Device for neutralizing treatment of chlorine-containing gas

A treatment device and gas technology, which is applied in the field of neutralization treatment devices for chlorine-containing gases, can solve the problems of complex equipment, high cost, and unsuitability for neutralization treatment, and achieve the effect of increasing the contact area and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

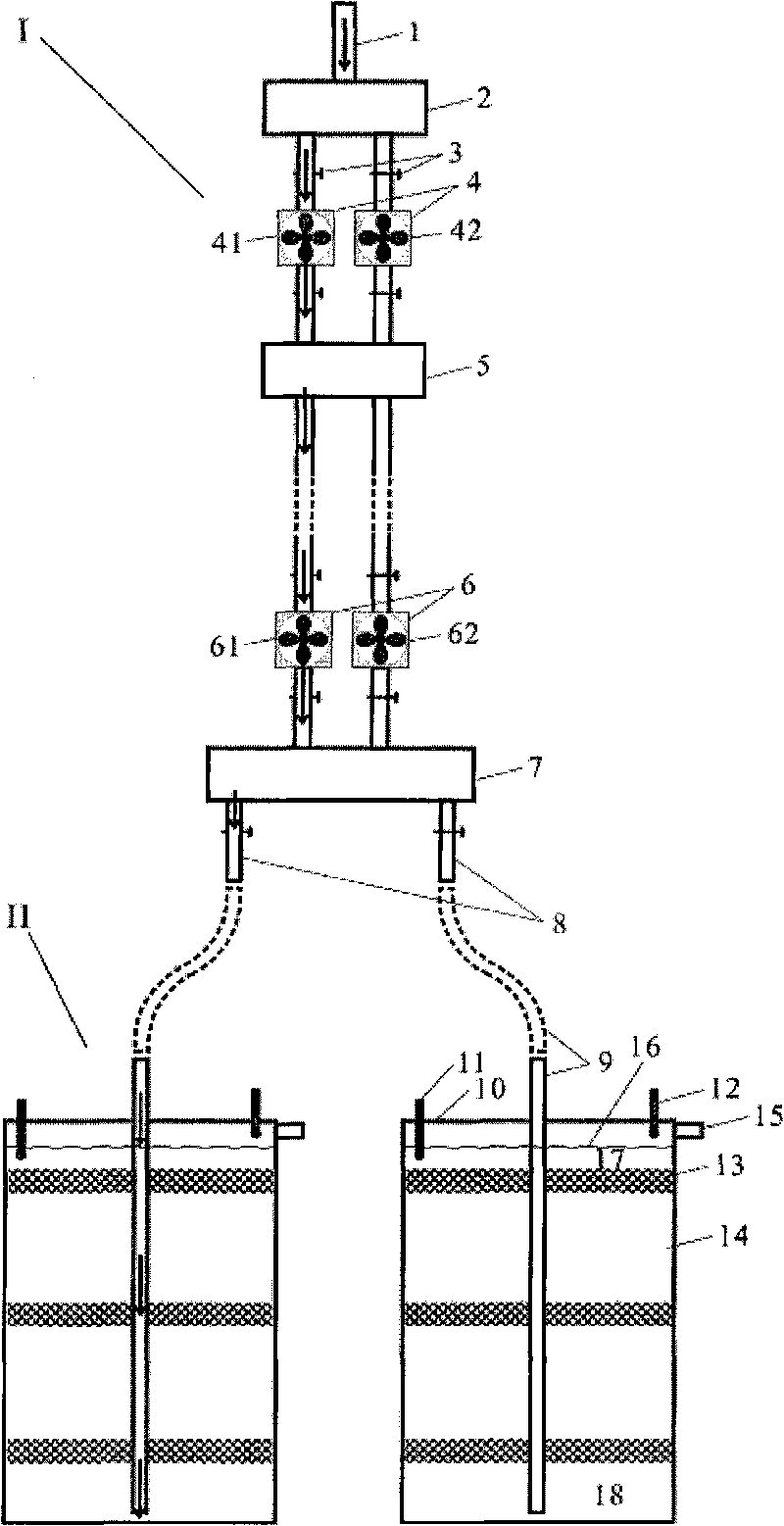

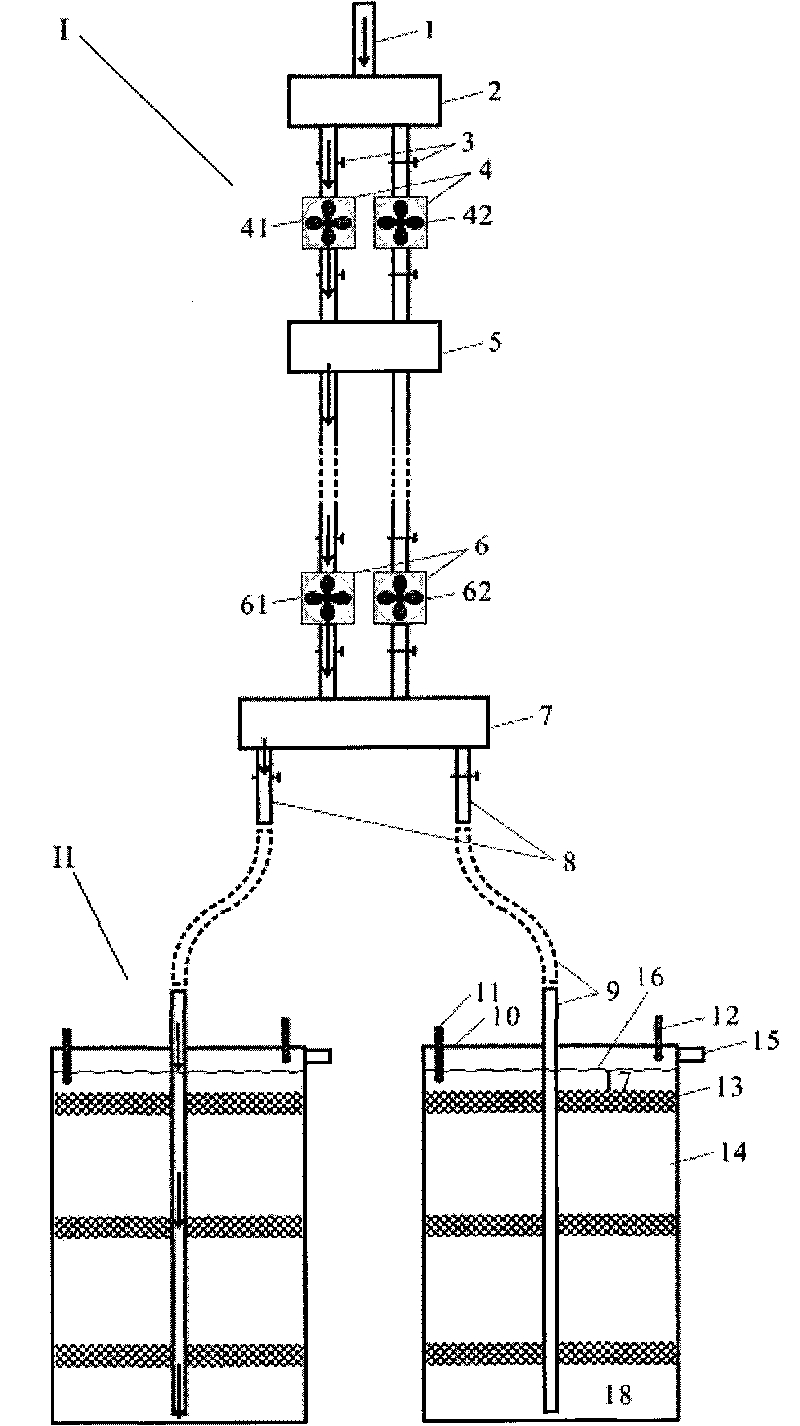

Embodiment 1

[0026] The high-temperature reaction exhaust gas discharged from the reactor has a flow rate of 150ml / min, Cl 2 Concentration (volume) 14%, the air flow of fans 41, 42, 61, 62 is 0.1m 3 / min. During the process of collecting and conveying the high-temperature reaction waste gas to the neutralization treatment device, the fan sucks in a large amount of air at the same time, so that the gas flow rate of the chlorine-containing gas entering the neutralization treatment device becomes the flow rate of the fan 0.1m 3 / min, Cl 2 The concentration (volume) is then:

[0027] (14%*150ml / min*1min) / (0.1m 3 / min*1min)=0.021%

[0028] This concentration far exceeds the maximum emission concentration allowed by the country of 85mg / m 3 (about 28ppm).

[0029] For the neutralization treatment equipment II in the neutralization treatment device, select a container 10 of 1000 × 2000 to fill with 18% NaOH solution 14, the liquid level 16 is 100mm away from the top of the container 10, and s...

Embodiment 2

[0031] The gas flow rate of the high-temperature reaction waste gas discharged from the reactor is 2500ml / min, Cl 2 Concentration (volume) 27%, the setting of chlorine-containing gas conveying equipment 1 in the neutralization treatment device is the same as embodiment one, under blower blower 4 and fan 6 effects, enters the chlorine-containing gas of neutralization treatment device, and its gas flow is fan's Flow 0.1m 3 / min, Cl 2 The concentration (volume) is then:

[0032] (27%*2500ml / min*1min) / (0.1m 3 / min*1min)=0.675%

[0033] The neutralization treatment equipment II of the neutralization treatment device is adjusted to use five layers of 150mm sponge partitions, the spacing between each layer of sponge partitions is 220mm, the distance between the bottom sponge partition and the bottom of the container 10 is 200mm, and the top layer The distance between the sponge partition plate and the liquid surface 16 of the NaOH solution is 70mm, and all the others are the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com