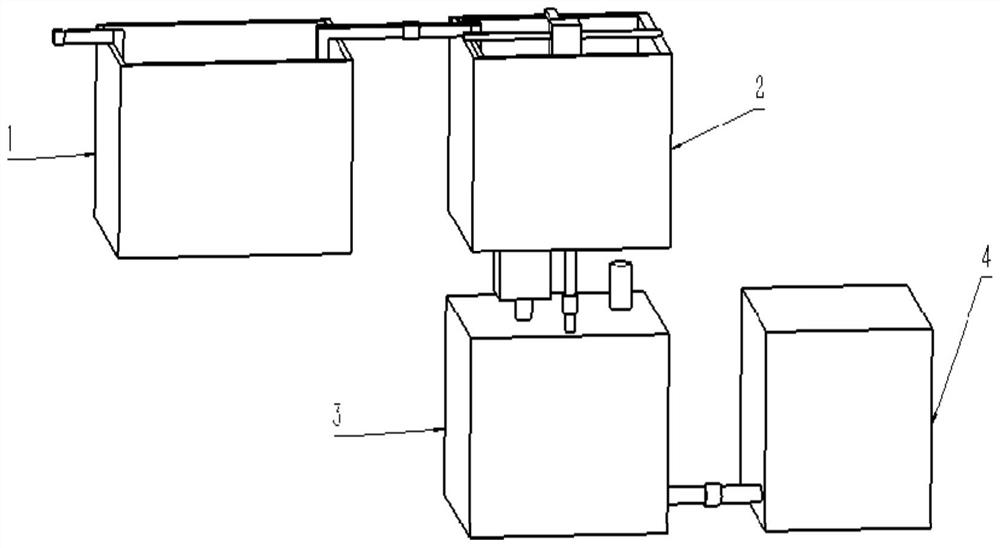

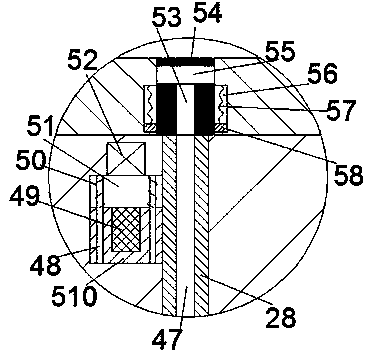

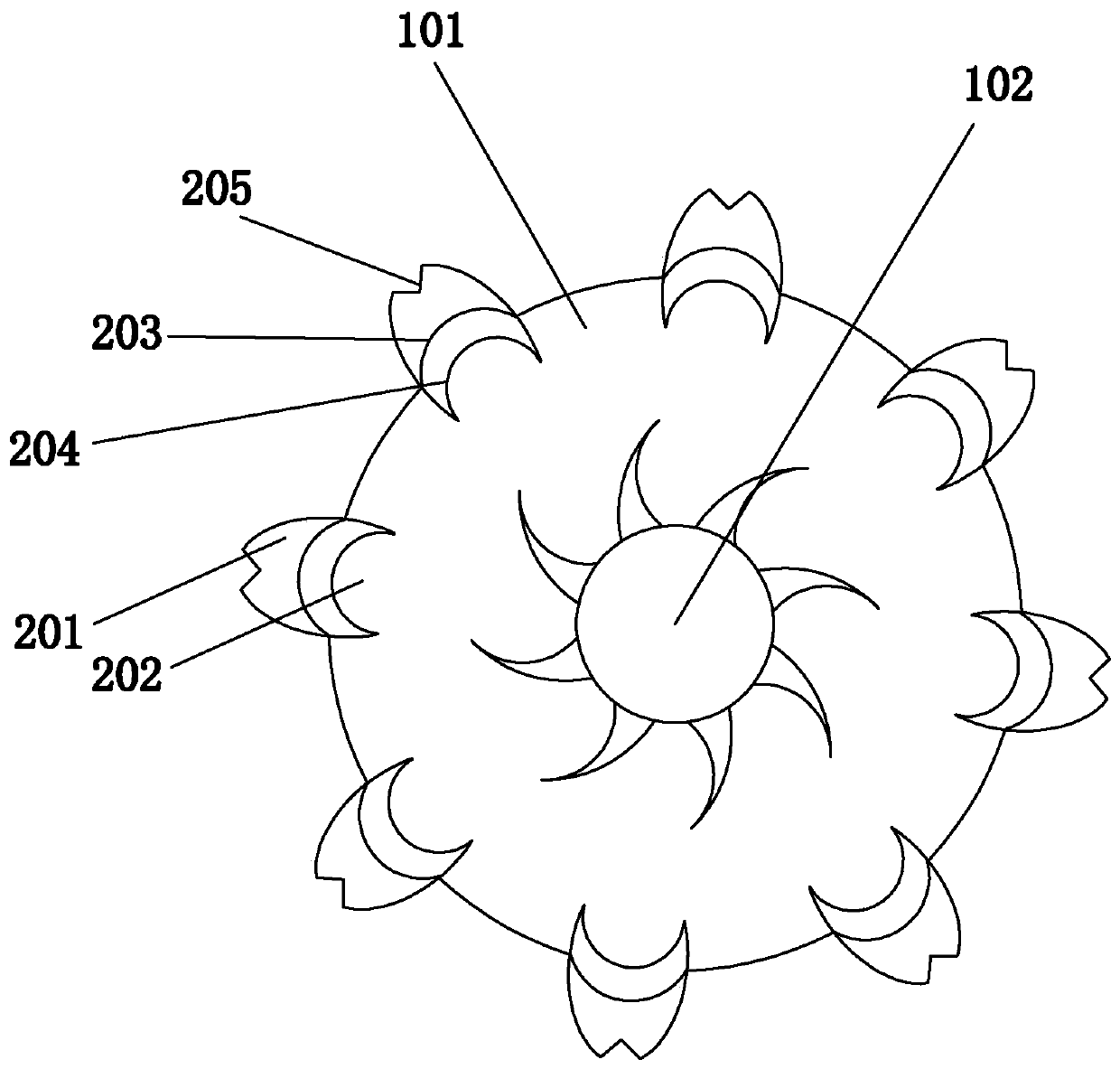

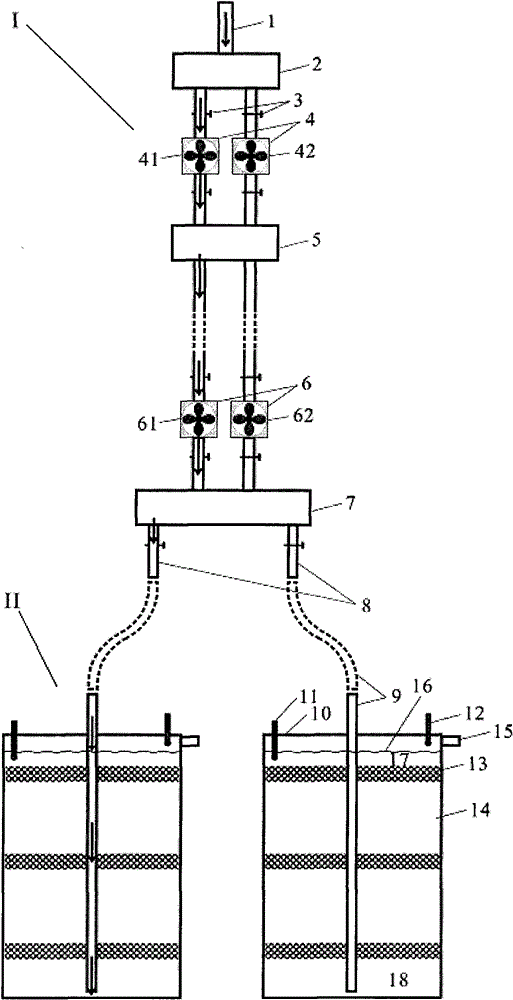

Phosphoric acid and gas ammonia neutralization reaction device

The invention discloses a phosphoric acid and gas ammonia neutralization reaction device comprising a phosphoric acid tube (1), gas ammonia tubes (2) and a reaction tank (3), wherein the phosphoric acid tube (1) and a plurality of gas ammonia tubes (2) are led into the lower end of the reactive tank (3) from the top of the reaction tank (3); the side surface of the upper end of the reactive tank (3) is provided with a discharge hole (4); and the side surface of the bottom end of the reaction tank (3) is provided with a discharge gate (5). In the invention, the phosphoric acid tube (1) and the gas ammonia tubes (2) are led into the lower end of the reaction tank (3) from the top of the reaction tank (3), the gas ammonia enters the reactor from multiple points, and therefore, the gas ammonia can more evenly react with the phosphoric acid. The discharge hole is arranged on the side surface of the upper end of the reaction tank, which is beneficial to the phosphoric acid and the gas ammonia to form the vertical convection in the reactive tank, and thereby, the neutralization reaction is more sufficient. The side surface of the lower end of the reaction tank is provided with the discharge gate (5), and therefore, liquid in the discharge gate can be rapidly discharged completely before scales in the reactive tank are cleaned, and cleaning is convenient.

Owner:SICHUAN YINGFENG IND

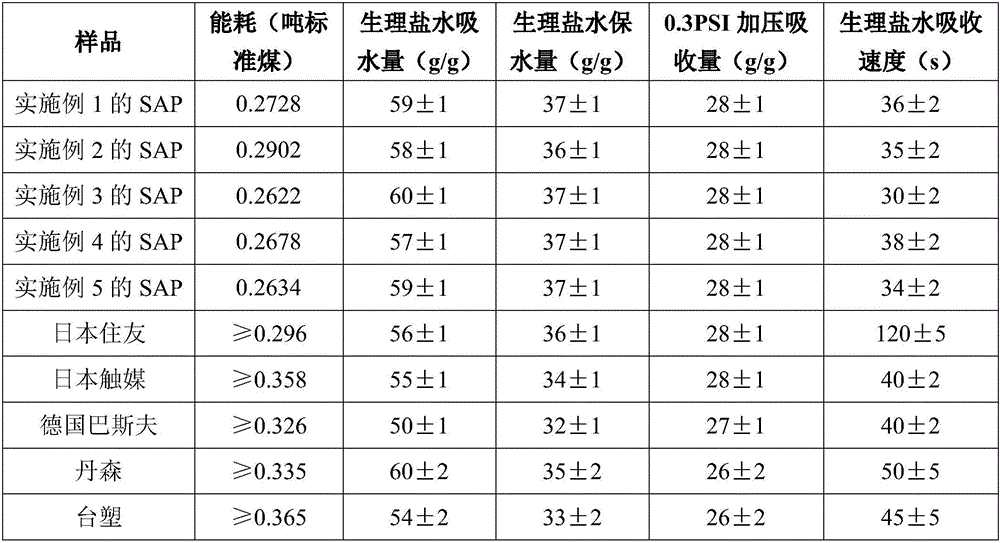

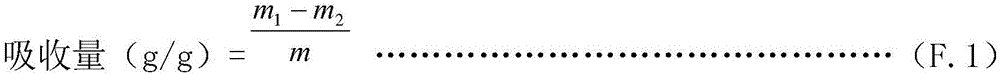

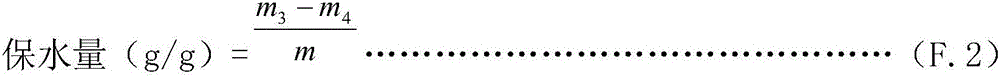

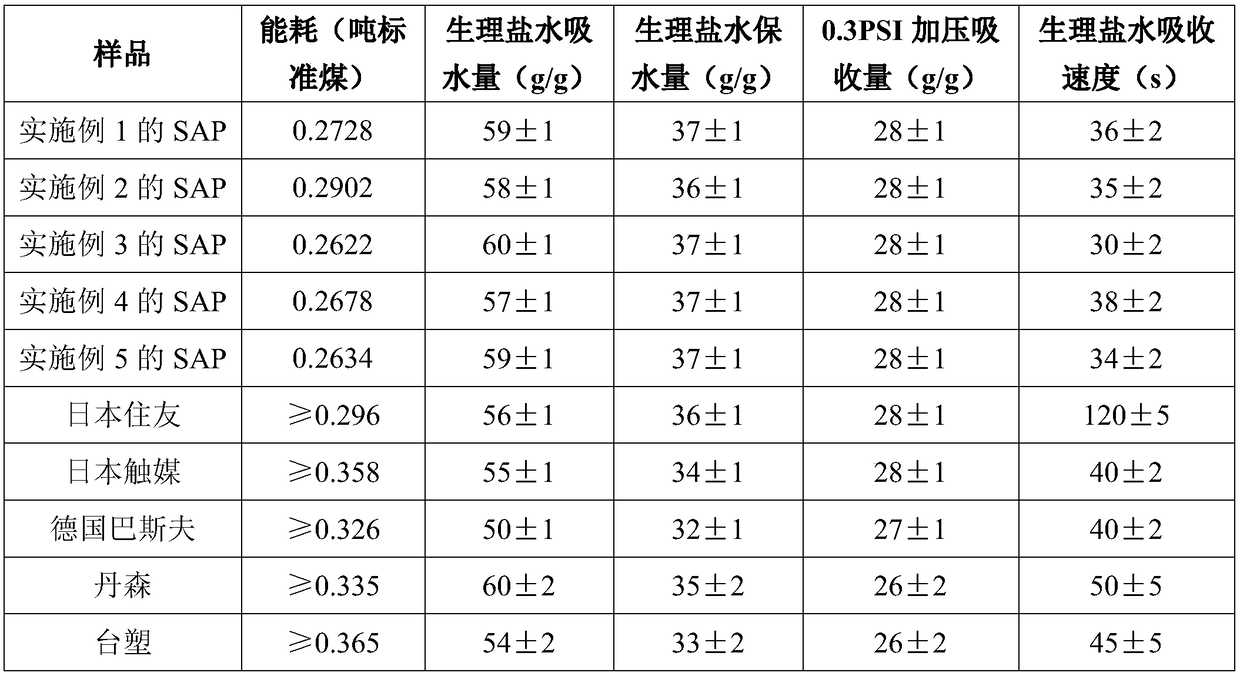

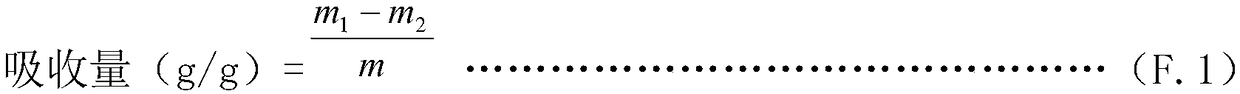

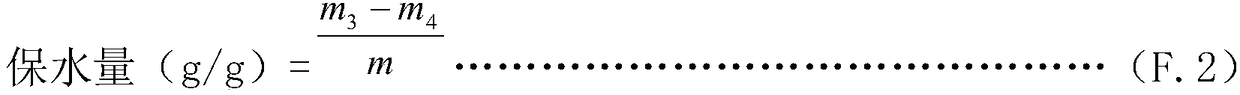

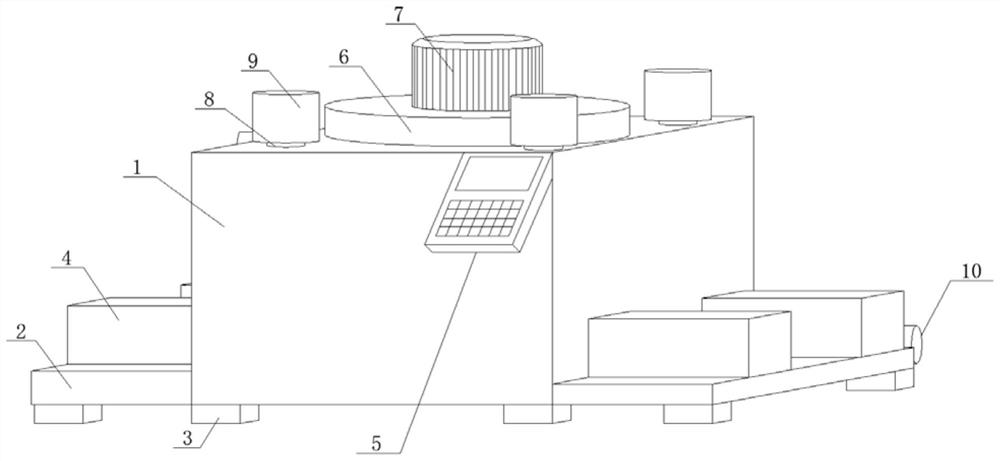

Process method for improving SAP (super absorbent polymer) preparation efficiency

The invention relates to the technical field of super absorbent polymer preparation, and in particular to a process method for improving SAP (super absorbent polymer) preparation efficiency. The process method includes the steps: (1) first neutralization; (2) second neutralization; (3) third neutralization; (4) fourth neutralization; (5) polymerization; (6) drying and crushing; (7) surface modification. The process method is scientific in preparation and sufficient in product neutralization, the specific surface area of products can be increased when original network structures and strength of the products are not changed in the polymerization process, polymerization degree of the products is stable, polymerization and drying time is shortened, the production efficiency of the products is improved, energy consumption is reduced, and absorption of the products is accelerated.

Owner:SHANDONG HAOYUE NEW MATERIALS CO LTD

Epoxy resin production wastewater recovery device

PendingCN112624422AImprove recycling efficiencyHigh densityWater treatment parameter controlDispersed particle separationEpoxyToxic gas

The invention provides an epoxy resin production wastewater recovery device, which comprises a water tank, a filtering device, a PH adjusting tank and a water tank, and is characterized in that a water inlet pipe is arranged on the water tank, a valve is arranged on the water inlet pipe, the water tank and the filtering device are connected through a first water pipe, a first water pump is arranged on the first water pipe, filtering walls are arranged on the outer wall of the periphery of the filtering device, the bottom of the water tank is connected with the PH adjusting tank through a second water pipe, a second water pump is arranged on the second water pipe, the PH adjusting tank is connected with the water tank through a third water pipe, and a third water pump is arranged in the middle of the third water pipe. According to the epoxy resin production wastewater recycling device, the quality of water obtained through filtering is better, two aeration plates conduct aeration up and down, the reaction rate is increased, the neutralization reaction is faster through the spraying means, the reaction can be more sufficient, no toxic gas is discharged, absorption is conducted through the absorption tower, and the environment is protected.

Owner:TIANJIN JINGDONG CHEM COMPOUND MATERIALS

Activated dye processing method

InactiveCN109078595ASimple structureEasy to useTransportation and packagingRotary stirring mixersEngineeringScrew thread

The invention discloses an activated dye processing method which adopts an activated dye processing device. The activated dye processing device comprises a body fixed onto a support, a first sliding groove bilaterally extends and is formed in the body and provided with an upward opening, an upward extending top seat is integrally arranged on the right side of the upper end of the body, a second sliding groove communicated with the first sliding groove is provided with a downward opening and formed in the top seat, a cylinder is fixedly mounted on the upper end surface of the top seat, a feeding groove communicated with the cylinder and the first sliding groove is formed in the body, a bilaterally slid reaction cylinder is mounted in the first sliding groove, a cylinder cavity with an upward opening is formed in the reaction cylinder, first bilaterally extending guide grooves are symmetrically formed in the front end wall of the first sliding groove, first guide blocks fixedly connectedwith the reaction cylinder is slidably arranged in the first guide grooves, and first threaded rods are mounted in the first guide blocks in a thread fit manner.

Owner:岑浩明

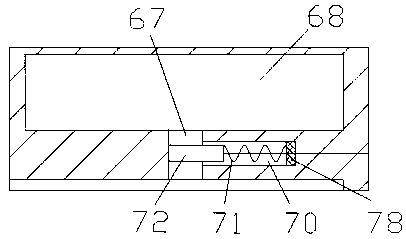

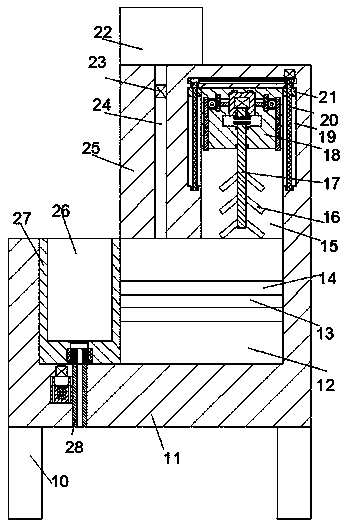

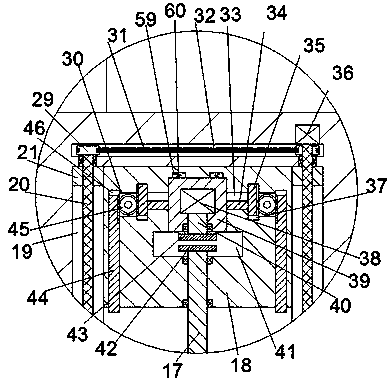

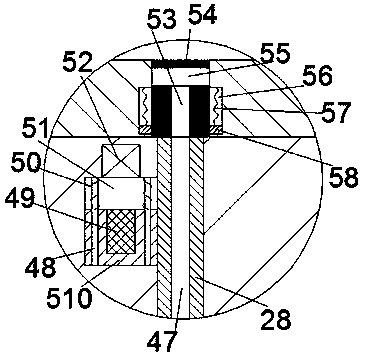

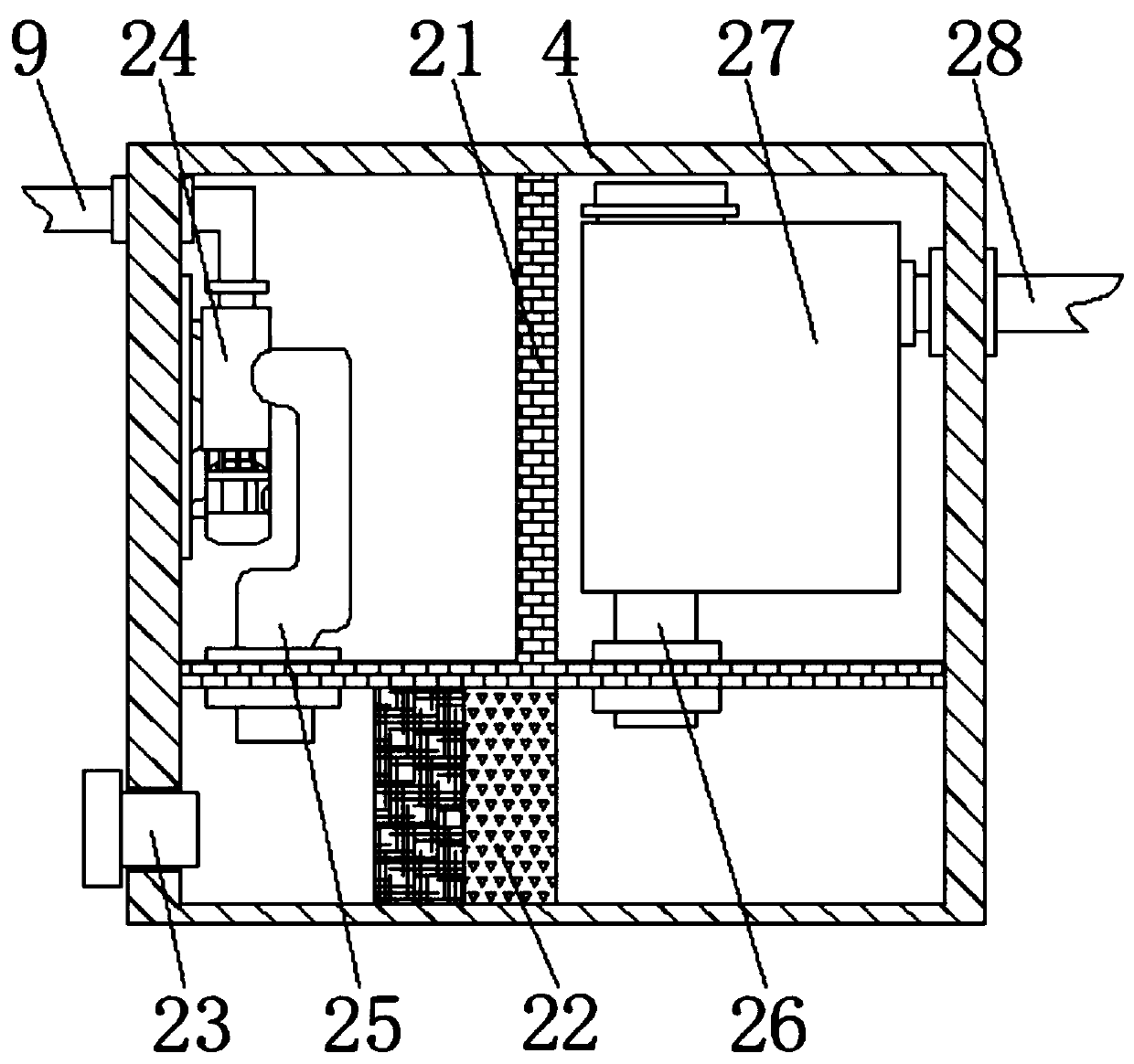

Solution recovery pretreatment device for lead-acid storage battery

InactiveCN111187919AAvoid overdoseAvoid deficienciesWaste accumulators reclaimingProcess efficiency improvementEngineeringMechanical engineering

The invention discloses a solution recovery pretreatment device for a lead-acid storage battery. The solution recovery pretreatment device comprises a main box body, wherein the main box body is internally provided with a lead-acid solution through cavity with an upward opening, the lower side of the lead-acid solution through cavity is provided with a stirring cavity in a communicated mode, the left side of the stirring cavity is provided with a floating block cavity in a communicated mode, the floating block cavity is connected with a floating block in a sliding fit mode, the lower end wallof the stirring cavity is fixedly connected with an acid-base sensor corresponding to the lead-acid solution through cavity, the upper side of the stirring cavity is provided with an alkali liquor feeding mechanism, the lower side of the stirring cavity is provided with a treatment liquid through cavity in a communicated mode, and a pH value in the stirring cavity is sensed through the acid-base sensor, so that the feeding of alkali liquor is controlled, and the alkali liquor is prevented from being excessive or insufficient; during neutralization reaction, a stirring rod keeps rotating, so that the neutralization is sufficient; and after the treatment liquid enters an extrusion cavity, filtering is completed under the extrusion of a piston push plate, so that lead paste remains on the surface of a filter screen, the lead paste is lifted through a lifting box, and a scraping plate stretches out to complete automatic scraping of the lead paste, so that the working efficiency is improved.

Owner:LONGYOU ZHIDA ENVIRONMENTAL PROTECTION EQUIP CO LTD

Preparation method of reactive dye

InactiveCN109046206ASimple structureEasy to useRotary stirring mixersTransportation and packagingEngineeringReactive dye

The invention discloses a preparation method of reactive dye. A reactive dye preparation device applied to the method comprises a machine body fixed on a support, the machine body is internally provided with a first sliding groove, the first sliding groove with an upward opening extends leftwards and rightwards, a top seat extending upwardly is integrally arranged on the right side of the upper end of the machine body, and a second sliding groove with a downward opening is formed in the top seat and is communicated with the first sliding groove; a cylinder is fixedly mounted on the upper end face of the top seat, a feeding groove communicated with the cylinder and the first sliding groove are formed in the top seat; a reaction cylinder capable of sliding leftwards and rightwards is mountedin the first sliding groove; a cylinder cavity with an upward opening is formed in the reaction cylinder; first guide grooves extending leftwards and rightwards are symmetrically formed in the frontend wall of the first sliding groove, and first guide blocks fixedly connected with the reaction cylinder are slidably arranged in the first guide grooves; first threaded rods are fittingly mounted inthe first guide blocks.

Owner:岑浩明

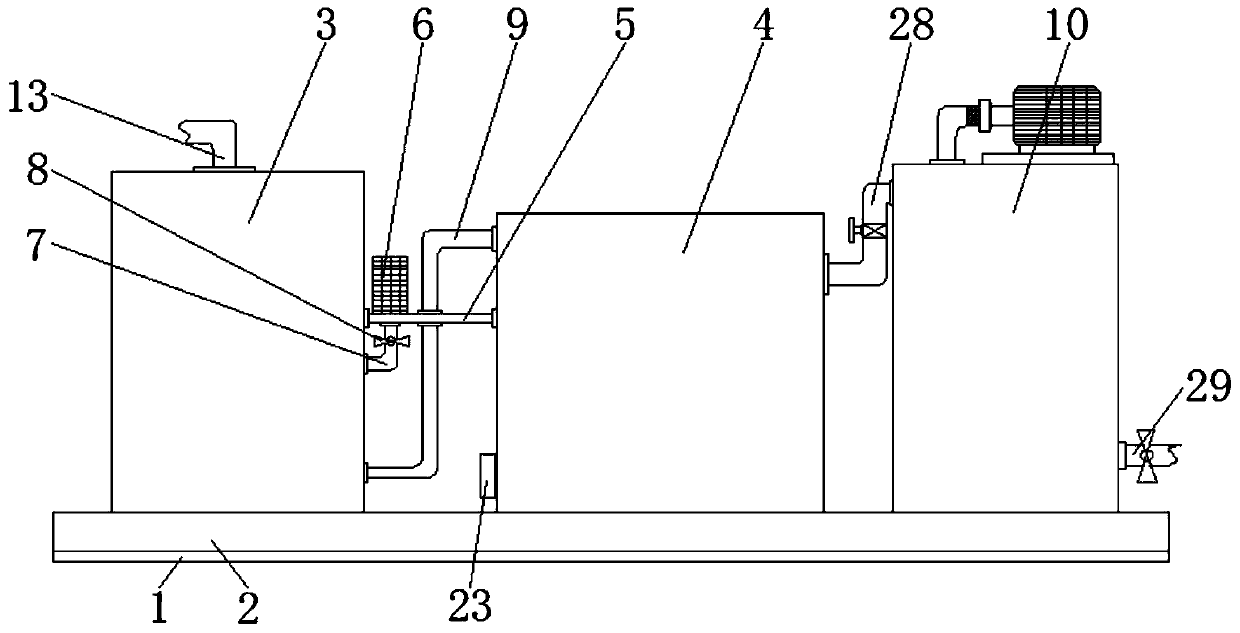

Intelligent waste gas treatment system for optical fiber preform production equipment

InactiveCN107670438ARealize rational utilizationMaintain Neutral AbsorbencyUsing liquid separation agentSpray towerWater pipe

The invention relates to an intelligent waste gas treatment system for optical fiber preform production equipment. The system comprises a spray tower, a reaction chamber, a pipeline mechanism, a waterpump, a first water pipe, a feeding chamber and a feeding pipe, wherein the reaction chamber is internally provided with a feeding mechanism and a mixing mechanism, the feeding mechanism comprises ablock, a vertical bar, a transverse board and two feeding units, and the mixing mechanism comprises a transverse bar, a second motor, a second driving shaft and two mixing units. According to the intelligent waste gas treatment system for optical fiber preform production equipment, the outer wall of the reaction chamber absorbs the heat of the waste gas through a wound pipe, so that a reaction liquid and the waste gas are neutralized at a faster speed, waste gas heat is used reasonably, and the neutralizing reaction is carried out completely due to the mixing mechanism, further, the feeding mechanism allows an alkaline agent in the feeding chamber to enter the reaction chamber from the feeding pipe, and the alkaline agent is dissolved in the reaction liquid, so that the reaction liquid recovers alkaline so as to keep neutralizing and absorbing acidic waste gas, and the system is more practical.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

Sewage treatment device for single-family house

InactiveCN110963621AChange pHFiltration neutralized fullyWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisWater resourcesEngineering

The invention discloses a sewage treatment device for a single-family house. The sewage treatment device comprises a friction fixing plate; the top of the friction fixing plate is fixedly connected with a fixed base; the left side of the top of the fixed base is fixedly connected with a first filtering and neutralizing tank; a second filtering and settling tank is fixedly connected to the top of the fixed base and is positioned on the left side of the first filtering and neutralizing tank; a fixed connecting plate is fixedly connected between the left side of the second filtering and settlingtank and the right side of the first filtering and neutralizing tank; the top of the fixed connecting plate is fixedly connected with an acid-base material comprehensive tank, and the bottom of the acid-base material comprehensive tank communicates with an acid-base neutralizer conveying pipe. The invention relates to the technical field of sewage treatment. According to the sewage treatment device for the single-family house, the problems that when domestic sewage of an existing single residence is treated, a large amount of clean water resources can only be used once, cyclic use of the cleanwater resources for the single-family house cannot be achieved, the water resources are wasted, and the use cost of users is increased are solved.

Owner:青岛良研信息科技有限公司

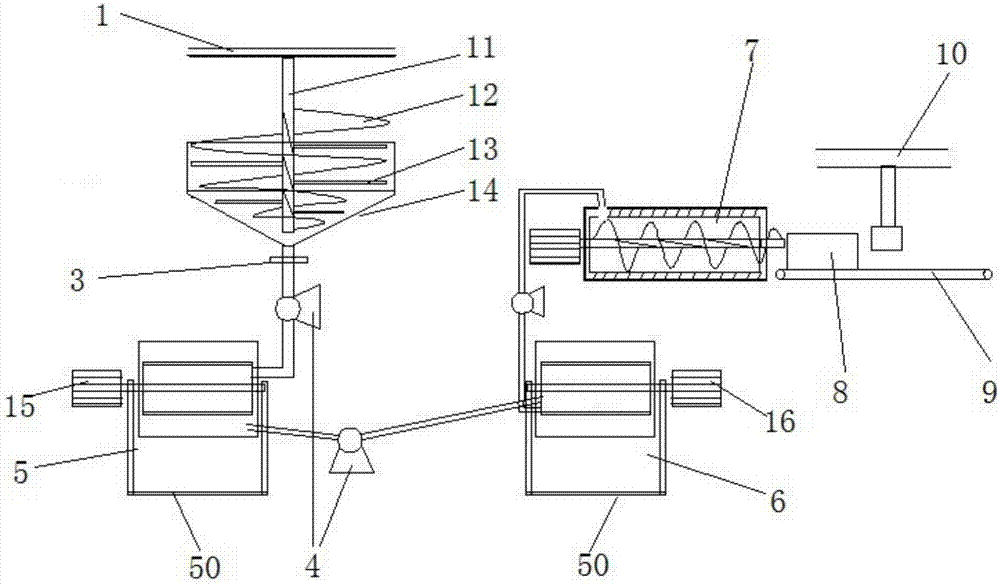

Soil remediation system and method

InactiveCN107377610AFully neutralizedReduce metal ions and harmful organic substancesContaminated soil reclamationEngineeringSoil remediation

The invention discloses a soil restoration system and method, comprising a stirring device, a rotating slurry repairing device, a secondary repairing device, a drying device and a briquetting forming device. end connection setting, the discharge end of the rotary slurry repair device is connected to the feed end of the secondary repair device, the discharge end of the secondary repair device is connected to the feed end of the drying device, and the drying device A conveyor belt is provided at the discharge end of the conveyor belt, and a briquette forming device is provided above the conveyor belt. The invention provides a soil restoration system and method, which performs multi-stage restoration of soil in the form of mud, and the repaired soil is convenient to transport.

Owner:SUZHOU SANTI INTELLIGENT TECH

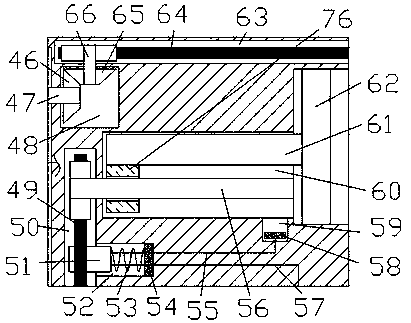

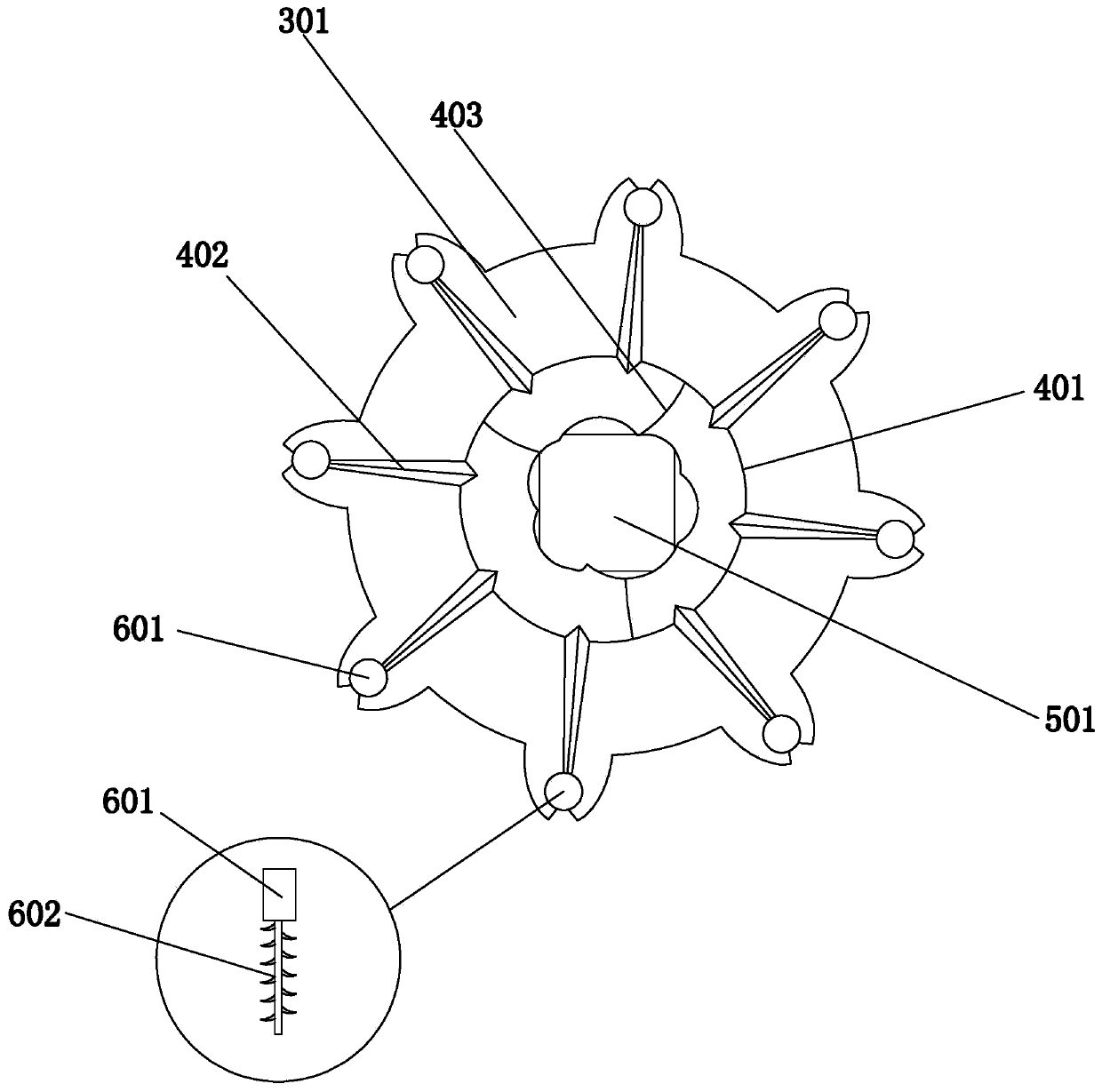

Neutralization device for amino acid extraction

PendingCN108927090AFully neutralizedNeutralize quickly and effectivelyChemical/physical/physico-chemical stationary reactorsFeed devicesImpellerGear wheel

The invention discloses a neutralization device for amino acid extraction, which comprises a device shell. An outlet pipe is fixedly inserted at the lower part of the right end of the device shell, arotating rod is inserted at the upper and lower sides of the middle part of the inner cavity of the device shell through bearings, the lower part of the outer side of the rotating rod is fixedly connected with stirring impellers, the upper part of the rotating rod is sleeved with a transmission shell through bearings, the left and right sides of the lower end of the transmission shell is fixedly connected onto the side wall of the inner cavity of the device shell through connecting rods, the rotating rod is fixedly sleeved with a first gear at the lower part of the inner cavity of the transmission shell, the left side of the upper end of the first gear is engaged with a second gear, and the left end of the second gear is fixedly connected with a transmission rod. The neutralization devicefor amino acid extraction makes the neutralization of two liquids more fully through the structure of the mixing impellers, and the neutralization of two materials more quickly and effectively throughthe structure of a triangular separator.

Owner:JINGMEN XINGUANG BIO ENG CO LTD

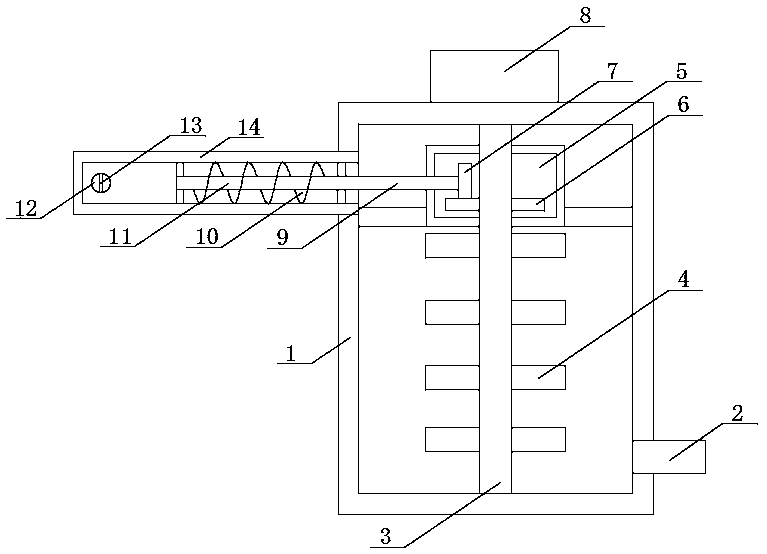

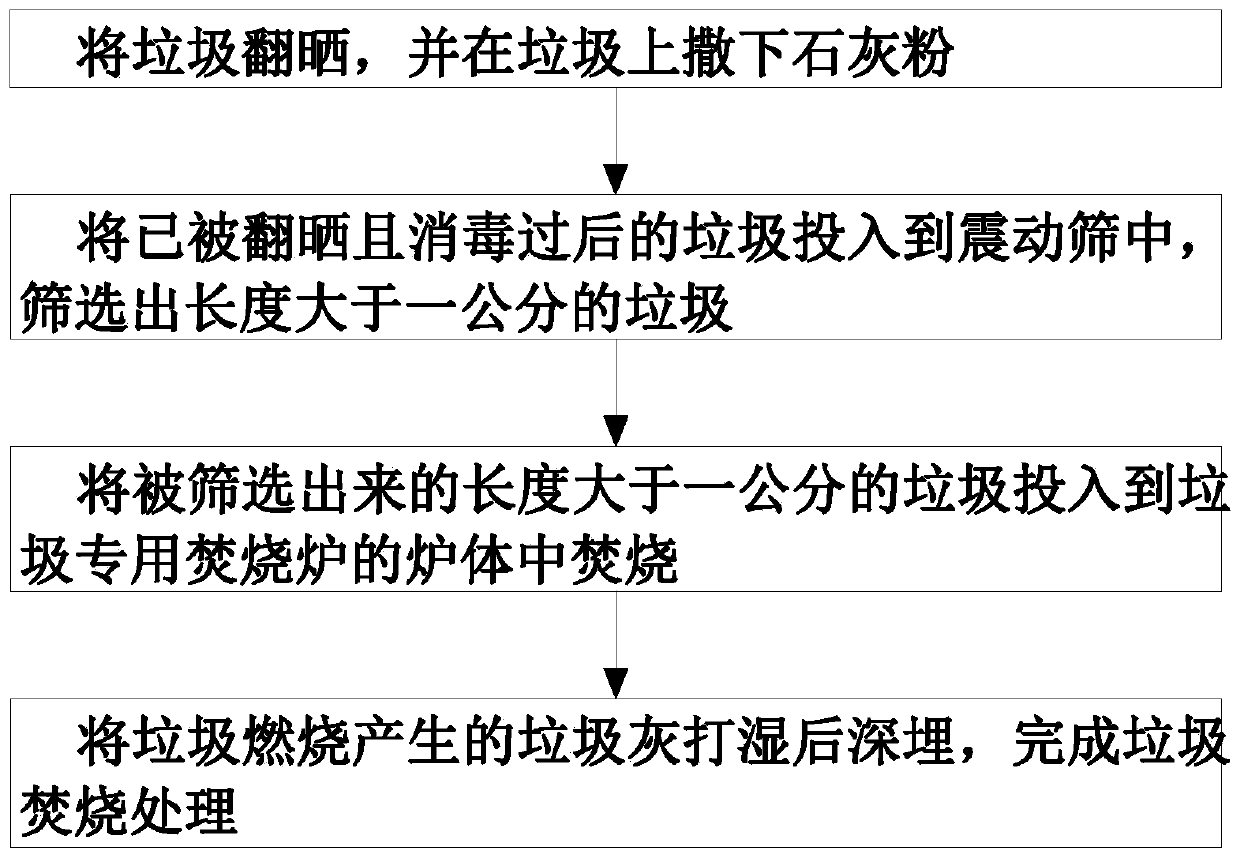

Waste incineration treatment method

ActiveCN109751603AImprove combustion efficiencyReduce pollutionDispersed particle separationIncinerator apparatusSolenoid valveExhaust fumes

The invention belongs to the technical field of waste treatment, and particularly relates to a waste incineration treatment method. A special incinerator for wastes, used in the method, comprises an incinerator body, a gas delivery pipe, a pressurizer, a solenoid valve, a waste gas treatment module and a controller; the controller is used for controlling on-off of the solenoid valve; the waste gastreatment module is located at the upper end of the incinerator body, and used for removing sulfides in waste gas; one end of the gas delivery pipe communicates with the upper end of the incineratorbody, and the gas delivery pipe is connected with the pressurizer and the solenoid valve in sequence; the other end of the gas delivery pipe communicates with the waste gas treatment module, and the gas delivery pipe is used for introducing the waste gas in the incinerator body into the waste gas treatment module; the pressurizer is used for pressurizing the waste gas in the gas delivery pipe; andthe solenoid valve is used for opening and closing the gas delivery pipe intermittently. According to the special incinerator, elastic waved plates are enabled to flap alkali liquor, so that the fullneutral reaction between the waste gas and the alkali liquor occurs; and thus, the situation that acid rain is formed after the waste gas is discharged to atmosphere and consequently environment is polluted is avoided.

Owner:陈利忠

Mould material module hot water dewaxing method for wax mould precision casting process

InactiveCN102601306AFully neutralizedTo achieve the purpose of removing sodium silicateFoundry mouldsFoundry coresWaxSodium silicate

The invention discloses a mould material module hot water dewaxing method for a wax mould precision casting process, belonging to the field of mould manufacture. The hot water dewaxing method comprises the following steps of: A) preparing dewaxing solution, wherein the dewaxing solution is mixed liquid of water and ammonium chloride (NH4Cl); B) storing a mould material module at room temperature; and C) putting the mould material module into the dewaxing solution for dewaxing. By adopting the method, wax and alkaline matter sodium silicate in the wax mould module can be effectively removed and the wax mould is not damaged.

Owner:SICHUAN DELI RAILWAY TECH

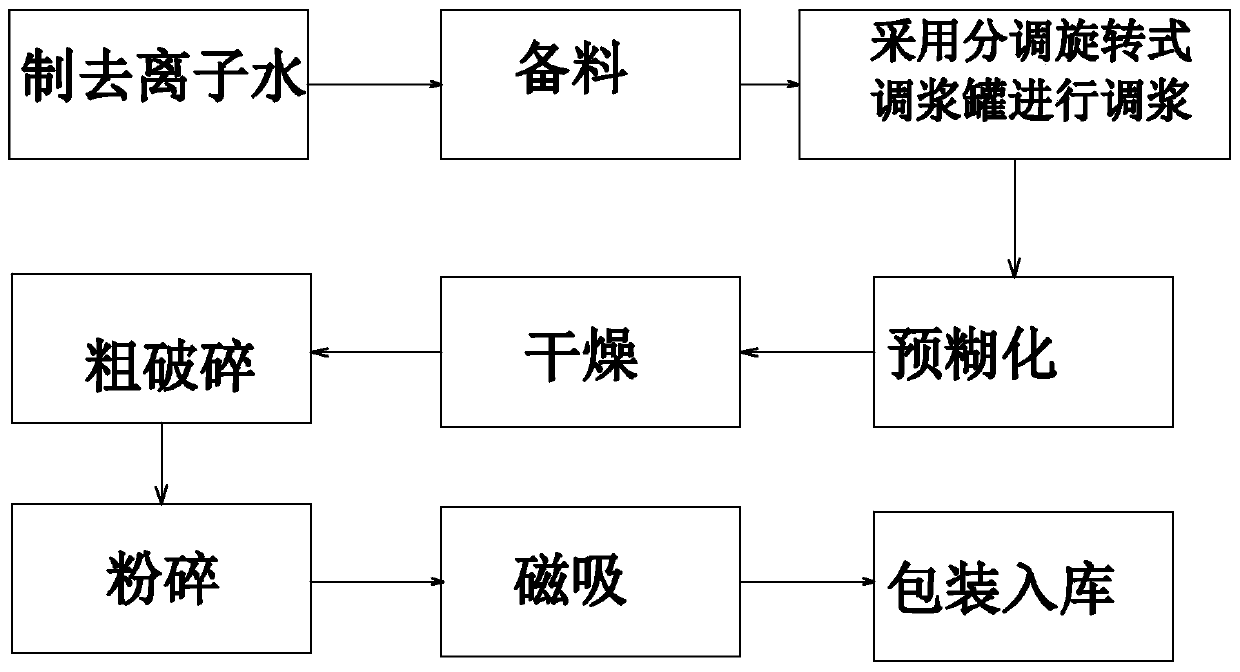

Production process and equipment of special pre-gelatinized starch for sweet soup balls

The invention discloses a production process and equipment of special pre-gelatinized starch for sweet soup balls. According to the technical scheme, the equipment is characterized in that the equipment comprises a tank body and a material distribution cover body matched with the tank body; a stirring screw rod is arranged in the middle of the tank body; eight independent tanks which are arrangedat equal intervals are welded on the outer wall of the tank body; one side of each independent tank is arranged in the tank body and is communicated with the interior of the tank body; first grid pieces are arranged in the independent tanks; the independent tanks are provided with arc-shaped notches at the side ends located in the tank body, and the arc-shaped notches are separated through secondgrid pieces; and parallel notches are formed in the other side ends, opposite to the arc-shaped notches, of the independent tanks, and the parallel notches are sealed through bent blocking plates. Starch which is soluble in cold water, high in viscosity and viscoelasticity and large in water absorption capacity is provided.

Owner:嘉兴欣欣食品科技有限公司

Novel combinations for use as toners in polyesters

InactiveUS20030209698A1Reduce extractionImprove anti-yellowing effectHydroxy-anthraquinone dyesSynthetic resin layered productsPolyesterUltraviolet

Combinations of individual colorant compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner combination permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such a combination of compounds is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive combination bluing agent thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

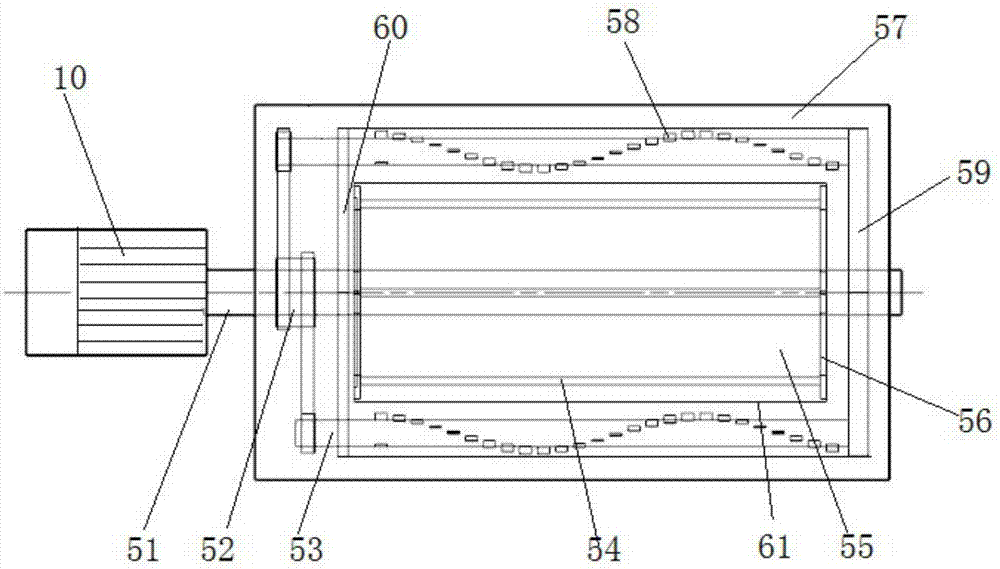

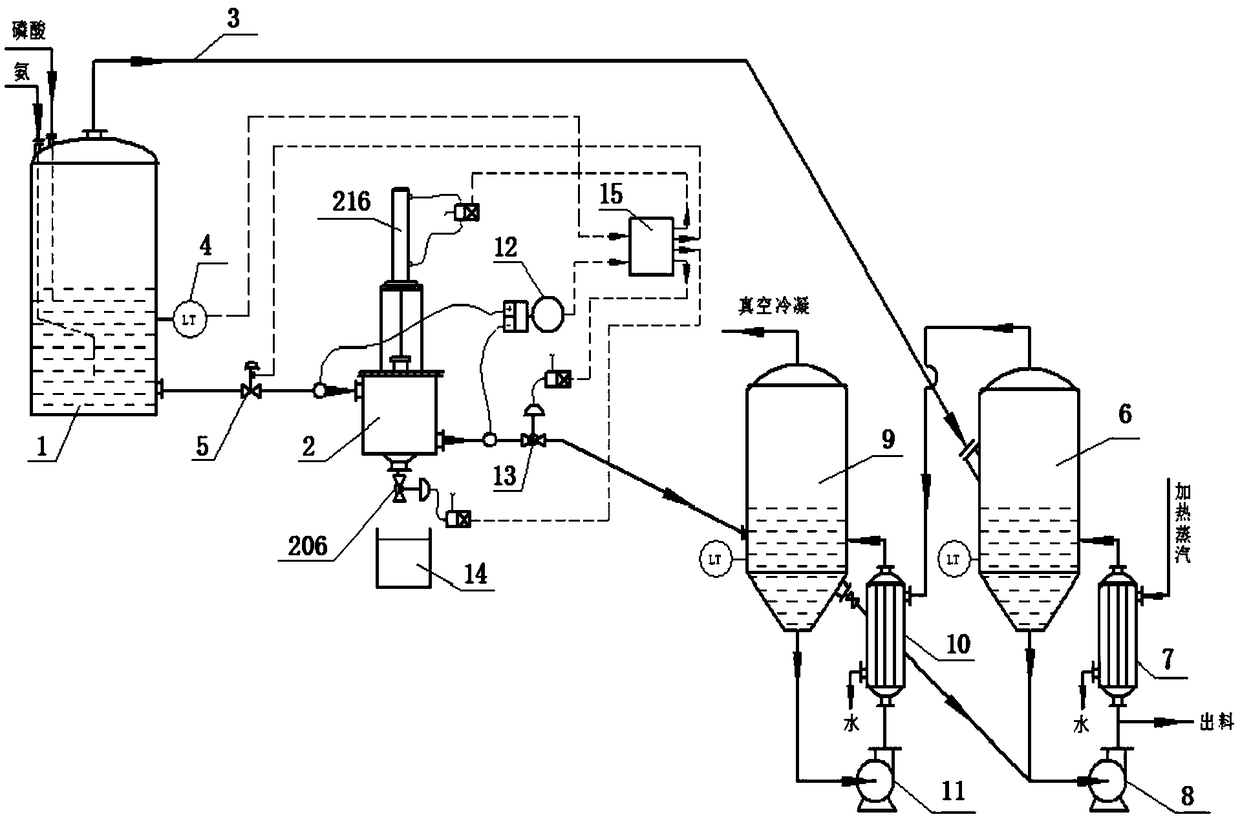

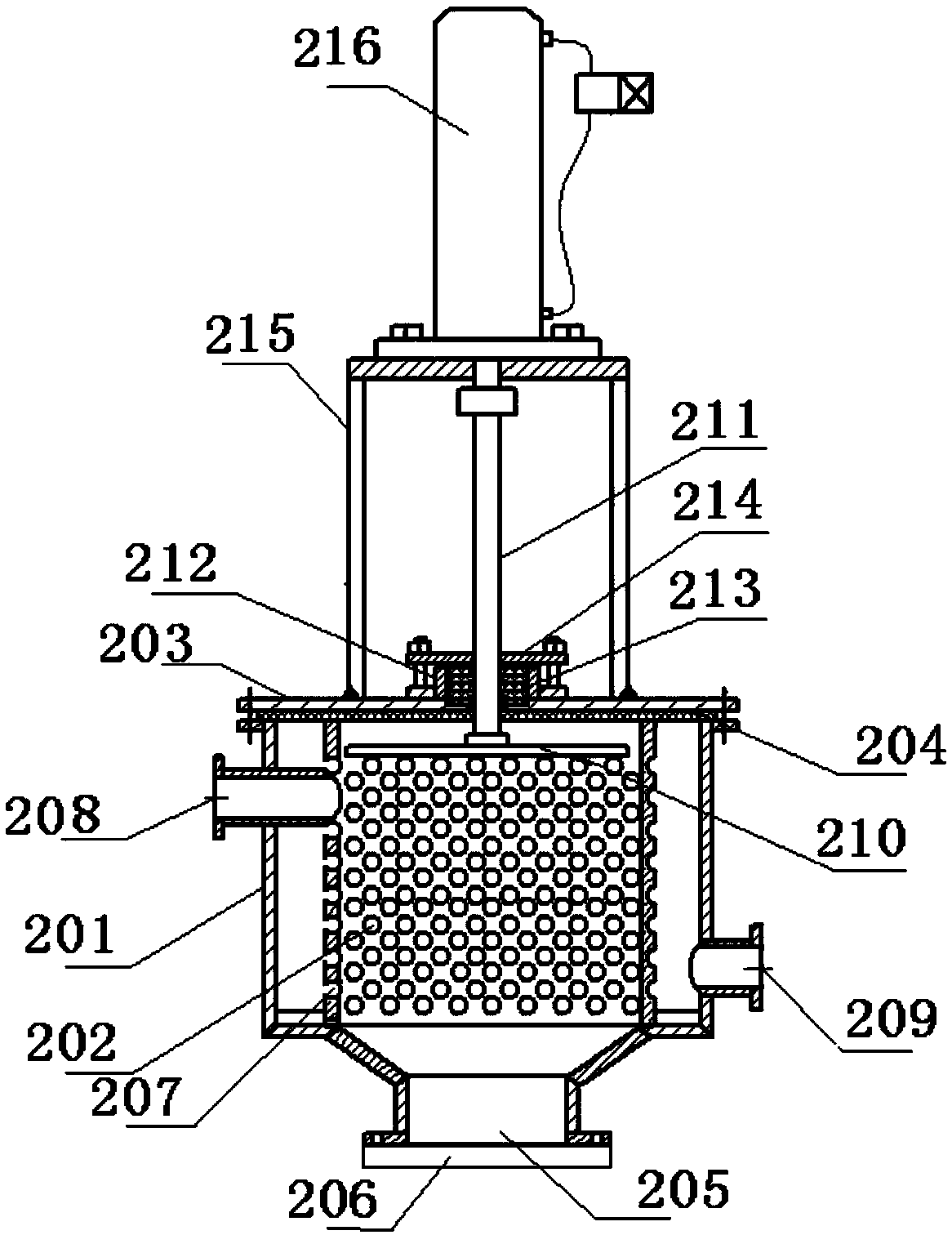

Slurry-process ammonium phosphate neutralization reaction system

ActiveCN109179354AReduce cloggingReduce labor intensityPhosphatesAlkali orthophosphate fertiliserSlagSlurry

The invention discloses a slurry-process ammonium phosphate neutralization reaction system, which comprises a neutralization tank, a sealing intercepting device, a first-effect flashing chamber and asecond-effect flashing chamber. The sealing intercepting device comprises a filtering outer cylinder, the upper end of which is provided with a sealing flange and the bottom surface of which is provided with a slag discharge port. The slag discharge port is connected to a slag discharge valve. The filtering outer cylinder sleeves a filtering inner cylinder, the bottom of which is communicated withthe slag discharge port and the top of which is contacted with the sealing flange. Liquid permeable holes are distributed on the sidewall of the filtering inner cylinder. The upper part of the filtering outer cylinder is provided with a feed pipe, which extends into the upper part of the filtering inner cylinder. The lower end of the filtering outer cylinder is provided with a discharge pipe. A pusher plate is also disposed in the filtering inner cylinder. The upper side of the pusher plate is connected with a push rod, which extends from the center hole of the sealing flange to the outside of the filtering inner cylinder. A sealing device is arranged at the center hole of the sealing flange. The push rod passes through a packing gland at the top of the sealing device to be connected to apiston rod of a cylinder positioned above the filtering outer cylinder. By the system, the influence on the operating environment is reduced, and work efficiency is improved.

Owner:中化重庆涪陵化工有限公司

A kind of anti-fresh cement efflorescence primer styrene-acrylic emulsion and preparation method thereof

Owner:上海巴德富实业有限公司

Novel combinations for use as toners in polyesters

InactiveUS20040157517A1Effective transparencyLow resultSynthetic resin layered productsHydroxy-anthraquinone dyesPolyesterUltraviolet

Combinations of individual colorant compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner combination permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such a combination of compounds is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive combination bluing agent thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:DANIELSON TODD D +3

A process for improving the efficiency of SAP preparation

The invention relates to the technical field of super absorbent polymer preparation, and in particular to a process method for improving SAP (super absorbent polymer) preparation efficiency. The process method includes the steps: (1) first neutralization; (2) second neutralization; (3) third neutralization; (4) fourth neutralization; (5) polymerization; (6) drying and crushing; (7) surface modification. The process method is scientific in preparation and sufficient in product neutralization, the specific surface area of products can be increased when original network structures and strength of the products are not changed in the polymerization process, polymerization degree of the products is stable, polymerization and drying time is shortened, the production efficiency of the products is improved, energy consumption is reduced, and absorption of the products is accelerated.

Owner:SHANDONG HAOYUE NEW MATERIALS CO LTD

Industrial waste liquid neutralizing device

InactiveCN111661909AImprove working environment and work efficiencyWell mixedWater/sewage treatment by neutralisationElectric machineryIndustrial waste

The invention discloses an industrial waste liquid neutralizing device, and relates to the field of industrial waste liquids. The industrial waste liquid neutralizing device comprises a neutralizing box body, supporting plates are horizontally welded to the two side edges of the neutralizing box body. Supporting cushion blocks are fixedly welded on the bottom surfaces of the neutralizing box bodyand the supporting plate; the top face of the supporting plate is horizontally connected with a pushing air cylinder through bolts. A control panel is obliquely welded to one side edge of the neutralizing box body, a top disc is horizontally welded to the top face of the neutralizing box body, a stirring motor is vertically connected to the top face of the top disc through bolts, butt joint screwholes are evenly formed in the top face of the neutralizing box body, and additive bottles are connected to the inner side edges of the butt joint screw holes through bolts. The device is simple in design structure and convenient to operate, neutralization is more sufficient under the action of multiple stirring, meanwhile, cleanness and sanitation are achieved in a non-contact additive feeding mode, and the working environment and the working efficiency are greatly improved.

Owner:杭州迦北科技有限公司

Device for neutralizing treatment of chlorine-containing gas

InactiveCN101732969BReduce volumeEfficient neutralizationDispersed particle separationEngineeringCl element

The invention relates to a device of neutralizing treatment of chlorine-containing gas, which is simple and economic, and can be used for the neutralizing treatment of the chlorine-containing gas in small flow rate(less than or equal to 1 m3 / h). The device comprises conveying equipment and neutralizing treatment equipment, wherein a gas output end of the conveying equipment is connected to the neutralizing treatment equipment; and the neutralizing treatment equipment comprises a container and a gas conveying tube, one end of the gas conveying tube is connected with the gas output end of the conveying equipment, the other end of the gas conveying tube is inserted to the bottom part of the container, the gas conveying tube is in sealed connection with the container, the middle part of the container is provided with sponge-shaped dividing plates by which the container is divided into an upper part and a lower part. The device has the advantages that: the neutralizing treatment of the chlorine-containing gas in small flow rate can be safely and continuously performed; the neutral reaction is performed more fully, and the effect is better; and after the chlorine-containing gas in smallflow rate is treated by the device, the content of C12 in exhaust gases is less than 1mg / m3 or 0.3mmp, and the emission meets the standard.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com