Suspension air flow type ardealite integrated treatment device and method

A processing device and a technology of phosphogypsum, which is applied in the field of suspended air flow type phosphogypsum integrated processing device, can solve the problems of inability to popularize and apply in large quantities, simple equipment, low technical level, etc., and achieve the convenience of industrialized mass production and automatic control, heat energy The effect of fully utilizing and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

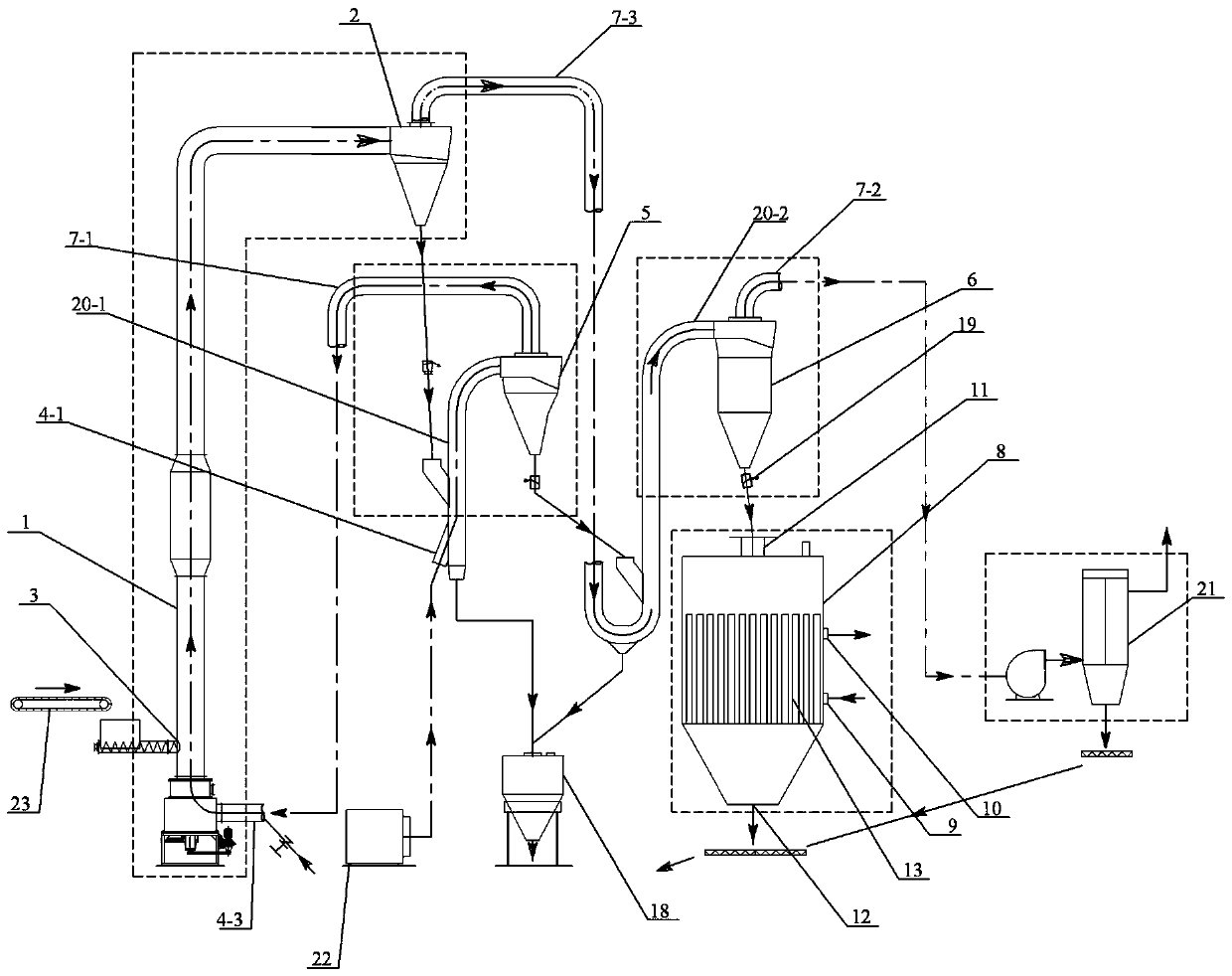

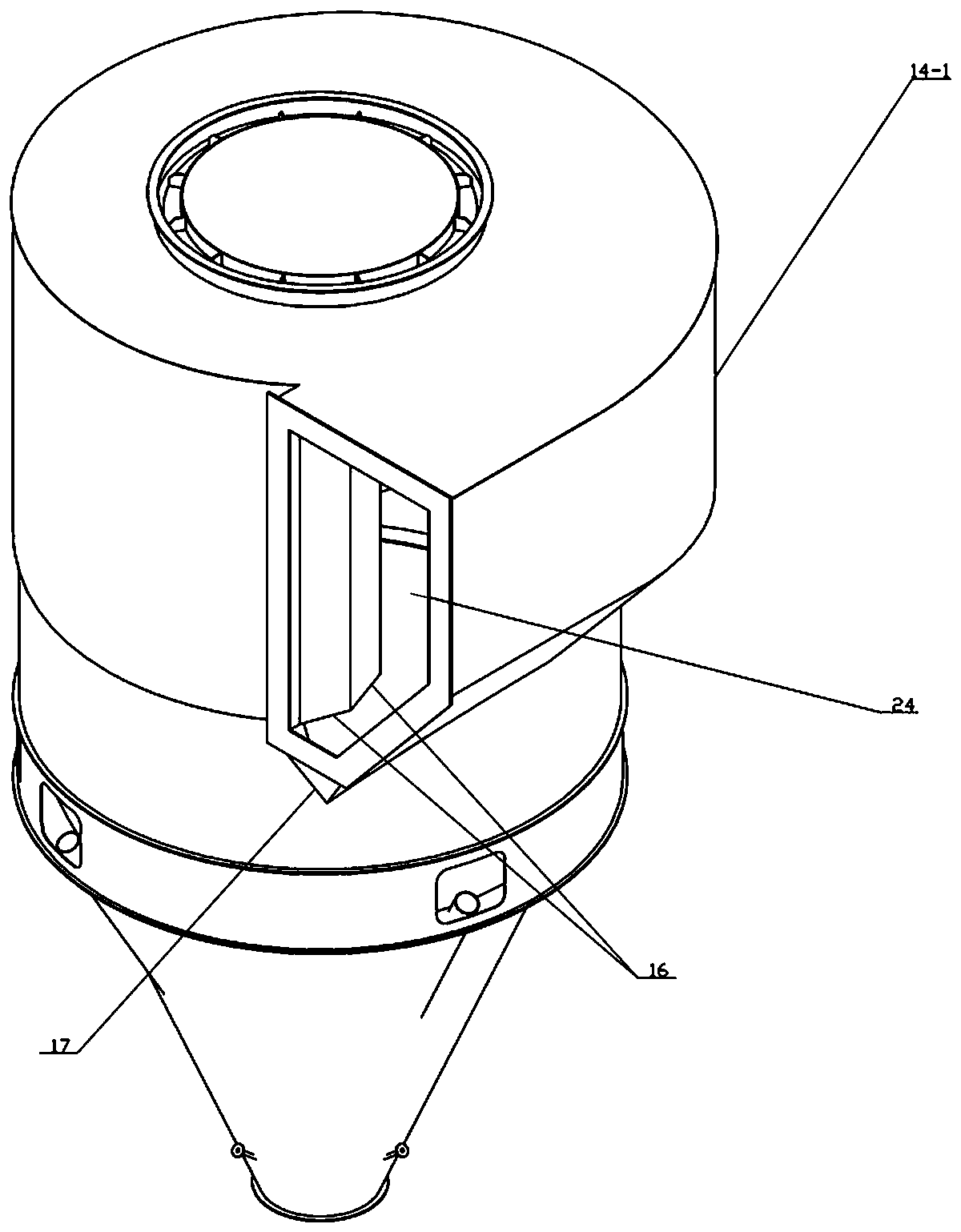

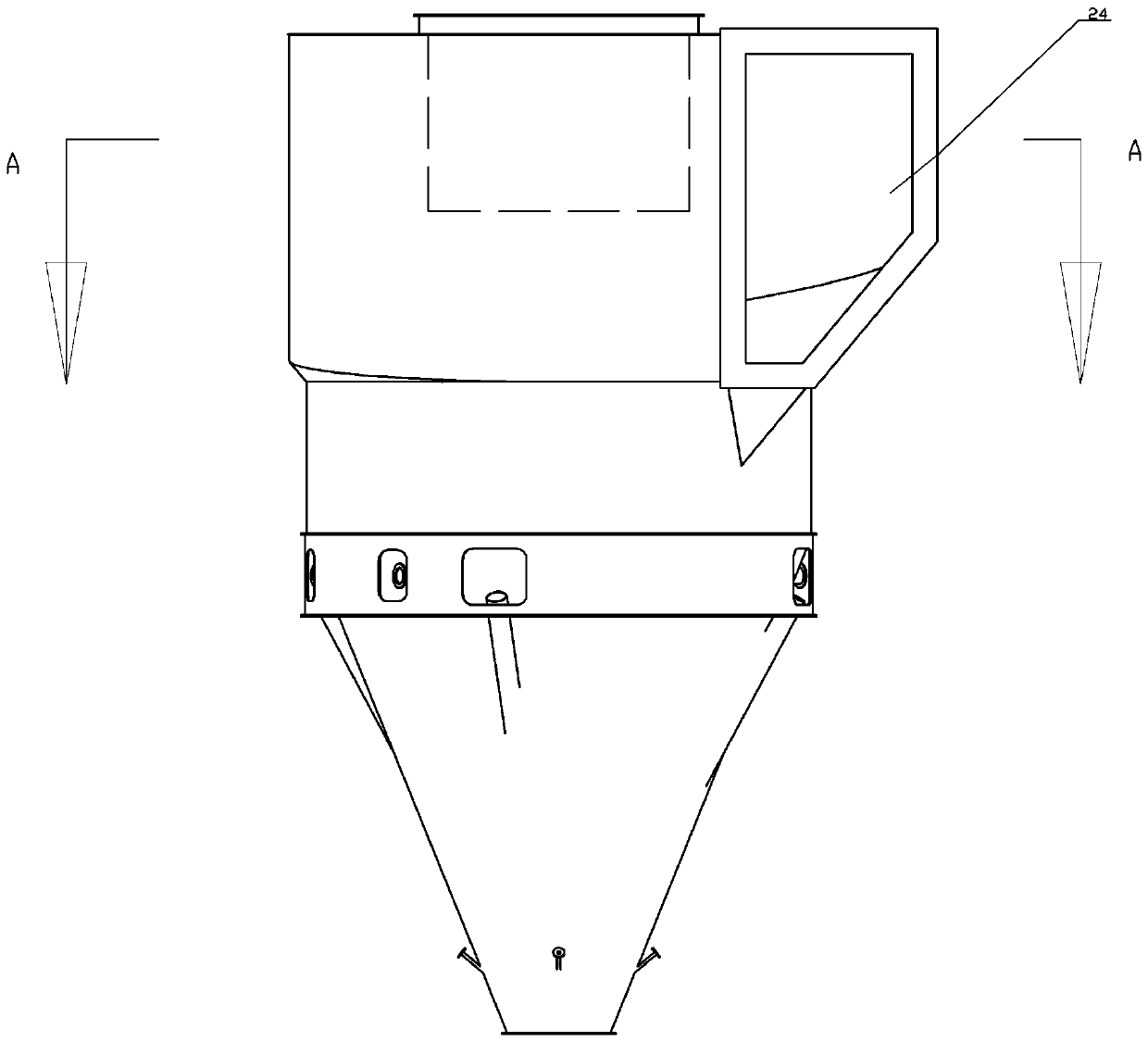

[0032] A suspended air flow type phosphogypsum integrated treatment device, such as Figure 1-5As shown, it includes a drying unit, a high-temperature impurity removal unit, a calcination unit, a cooling unit, and a monitoring and control unit that are connected in sequence. The cyclone separator 2, the outlet of the pulse airflow dryer 1 is connected to the cyclone separator 2 through the induced draft fan, and the two sides of the lower part of the pulse airflow dryer 1 are respectively equipped with a feeding port 3 (supplied by a belt feeder 23 ) and the third hot air inlet 4-2, the bottom of the cyclone separator 2 is provided with a third discharge system. The high-temperature impurity removal unit includes the impurity removal furnace 5 and the first main heat exchange tube 20-1 connected to the upper side of the impurity removal furnace 5 and the first discharge system. The first main heat exchange tube 20-1 is connected with a first The feeding system and the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com