Slurry-process ammonium phosphate neutralization reaction system

A technology of reaction system and slurry, applied in phosphate fertilizer, application, phosphate, etc., can solve the problems of heavy production cleaning workload, unused heat source, visual pollution of steam, etc., achieve low labor intensity of workers, significant energy saving effect, ammonia The effect of less outgassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

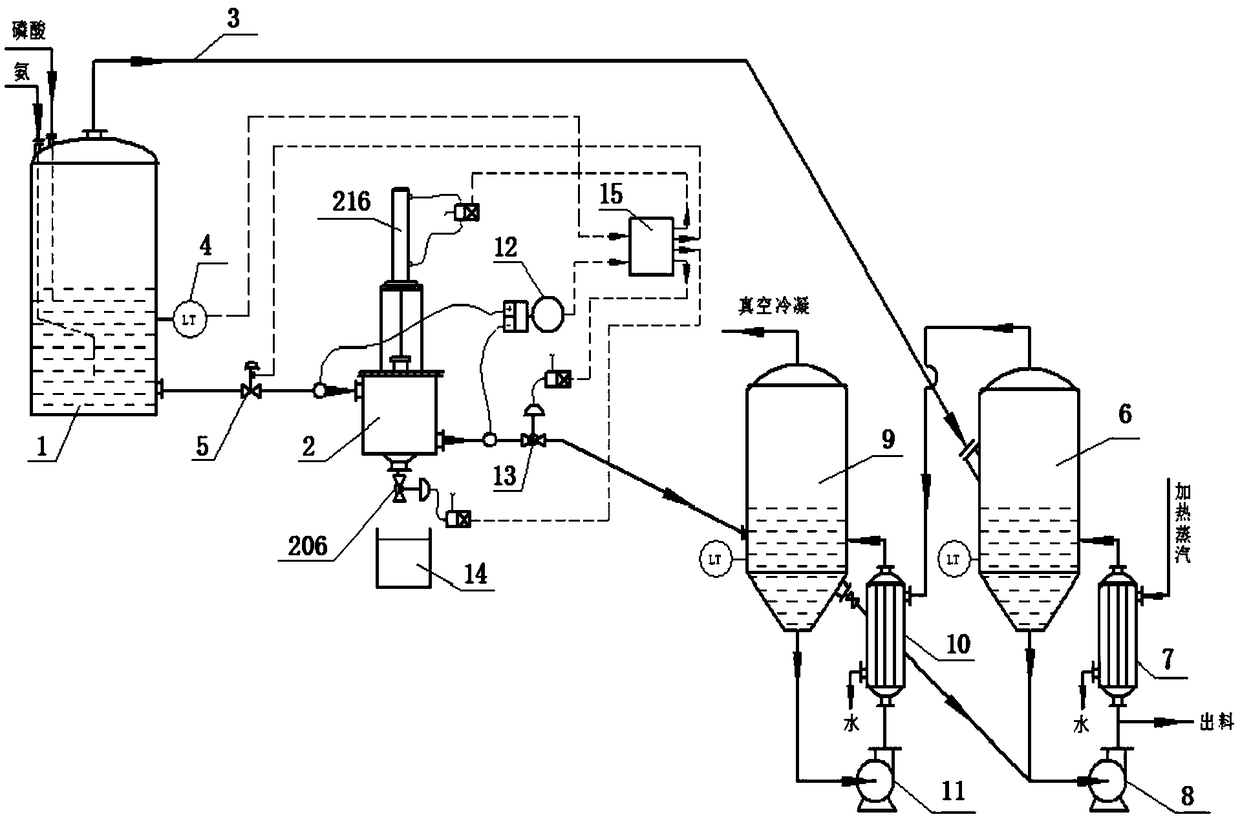

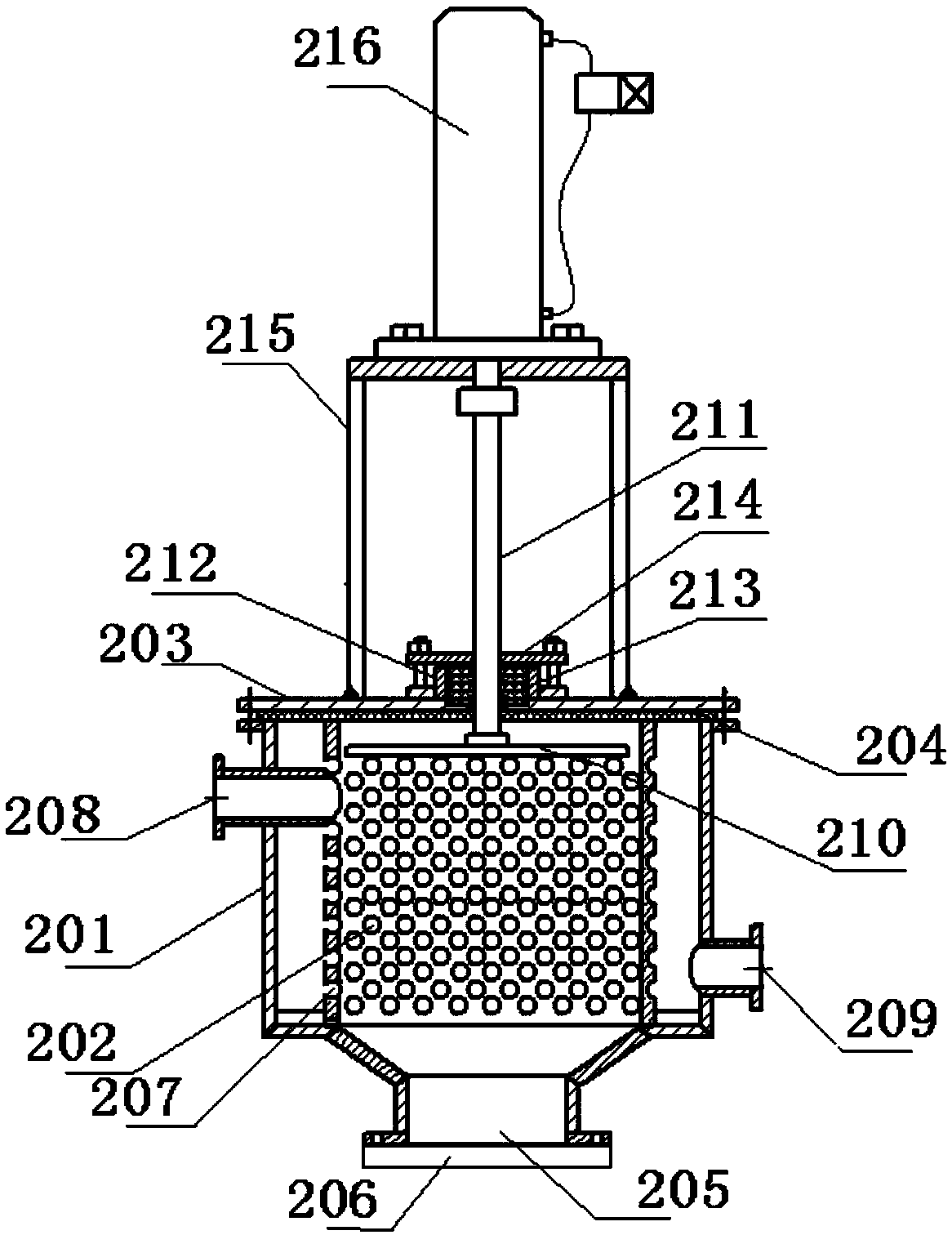

[0032] Example 1, such as figure 1 As shown, a slurry method ammonium phosphate neutralization reaction system includes a neutralization tank 1, a sealed interception device 2, a first-effect flash chamber and a second-effect flash chamber.

[0033] The neutralization tank 1 is a sealed neutralization tank, the top of which is provided with a first steam pipeline 3, and its lower end is provided with a slurry outlet, and the slurry outlet is connected to the feed pipe 208 of the sealing interception device 2 through the first slurry pipeline, A liquid level transmitter 4 is installed in the neutralization tank 1. The liquid level transmitter 4 adopts a diaphragm-sealed double-flange plug-in differential pressure transmitter, the model is EJA118N, and the first slurry pipeline is provided with a first Control the valve 5, and the liquid level transmitter 4 transmits the detected liquid level signal to the display controller 15, and the display controller 15 controls the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com