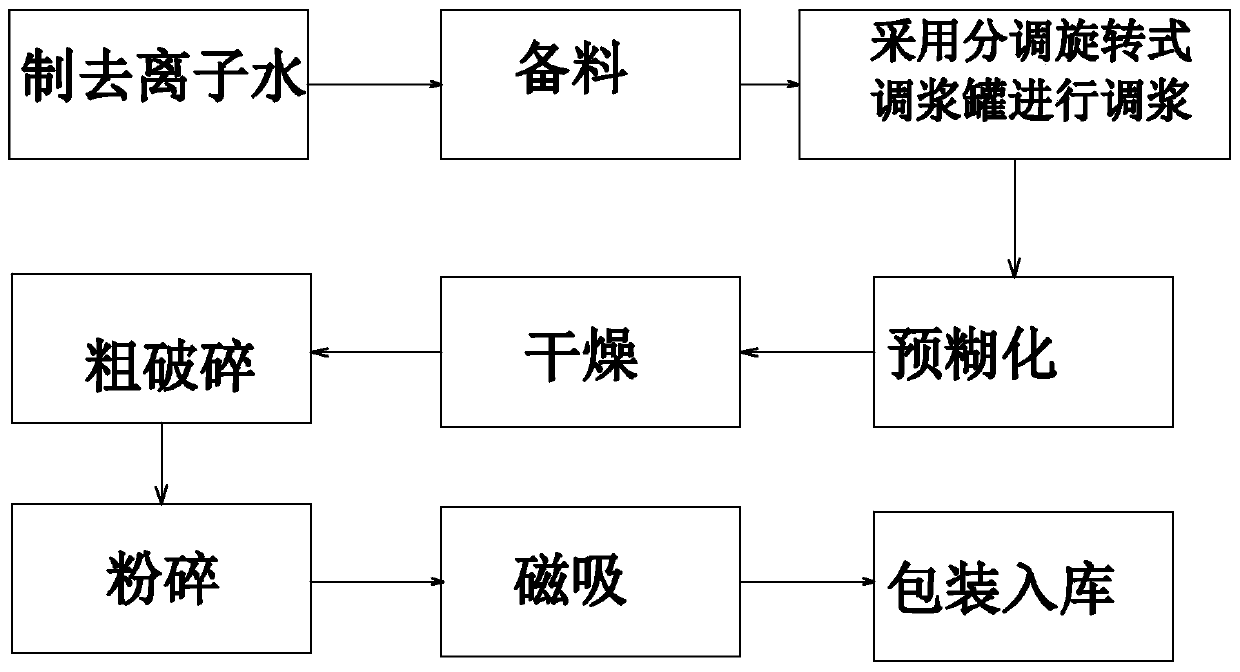

Production process and equipment of special pre-gelatinized starch for sweet soup balls

A technology of pregelatinized starch and production technology, which is applied in food science and other fields, can solve the problems of low water absorption, low molding rate, and affecting product sales, and achieve the effect of large water absorption and high viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] refer to Figure 1 to Figure 3 The embodiments of the present invention will be further described.

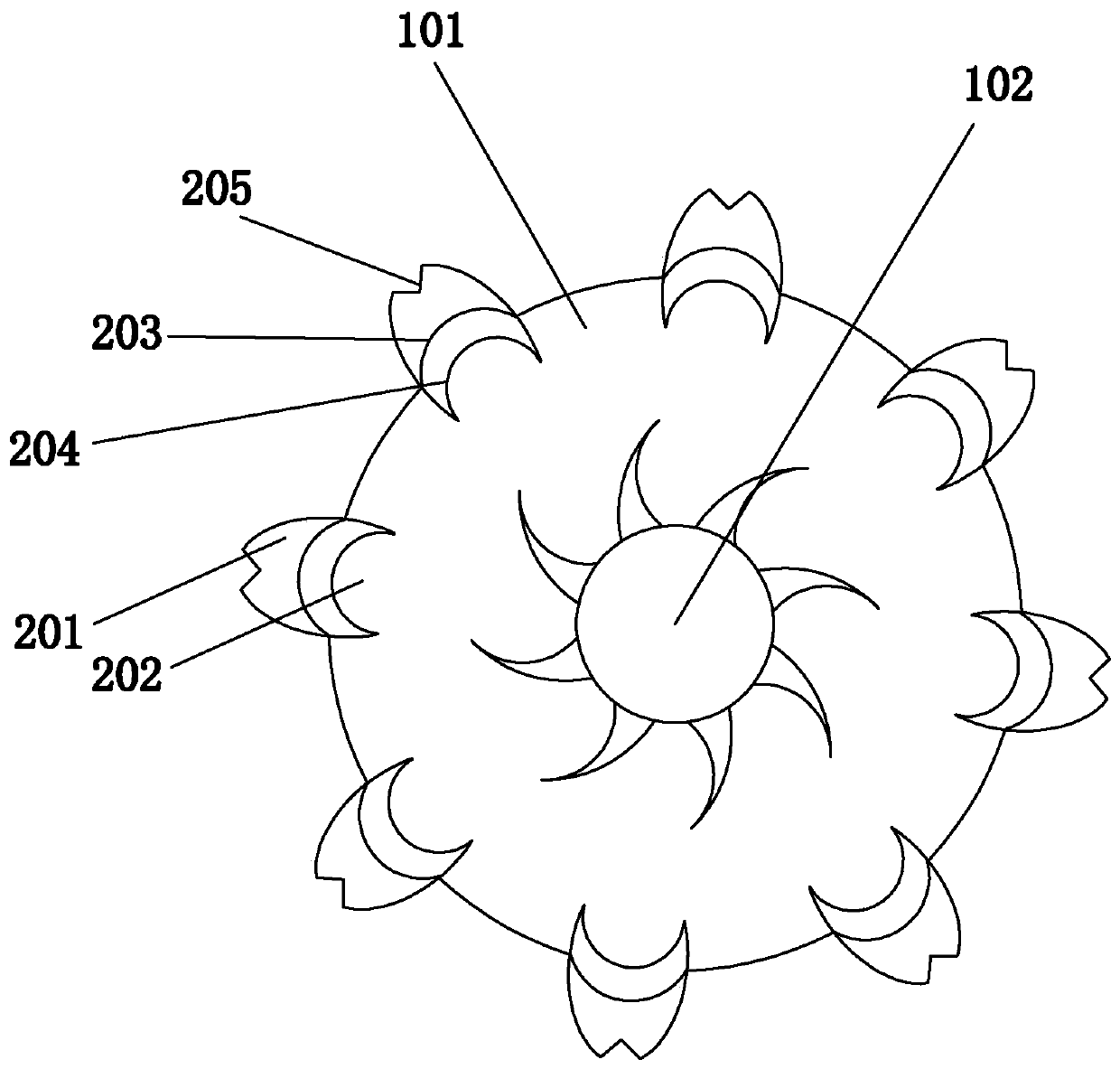

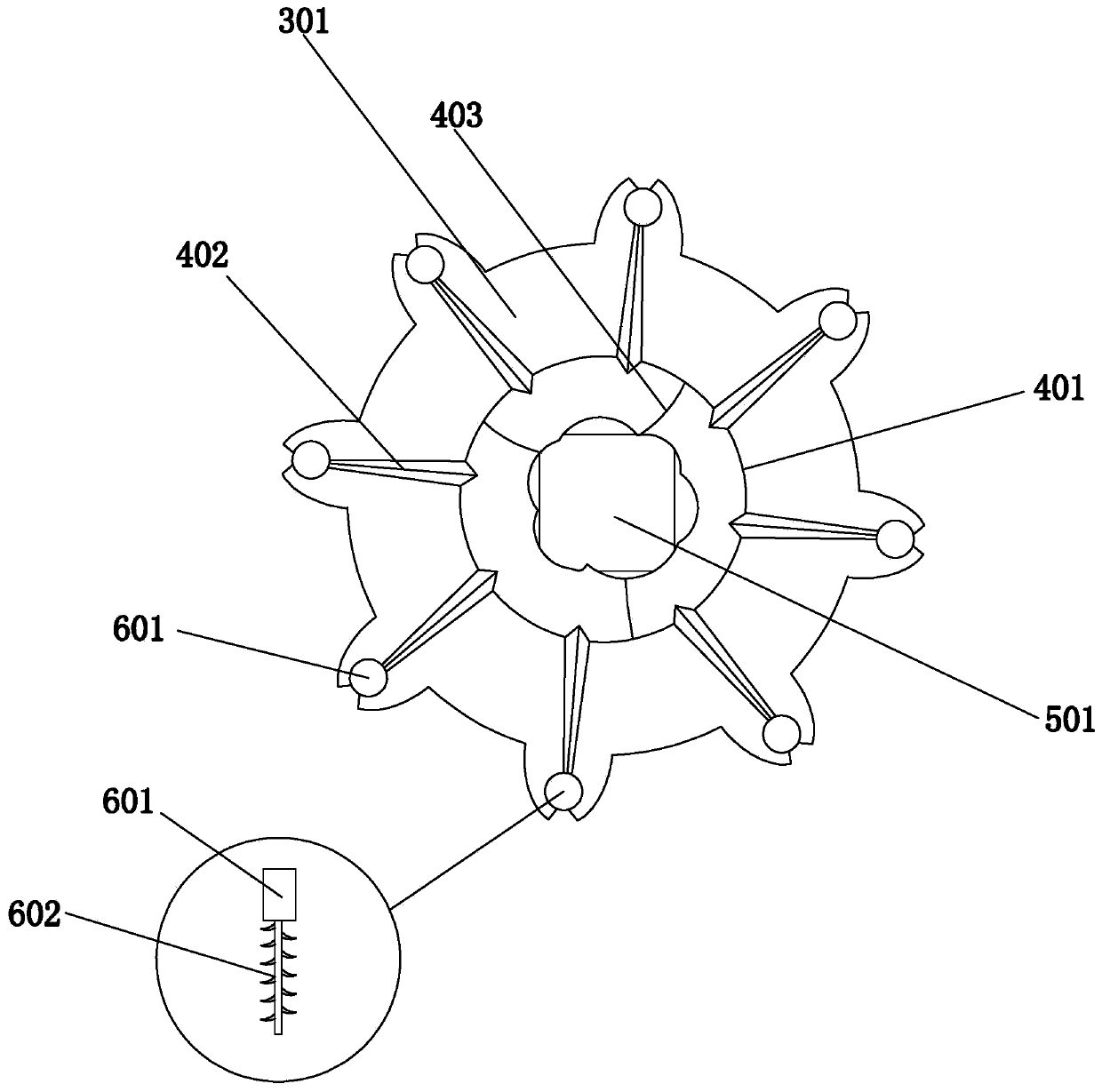

[0027] The present invention is further set as follows: the sub-adjustment rotary pulping structure in the step (3): includes a tank body 101 and a material distribution cover matched with the tank body 101, and a stirring screw 102 is arranged in the middle of the tank body 101 , 8 independent tanks 201 arranged at equal intervals are welded on the outer wall of the tank body 101, one side of the independent tanks 201 is placed in the tank body 101 and communicated with the inside of the tank body 101, and a first grid is arranged in the independent tank 201 sheet 203, the independent tank 201 is placed on the inner side of the tank body 101 and is provided with an arc-shaped notch 204, and the arc-shaped notch 204 is separated by the second grid sheet 204, and the other side of the independent tank 201 opposite to the arc-shaped notch 204 There are parallel notches at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com