Phosphoric acid and gas ammonia neutralization reaction device

A reaction device, ammonia gas technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of undetectable, large power consumption, unfavorable production and energy saving, etc., to achieve easy cleaning, reduce energy consumption, and uniform neutralization reaction and full effect

Inactive Publication Date: 2010-05-26

SICHUAN YINGFENG IND

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

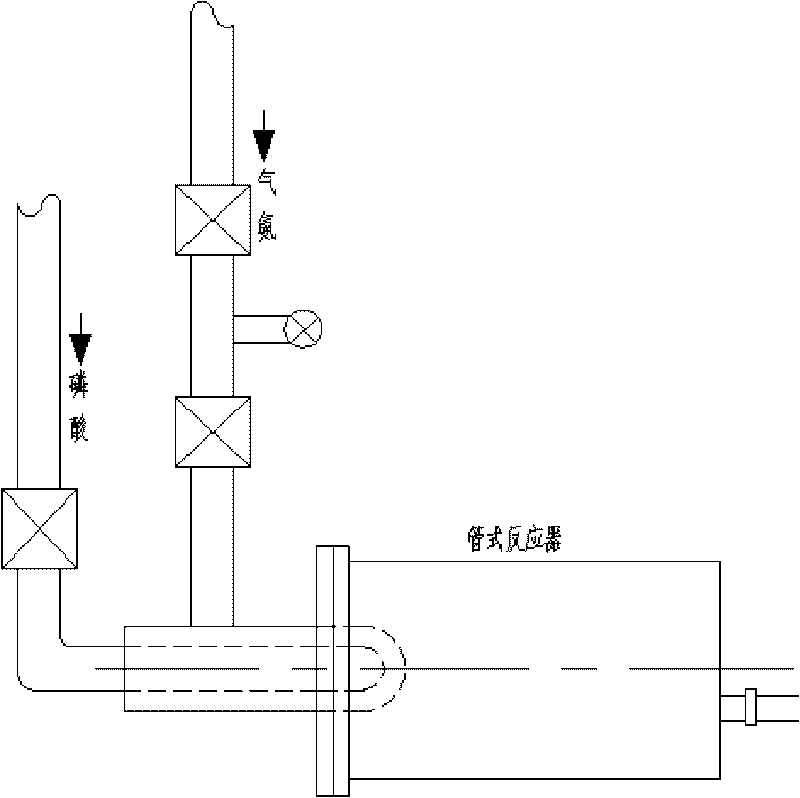

In this ammonium phosphate production process, a fully enclosed tubular neutralization reactor (such as figure 1 shown) to neutralize phosphoric acid and gaseous ammonia, but due to its structure, phosphoric acid and neutralized slurry can easily cause pipeline blockage after scaling inside, and this fully enclosed structure also brings great trouble to cleaning. Inconvenient, so it leads to longer parking time and lower production efficiency during the production process

In addition, the above-mentioned fully enclosed tubular neutralization reactor also has the following disadvantages during use: in order to make the neutralization reaction between phosphoric acid and ammonia gas uniform and sufficient, it is usually necessary to install a stirrer in the reactor, so the power consumption is large, and it is not necessary to Conducive to production and energy saving; the fully enclosed structure prevents the operator from detecting the liquid level in the reactor, so it is difficult to optimize the control of the amount of phosphoric acid and ammonia gas; A lot of heat, so there is a lot of water vapor in the reactor, and the tubular reactor has no vent hole, so there is more water in the neutralization slurry, which is very unfavorable for the subsequent slurry concentration process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

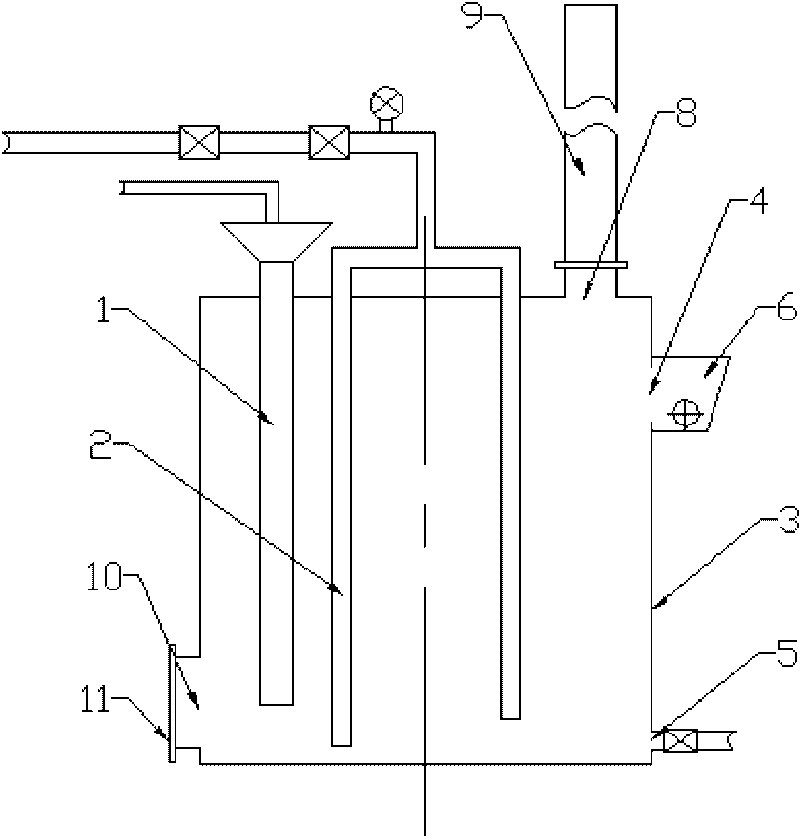

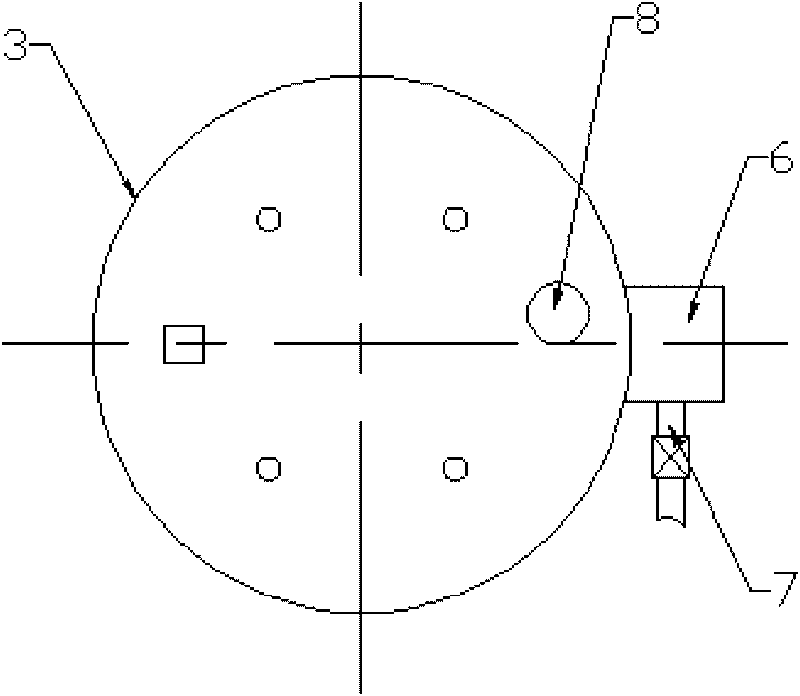

The invention discloses a phosphoric acid and gas ammonia neutralization reaction device comprising a phosphoric acid tube (1), gas ammonia tubes (2) and a reaction tank (3), wherein the phosphoric acid tube (1) and a plurality of gas ammonia tubes (2) are led into the lower end of the reactive tank (3) from the top of the reaction tank (3); the side surface of the upper end of the reactive tank (3) is provided with a discharge hole (4); and the side surface of the bottom end of the reaction tank (3) is provided with a discharge gate (5). In the invention, the phosphoric acid tube (1) and the gas ammonia tubes (2) are led into the lower end of the reaction tank (3) from the top of the reaction tank (3), the gas ammonia enters the reactor from multiple points, and therefore, the gas ammonia can more evenly react with the phosphoric acid. The discharge hole is arranged on the side surface of the upper end of the reaction tank, which is beneficial to the phosphoric acid and the gas ammonia to form the vertical convection in the reactive tank, and thereby, the neutralization reaction is more sufficient. The side surface of the lower end of the reaction tank is provided with the discharge gate (5), and therefore, liquid in the discharge gate can be rapidly discharged completely before scales in the reactive tank are cleaned, and cleaning is convenient.

Description

technical field [0001] The invention relates to ammonium phosphate production equipment, in particular to a neutralization reaction device for phosphoric acid and ammonia gas. Background technique [0002] The process of preparing ammonium phosphate by the concentration method of neutralizing slurry is to neutralize dilute phosphoric acid with ammonia first, and then evaporate and concentrate the neutralized slurry to prepare ammonium phosphate. In this ammonium phosphate production process, a fully enclosed tubular neutralization reactor (such as figure 1 shown) to neutralize phosphoric acid and gaseous ammonia, but due to its structure, phosphoric acid and neutralized slurry can easily cause pipeline blockage after scaling inside, and this fully enclosed structure also brings great trouble to cleaning. It is inconvenient, so it leads to longer parking time and lower production efficiency during the production process. In addition, the above-mentioned fully enclosed tubul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B25/28

Inventor 杨贵勇

Owner SICHUAN YINGFENG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com