A process for improving the efficiency of SAP preparation

A process method and technology of preparation efficiency, applied in the coating and other directions, can solve the problems of affecting product quality, high energy consumption, long drying time, etc., and achieve the effects of fast product absorption, low energy consumption, and improved reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

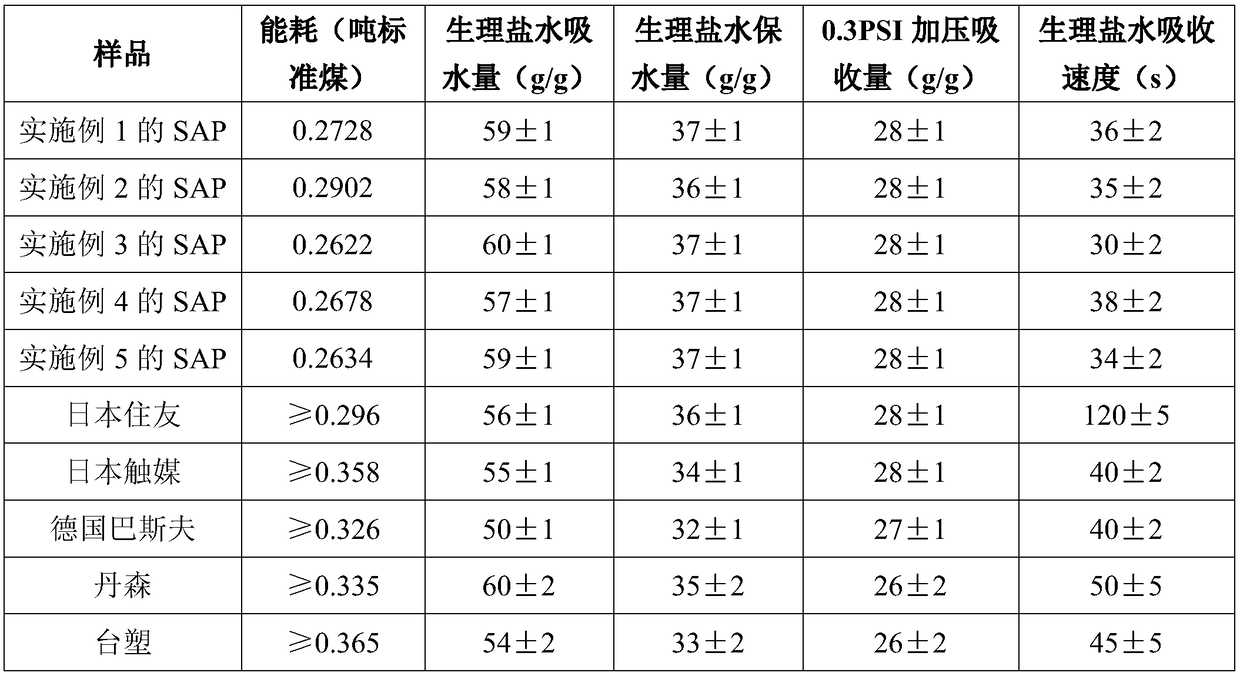

Examples

Embodiment 1

[0027] The process method for improving SAP preparation efficiency adopts the following steps:

[0028] (1) One-time neutralization: dropwise adding a mass fraction of 25% sodium carbonate solution in acrylic acid, stirring while adding dropwise, when the neutralization degree reaches 25%, add tert-butyl hydroperoxide of 1‰ of acrylic acid quality, After mixing evenly, let it stand for 5 minutes to obtain the mixed solution 1;

[0029] (2) Secondary neutralization: continue to add 20% sodium carbonate solution to the mixed solution 1, and stir while adding it dropwise. Set aside for 5 minutes to obtain the mixed solution 2;

[0030] (3) Three times of neutralization: continue to add 20% sodium carbonate solution to the mixed solution 2, and stir while adding it dropwise. When the neutralization degree reaches 75%, add methanol with acrylic acid mass of 1‰, mix well and let stand for 5 minutes , to obtain the mixed solution 3;

[0031] (4) Four times of neutralization: conti...

Embodiment 2

[0036] A kind of processing method that improves SAP preparation efficiency, adopts following operation steps:

[0037] (1) One-time neutralization: add sodium bicarbonate solution with a mass fraction of 35% to acrylic acid, and stir while adding, until the neutralization degree reaches 30%, add hydrogen peroxide with acrylic acid mass of 10‰, and mix well After standing still for 20min, the mixture 1 was obtained;

[0038] (2) Secondary neutralization: continue to add 30% sodium bicarbonate solution to the mixed solution 1, and stir while adding it dropwise. When the neutralization degree reaches 50%, add glycidyl ether with acrylic acid mass of 10‰, and mix well After standing still for 20min, the mixture 2 was obtained;

[0039] (3) Three times of neutralization: continue to add 30% sodium bicarbonate solution to the mixed solution 2, and stir while adding it dropwise. When the neutralization degree reaches 80%, add ethanol with acrylic acid mass of 10‰, mix well and let ...

Embodiment 3

[0045] A kind of processing method that improves SAP preparation efficiency, adopts following operation steps:

[0046] (1) One-time neutralization: add sodium bicarbonate solution with a mass fraction of 30% to acrylic acid, and stir while adding, until the neutralization degree reaches 27%, add potassium persulfate with acrylic acid mass of 5‰, and mix well After standing still for 15 minutes, the mixed solution 1 was obtained;

[0047] (2) Secondary neutralization: continue to add 25% sodium bicarbonate solution to the mixed solution 1, and stir while adding it dropwise. When the neutralization degree reaches 46%, add trimethoxysilane with an acrylic acid mass of 5‰, and mix After uniformity, let it stand for 15 minutes to obtain the mixed solution 2;

[0048] (3) Three times of neutralization: continue to add 25% sodium bicarbonate solution to the mixed solution 2, and stir while adding it dropwise. When the neutralization degree reaches 78%, add isooctane with acrylic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com