Preparation method of carbon dioxide based block copolymer

A technology of block copolymers and carbon dioxide, which is applied in the field of preparation of carbon dioxide-based biodegradable block copolymers, can solve the problems of high cost, metal catalyst residue, low reaction efficiency, etc., and achieves no effect on performance and color, and wide range of raw materials , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In some embodiments, the preparation method of the present invention includes the following steps:

[0040] (1) In an anhydrous and oxygen-free environment, cyclic acid anhydride monomers, lactone monomers and epoxy compounds are mixed to obtain a monomer mixture;

[0041] (2) mixing the monomer mixture, the catalyst and the initiator to obtain a raw material mixture;

[0042] (3) charging carbon dioxide into the raw material mixed solution to cause a polymerization reaction, and after the reaction is completed, quench the reaction to obtain a crude product;

[0043] (4) adding the crude product into an organic solvent for precipitation, separating and drying the obtained precipitate to obtain the carbon dioxide-based block copolymer.

[0044] In some embodiments, the cyclic acid anhydride monomers are maleic anhydride, phthalic anhydride, 1-cyclopentene-1,2-dicarboxylic anhydride, cyclobutane dicarboxylic anhydride and bicyclo[2.2. 1] One or more of hept-5-ene-2,3-di...

Embodiment 1

[0073] A preparation method of a carbon dioxide-based biodegradable copolymer is as follows:

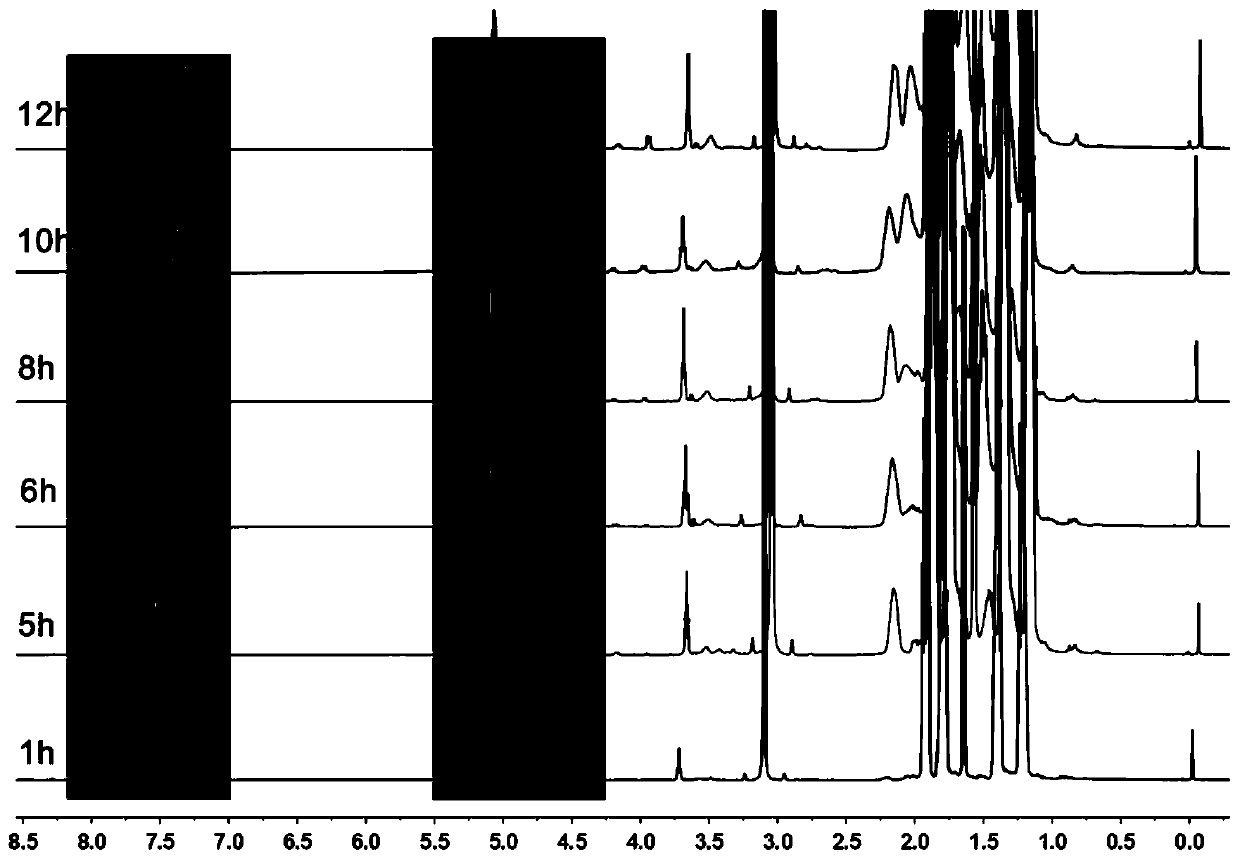

[0074] (1) In an anhydrous and oxygen-free environment, add 0.88g, 0.85g, and 6mL of phthalic anhydride, lactide, and cyclohexene oxide into the reaction kettle at a molar ratio of 1:1:10, Then add triethylborane, 1,8-diazabicycloundec-7-ene and water in a molar ratio of 2:1:2, and add 118 μL, 9 μL, and 2.1 μL, respectively. React at 80°C for 10 h, release carbon dioxide, react for another 2 h, then cool to room temperature, and feed air to terminate the reaction.

[0075] (2) Methanol was added to the crude product obtained in step (1), and magnetically stirred for more than 30 minutes to obtain a precipitated white solid, which was separated by filtration, and the obtained white solid was vacuum-dried at room temperature to constant weight.

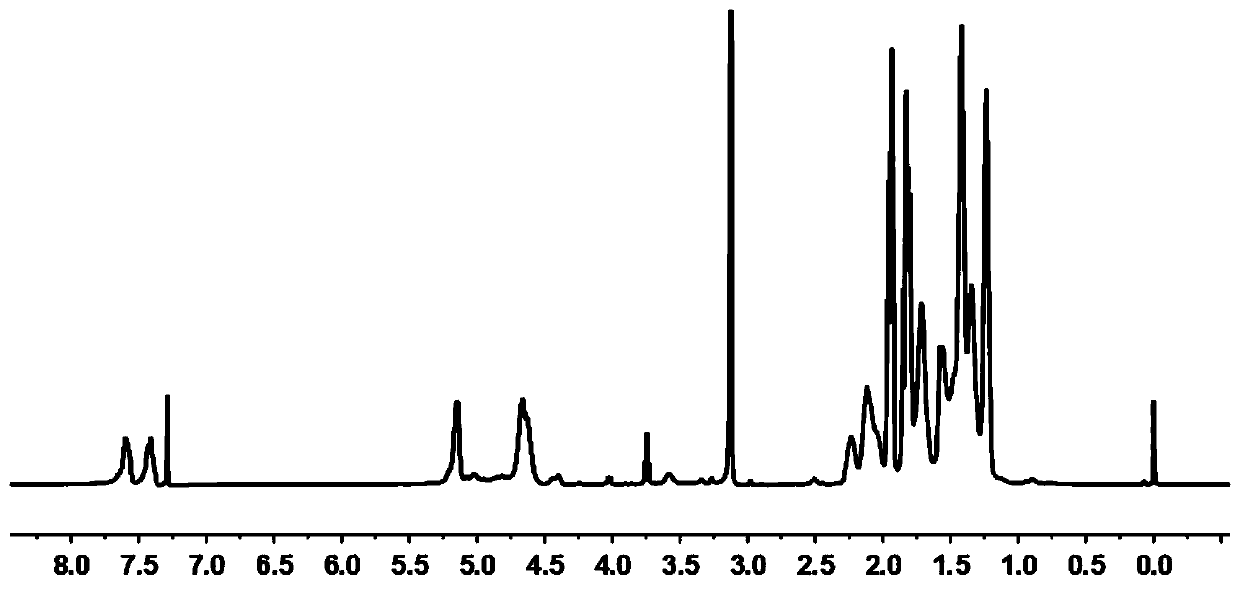

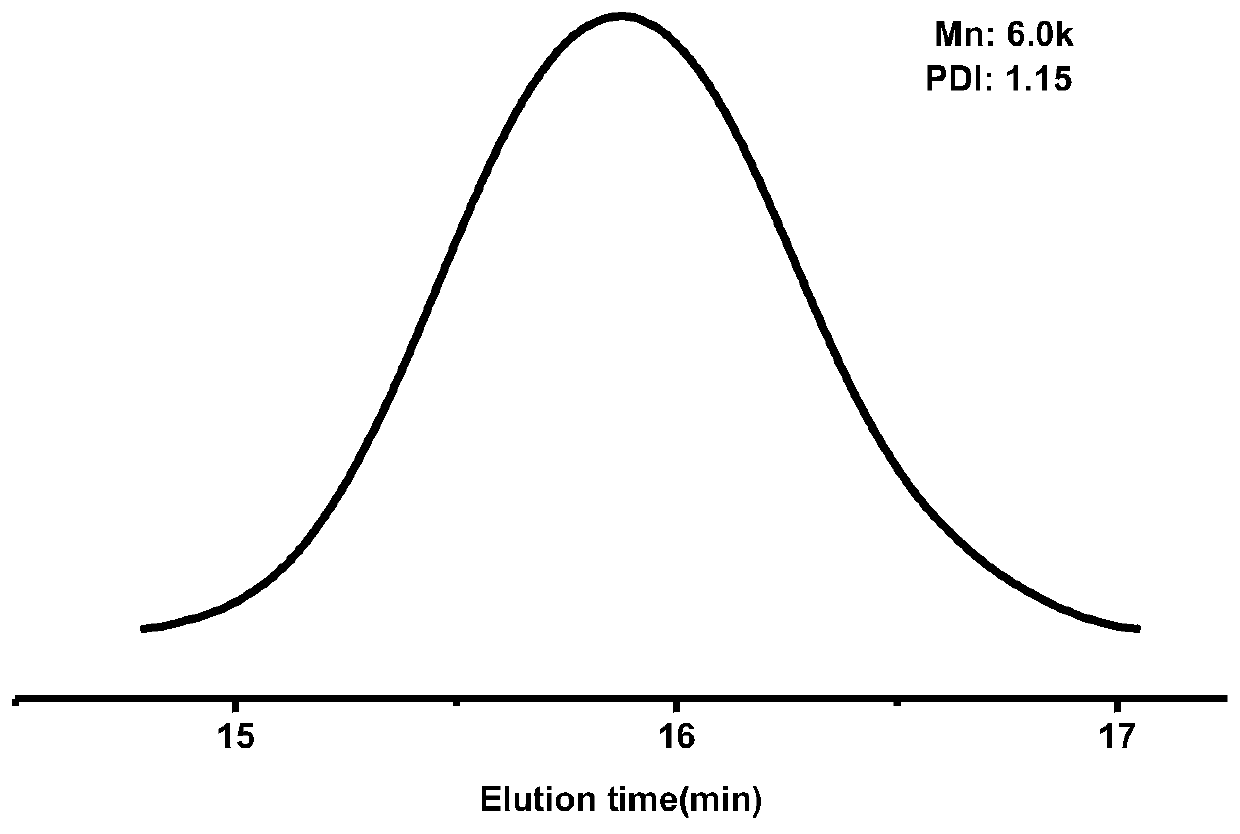

[0076] (3) Use H NMR spectrum to characterize the structure of the block copolymer, and use gel permeation chromatography to characterize th...

Embodiment 2

[0088] A preparation method of a triblock carbon dioxide-based biodegradable block copolymer is as follows:

[0089] (1) In an anhydrous and oxygen-free environment, add 3.10g, 3.57g, and 6mL of maleic anhydride, ε-caprolactone, and ethylene oxide into the reaction kettle at a molar ratio of 1:1:5, Then add triethylamine, 4-dimethylaminopyridine and benzyl alcohol according to the molar ratio of 1:1:1, add 43.5μL, 38.20mg, 32.5μL respectively. Filled with 1MPa carbon dioxide. React at 80°C for 4h, release carbon dioxide, react for another 1h, then cool to room temperature, and feed air to terminate the reaction.

[0090] (2) Methanol was added to the crude product obtained in step (1), and magnetically stirred for more than 30 minutes to obtain a precipitated white solid, which was separated by filtration, and the obtained white solid was vacuum-dried at room temperature to constant weight.

[0091] (3) Use H NMR spectrum to characterize the structure of the block copolymer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com