Chemical nitric acid wastewater treatment device

A technology of sewage treatment device and nitric acid, which is applied in the fields of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Sewage does not meet discharge standards, pollutes the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

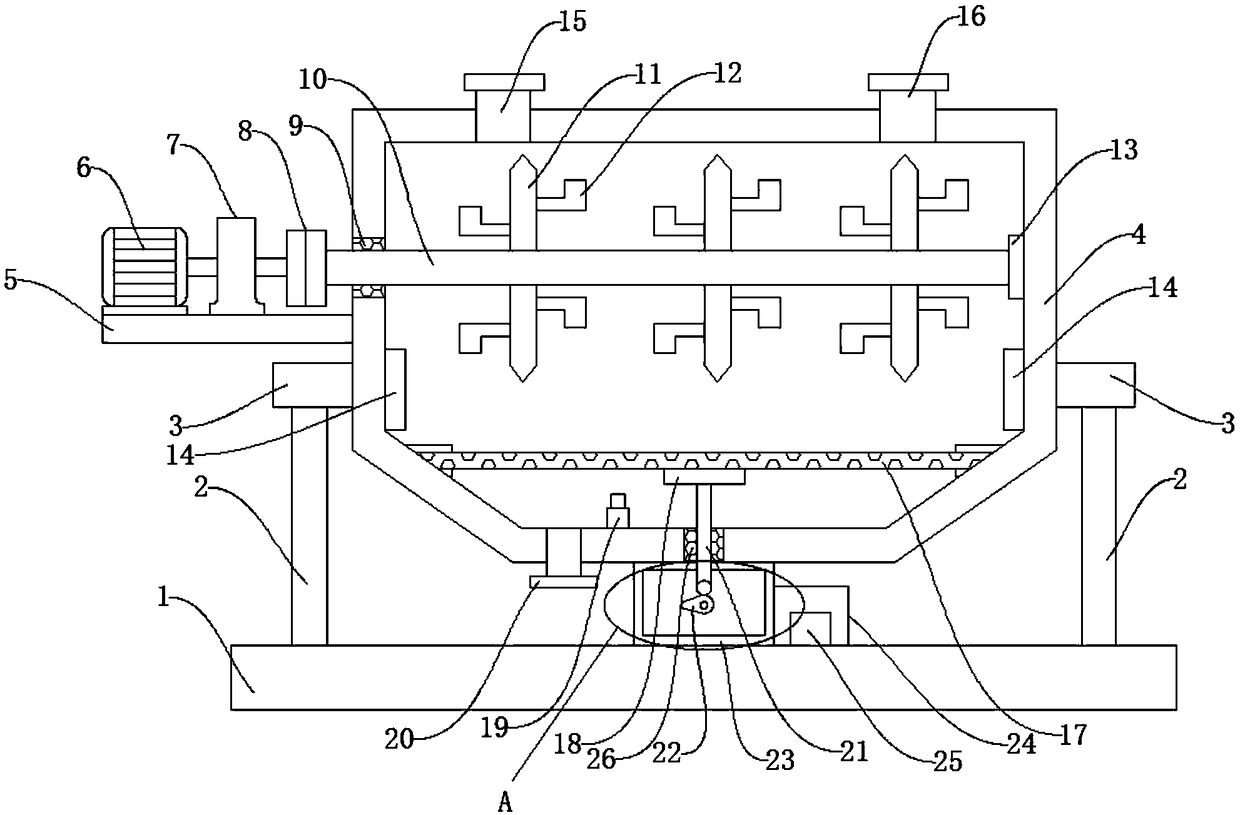

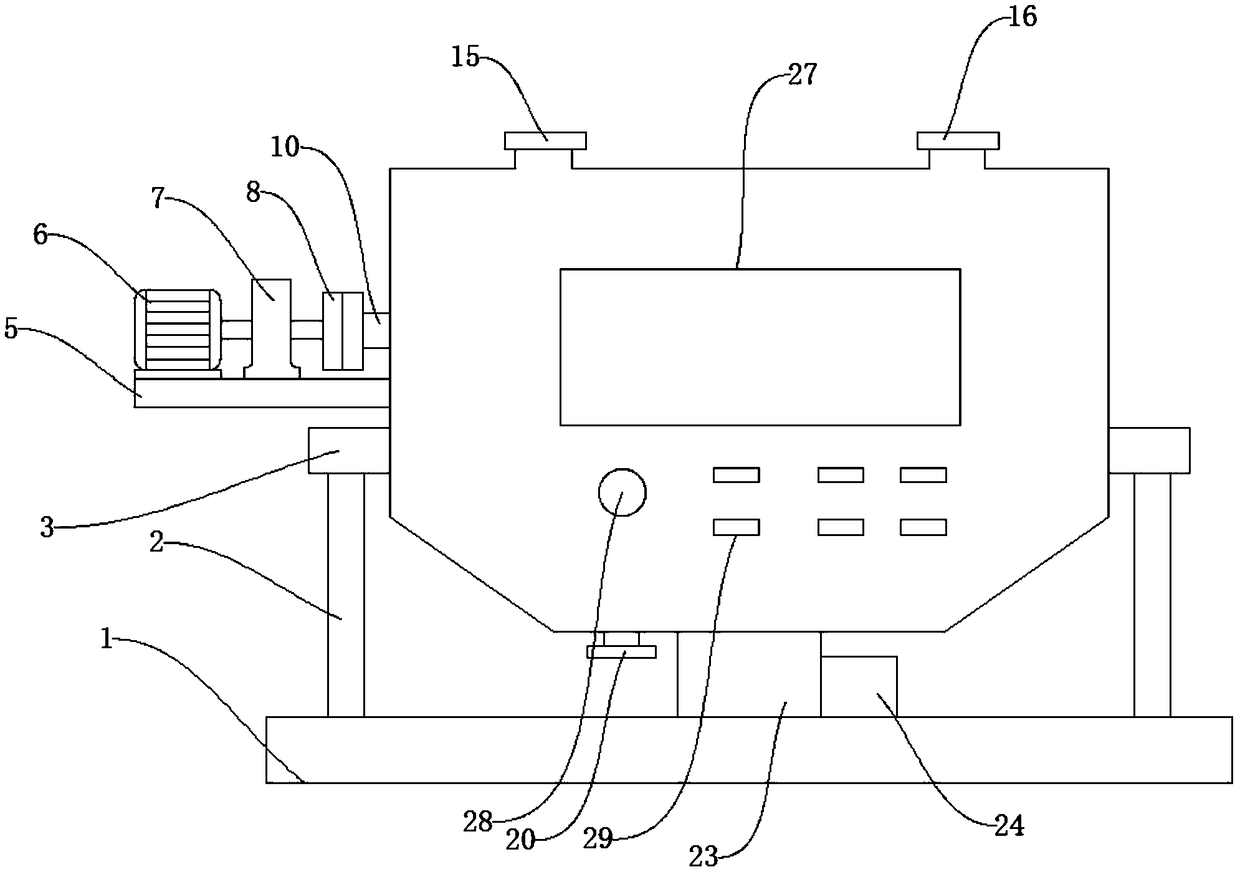

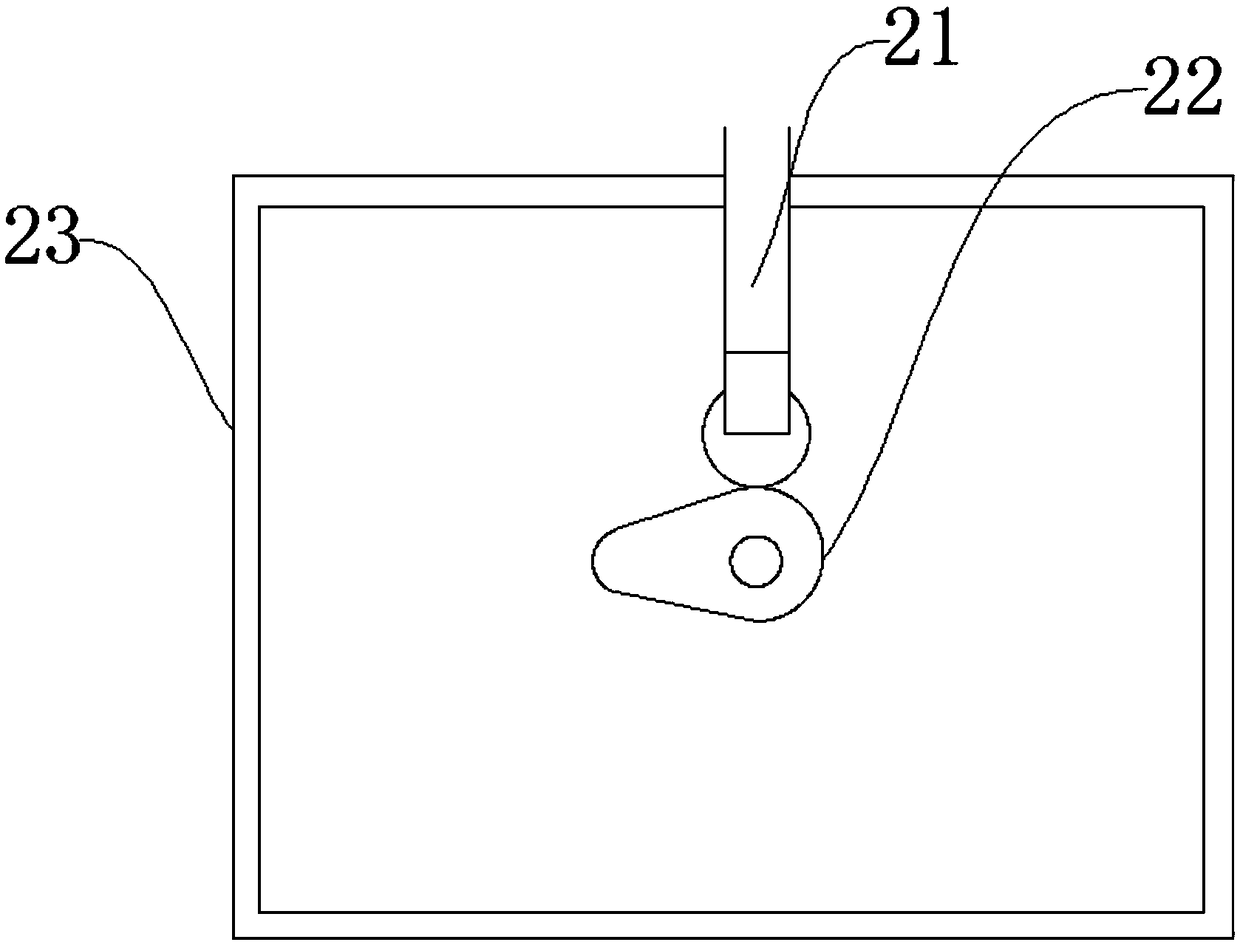

[0031] Such as Figure 1-Figure 5As shown, a chemical nitric acid wastewater treatment device includes a bottom plate 1, a device main body 4, a stirring shaft 10, a pH sensor 19, and a controller 25. A support plate 2 is arranged above the bottom plate 1, and the support plate 2 is used to support and fix the fixing seat. 3. There is a fixed seat 3 above the support plate 2, and the fixed seat 3 is used to fix the main body 4 of the device. The main body 4 of the device is arranged between the fixed seats 3. The main body 4 of the device is used to treat sewage. , the fixed plate 5 is used to install the first motor 6, the first motor 6 is installed above the fixed plate 5, the model of the first motor 6 is Y90L-2, in order to provide power, the first motor 6 side is equipped with a reducer 7, The side of the speed reducer 7 away from the first motor 6 is provided with a coupling 8, the coupling 8 is used to connect the stirring shaft 10 and the speed reducer 7, and the side ...

no. 2 example

[0033] The difference between the second embodiment and the first embodiment is that the device main body 4 is connected to the fixing base 3 by bolts, the stirring blade 12 is made of 304L stainless steel, and the sewage inlet pipe 15 is connected to the device main body 4 by threads.

[0034] Specifically, the device main body 4 is connected to the fixed seat 3 by bolts, which helps to ensure the firmness of the connection between the device main body 4 and the fixed seat 3, and improves the safety of the device main body 4; the material of the stirring blade 12 is 304L stainless steel, 304L stainless steel is a kind of ultra-low carbon stainless steel, which has good nitric acid corrosion resistance. This setting helps to prolong the service life of the mixing blade 12; the sewage inlet pipe 15 is connected to the main body 4 of the device through threads, and this setting helps to improve the performance of the device. The sealing of the main body 4 prevents sewage from ove...

no. 3 example

[0036] The difference between the third embodiment and the first embodiment is: the material of the filter screen 17 is 304L stainless steel, the filter screen 17 is connected with the device main body 4 by screws, and the sewage outlet pipe 20 is connected with the device main body 4 by screw threads.

[0037] Specifically, the material of filter screen 17 is 304L stainless steel, and 304L stainless steel is a kind of ultra-low carbon stainless steel, has good nitric acid corrosion resistance, and setting like this helps to prolong the service life of filter screen 17; Filter screen 17 and device main body 4 Connected by screws, this setting helps to improve the stability of the filter screen 17 positions and prevents the filter screen 17 from being damaged; the sewage outlet pipe 20 is threaded with the device main body 4, and this setting helps to improve the sealing of the device main body 4, Prevent sewage from overflowing.

[0038] In the above-mentioned structure, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com