Industrial waste liquid neutralizing device

A technology of industrial waste liquid and tank, which is applied in the field of industrial waste liquid neutralization devices, can solve problems such as insufficient agitation, influence of neutralization reaction, pollution of the environment and staff, and achieve the effect of improving the working environment and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

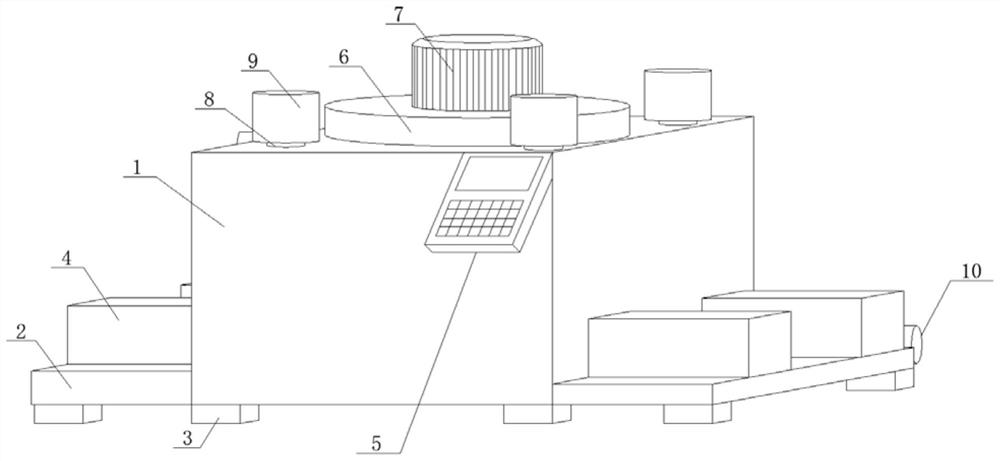

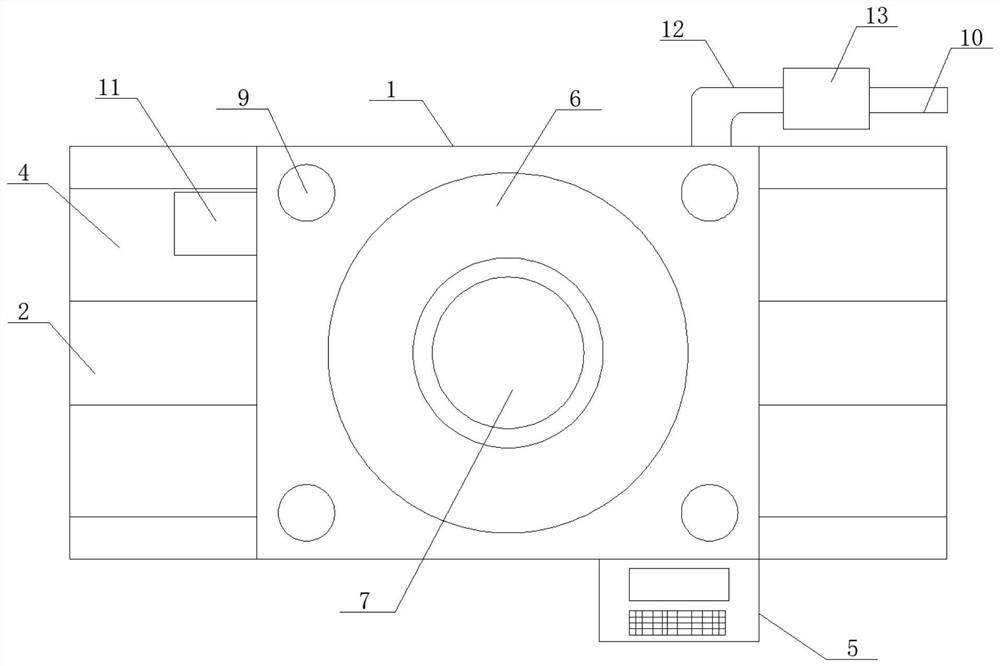

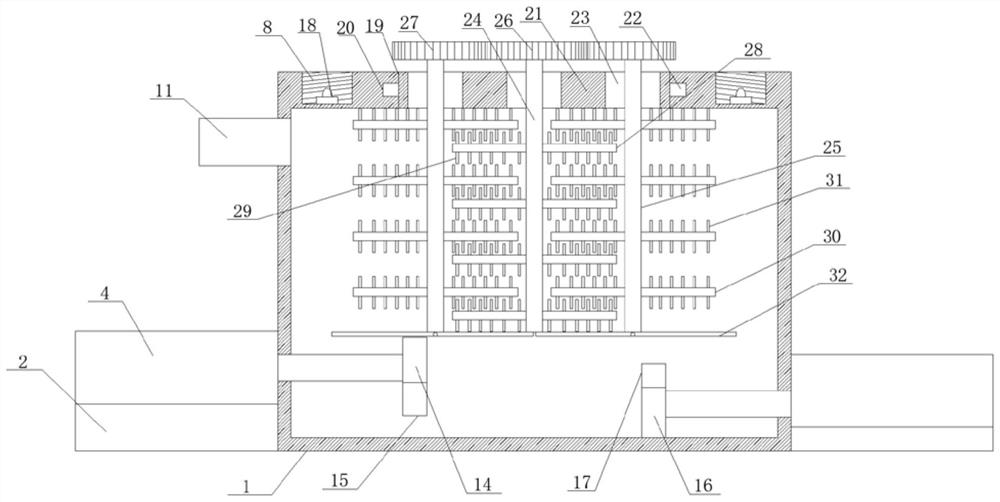

[0028] see Figure 1-2 , in an embodiment of the present invention, an industrial waste liquid neutralization device includes a neutralization box 1, the two sides of the neutralization box 1 are horizontally welded with a support pallet 2, and the neutralization box 1 and the support pallet 2 The bottom surface of the base is fixedly welded with support pads 3, and the number of support plates 2 is two, and the two support plates 2 are arranged horizontally and symmetrically on both sides of the neutralization box 1 near the bottom surface, and the two support plates The bottom surface of the plate 2 and the bottom surface of the neutralization box 1 are kept at the same horizontal plane position, the thickness of the two support pallets 2 is not the same, the number of the support pads 3 is several, and the multiple support pads 3 are respectively Fixedly installed on the bottom surface of the neutralization box 1 and the support pallet 2 near the edge, the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com