A method for preparing water-based fracturing fluid by using multi-effect thickener

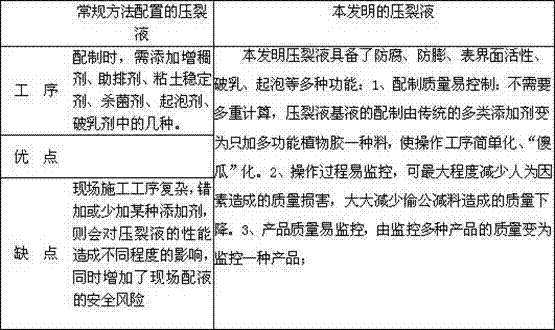

A water-based fracturing and thickening agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as complex procedures and impact on fracturing fluid performance, improve liquid quality, and destroy crude oil emulsification , the effect of reducing surface and interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of multi-effect thickener: Weigh the raw materials according to the following weights for mixing and compounding:

[0038] Vegetable gum or hydroxypropyl, hydroxyethyl, carboxymethylated derivatives of vegetable gum 1000kg

[0039] Inorganic alkali 200kg

[0040] R1X 50kg

[0041] R2X 300kg

[0042] R3X 300kg

[0043] Inorganic or organic acid 200kg

[0044] Water 550kg

[0045] The substance after the chemical reaction is dried and pulverized to obtain the multi-effect thickener; the R1 means that the molecular formula is substances, where m≤5, n≤5; R2 means that the molecular formula is substances, where m≤5; R3 means that the molecular formula is substances, where m≥2, n≥3; X refers to chlorine (Cl) or bromine (Br), and in this example, X refers to chlorine (Cl);

[0046] The vegetable gum refers to one of guar gum, coriander gum, kale gum, cellulose, konjac gum, and quercetin bean gum. This example is guar gum.

[0047] Described inorganic a...

Embodiment 2

[0049] Basically the same as Example 1, the difference is

[0050] Vegetable gum or hydroxypropyl, hydroxyethyl, carboxymethylated derivatives of vegetable gum 1000kg

[0051] Inorganic alkali 10kg

[0052] R1X 10kg

[0053] R2X 10kg

[0054] R3X 10kg

[0055] Inorganic or organic acid 10kg

[0056] water 100kg

[0057] In this embodiment, X refers to bromine (Br); plant gum: coumarin is used; the inorganic base is calcium hydroxide, and organic acid: oxalic acid is used.

Embodiment 3

[0059] Basically the same as Example 1, the difference is

[0060] Vegetable gum or hydroxypropyl, hydroxyethyl, carboxymethylated derivatives of vegetable gum 1000kg

[0061] Inorganic alkali 300kg

[0062] R1X 100kg

[0063] R2X 500kg

[0064] R3X 500kg

[0065] Inorganic or organic acid 300kg

[0066] Water 1000kg

[0067] In this embodiment, X refers to bromine (Br); the derivative of coumarin hydroxypropyl is used; the inorganic base is calcium hydroxide, and the organic acid: oxalic acid is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com