Patents

Literature

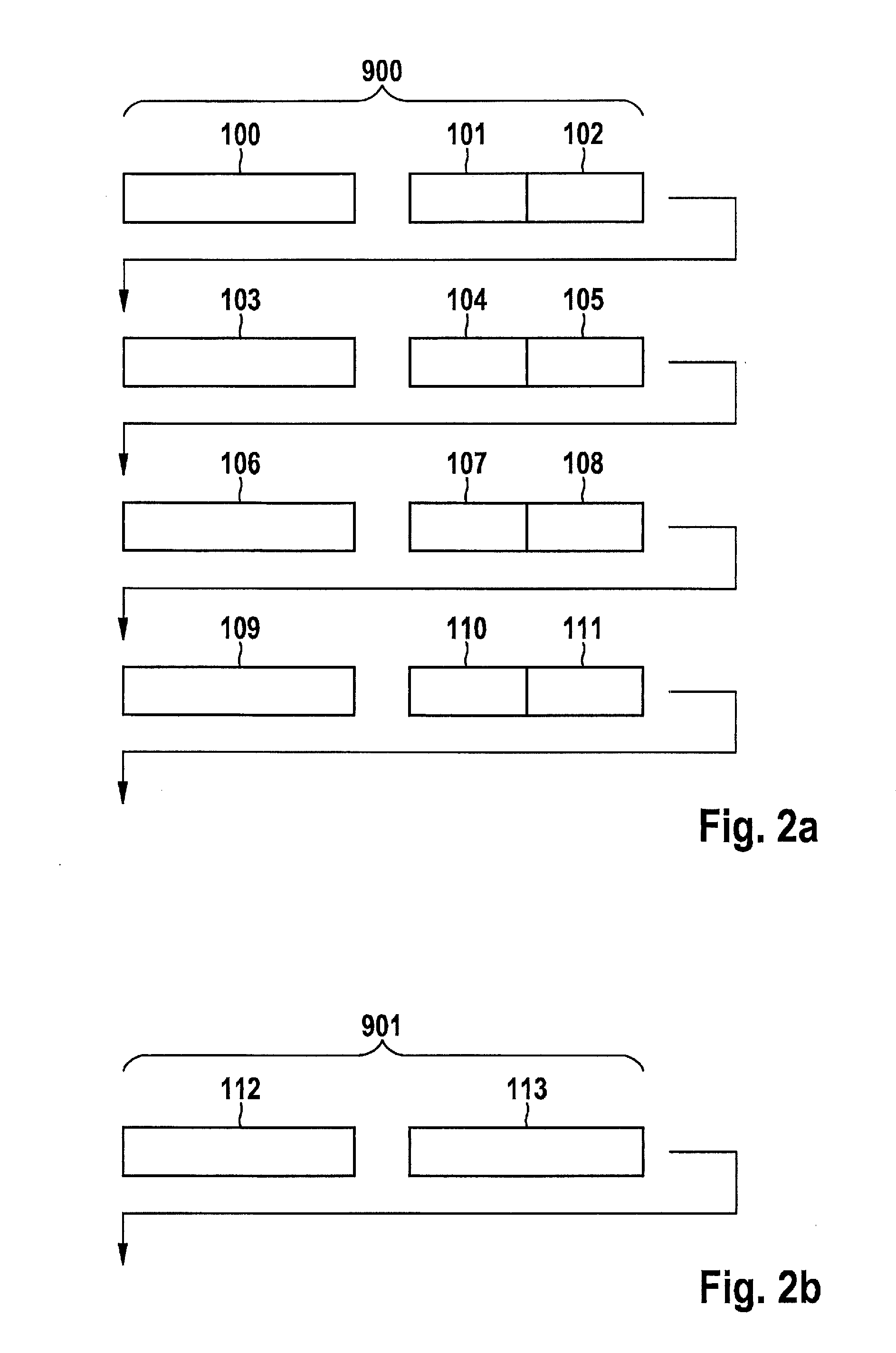

124results about How to "Shorten application time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

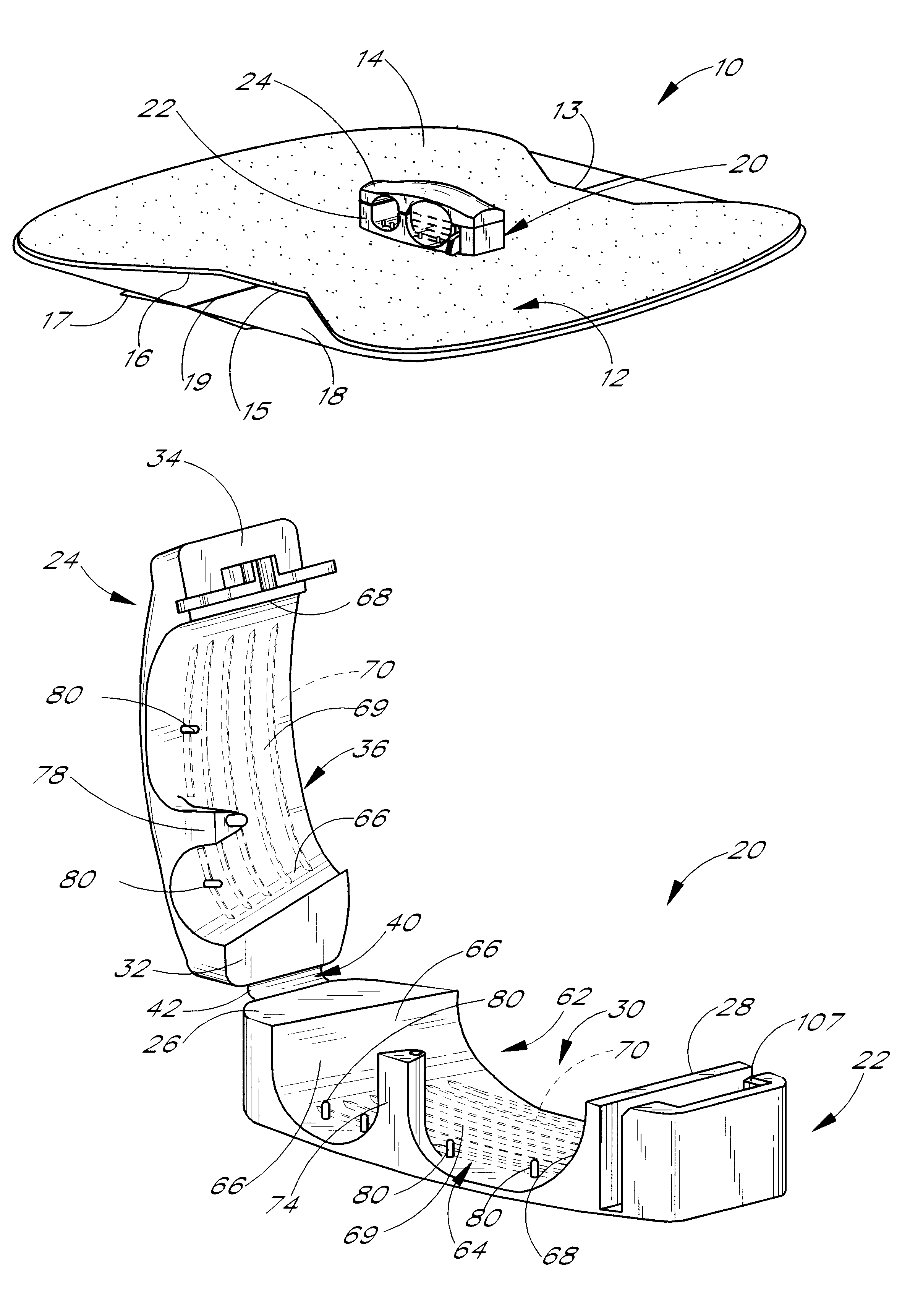

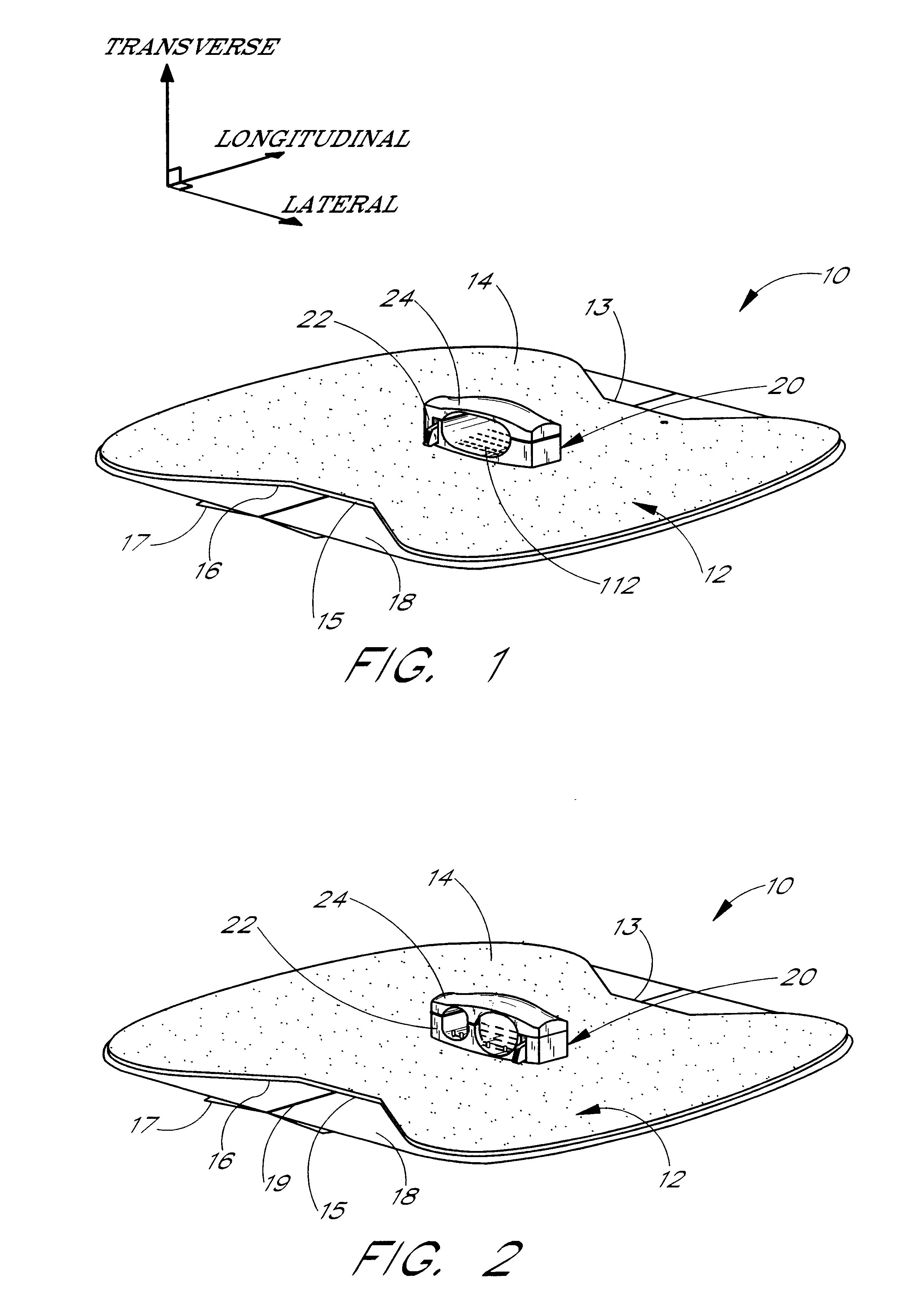

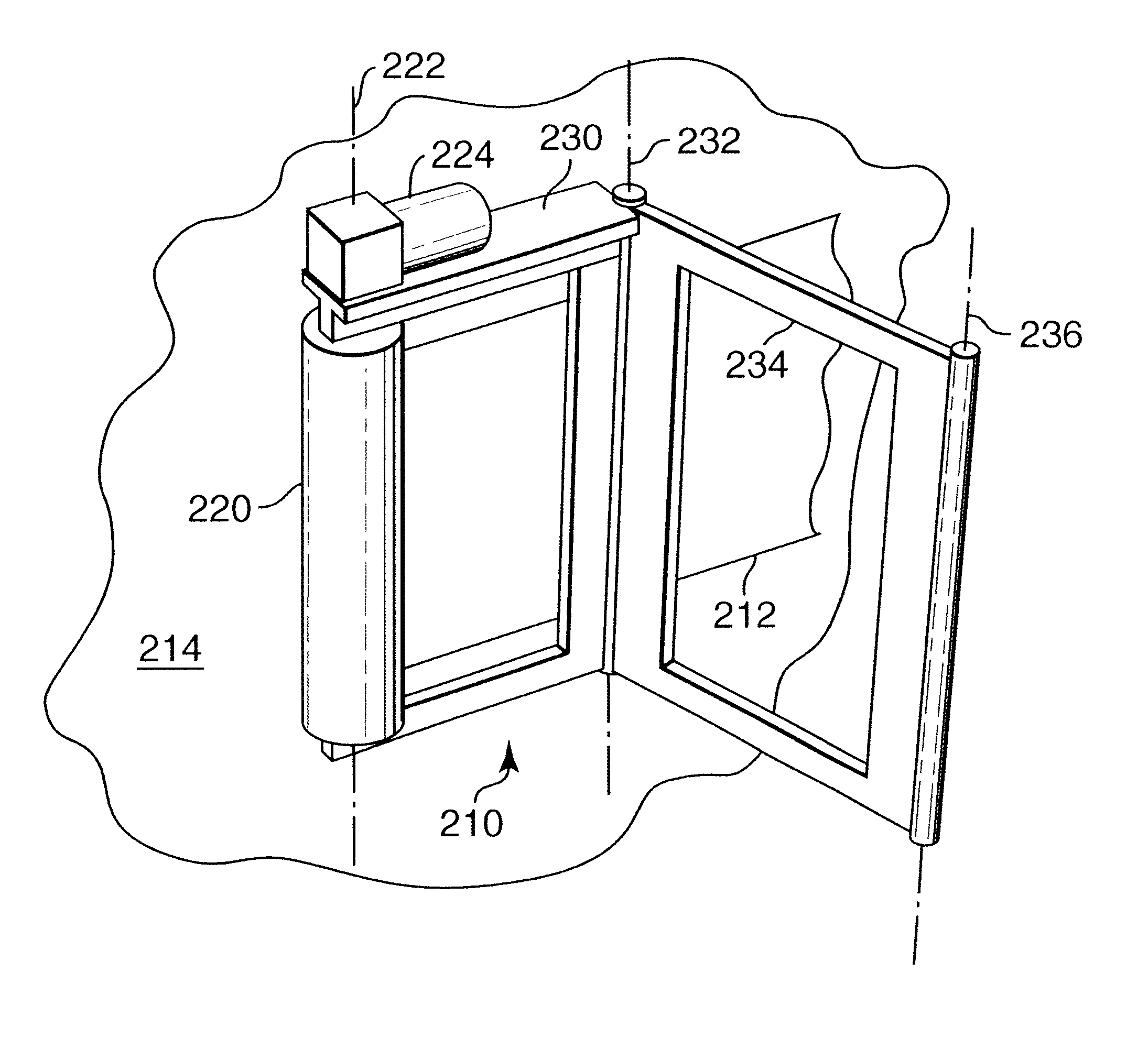

Anchoring system for a medical article

InactiveUS6283945B1Eliminate useEliminates accidental needle sticksSurgeryCatheterMedical treatmentCatheter device

An anchoring system secures a catheter to the body of a patient and arrests axial movement of the catheter without meaningfully impairing fluid flow through the catheter. The anchoring system includes an anchor pad that adheres to the patient's skin and supports a retainer. The retainer releasably receives a portion of the catheter and includes one or more retention mechanisms. The retention mechanisms inhibit axial movement of the catheter relative to the retainer when the catheter is secured therein. In one mode, the retention mechanism is positioned within a channel of the retainer and includes at least first and second members that project from opposite sides of the channel. The members are arranged to cooperate with one another when the cover is closed so as to capture a structural portion of the catheter between the first and second members without substantially occluding an inner lumen of the catheter.

Owner:VENETEC INT INC

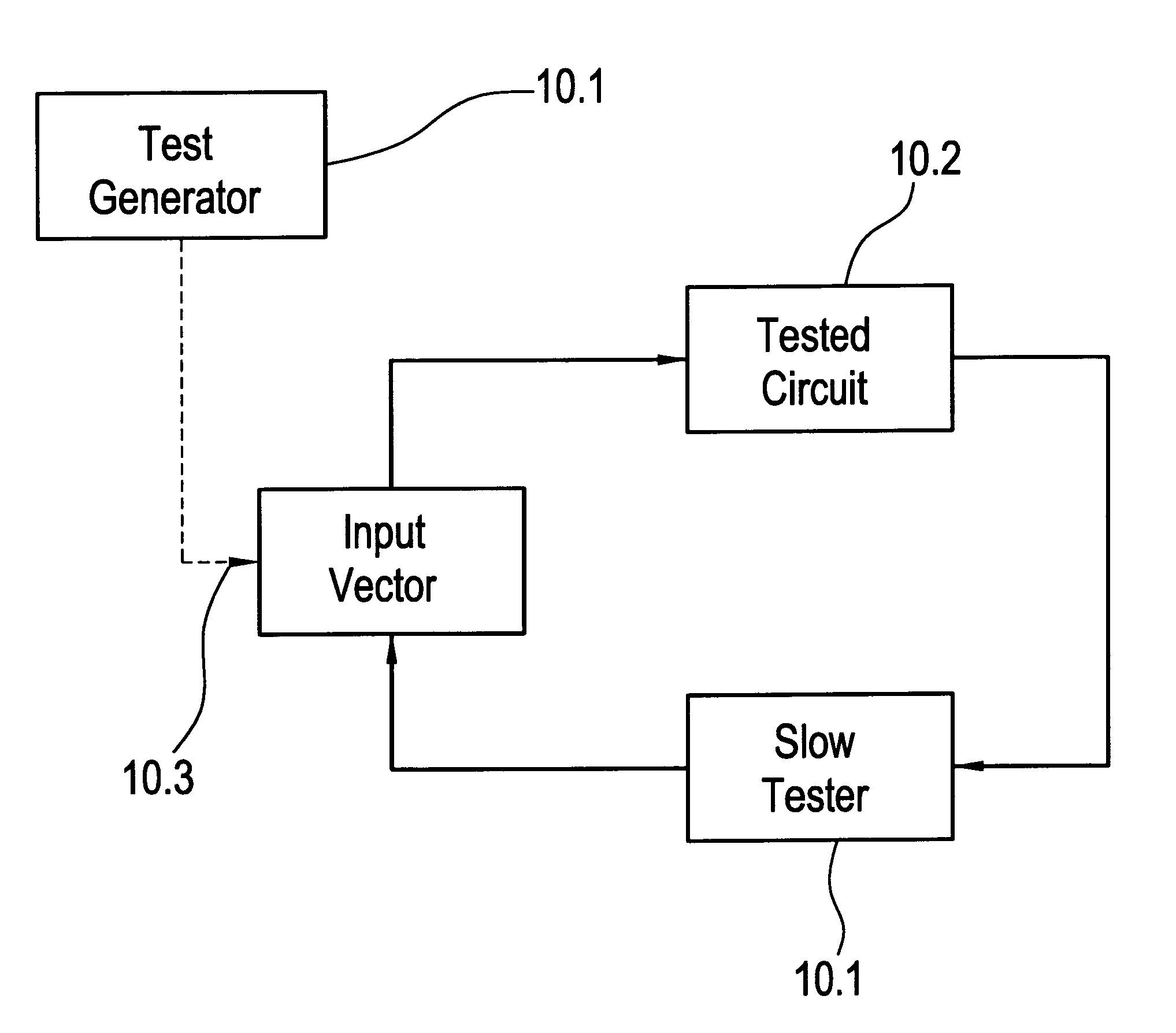

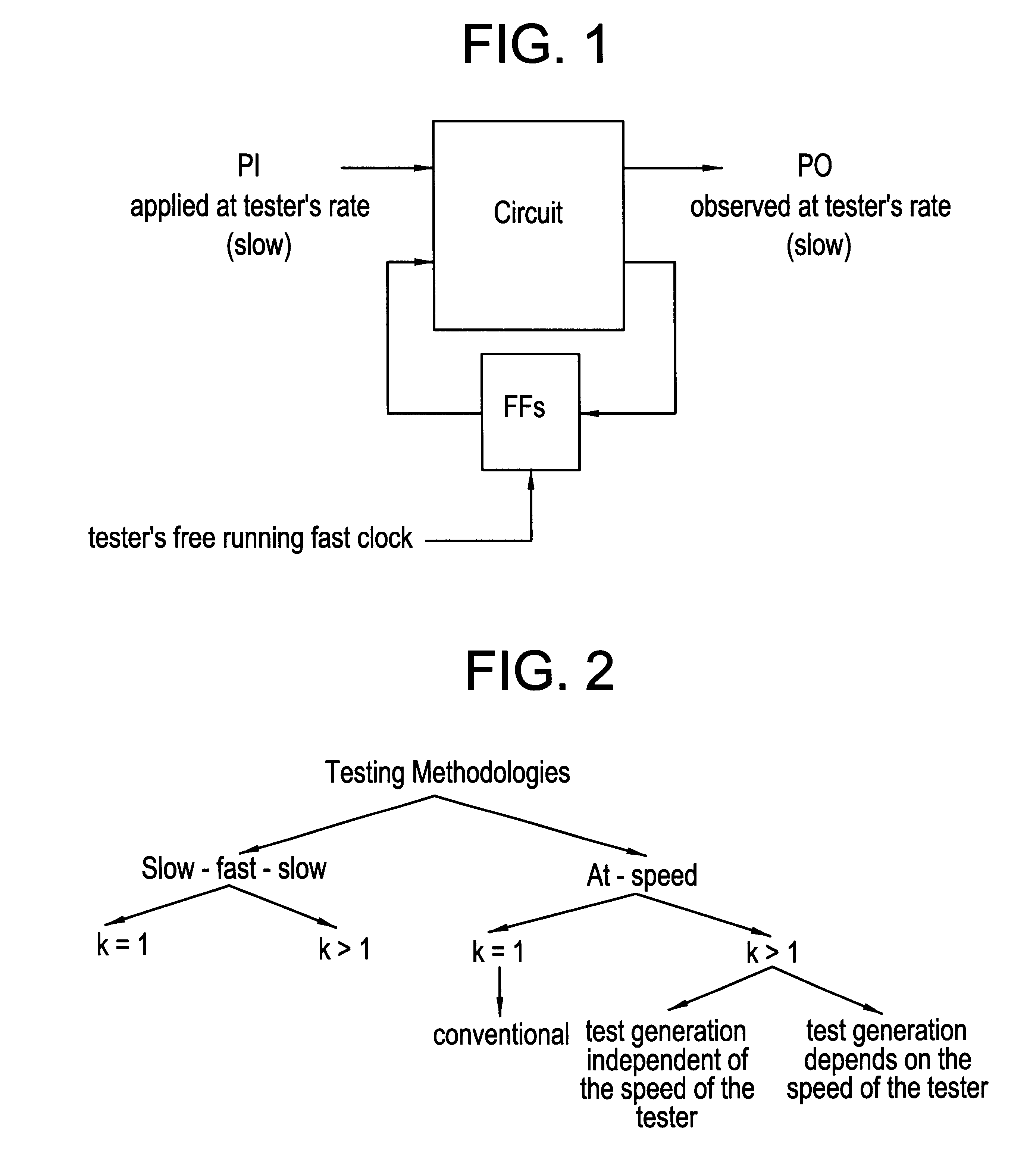

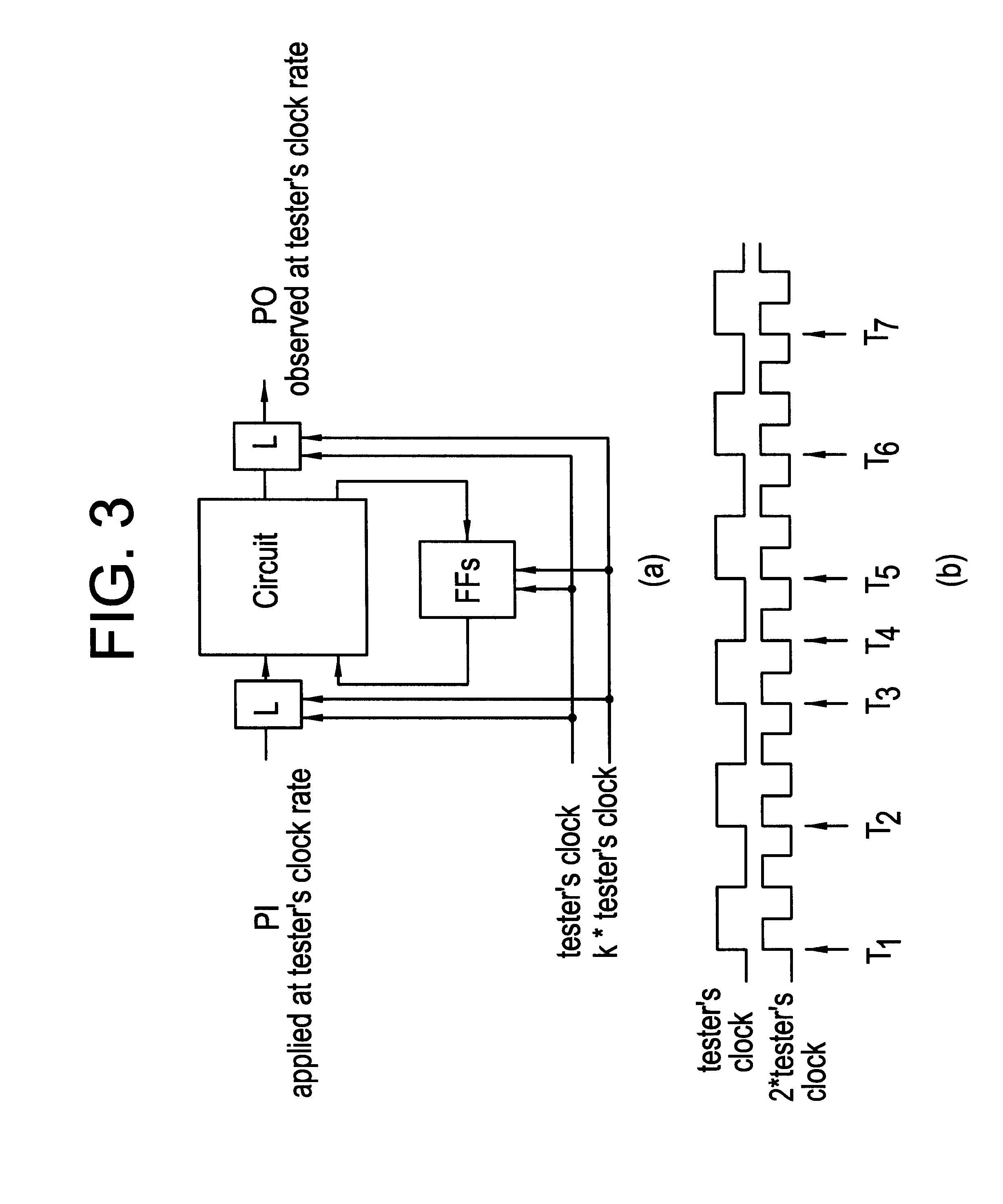

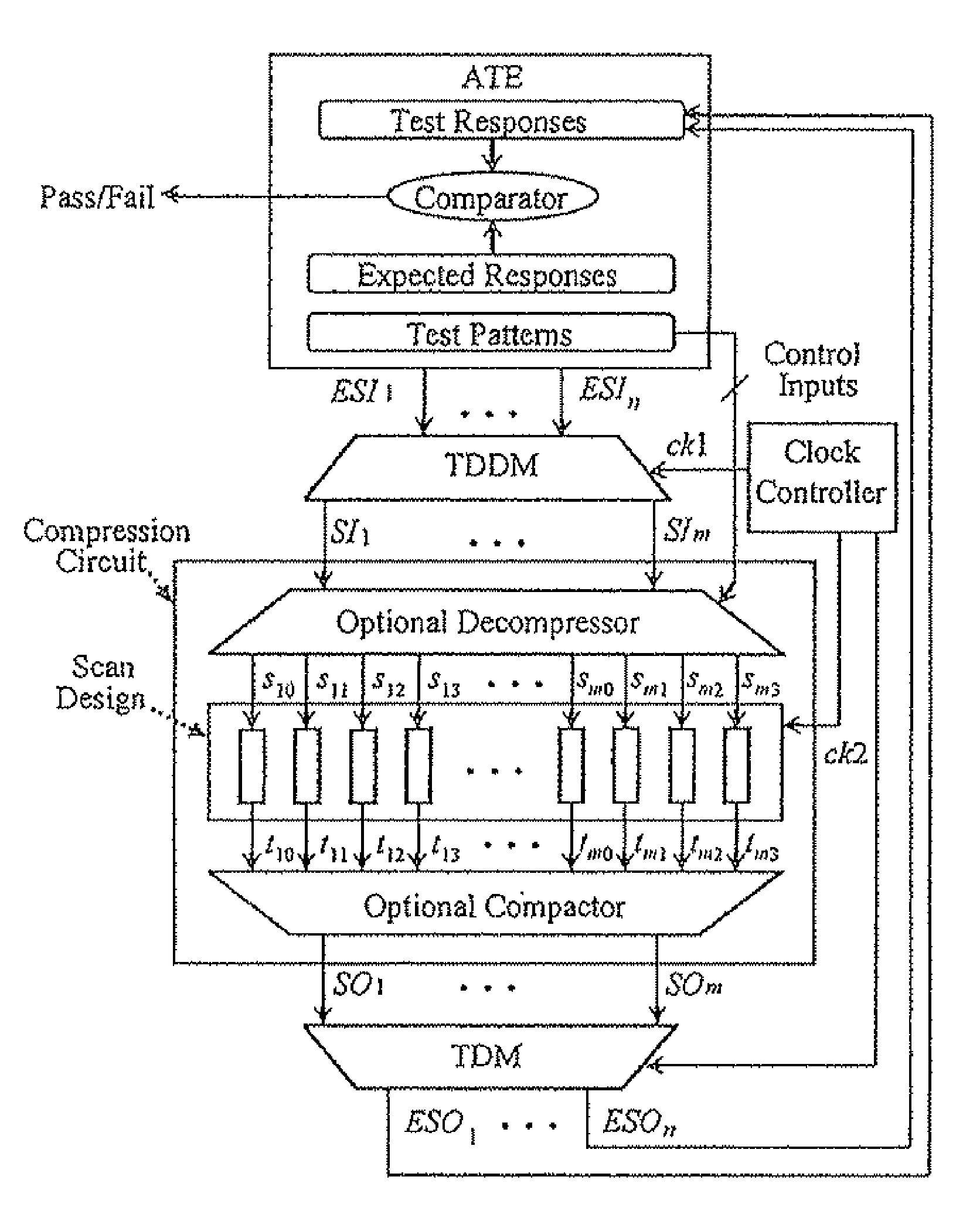

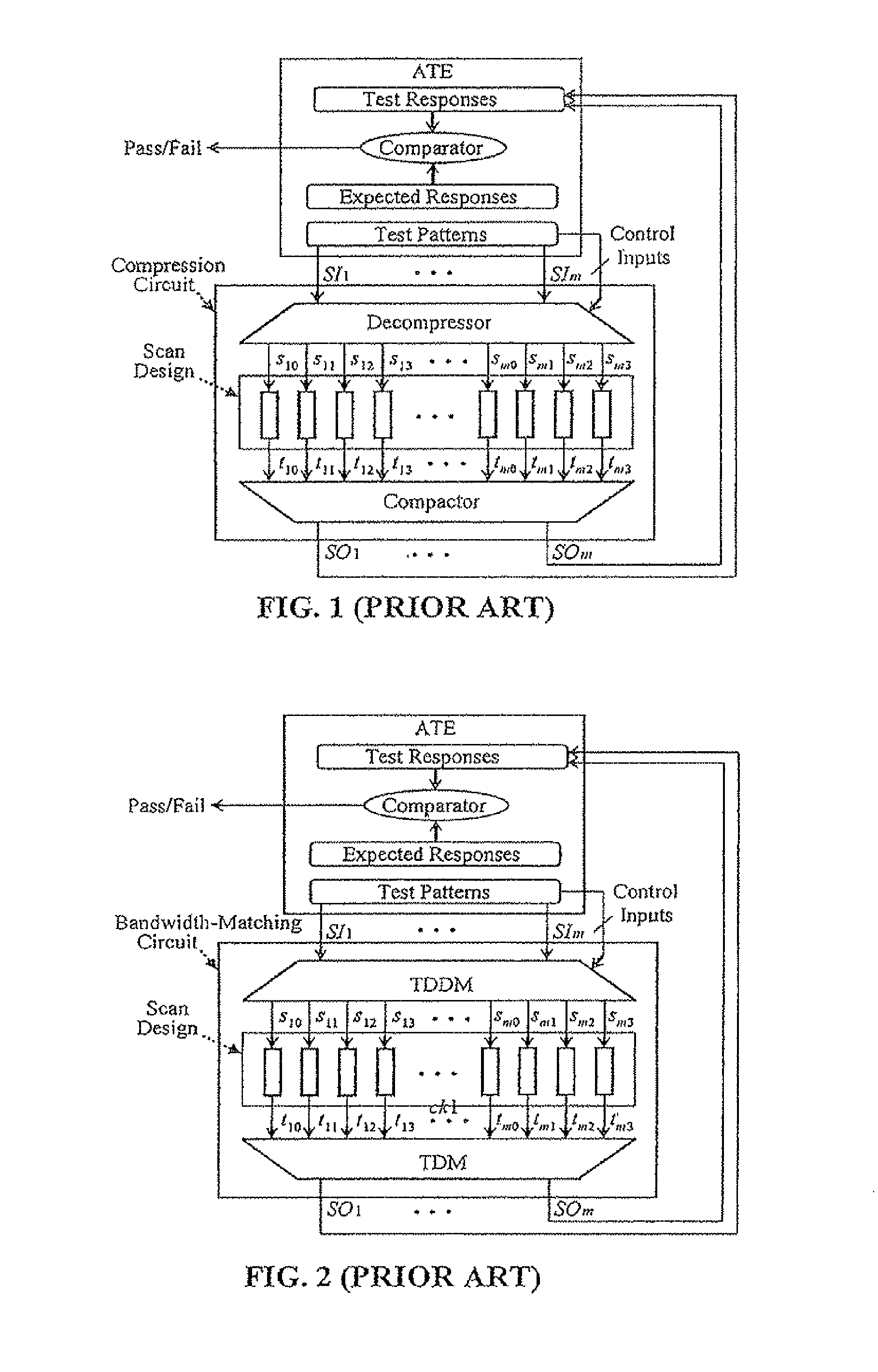

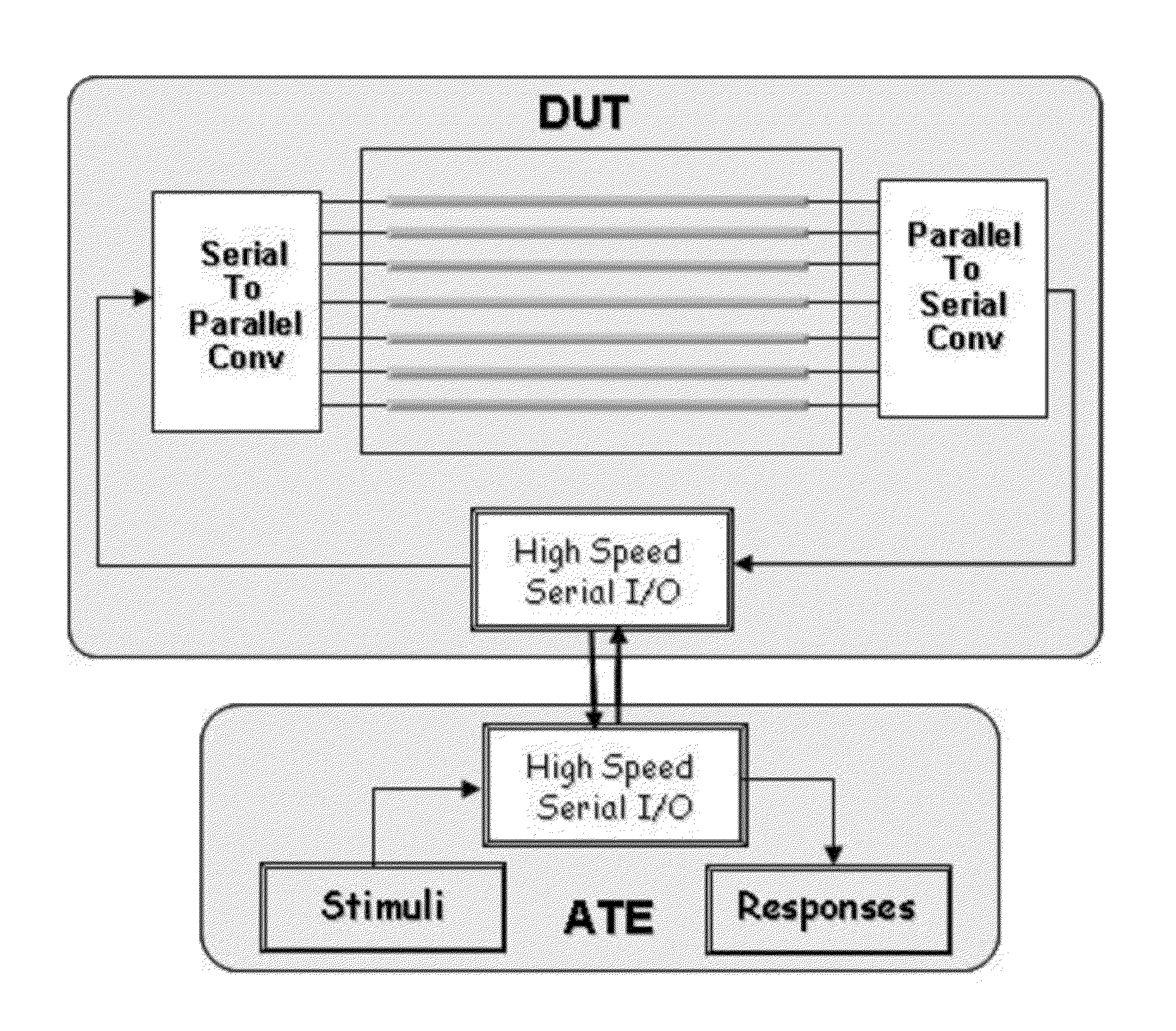

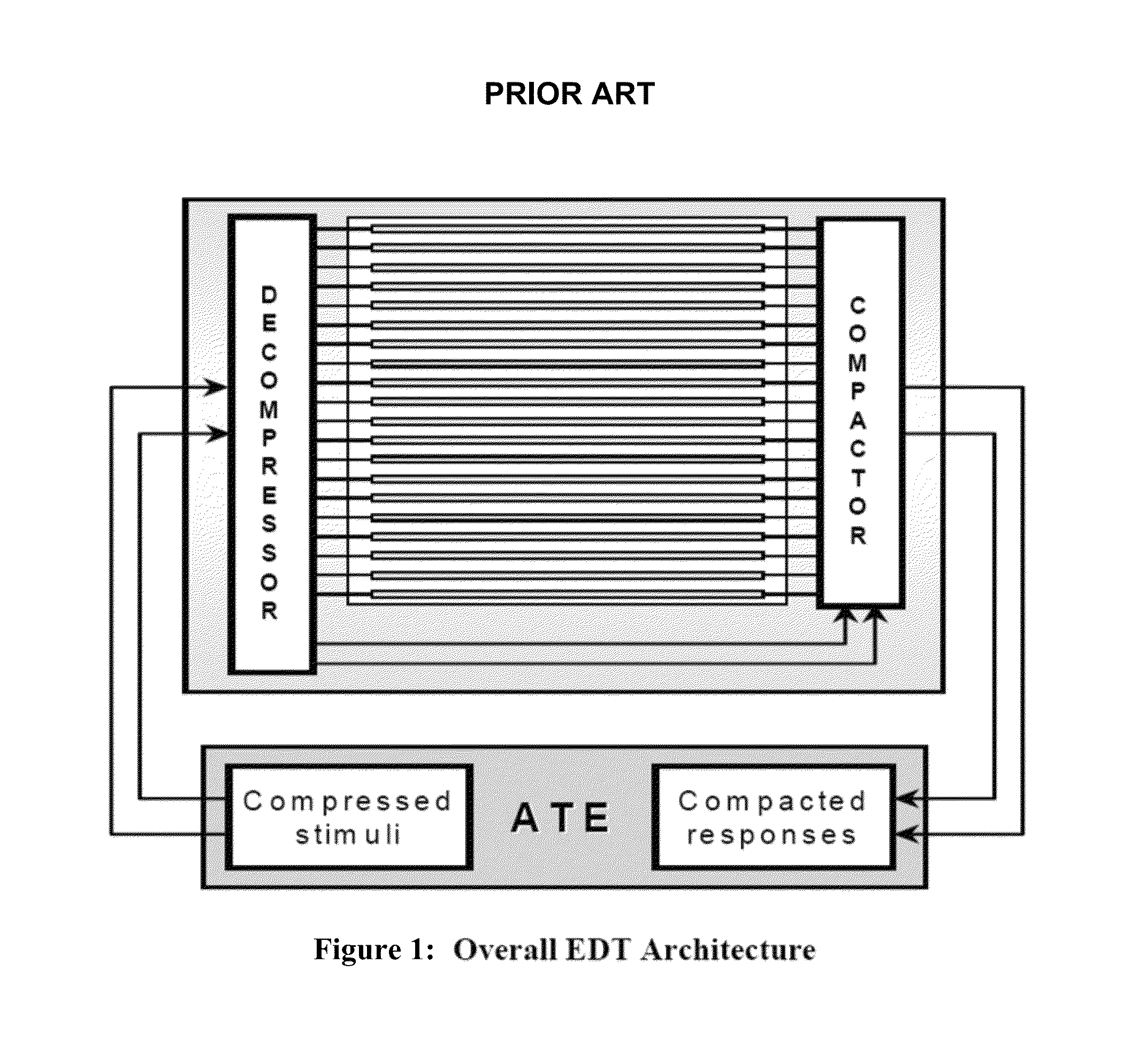

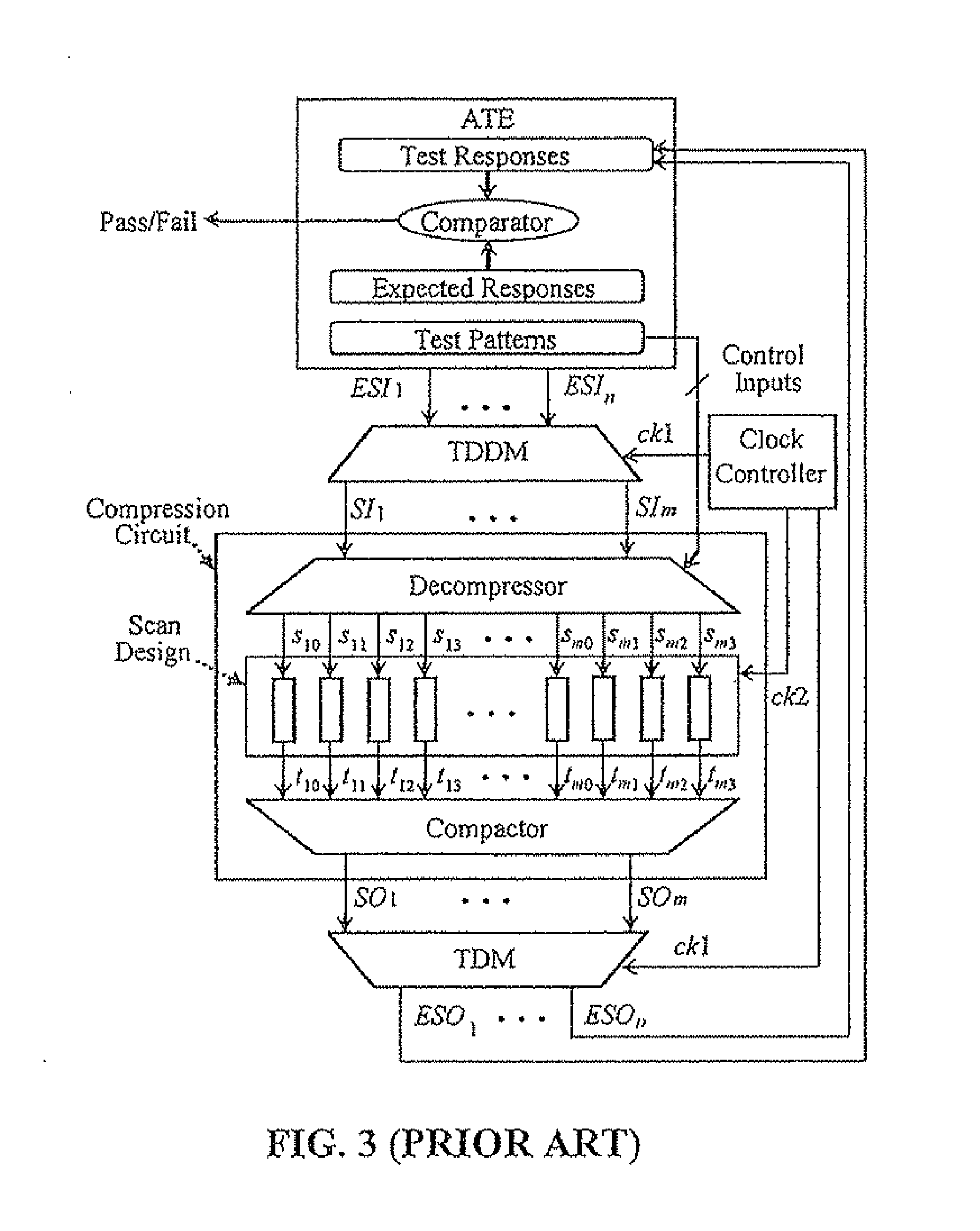

System and method for testing high speed VLSI devices using slower testers

InactiveUS6345373B1Shorten application timeLow fault coverageDigital circuit testingError detection/correctionGeneration processFault coverage

At-speed strategies for testing high speed designs on slower testers. At-speed testing schemes is provided that integrates the tester's speed limitations with the test generation process. Due to constraints placed at the test generation process, these schemes might result in a reduced fault coverage. To increase the fault coverage and reduce the test application time, the slow-fast-slow and at-speed strategies can be combined for testing high speed designs on slower testers. A slow tester that uses test vectors that are generated while taking into account the speed of the tester.

Owner:NEC CORP +1

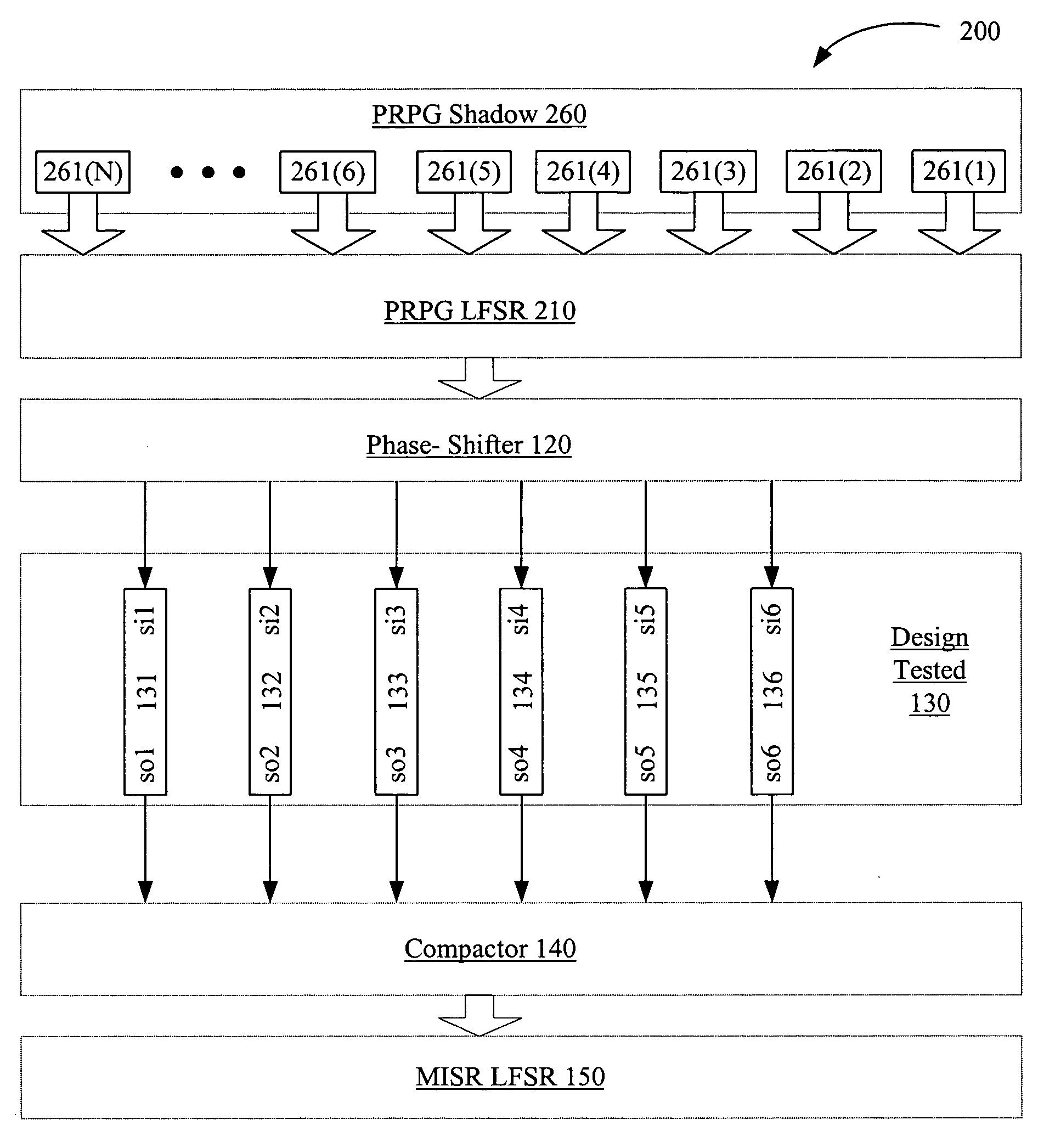

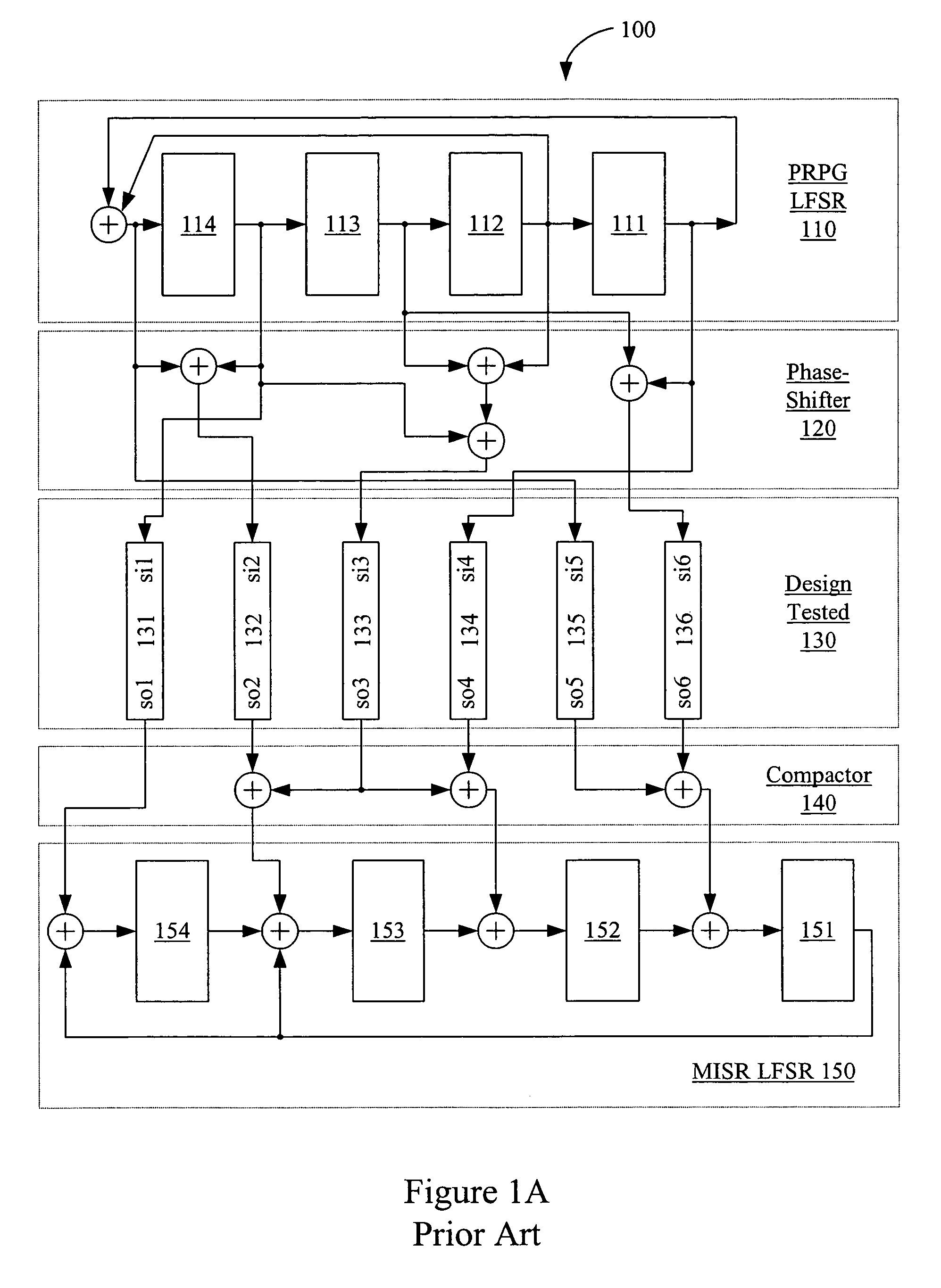

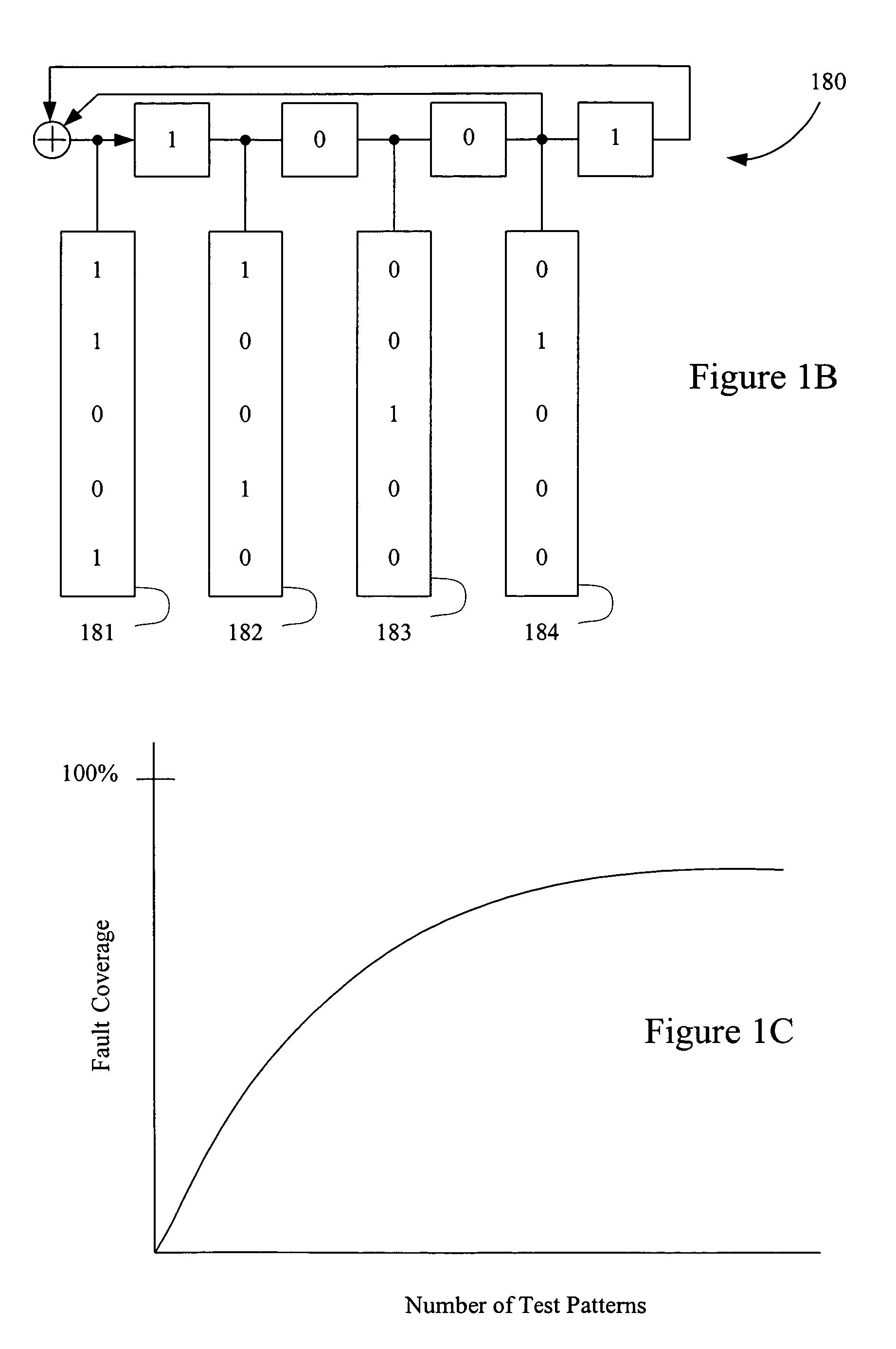

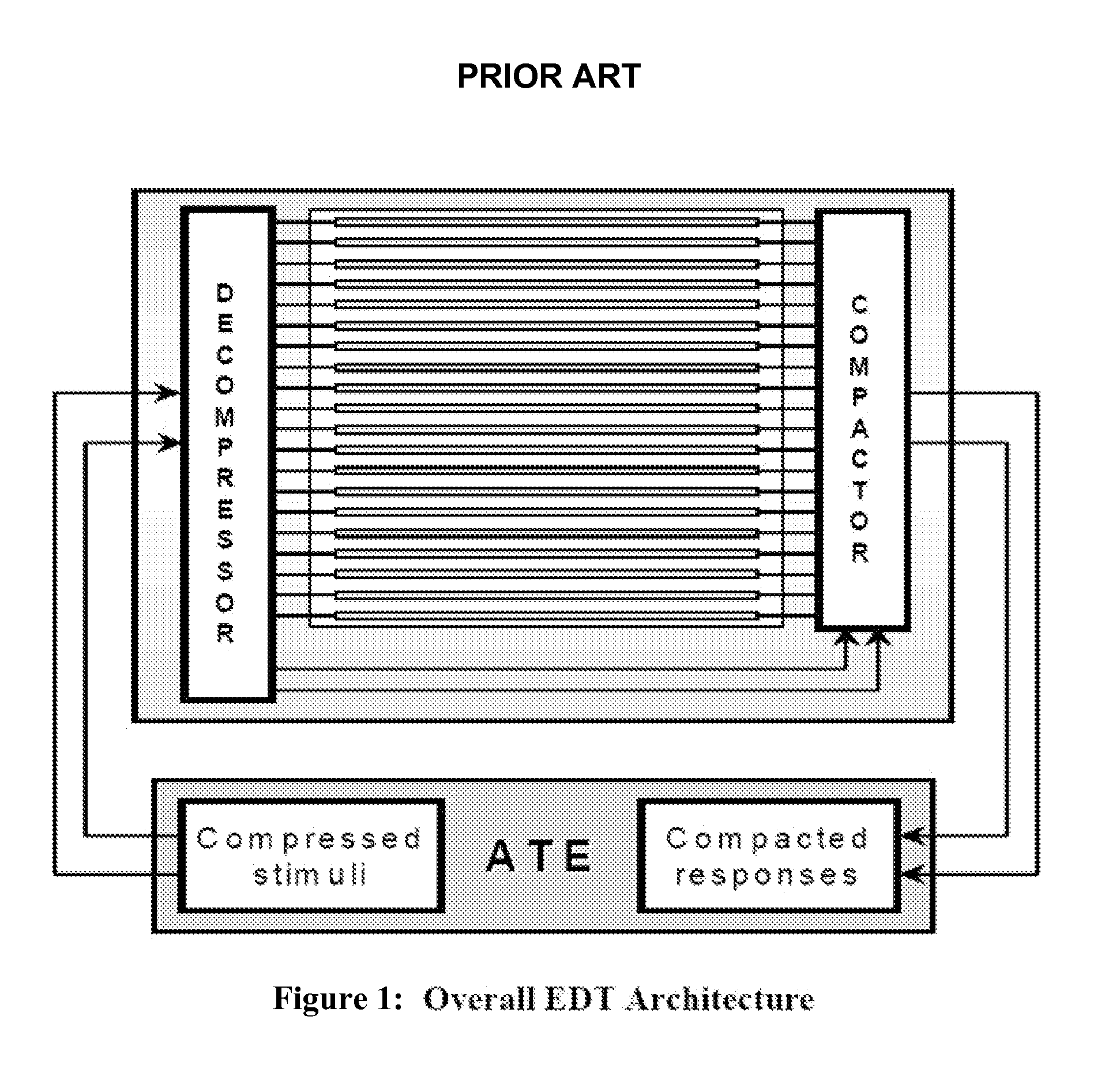

Efficient compression and application of deterministic patterns in a logic BIST architecture

InactiveUS6950974B1Reducing test cycle countShorten the counting processElectronic circuit testingDevice under testTheoretical computer science

Deterministic ATPG test coverage is provided in a logic BIST architecture while reducing test application time and test data volume, as compared to deterministic ATPG patterns. The logic BIST architecture can include a PRPG shadow operatively coupled to a PRPG circuit. The PRPG shadow allows re-seeding of the PRPG circuit with zero cycle overhead. Two compressions can be provided. In a first compression, multiple tests for faults are compressed into one pattern. In a second compression, multiple deterministic ATPG patterns can be compressed into one seed. All patterns provided from the PRPG can be controlled by these seeds so that all care bits are properly set, while all other scan cells are set to pseudo-random values from the PRPG. In this manner, the PRPG can rapidly deliver highly pertinent data to the scan chains of the device under test.

Owner:SYNOPSYS INC

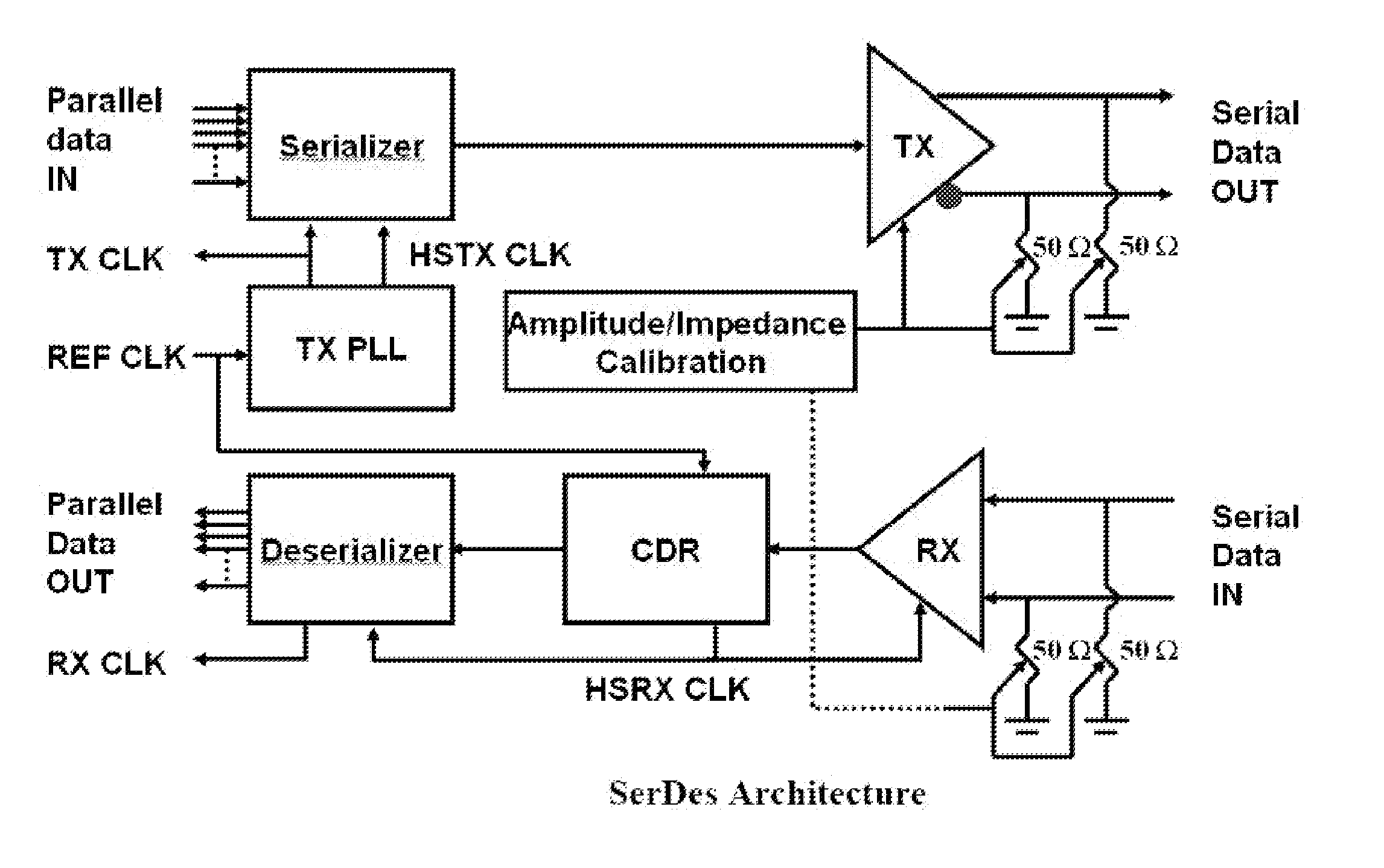

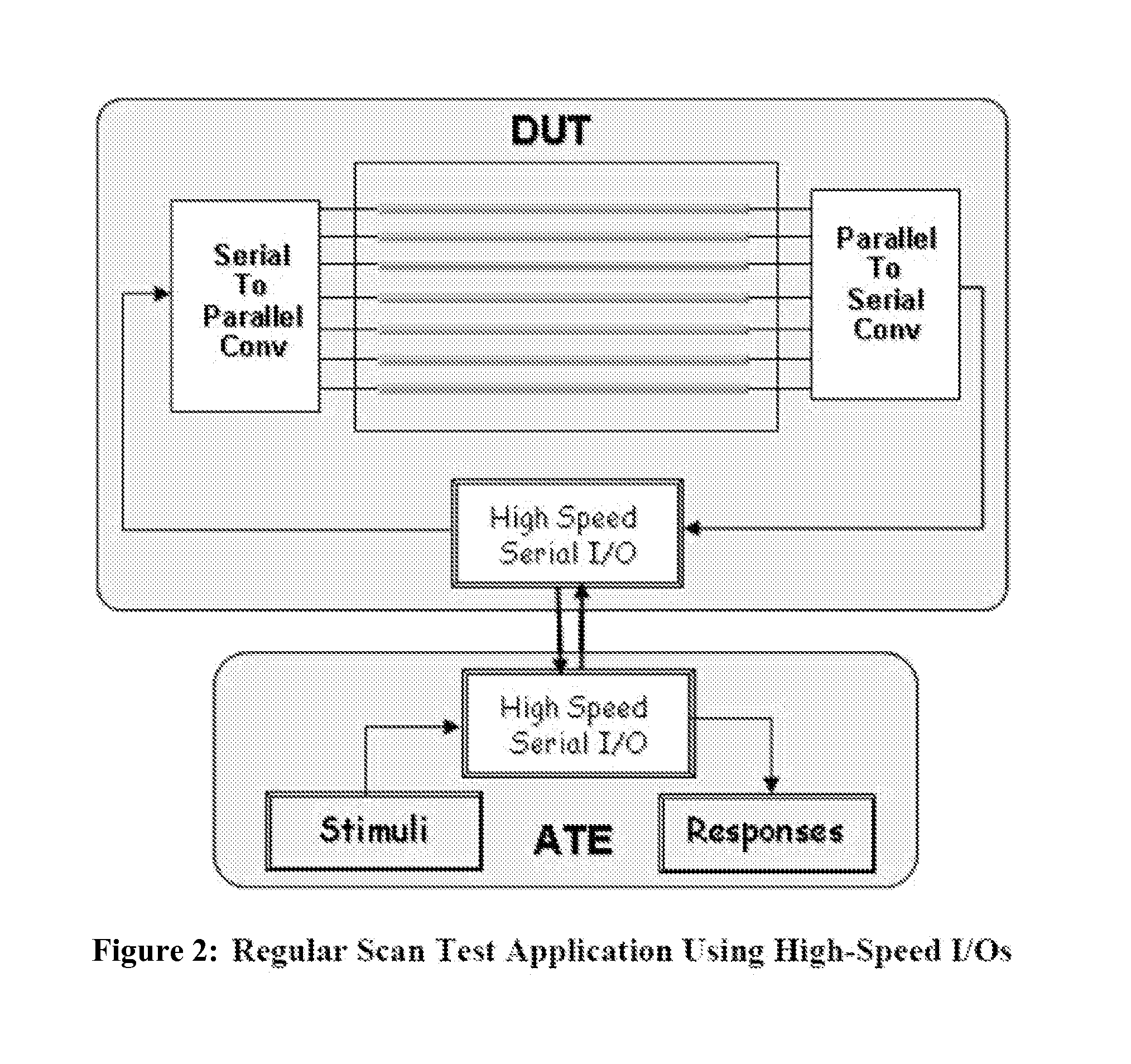

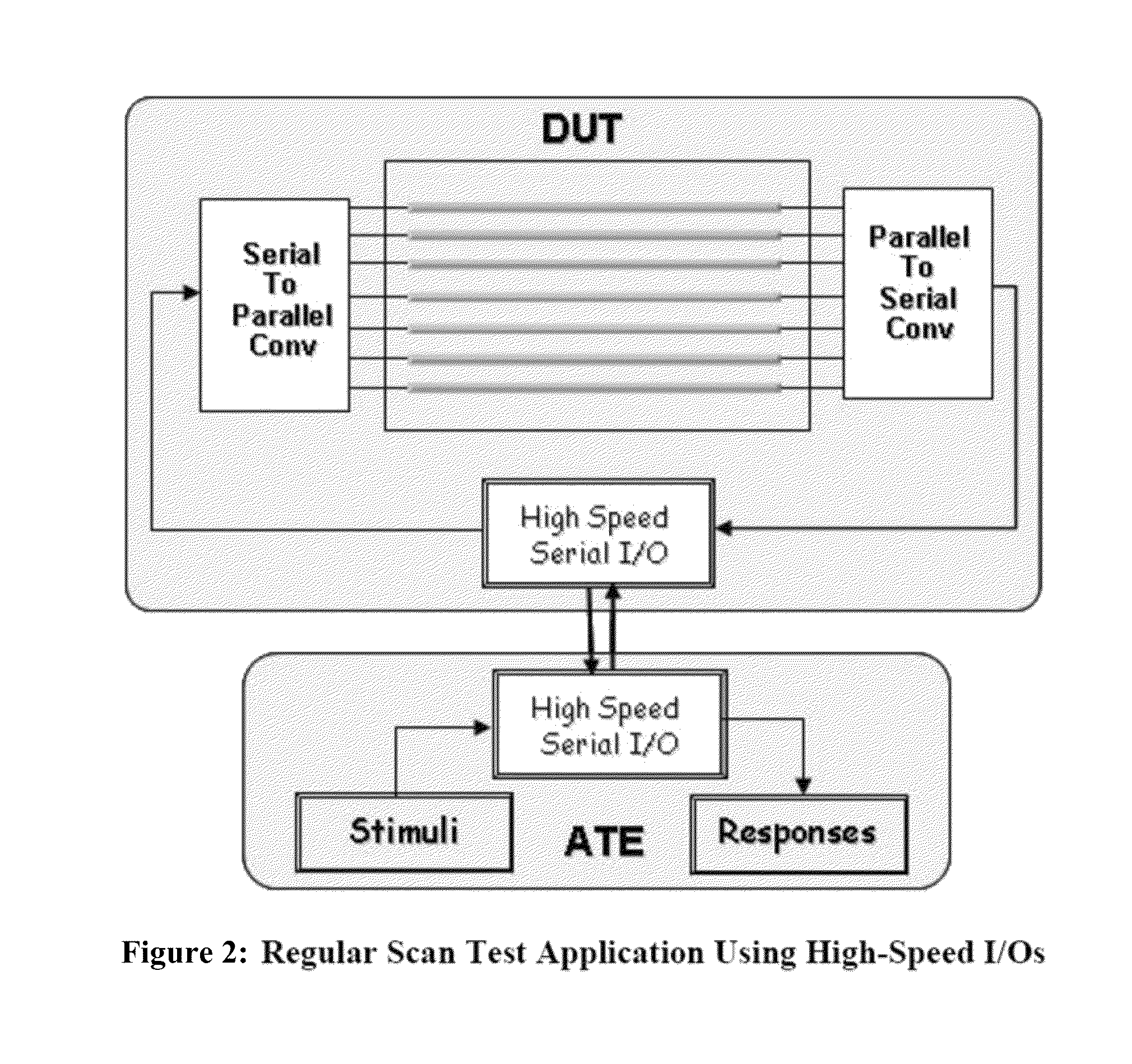

Scan Test Application Through High-Speed Serial Input/Outputs

ActiveUS20100313089A1Reduce data volumeMinimize application timeElectronic circuit testingLogical operation testingData bufferData conversion

Methods and devices for using high-speed serial links for scan testing are disclosed. The methods can work with any scheme of scan data compression or with uncompressed scan testing. The protocol and hardware to support high speed data transfer reside on both the tester and the device under test. Control data may be transferred along with scan data or be partially generated on chip. Clock signals for testing may be generated on chip as well. In various implementations, the SerDes (Serializer / Deserializer) may be shared with other applications. The Aurora Protocol may be used to transport industry standard protocols. To compensate for effects of asynchronous operation of a conventional high-speed serial link, buffers may be used. The high-speed serial interface may use a data conversion block to drive test cores.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

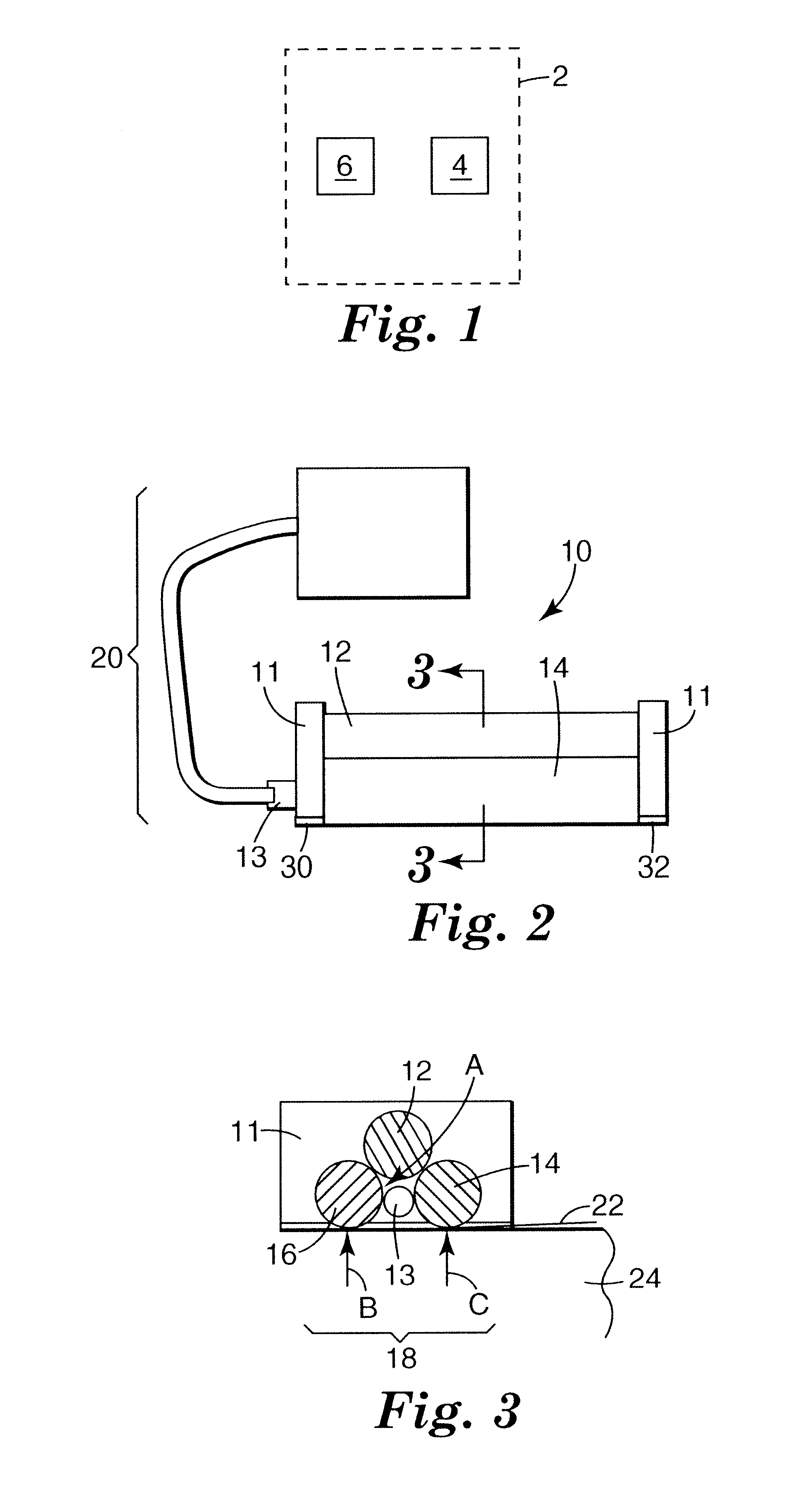

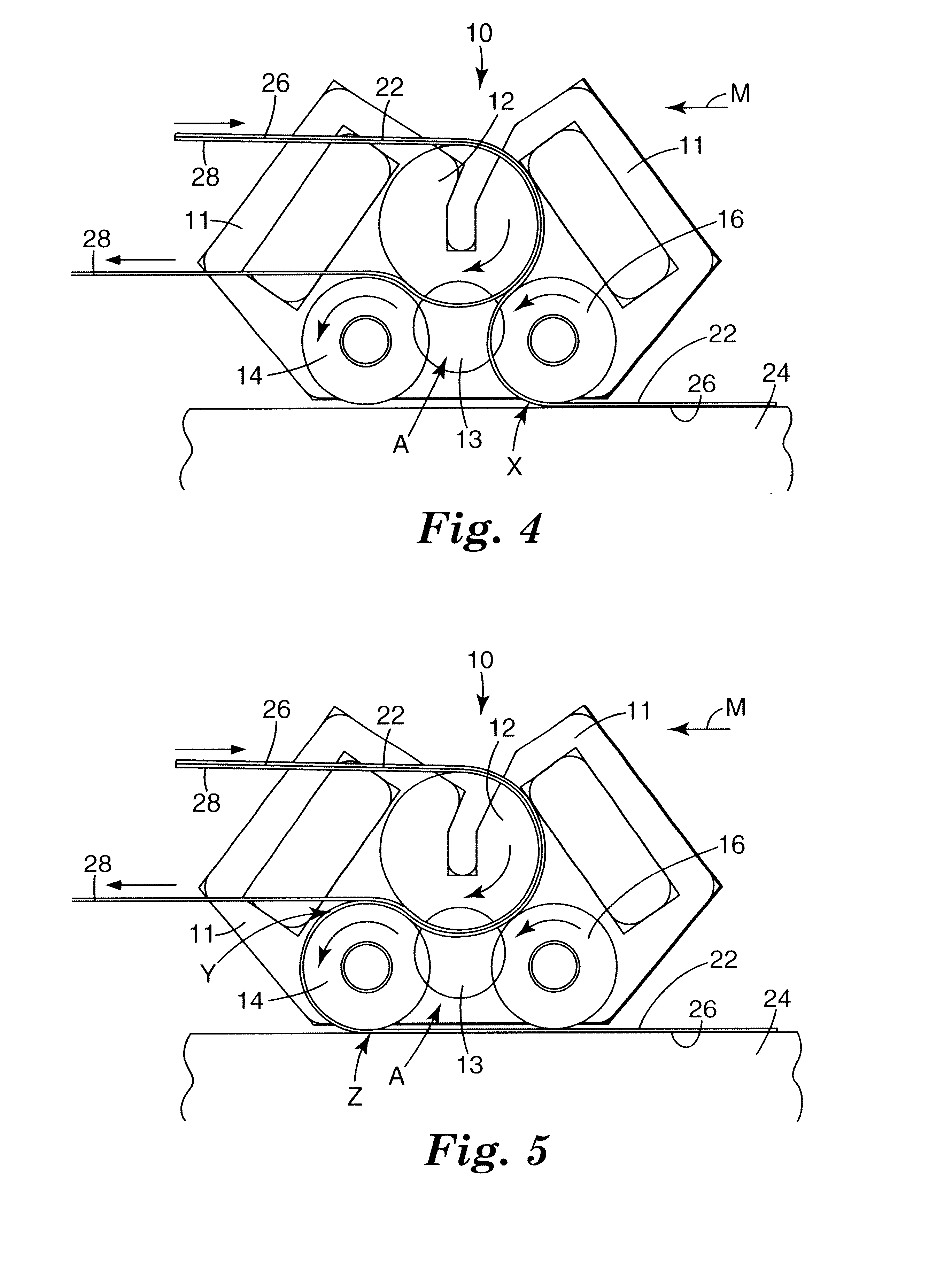

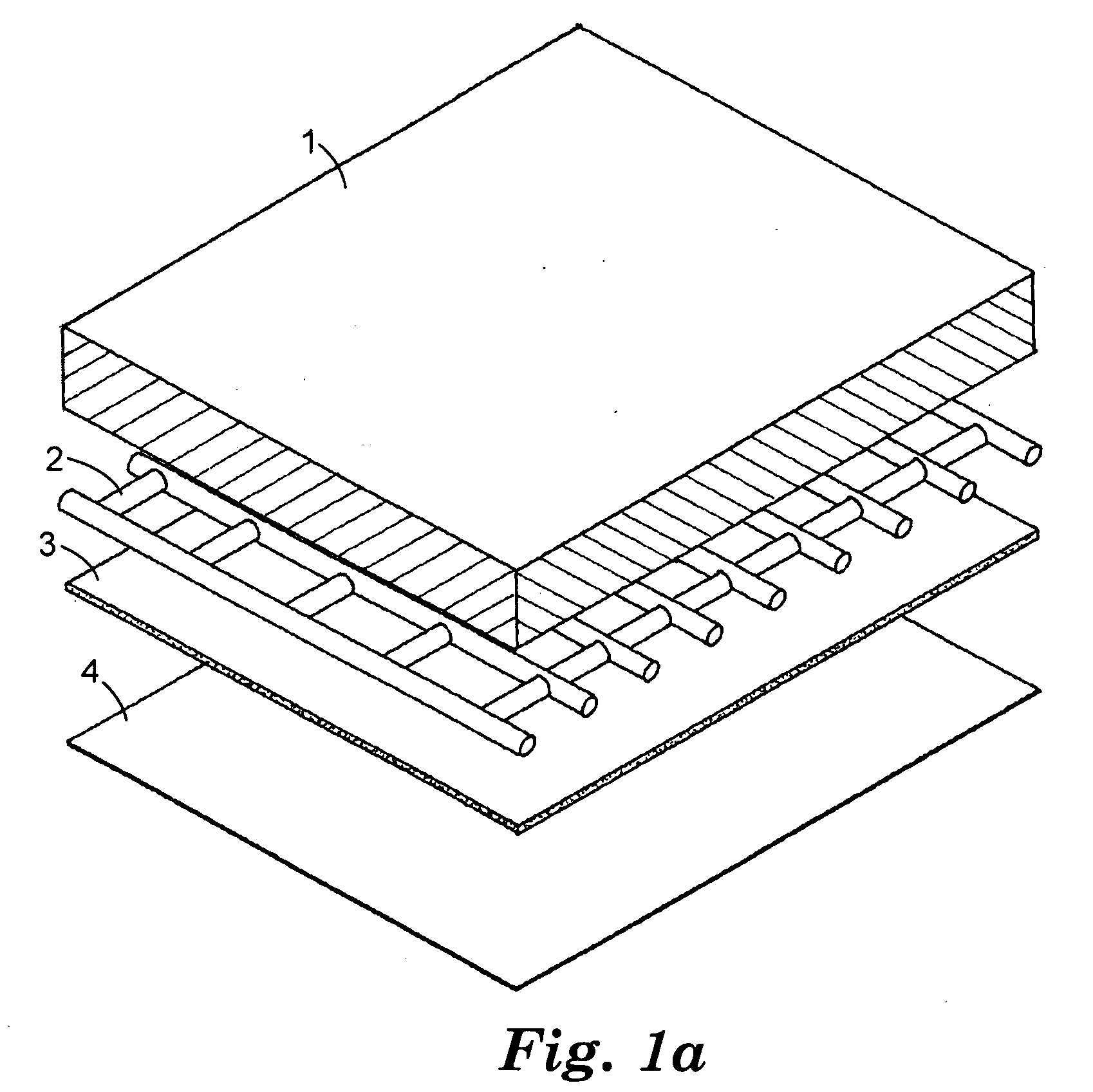

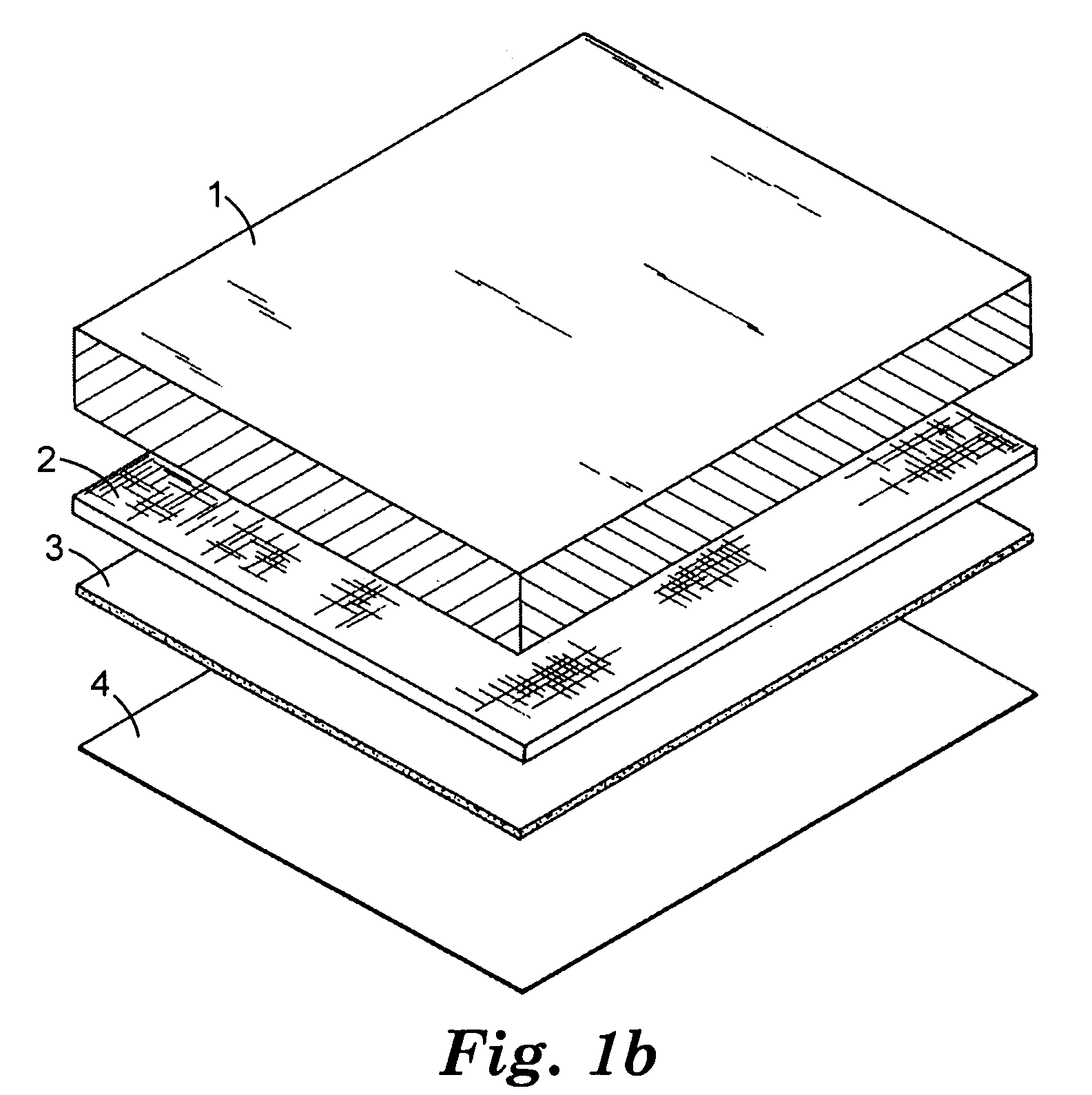

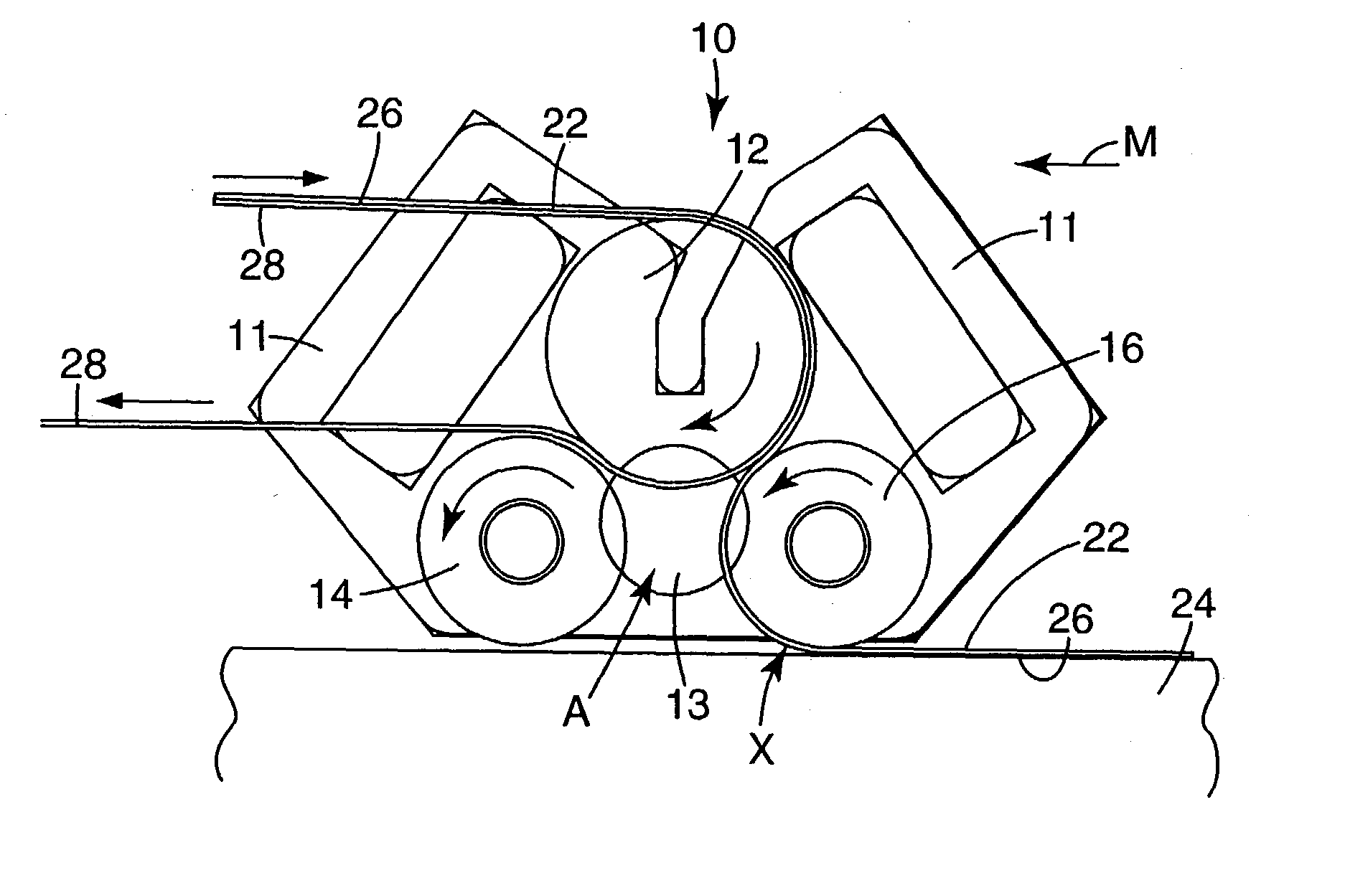

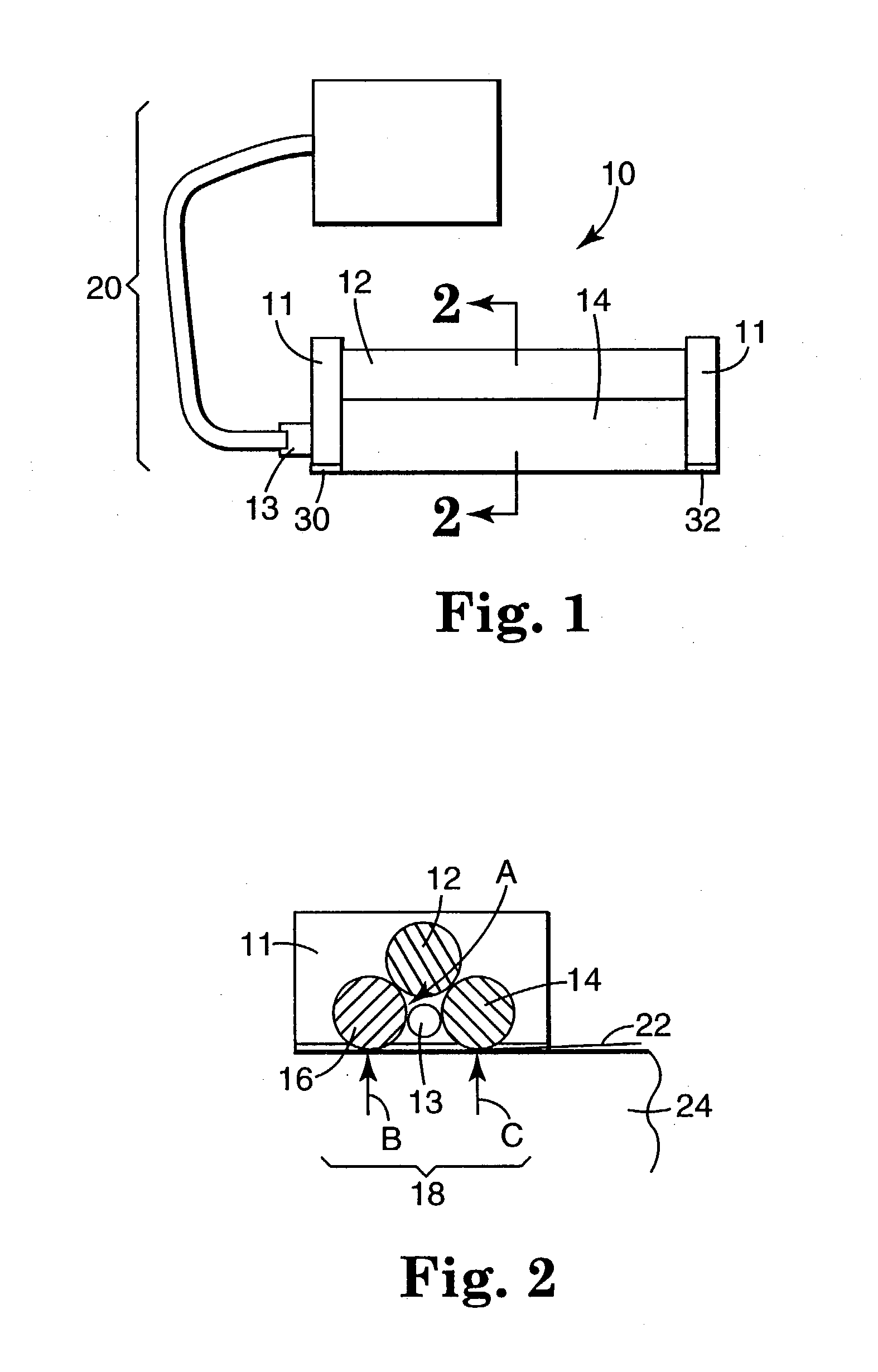

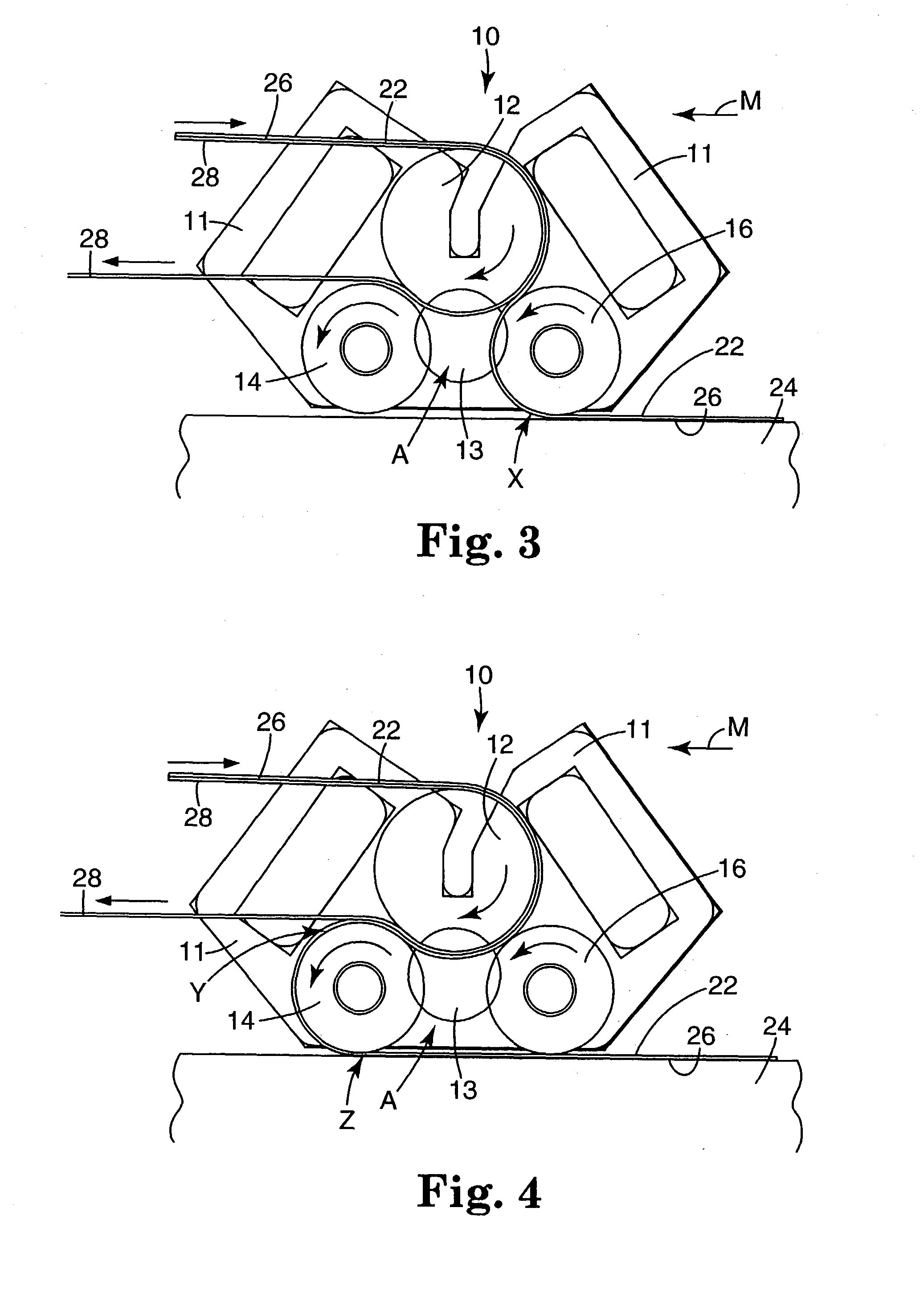

Film lamination and removal system and methods of use

InactiveUS6706131B2Good lookingIncreased durabilityMechanical working/deformationCovering/liningsVacuum assistedAdhesive

Vacuum-assisted film laminating and removal systems and methods of using the same. The systems include a vacuum-assisted laminator for applying large format films to substrates where lamination pressure is generated at least partially by a vacuum drawn in a vacuum cavity. The removal apparatus applies tension over the width of the adhesive film, thereby removing the film from the substrate along the release line that extends over the width of the film. The systems and methods can be used to apply and remove large-scale adhesive films from substrates.

Owner:3M INNOVATIVE PROPERTIES CO

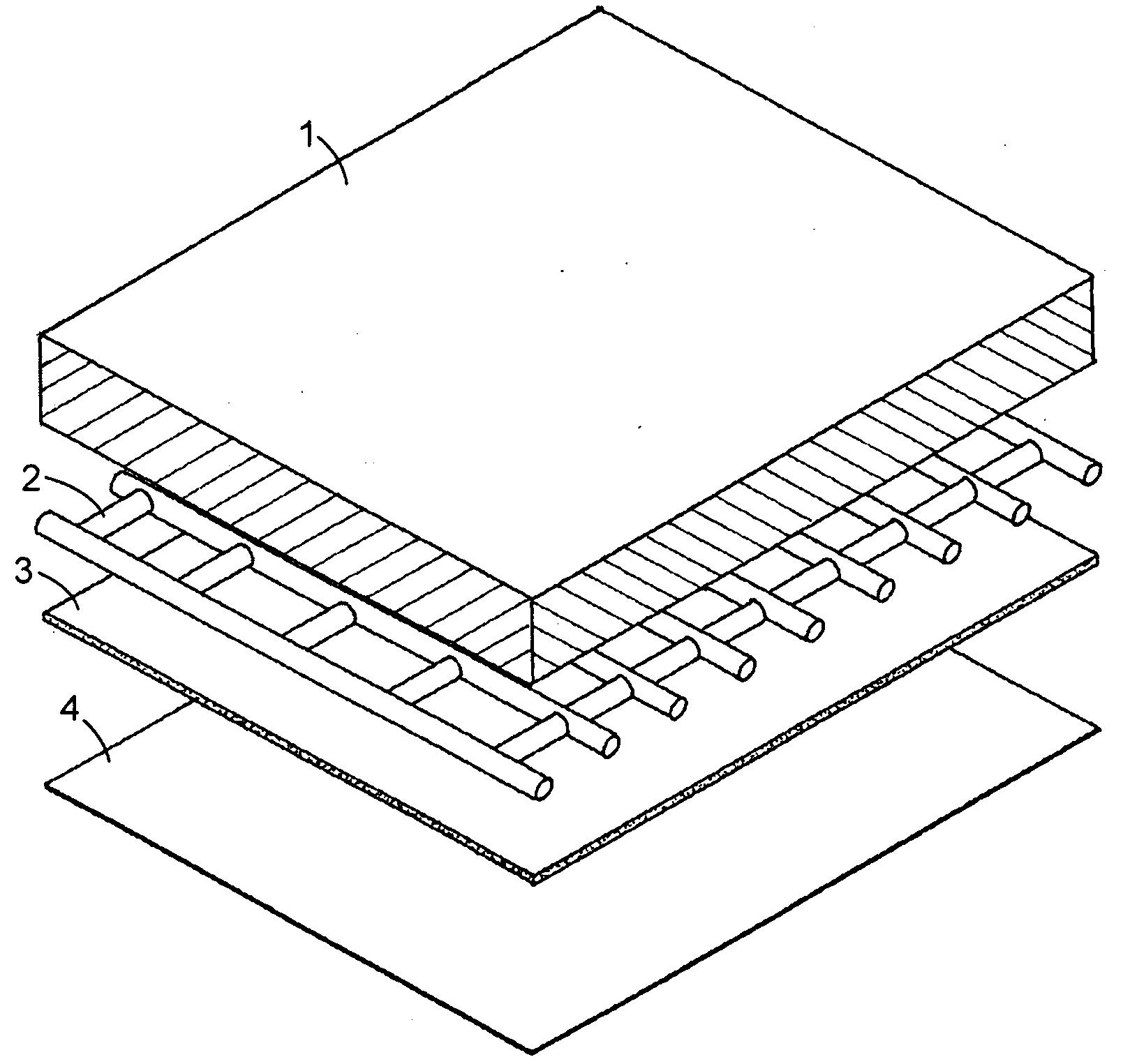

Multi-layer intumescent fire protection barrier with adhesive surface

InactiveUS20090255619A1Reduce the time required for installationImprove securityCovering/liningsWallsFire protectionEngineering

An intumescent fire protection barrier in the form of an adhesive sheet or continuous roll of tape. The barrier comprises laminated layers of an intumescent material, a reinforcing matrix, a pressure sensitive adhesive and a release liner. The intumescent material is adhesively applied to a structural steel substrate and expands by at least 10 times its original thickness during a fire to provide fire protection to the substrate. Multiple layers of the fire protection barrier may be installed on top of one another. This application method dramatically reduces installation time as compared with sprayed on fire protection coatings.

Owner:3M INNOVATIVE PROPERTIES CO

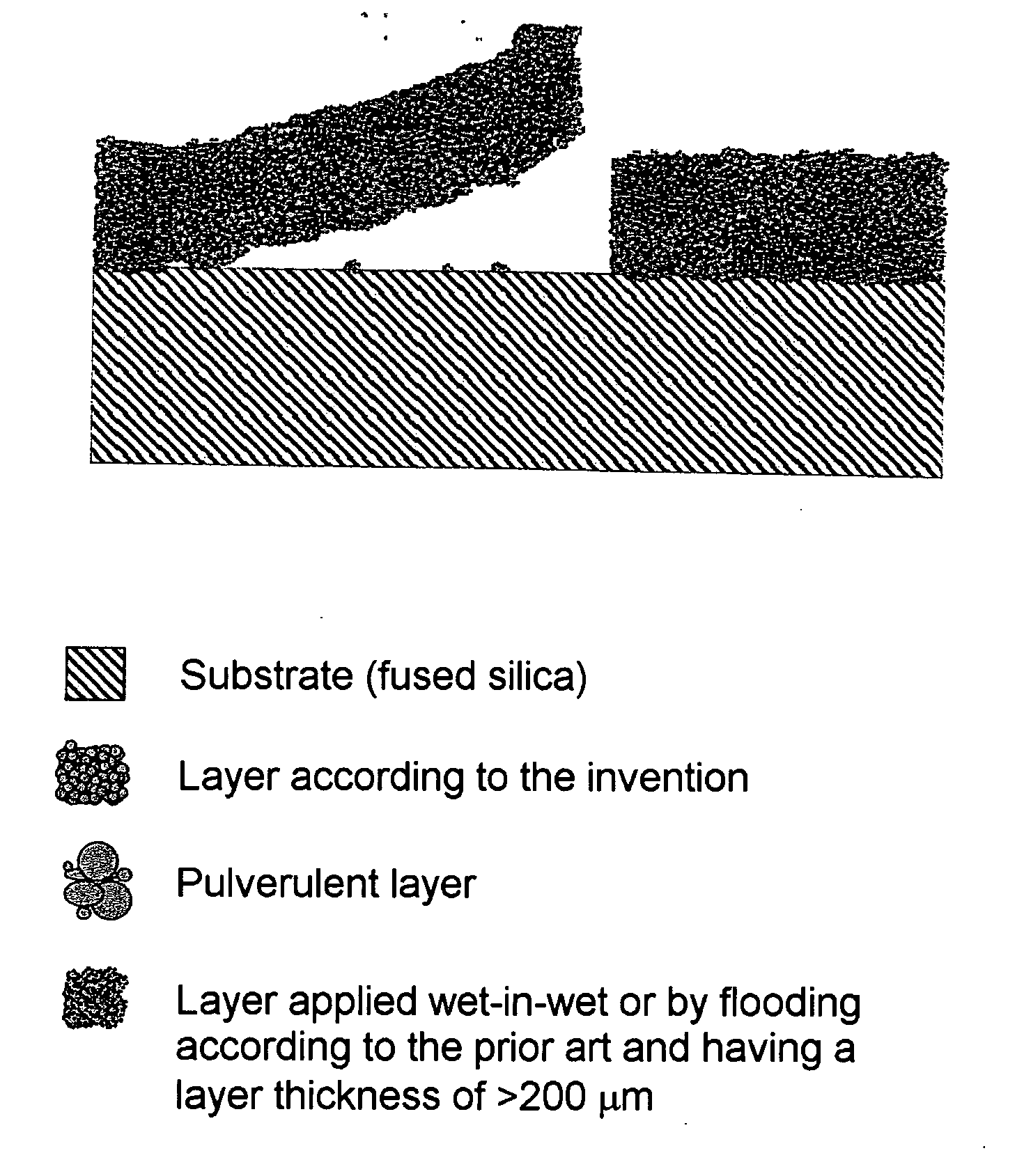

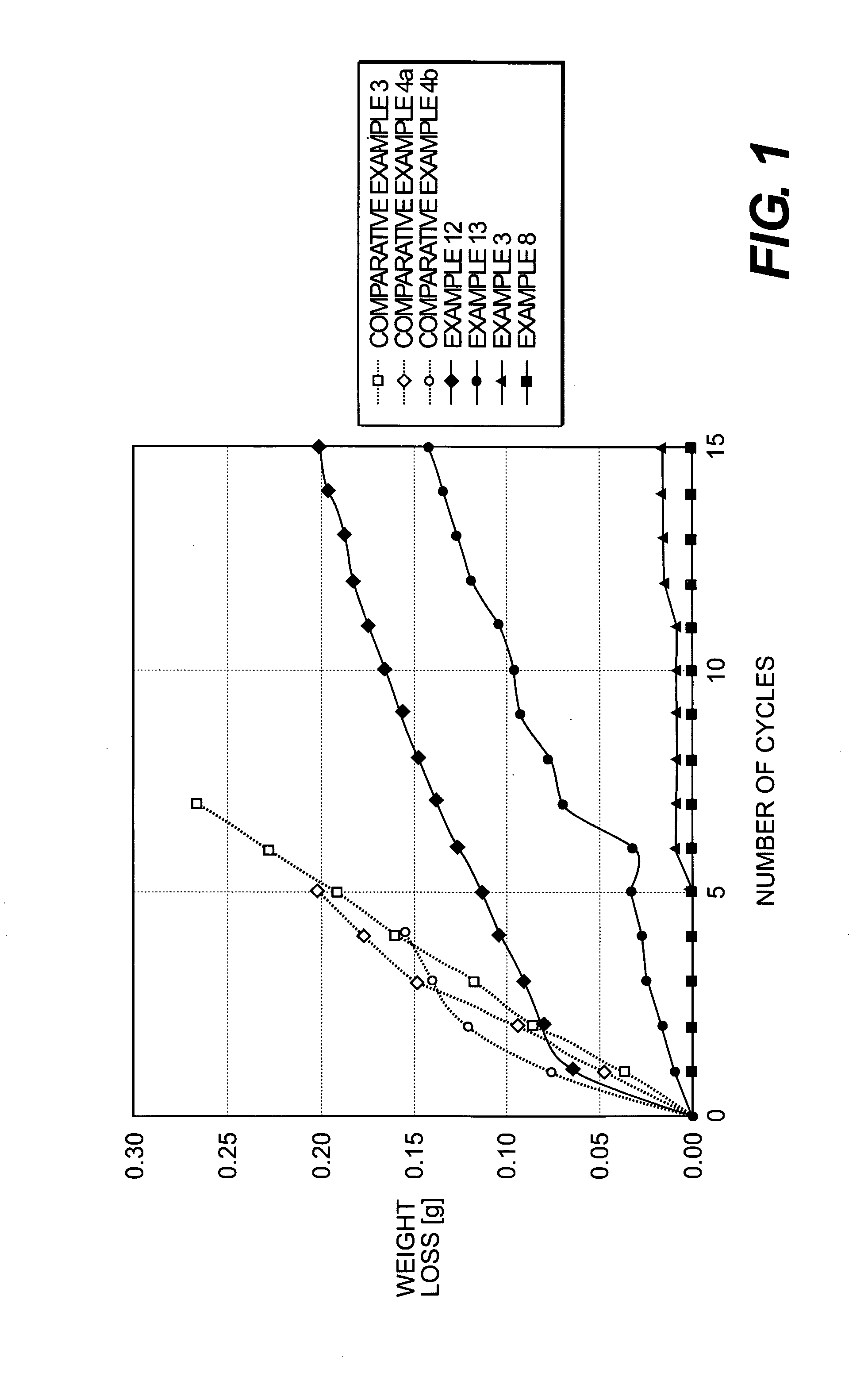

Firmly adhering silicon nitride-containing release layer

InactiveUS20090119882A1Relieve pressureSinter activity is reducedMaterial nanotechnologyBy pulling from meltNonferrous metalSolid particle

The invention relates to a slip for producing a durable, firmly adhering release layer on a substrate, comprising a suspension of solid particles, wherein the solid particles comprise 67-95% by weight of silicon nitride and 5-33% by weight of an SiO2-based high-temperature binder and the SiO2-based high-temperature binder is derived from SiO2 precursors and has been pretreated by heat treatment in a temperature range of 300-1300° C.The invention further provides shaped bodies comprising a substrate having a durable, firmly adhering release layer and also processes for producing them. The shaped bodies of the invention are suitable for use in the field of corrosive nonferrous metal melts.

Owner:3M INNOVATIVE PROPERTIES CO

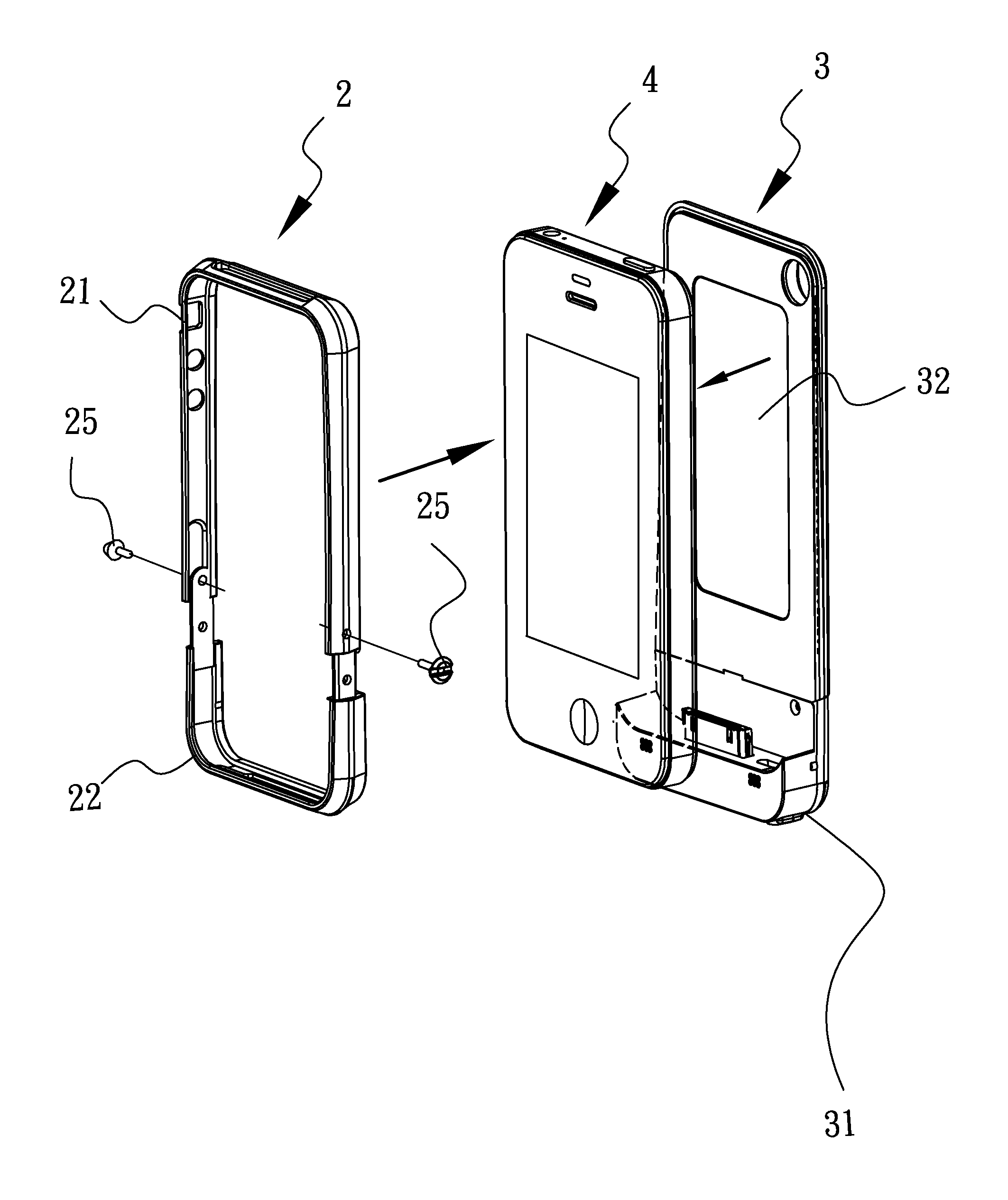

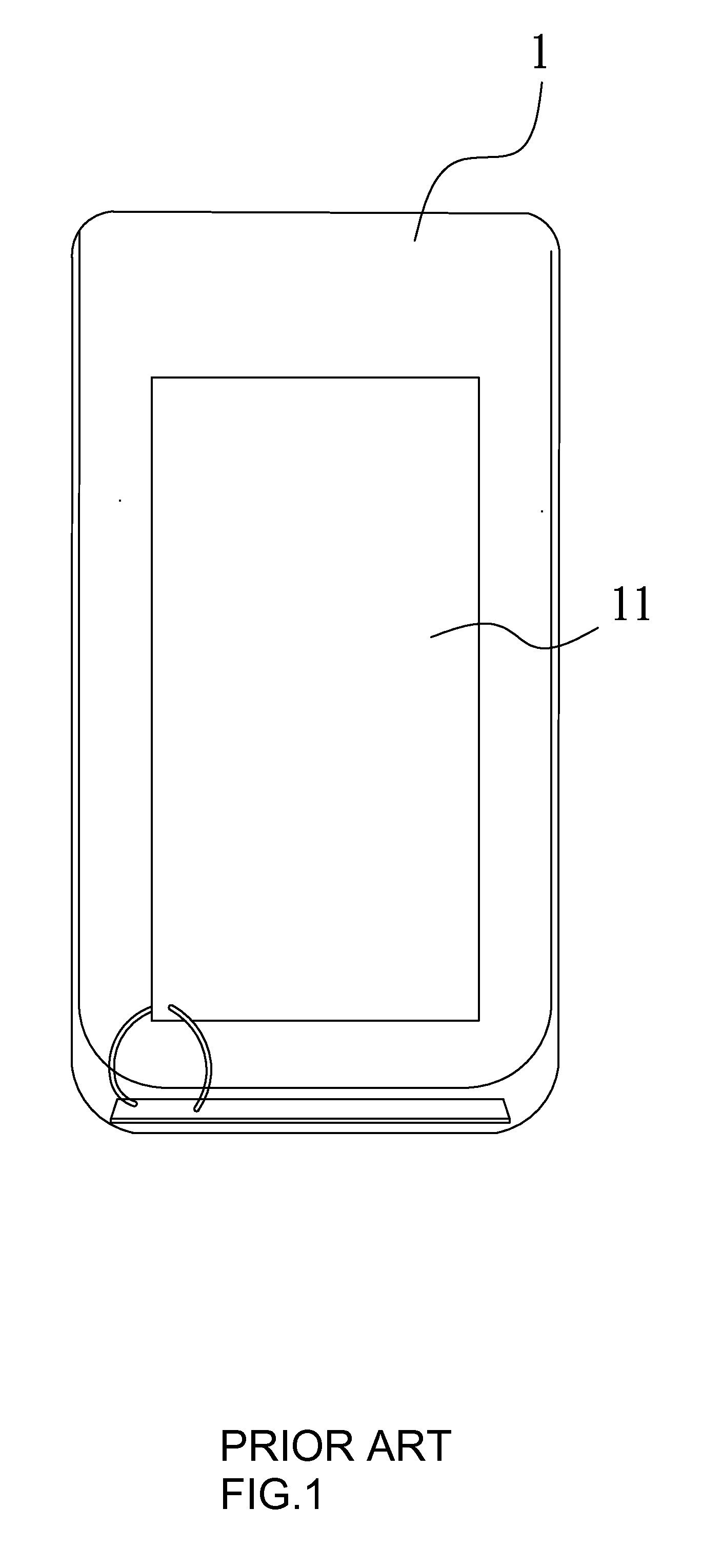

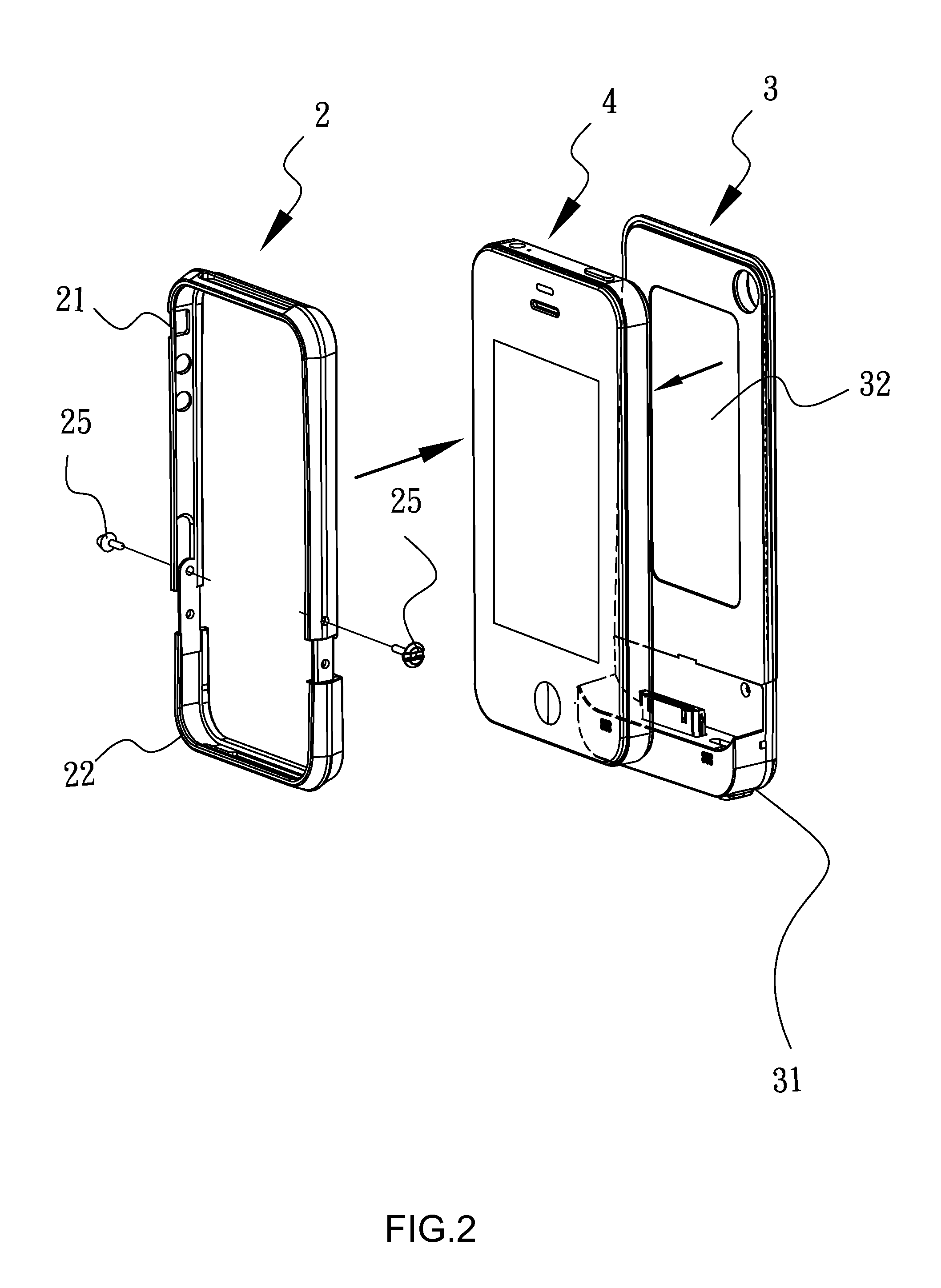

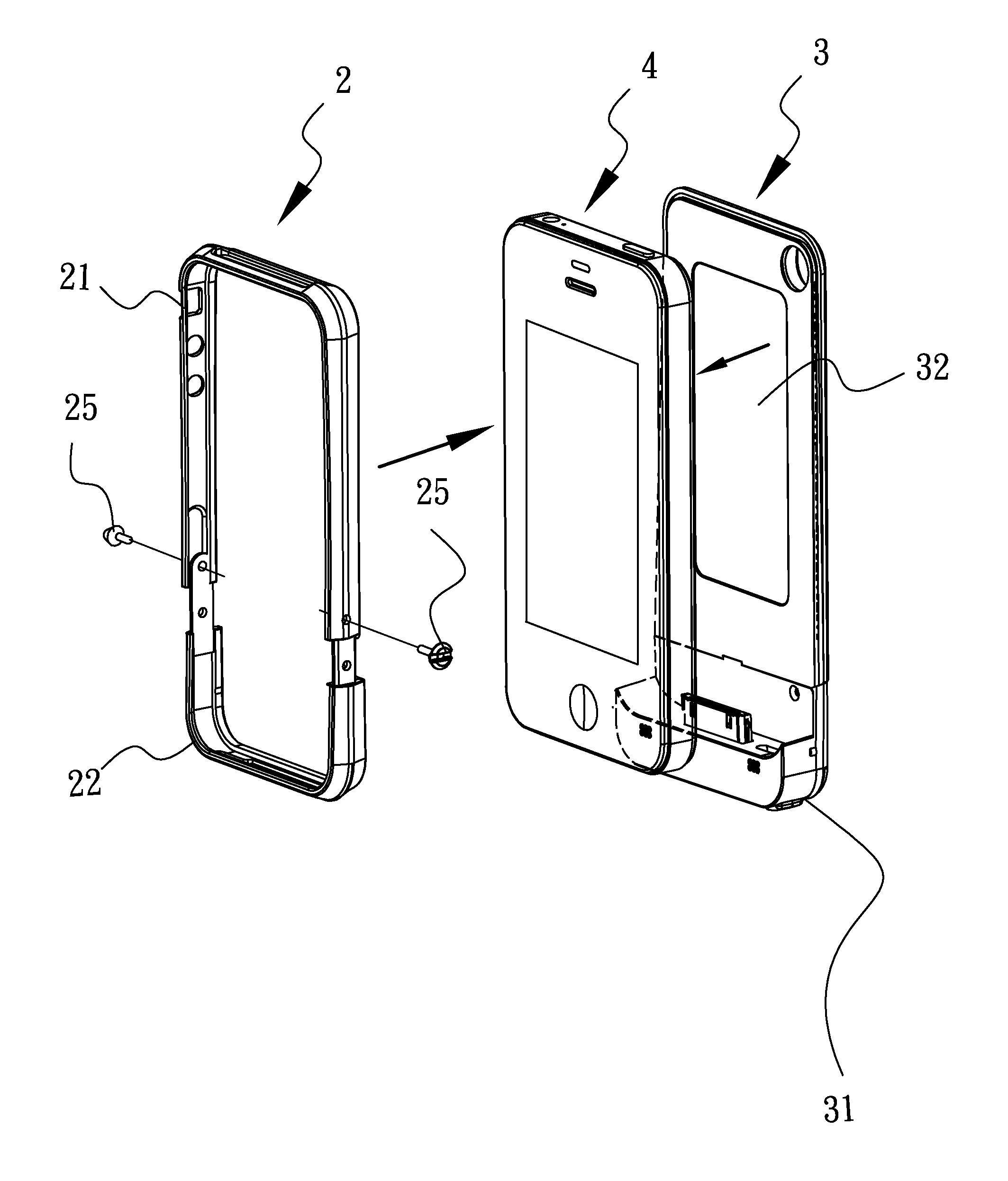

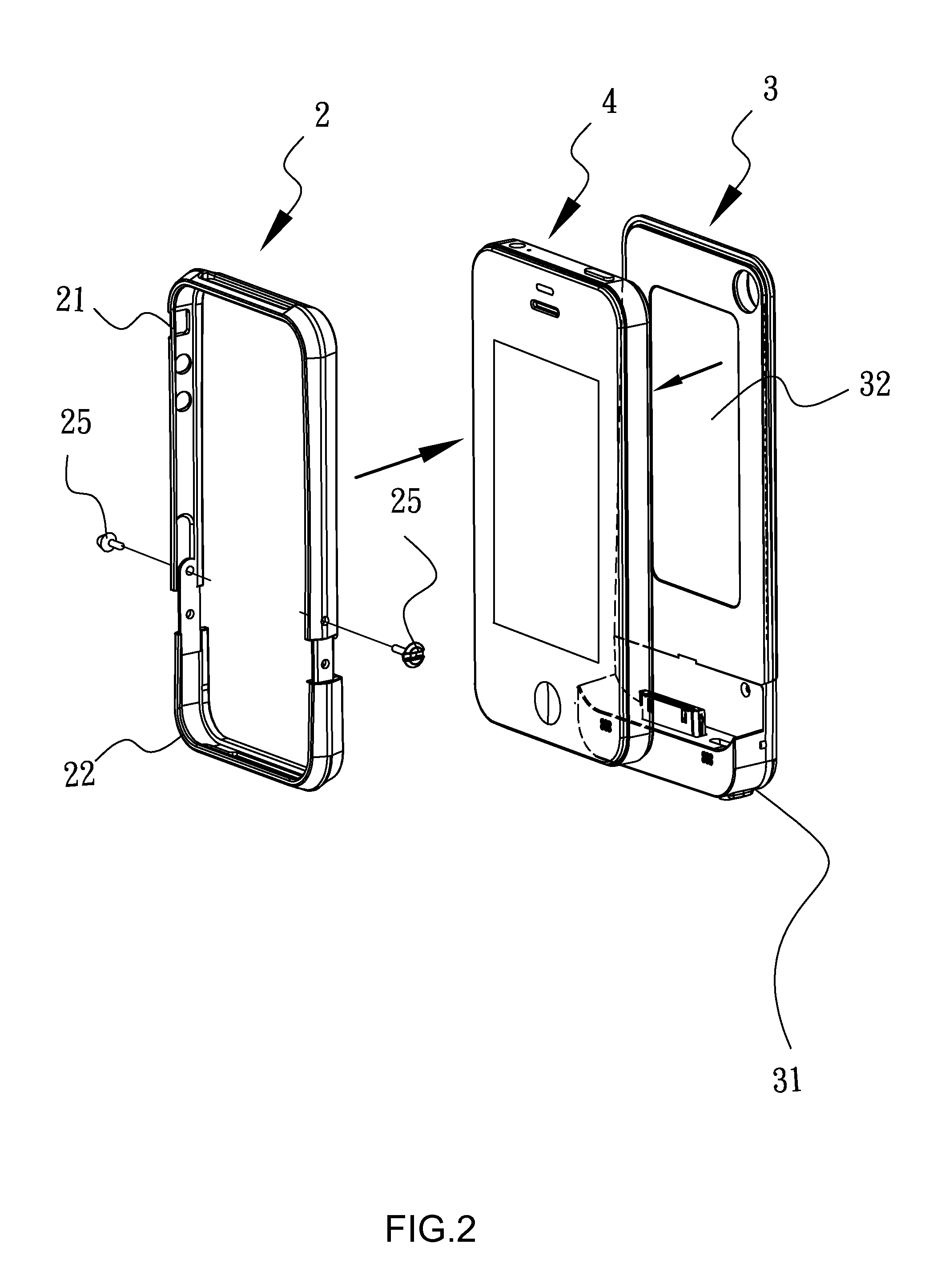

Protective frame for mobile communication device

InactiveUS20130088815A1Minimize size and weightSave spaceDigital data processing detailsElectrical apparatus contructional detailsProtective relayEngineering

The invention relates to a protective frame for a mobile communication device having a power charging port. The protective frame has a retractable frame body, including a main frame body; a sliding element for reciprocatingly sliding along a direction with respect to the main frame body between a retracted protection position where the mobile communication device is fixedly framed by the retractable frame body and a stretched auxiliary power supply position; and a fastening element for fixing the sliding element with respect to the main frame body at the retracted protection position and the stretched auxiliary power supply position. The protective frame also includes an auxiliary battery adapted for being detachably installed in the retractable frame body and electrically connected to the power charging port of the mobile communication device, when the sliding element are fixed with respect to the main frame body at the stretched auxiliary power supply position.

Owner:TAER INNOVATION

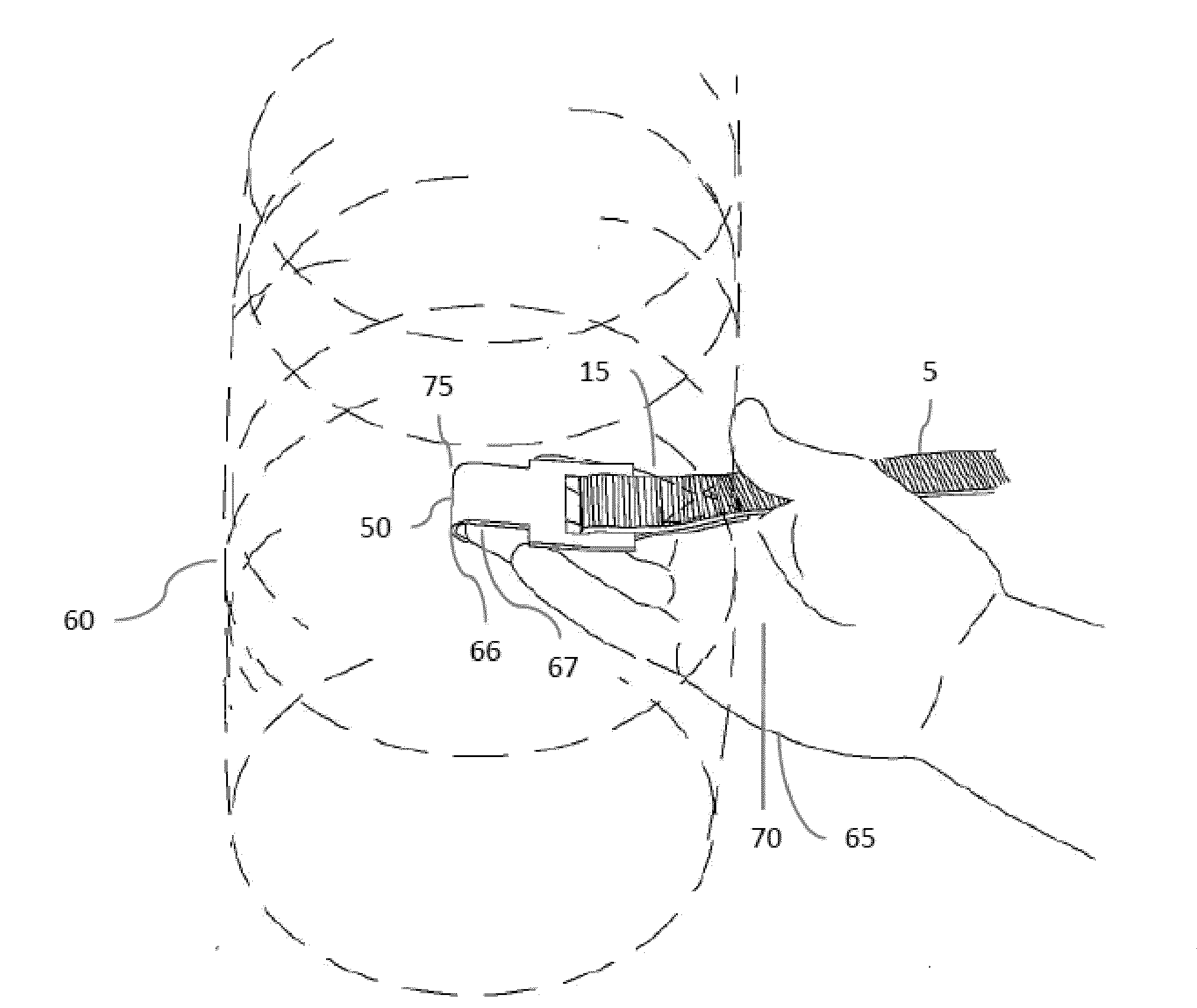

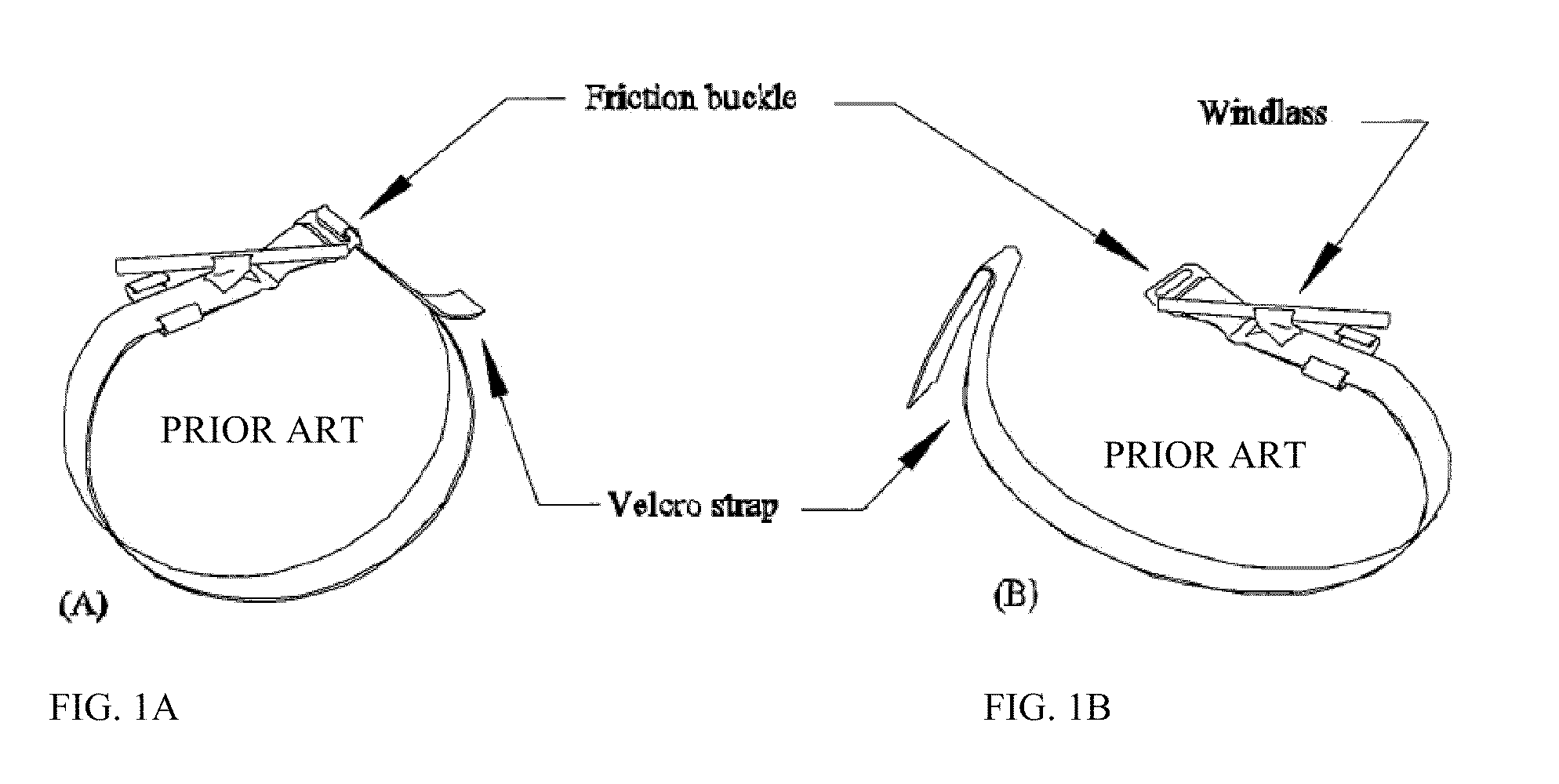

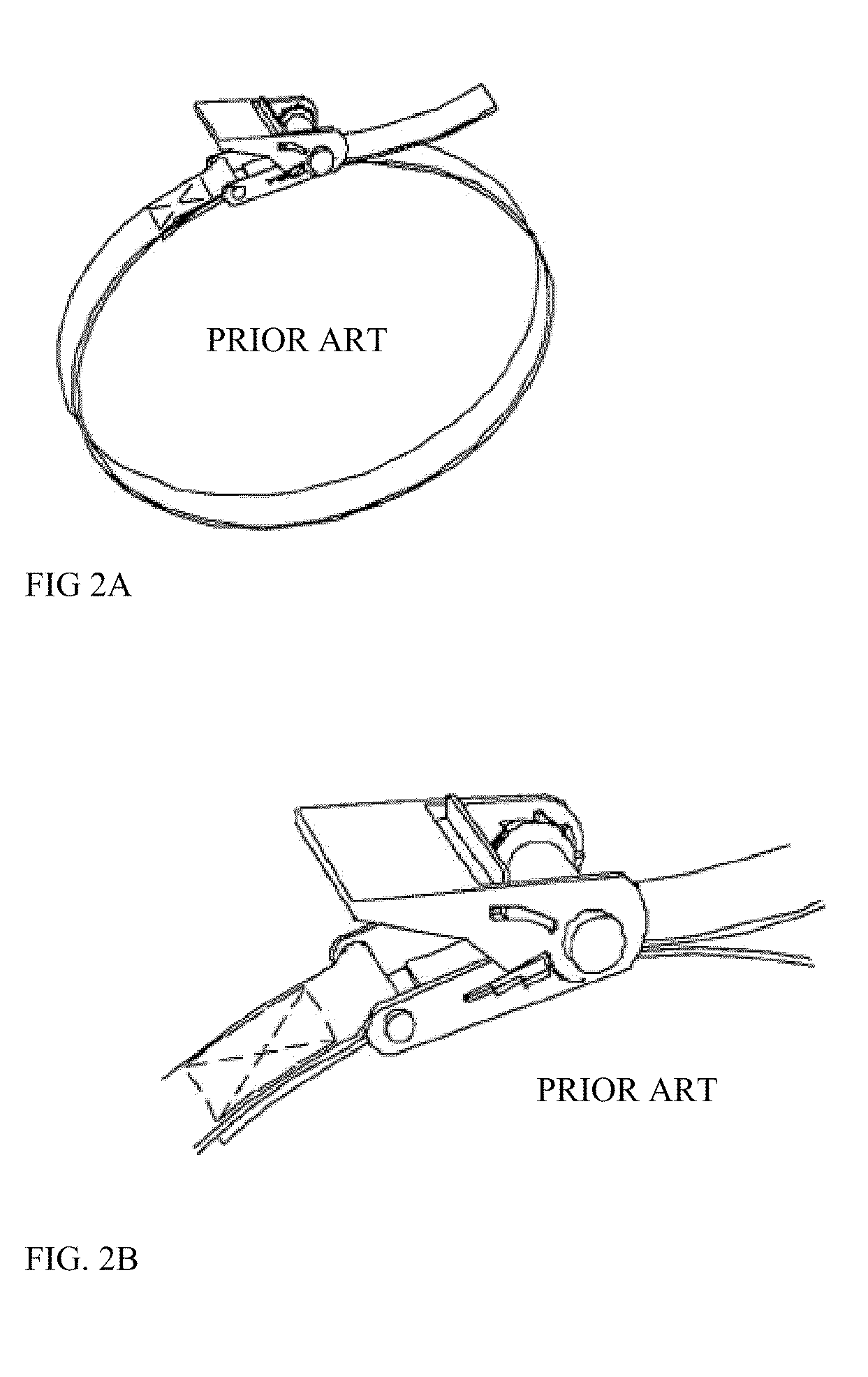

Ratchet hook tourniquet

InactiveUS20100049241A1Rapid and secure applicationShorten application timeTourniquetsMechanical engineeringTourniquet time

A novel tourniquet device is disclosed comprising a belt with a separable first end and second end, preferably coupled by hook-and-pin means, said hook being designed so as to be easily discernable from fabric by touch and easily manipulated manually. Constrictive tension is applied preferably by a ratchet action mechanism amongst other means.

Owner:PERSSON JAMES L

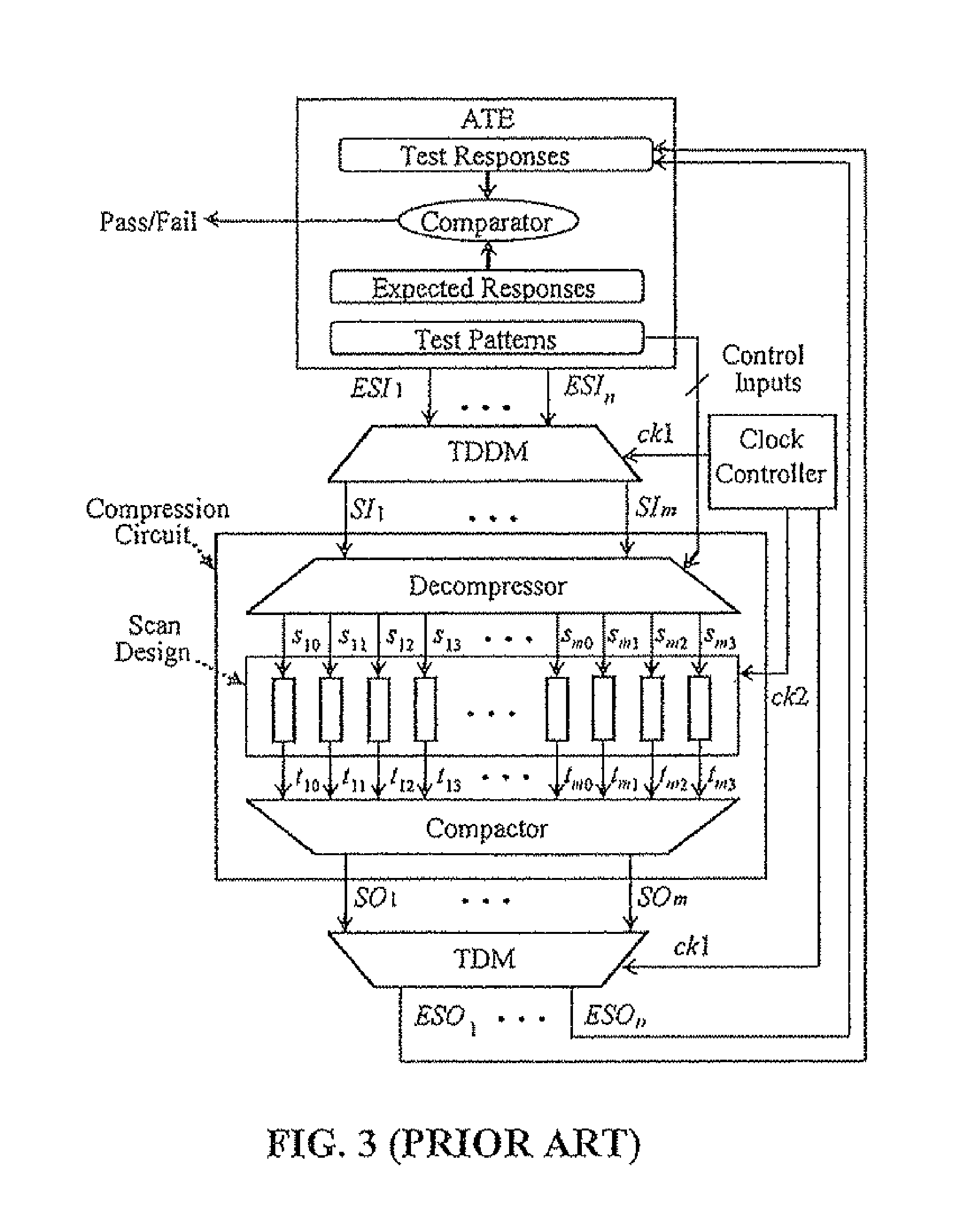

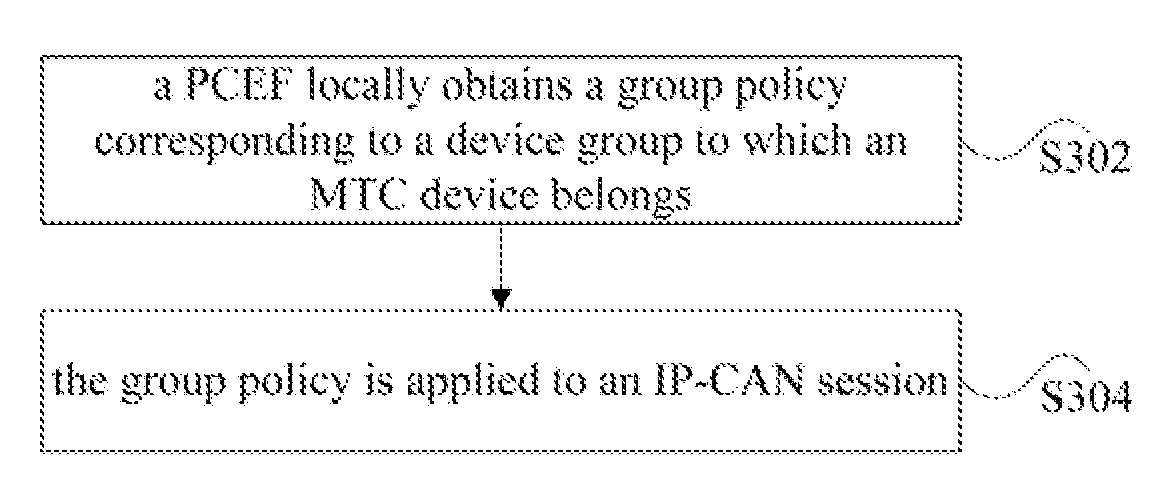

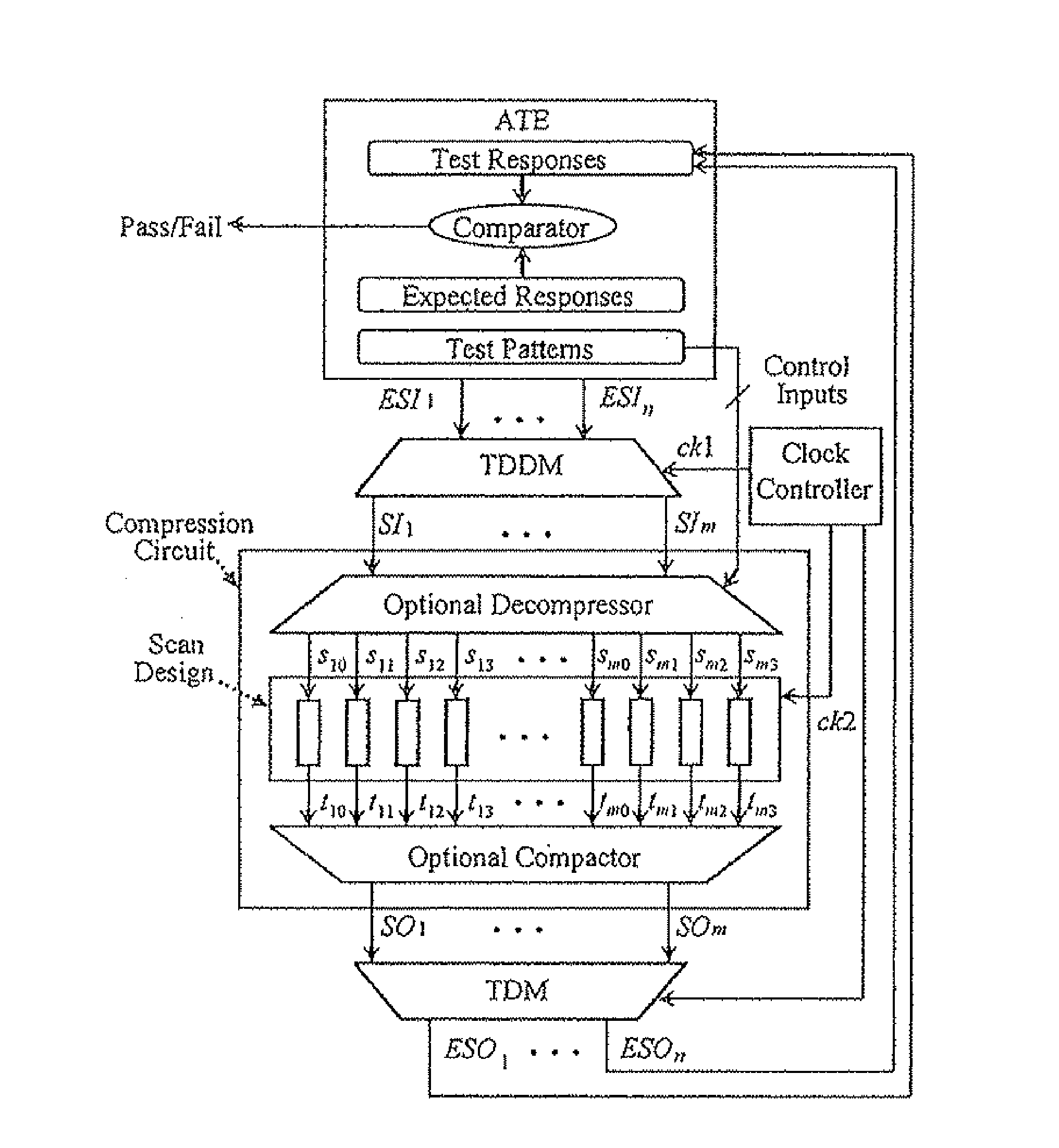

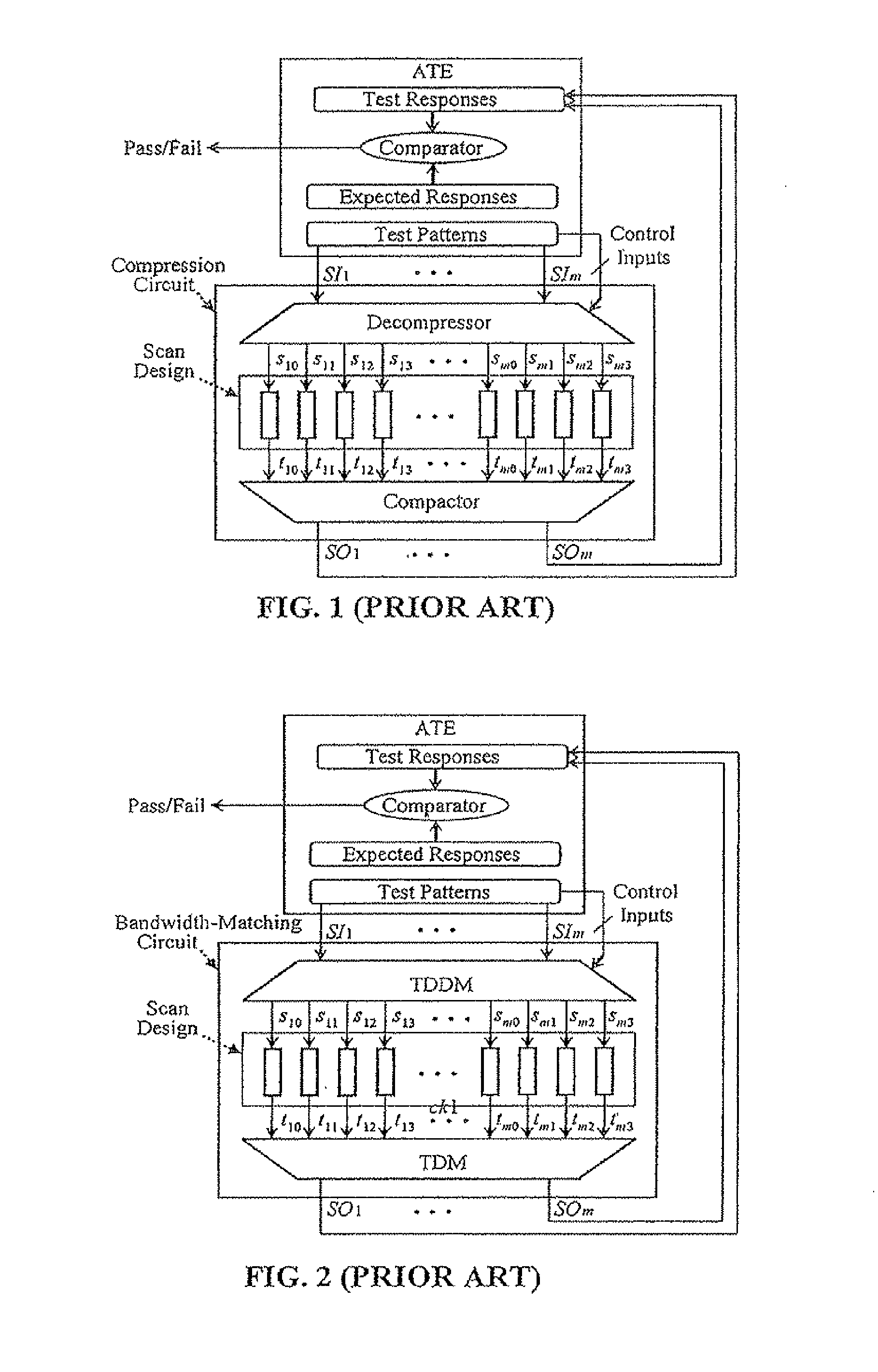

Method and apparatus for testing 3D integrated circuits

InactiveUS8522096B2Reduce testing costsIncrease data rateElectronic circuit testingFault coverageEngineering

A method and apparatus for testing a scan-based 3D integrated circuit (3DIC) using time-division demultiplexing / multiplexing allowing for high-data-rate scan patterns applied at input / output pads converting into low-data-rate scan patterns applied to each embeddded module in the 3DIC. A set of 3D design guidelines is proposed to reduce the number of test times and the number of through-silicon vias (TSVs) required for both pre-bond testing and post-bond testing. The technique allows reuse of scan patterns developed for pre-bond testing of each die (layer) for post-bond testing of the whole 3DIC. It further reduces test application time without concerns for I / O pad count limit and risks for fault coverage loss.

Owner:SYNTEST TECH

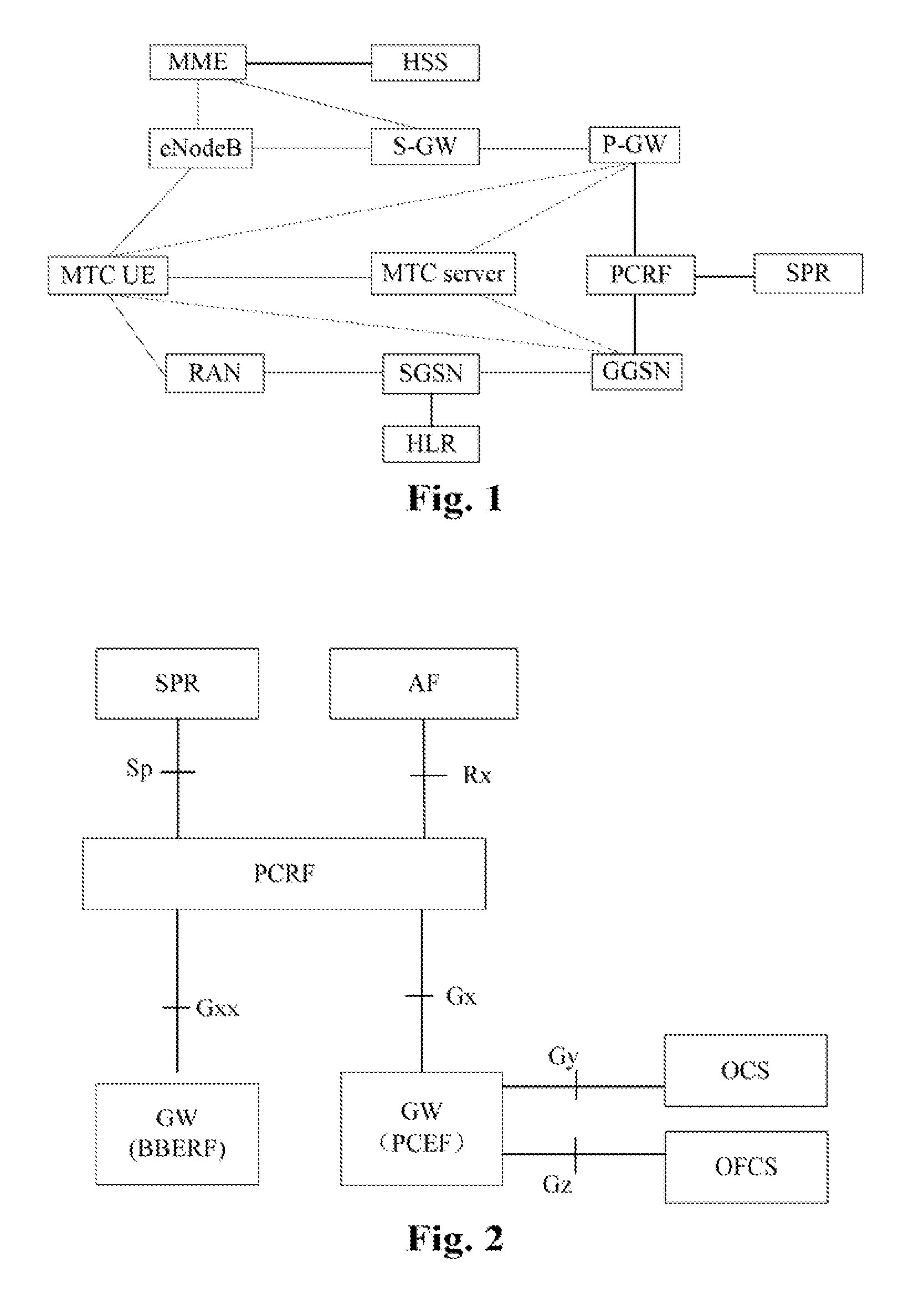

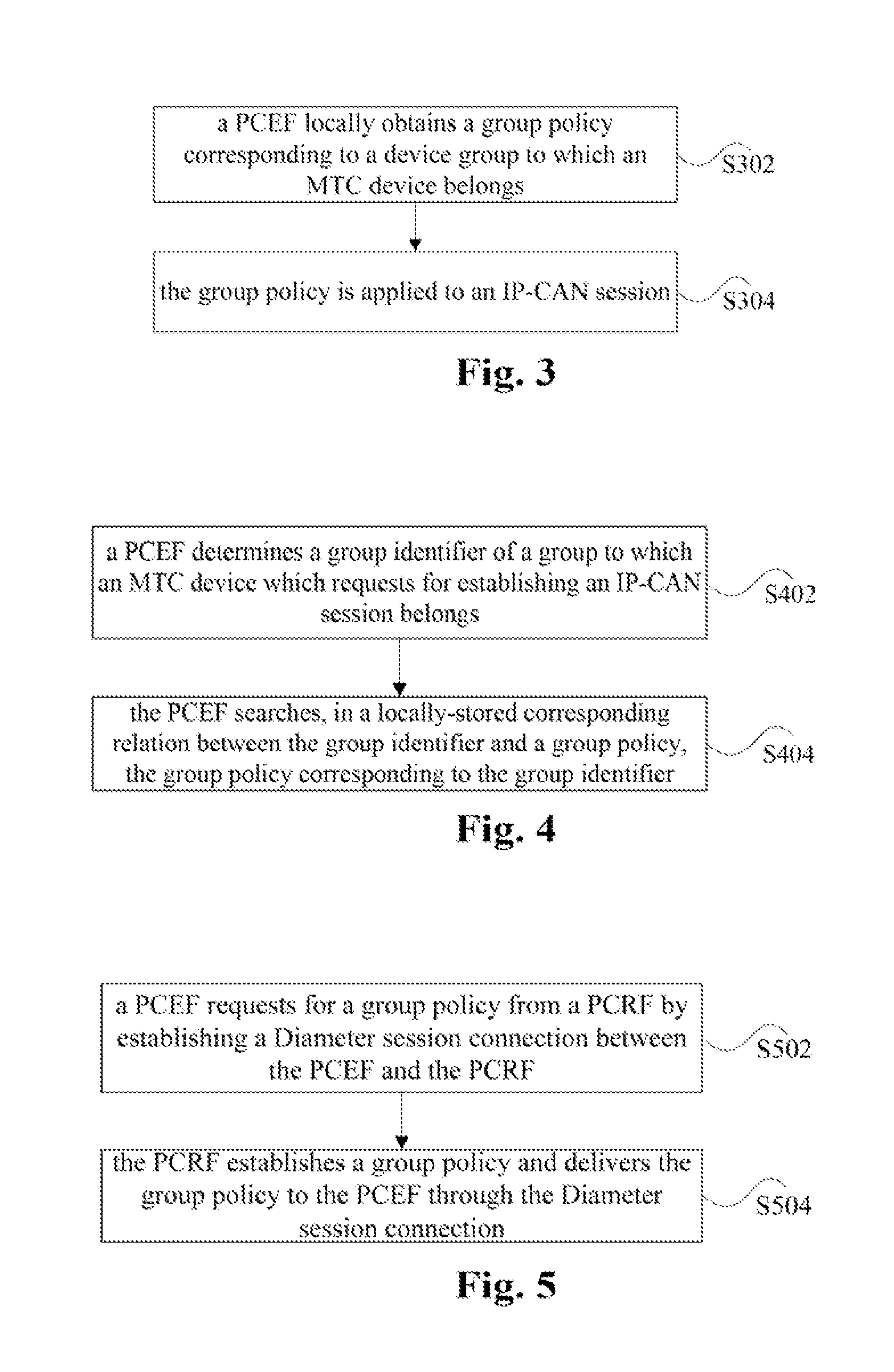

Policy application method for machine type communication, and policy and charging enforcement function

InactiveUS20130044646A1Shorten application timeSave network resourcesSpecial service provision for substationMultiplex system selection arrangementsAccess networkProtocol for Carrying Authentication for Network Access

A policy application method for Machine Type Communication (MTC) and a Policy and Charging Enforcement Function (PCEF) are provided by the disclosure. The method comprises that in a course in which an MTC device attached to a PCEF establishes an Internet Protocol-Connectivity Access Network (IP-CAN) session, the PCEF locally obtains a group policy corresponding to a device group to which the MTC device belongs (S302); the group policy is applied in the IP-CAN session (S304). The technical solution of the disclosure reduces the time required by applying the MTC policy by the PCEF, saves network resources, and increases utilization of the network resources.

Owner:ZTE CORP

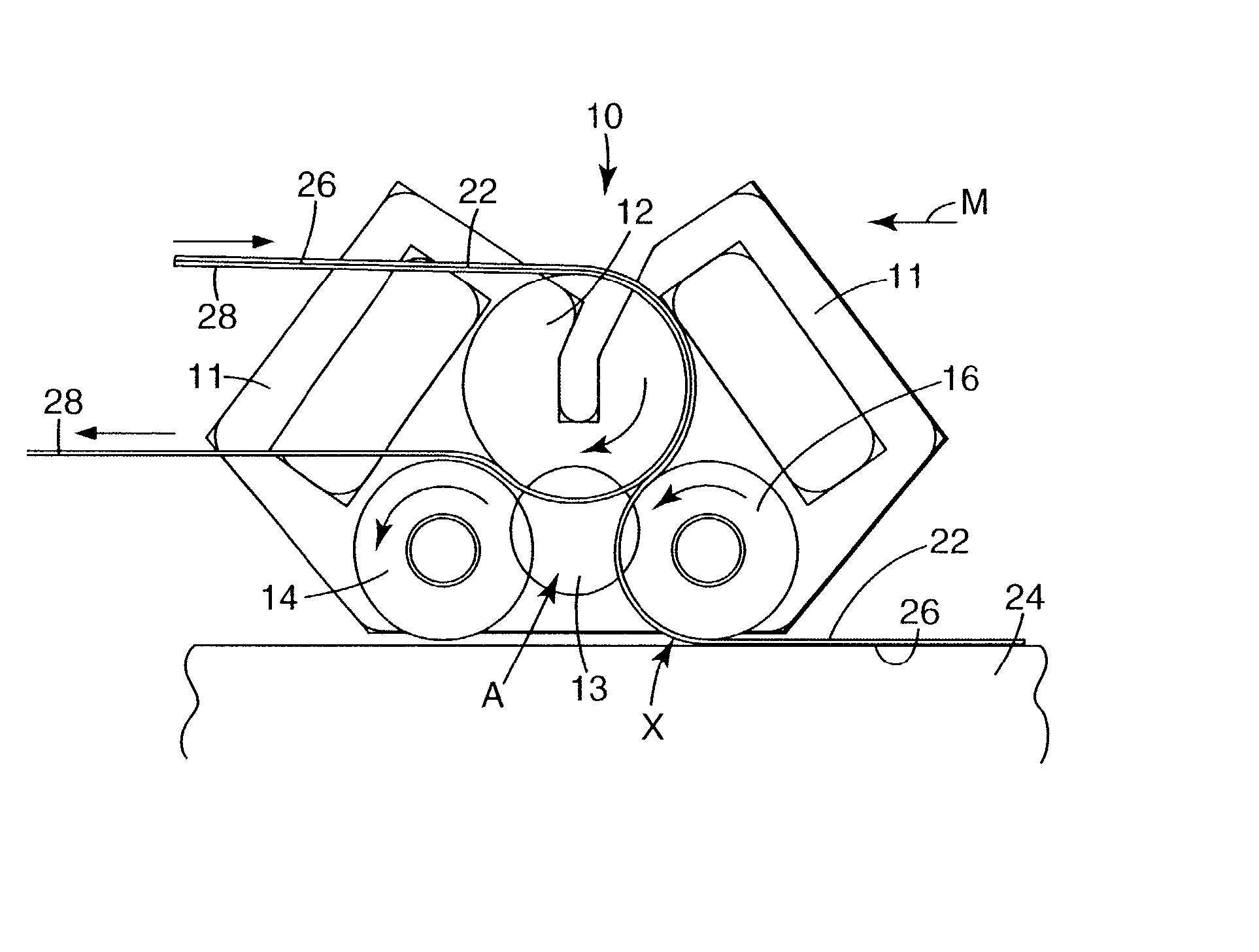

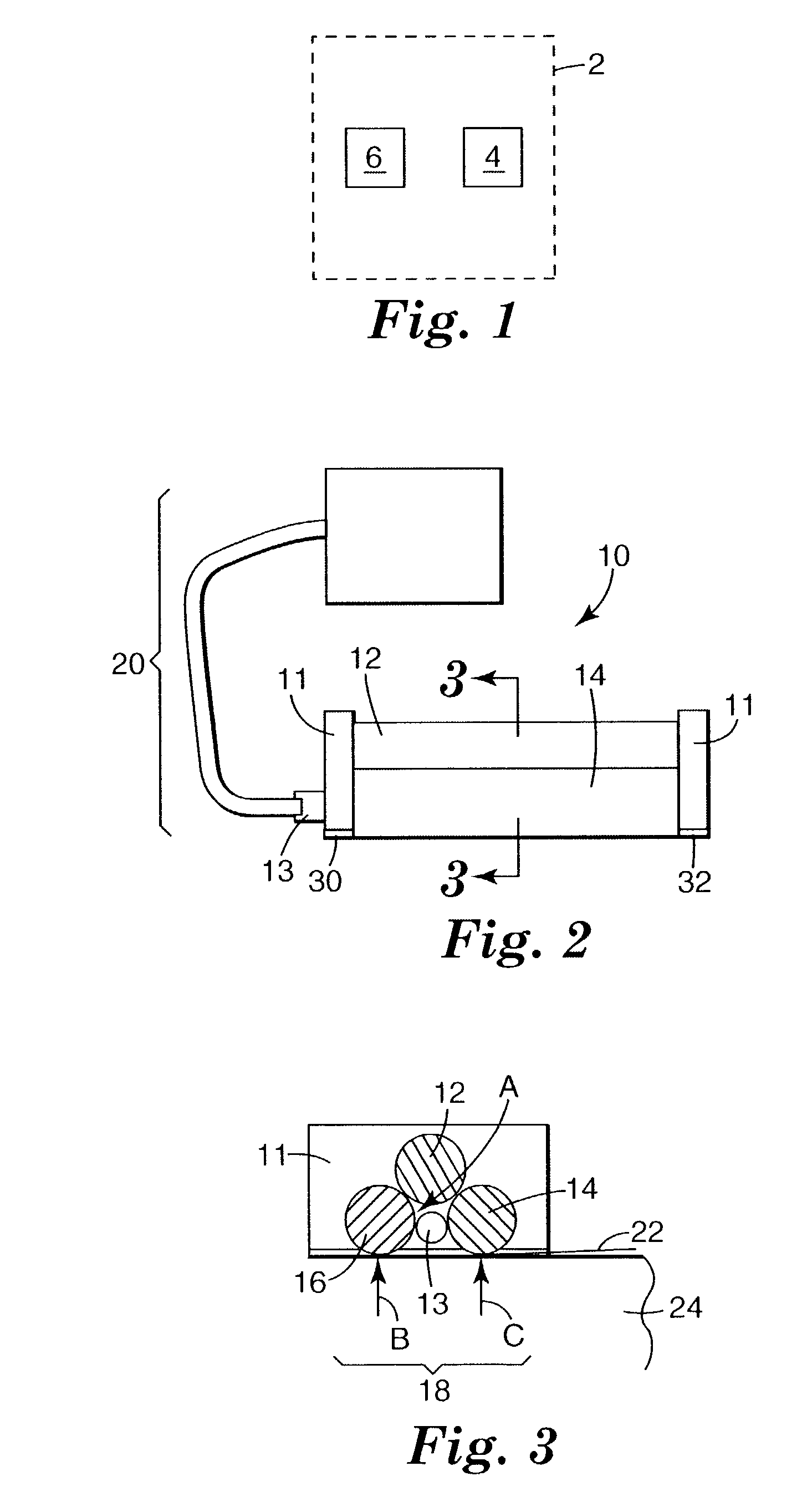

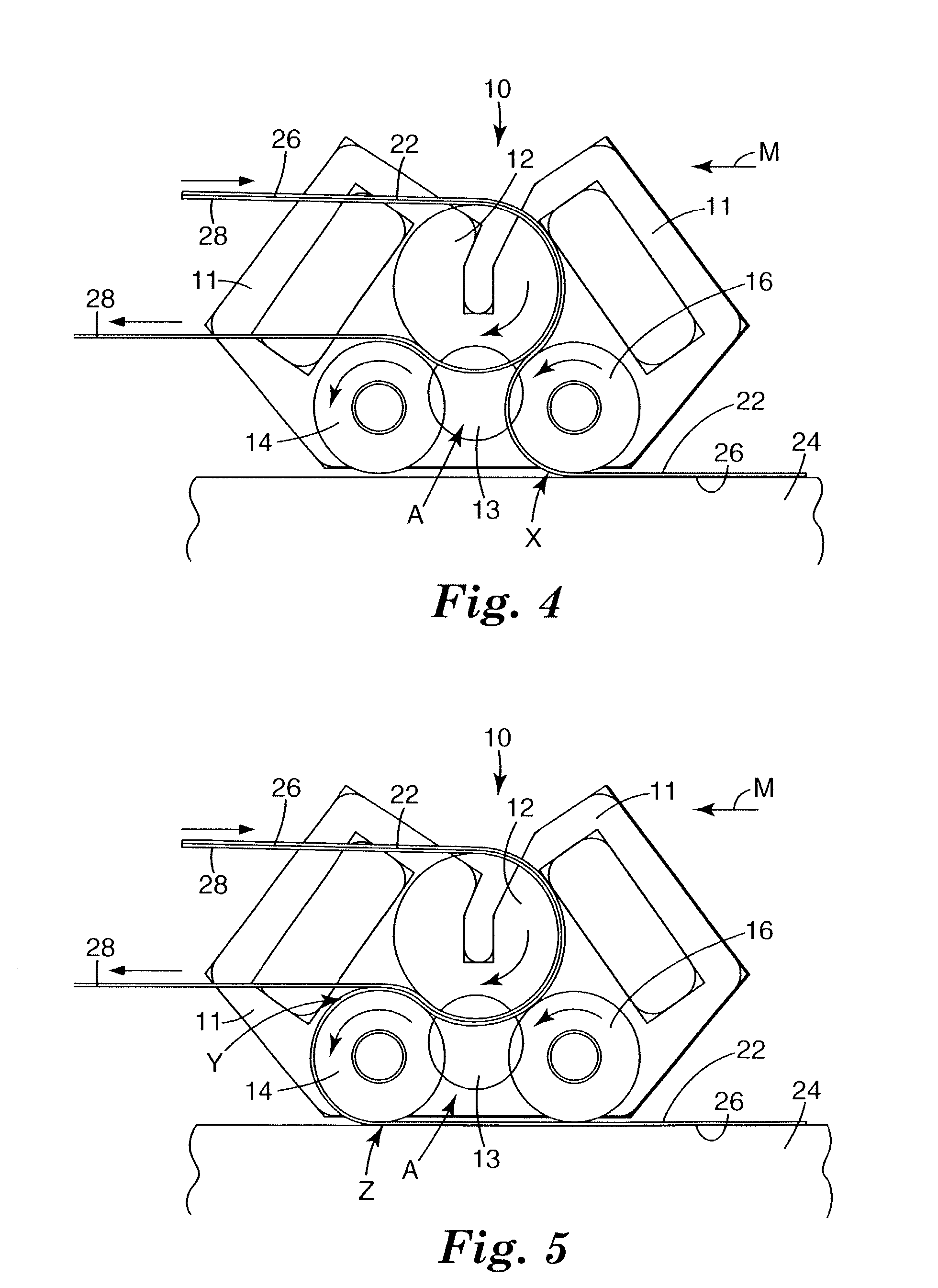

Film lamination and removal system and methods of use

InactiveUS20030015298A1Reduce riskReduce and prevent likelihoodMechanical working/deformationCovering/liningsVacuum assistedAdhesive

Vacuum-assisted film laminating and removal systems and methods of using the same. The systems include a vacuum-assisted laminator for applying large format films to substrates where lamination pressure is generated at least partially by a vacuum drawn in a vacuum cavity. The removal apparatus applies tension over the width of the adhesive film, thereby removing the film from the substrate along the release line that extends over the width of the film. The systems and methods can be used to apply and remove large-scale adhesive films from substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Protective frame for mobile communication device

InactiveUS8634887B2Preferable option and application flexibilityEfficient implementationDigital data processing detailsSubstation equipmentEngineeringCommunication device

The invention relates to a protective frame for a mobile communication device having a power charging port. The protective frame has a retractable frame body, including a main frame body; a sliding element for reciprocatingly sliding along a direction with respect to the main frame body between a retracted protection position where the mobile communication device is fixedly framed by the retractable frame body and a stretched auxiliary power supply position; and a fastening element for fixing the sliding element with respect to the main frame body at the retracted protection position and the stretched auxiliary power supply position. The protective frame also includes an auxiliary battery adapted for being detachably installed in the retractable frame body and electrically connected to the power charging port of the mobile communication device, when the sliding element are fixed with respect to the main frame body at the stretched auxiliary power supply position.

Owner:TAER INNOVATION

Scan test application through high-speed serial input/outputs

ActiveUS8726112B2Reduce test data volumeMinimize timeElectronic circuit testingData compressionAsynchronous operation

Methods and devices for using high-speed serial links for scan testing are disclosed. The methods can work with any scheme of scan data compression or with uncompressed scan testing. The protocol and hardware to support high speed data transfer reside on both the tester and the device under test. Control data may be transferred along with scan data or be partially generated on chip. Clock signals for testing may be generated on chip as well. In various implementations, the SerDes (Serializer / Deserializer) may be shared with other applications. The Aurora Protocol may be used to transport industry standard protocols. To compensate for effects of asynchronous operation of a conventional high-speed serial link, buffers may be used. The high-speed serial interface may use a data conversion block to drive test cores.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Method and apparatus for testing 3D integrated circuits

InactiveUS20120110402A1Reduce testing costsIncrease data rateElectronic circuit testingLogical operation testingFault coverageEngineering

A method and apparatus for testing a scan-based 3D integrated circuit (3DIC) using time-division demultiplexing / multiplexing allowing for high-data-rate scan patterns applied at input / output pads converting into low-data-rate scan patterns applied to each embeddded module in the 3DIC. A set of 3D design guidelines is proposed to reduce the number of test times and the number of through-silicon vias (TSVs) required for both pre-bond testing and post-bond testing. The technique allows reuse of scan patterns developed for pre-bond testing of each die (layer) for post-bond testing of the whole 3DIC. It further reduces test application time without concerns for I / O pad count limit and risks for fault coverage loss.

Owner:SYNTEST TECH

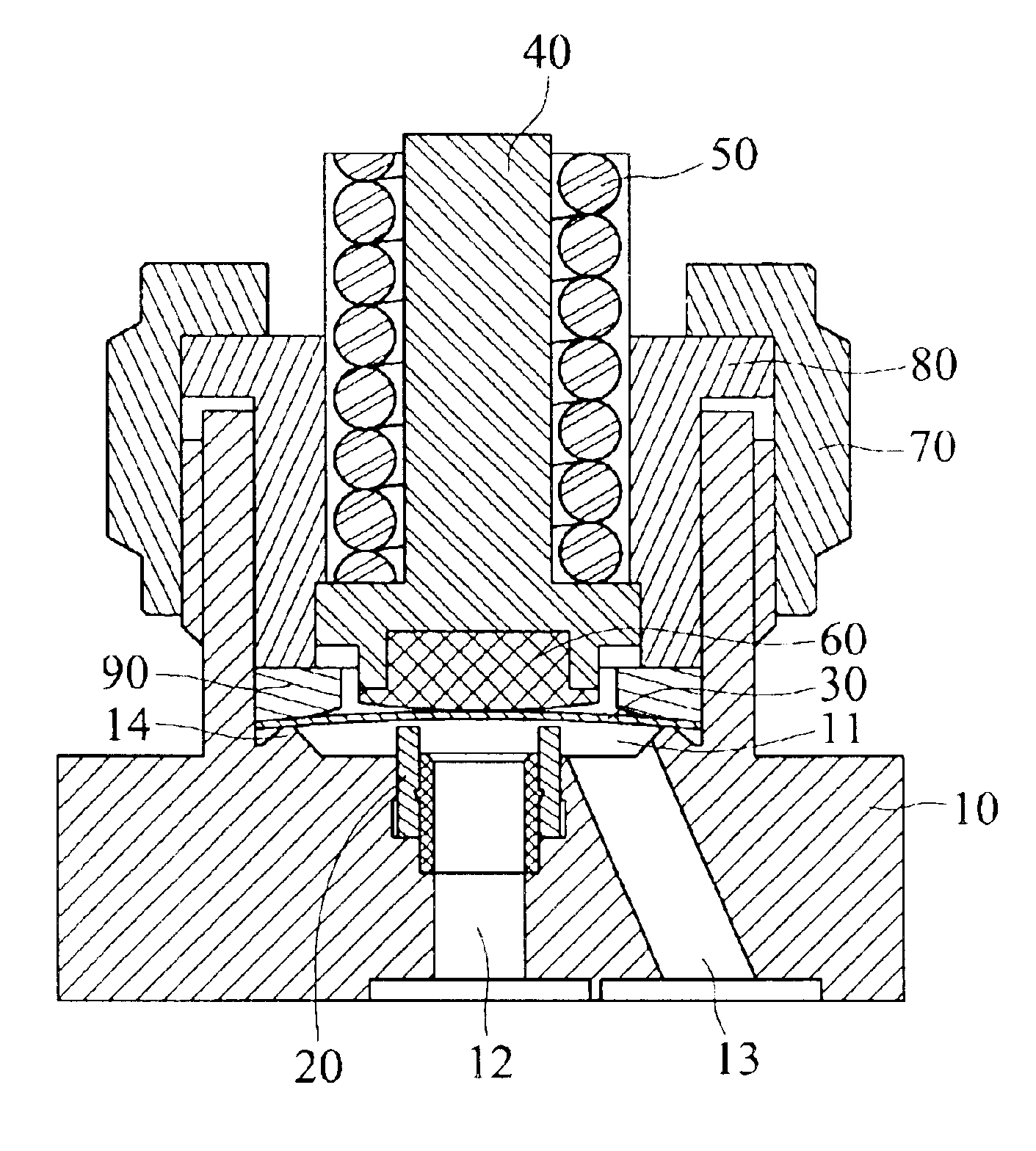

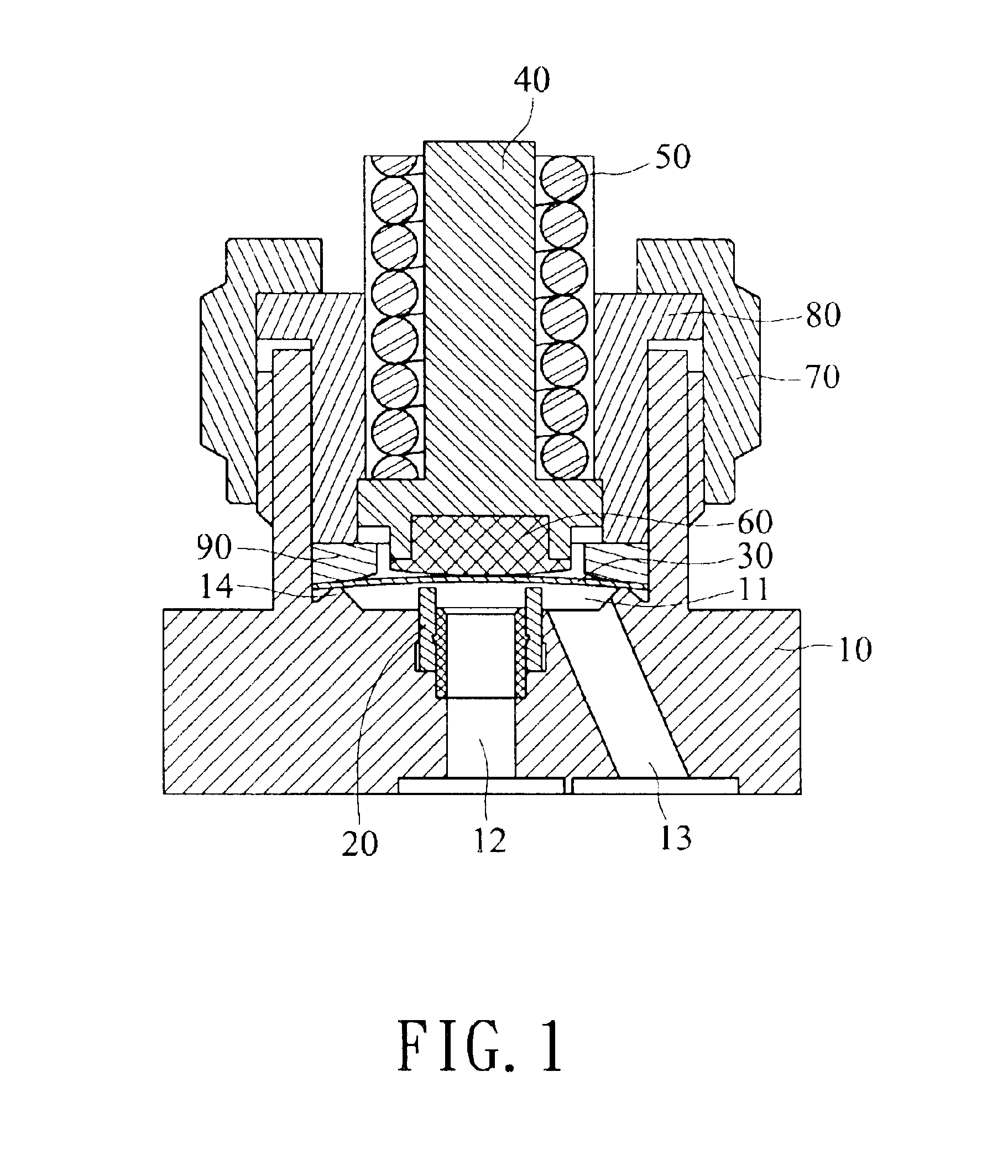

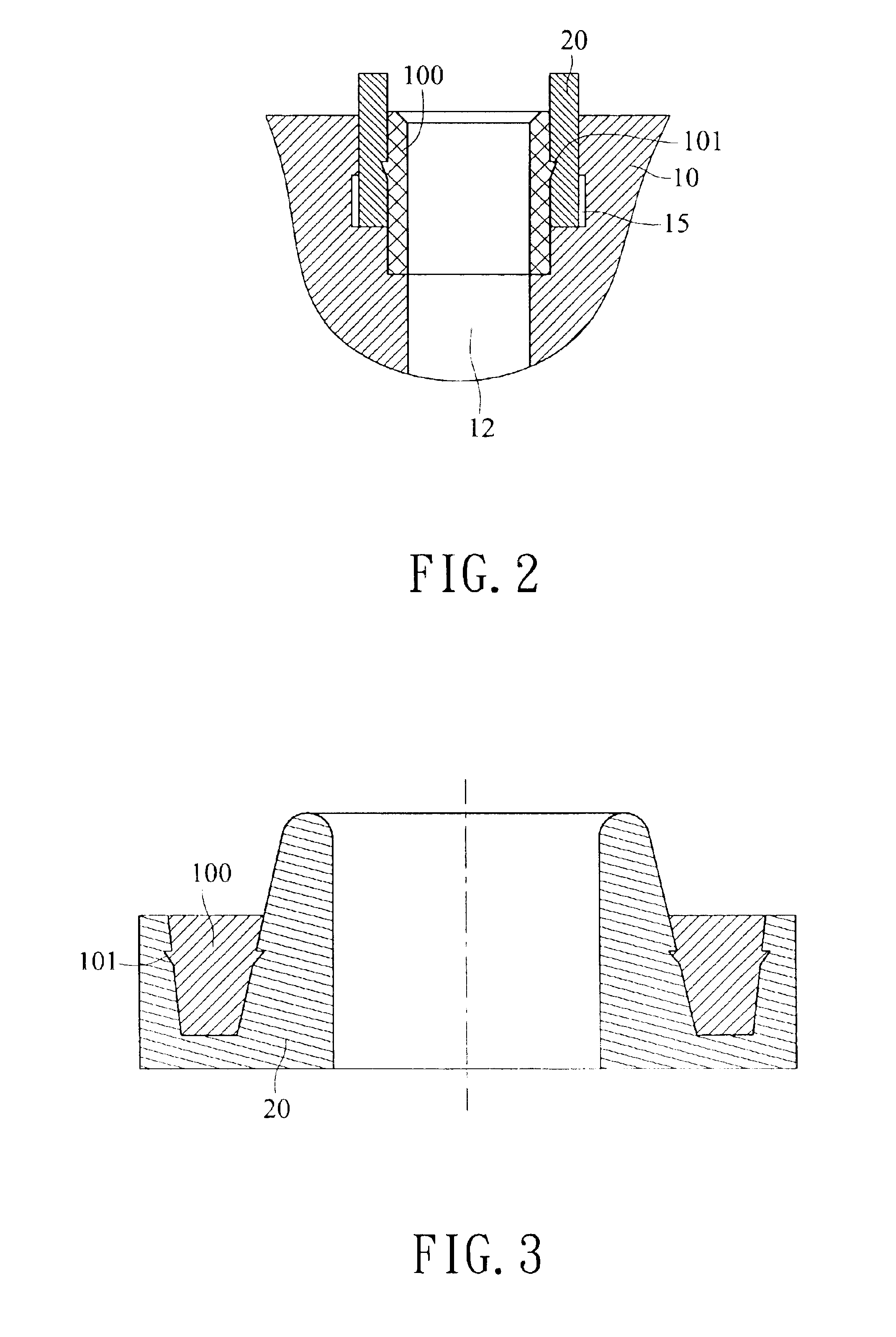

Diaphragm valve

InactiveUS6854713B2Low leakage rateIncrease time of applicationDiaphragm valvesEngine diaphragmsLeakage rateAirflow

The diaphragm valve uses a metal dish-type diaphragm set to control the inflow and outflow of fluid. The metal dish-type diaphragm set is above an air flow channel to control the stem above the metal dish-type diaphragm set, and the air will be blocked by pressing the metal dish-type diaphragm to make it fit the metal valve base in the air flow channel; this non-metal valve base is fixed in the air flow channel by a fixed shrunk ring with a taper cross section, and the in-between metal diaphragm in the metal dish-type diaphragm set is annular in the center to reduce the metallic friction between metal diaphragms, to increase application times and to lower the leakage rate of the diaphragm valve.

Owner:IND TECH RES INST

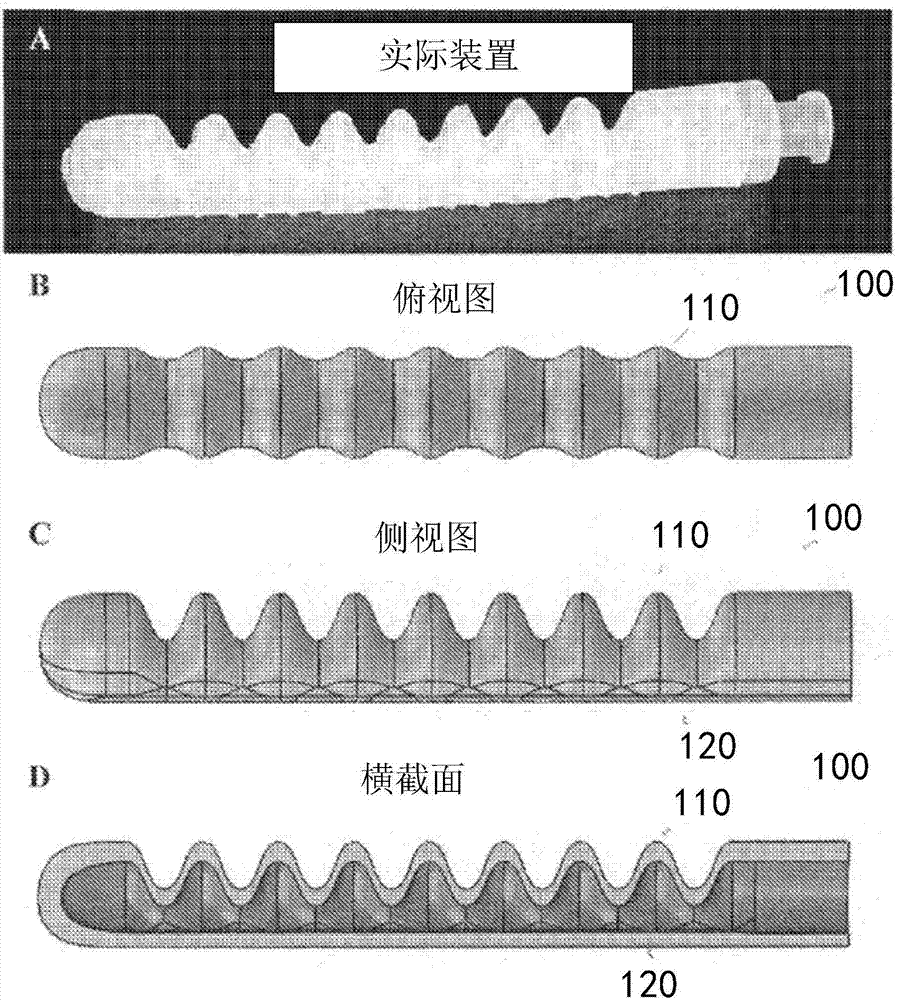

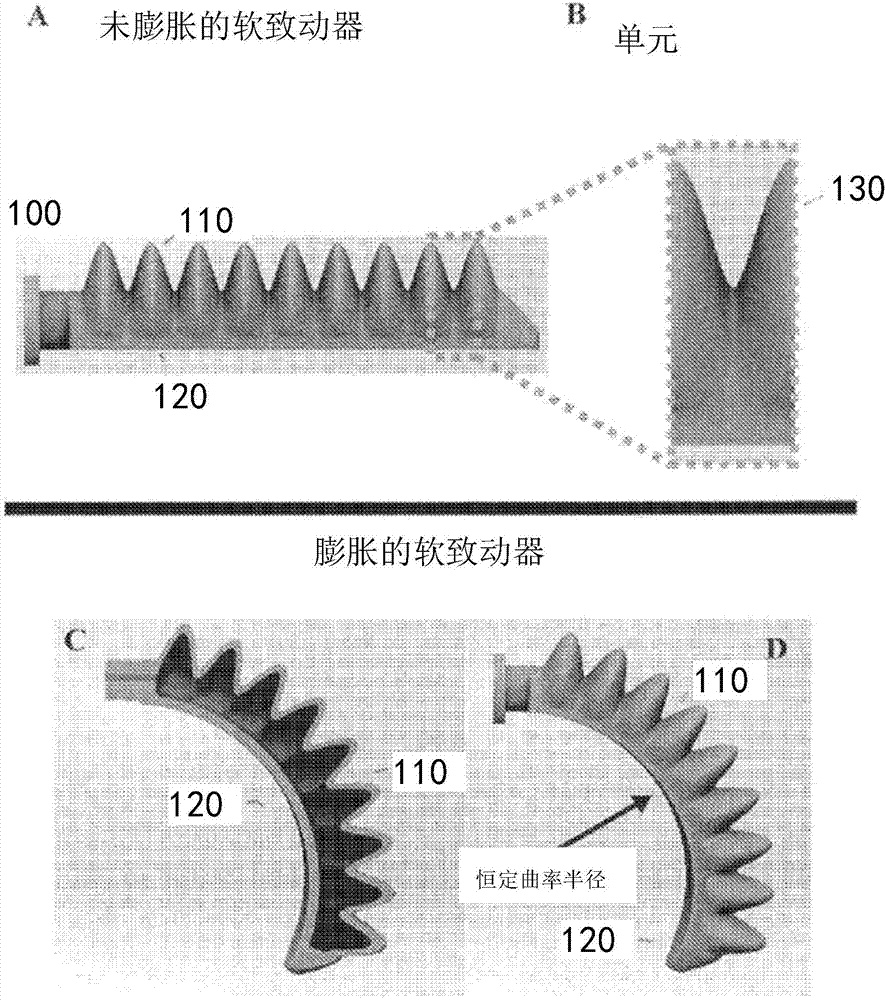

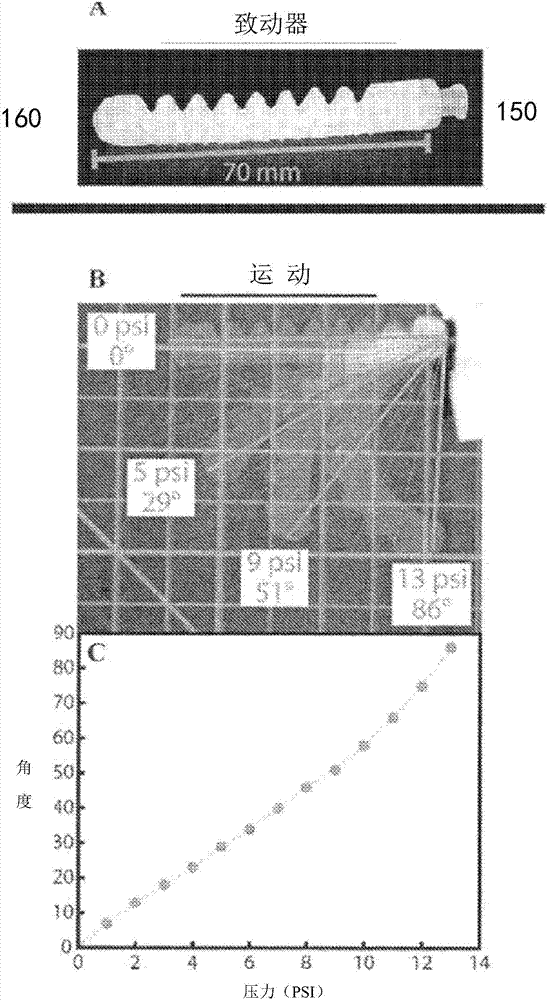

Soft robotic actuators utilizing asymmetric surfaces

InactiveCN107002721ASimplify the modeling processSimplify the design processProgramme-controlled manipulatorGripping headsInternal pressureControl theory

A soft robotic actuator is disclosed. The actuator includes a first portion with a substantially constant profile and a second portion with a regularly varying profile, and bends in a pressure-dependent fashion as the internal pressure within the actuator is increased or decreased. The present invention addresses the needs described above by providing actuators that are configured to perform new fundamental motions through the inclusion of design elements which can be configured, through the manipulation of a relatively short list of parameters, to undergo specific pressure-actuated changes which can be designed using quantitative modeling techniques.

Owner:SOFT ROBOTICS

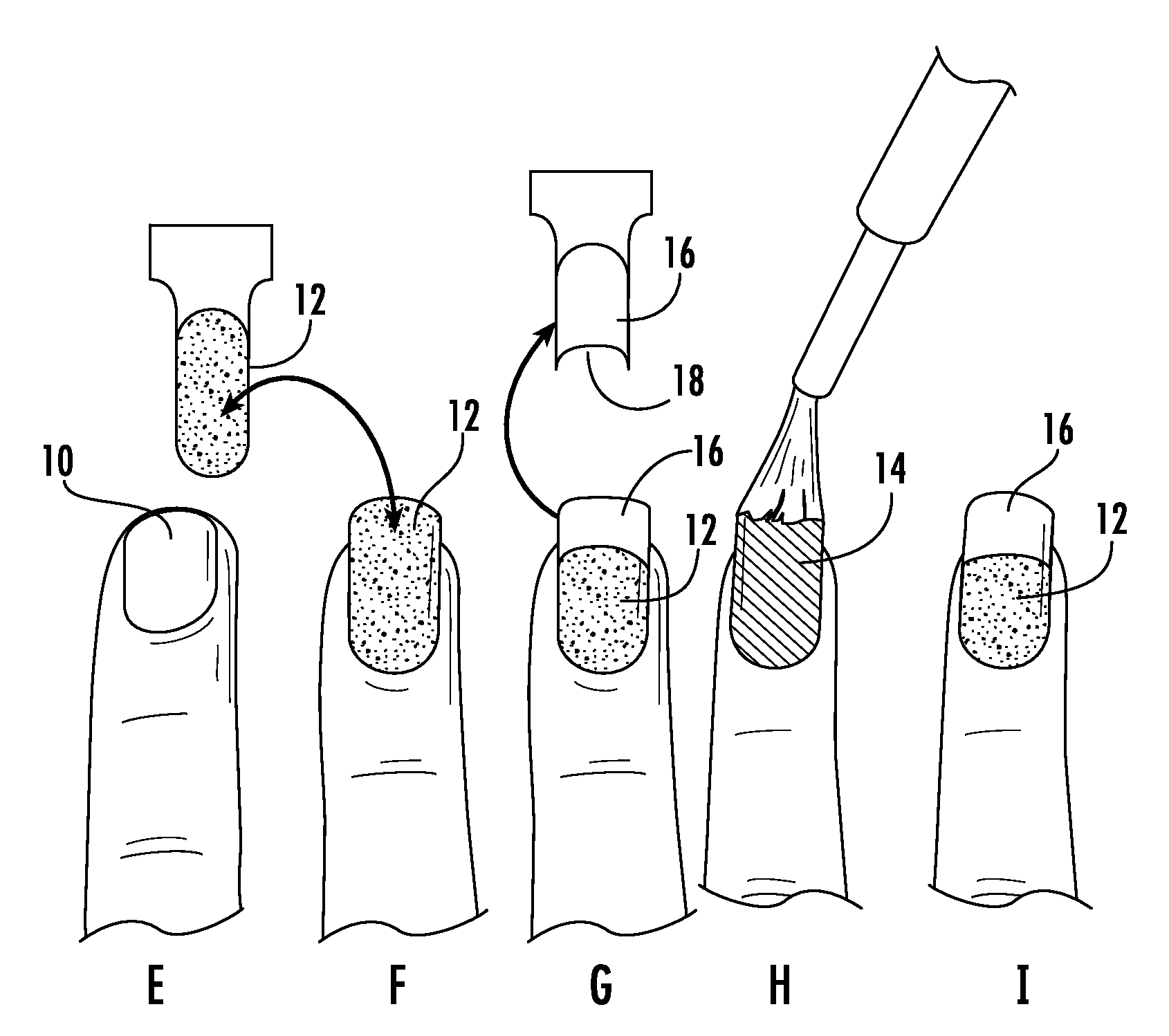

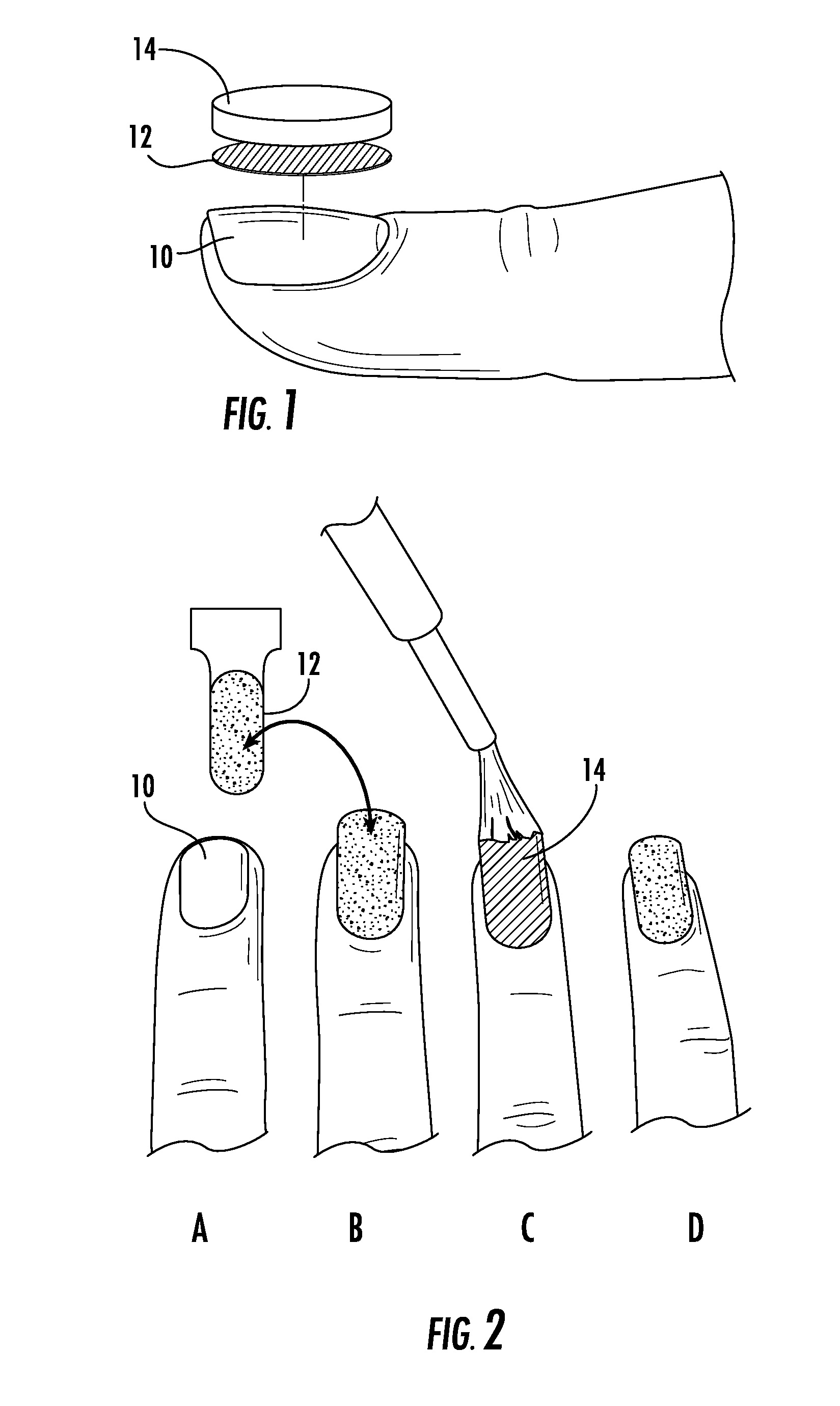

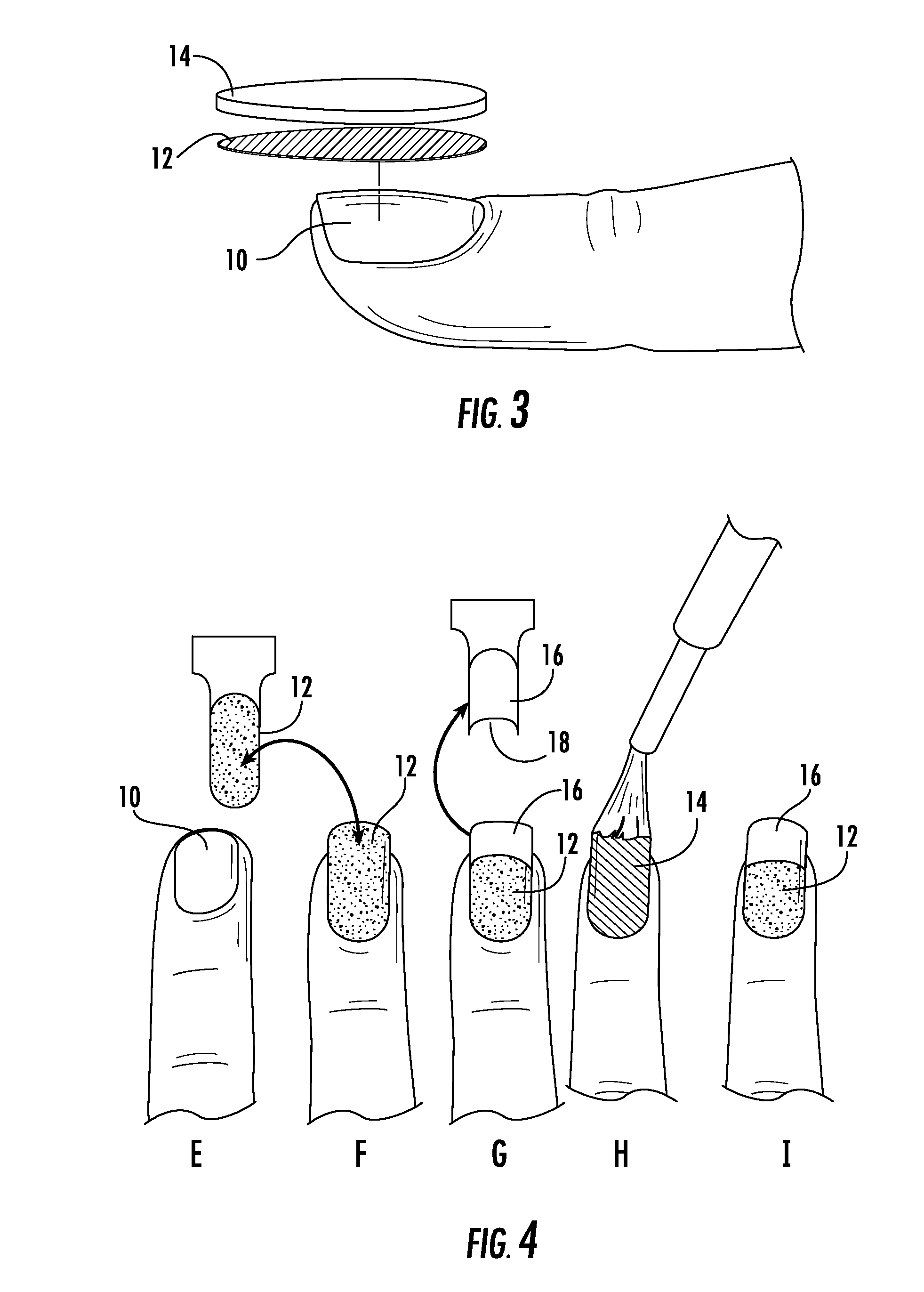

Method and Apparatus for Enhancing UV Gel Nail Application

ActiveUS20120103354A1Shorten application timeReduce exposureCurling devicesManicure/pedicureUltravioletChemistry

A method of applying a UV gel manicure to a fingernail and a method for achieving a UV gel fingernail extension. First a nail appliqué made of dry nail enamel is applied to a fingernail. A UV gel is then applied with a brush on top of nail appliqué and is cured using a UV lamp. The result is a UV manicure that applied faster than a conventional UV manicure and it is healthier for a nail. UV nail extensions are achieved by applying an appliqué which overhangs from a fingernail and applying and curing UV gel on top of the appliqué.

Owner:PARK FA YOUNG

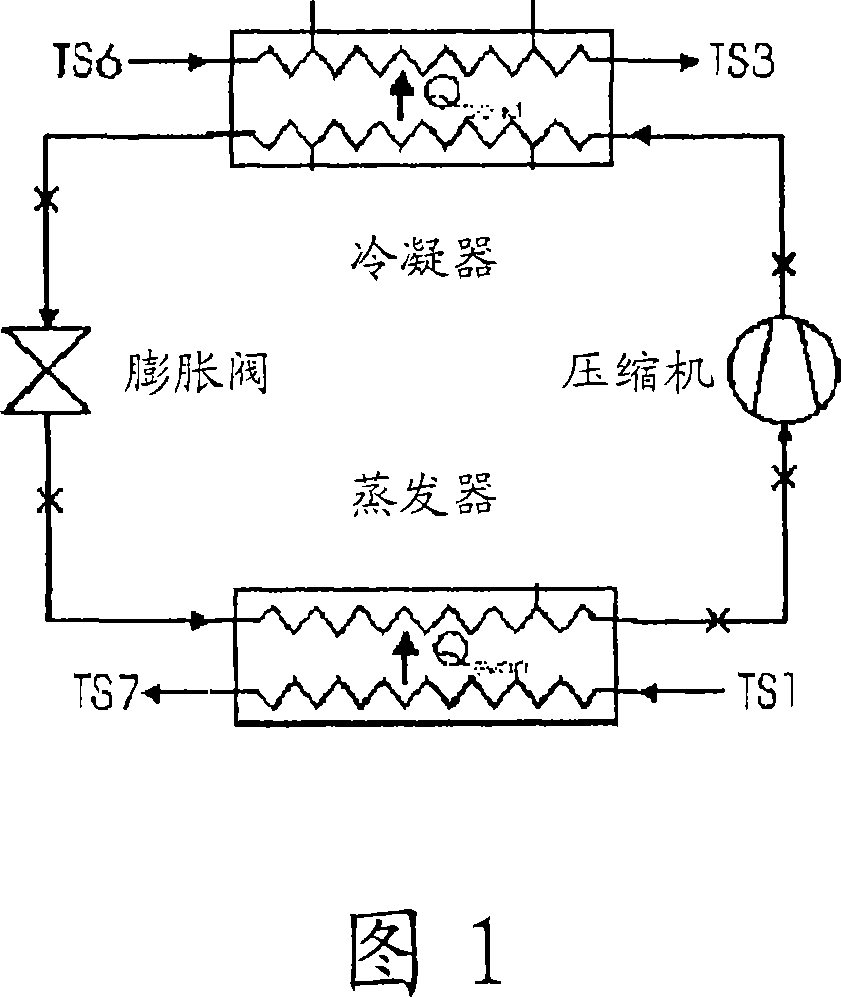

R502, r12 or r22 substitute mixed refrigerant and refrigeration system using thereof

InactiveCN101006154AAvoid destructionLow application costOrganic chemistryCompression machines with non-reversible cycleEngineeringRefrigeration

The present invention relates to a refrigerant mixture for substituting R502, R22 or R12 used in a vapor compression refrigerator or air conditioner and a refrigeration system using the same. More specifically, the present invention relates to a refrigerant mixture comprising a combination of two or three components, which is capable of being used without causing ozone layer destruction and global warming and at the same time, without replacement of the existing refrigeration system, wherein the components are selected from the group consisting of propylene, propane, 1,1,1,2-tetrafluoroethane, pentafluoroe thane, 1,1,1-trifluoroethane, 1,1-difluoroethane, dimethylether and isobutane; and a refrigeration system using the same.

Owner:咸允植 +1

Steered vacuum-assisted laminating apparatus and methods of use

InactiveUS20030116265A1Precise applicationGood lookingMechanical working/deformationLamination ancillary operationsVacuum assistedSteering system

Steered vacuum-assisted laminating apparatus and methods of using the same are disclosed. The apparatus includes a vacuum-assisted laminator for applying large format films to substrates where lamination pressure is generated at least partially by a vacuum drawn in a vacuum cavity. The apparatus also includes a steering system to control the vertical position the laminator and a vehicle to move the laminator along the substrate in a desired direction.

Owner:3M INNOVATIVE PROPERTIES CO

DTPA modified material and preparation method for rapid-full-dissociation type DGT (Diffusive gradients in thin films) coupling phase prepared therefrom

ActiveCN105148846AGuaranteed in-situ applicationExpand application spaceOther chemical processesColloidal chemistry detailsCouplingAmmonia

The invention relates to a DTPA modified material and a preparation method for a rapid-full-dissociation type DGT (Diffusive gradients in thin films) coupling phase prepared therefrom. DTPA reacts with Mg<2+> and Al<3+> under alkaline conditions. The method comprises the steps: (1) adding 24.4ml of ammonia water (NH4(OH)) and methanol into 73.20ml of water, uniformly mixing the ammonia water, the methanol and the water, then, adding 32.78g of DTPA into the mixture, and thoroughly dissolving DTPA; (2) fetching another beaker, adding 593.34ml of water and 197.78ml of ammonia water into the beaker, uniformly mixing the water and the ammonia water thoroughly; and (3) simultaneously adding solutions obtained in the step (1) and the step (2) into a solution containing MgCl2.6H2O and AlCl3.6H2O so as to prepare the DTPA modified material, carrying out spray drying, then, sieving the dried DTPA modified material by a sieve with the pore size of 200 meshes (75 microns) so as to form a heavy-metal adsorption material for a DGT coupled film, then, adding the heavy-metal adsorption material into a polyacrylamide gel solution, and carrying out reaction at a certain temperature, thereby preparing the DGT coupled film. The gel film prepared by the method disclosed by the invention has the effects of heavy-metal adsorption and short-time full dissociation, and the disadvantage that the dissociation of the former heavy-metal coupling phase is slow and incomplete is overcome. The materials used are cheap and are easily prepared, and no secondary pollution is caused, so that the popularization and application of a DGT technology are facilitated.

Owner:TIANJIN TIANRUN YIKANG ENVIRONMENTAL PROTECTION TECH CO LTD

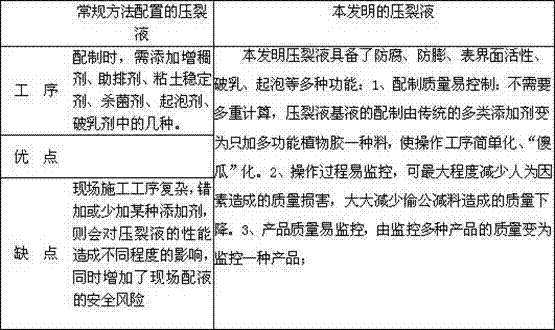

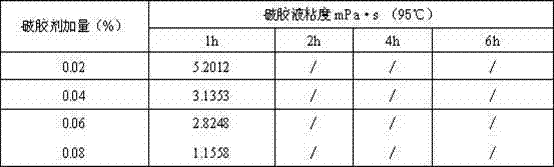

A method for preparing water-based fracturing fluid by using multi-effect thickener

InactiveCN102286276AOptimized formulaQuality improvementDrilling compositionDemulsifierFoaming agent

The invention discloses a method for preparing a water-based fracturing fluid by using a multi-effect thickener, which is characterized in that the fracturing fluid is composed of a base fluid and a cross-linking fluid containing a gel breaker, and is mixed according to the following parts by weight Uniform: 60-99.99 parts of base liquid, 0.01-40.0 parts of cross-linking liquid containing gel breaker; the base liquid is mixed according to the following parts by weight: 99-99.9 parts of water, multi-effect Thickener is 0.1-1.0 parts; the cross-linking liquid containing breaker is mixed according to the following parts by weight: water is 0-99.9 parts, cross-linking agent is 0.1-100.0 parts and breaker is 0.001- 0.1 part. The water-based fracturing fluid formulated with this multi-effect thickener can meet the requirements of use without adding bactericides, clay stabilizers, surfactants, demulsifiers, and foaming agents. Under the condition that the performance indicators of the fracturing fluid are equivalent to those of the traditional fracturing fluid, the operation process is simplified, which is more conducive to improving the quality of the fluid, reducing the conditions required for monitoring, reducing construction procedures and time applications.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

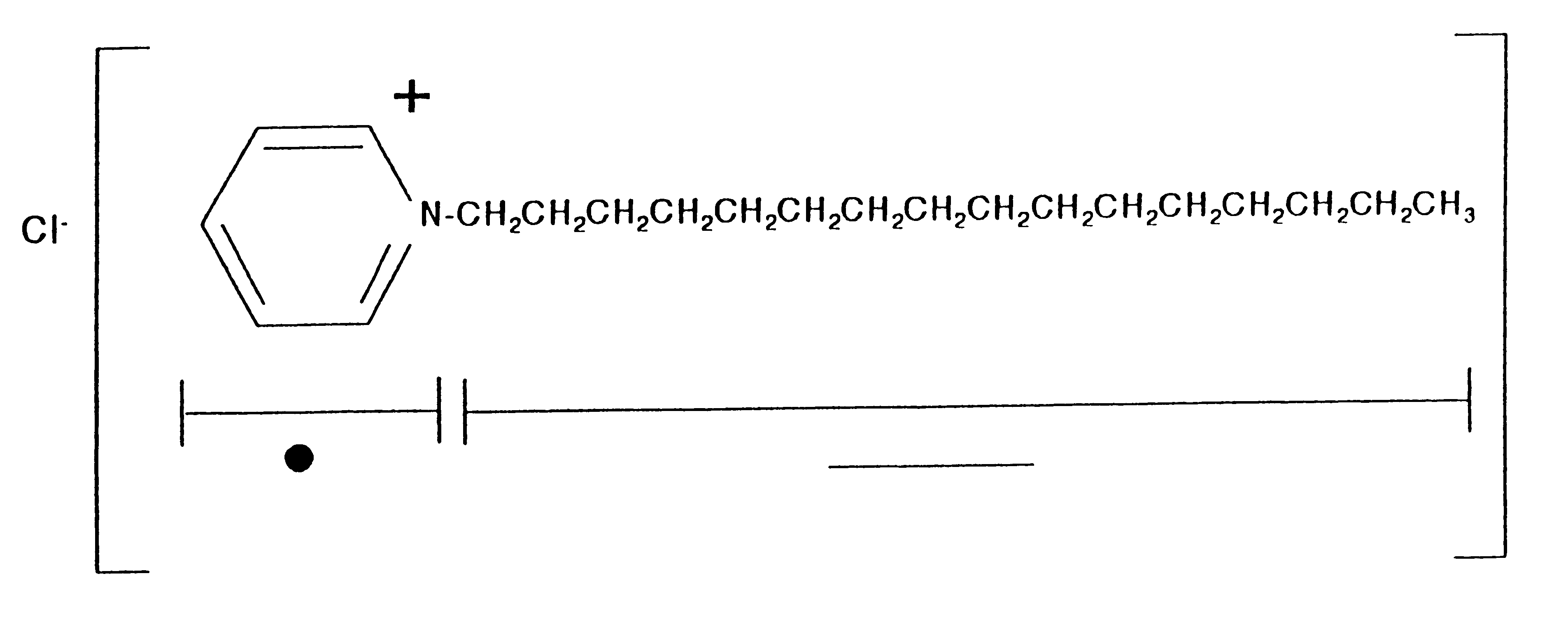

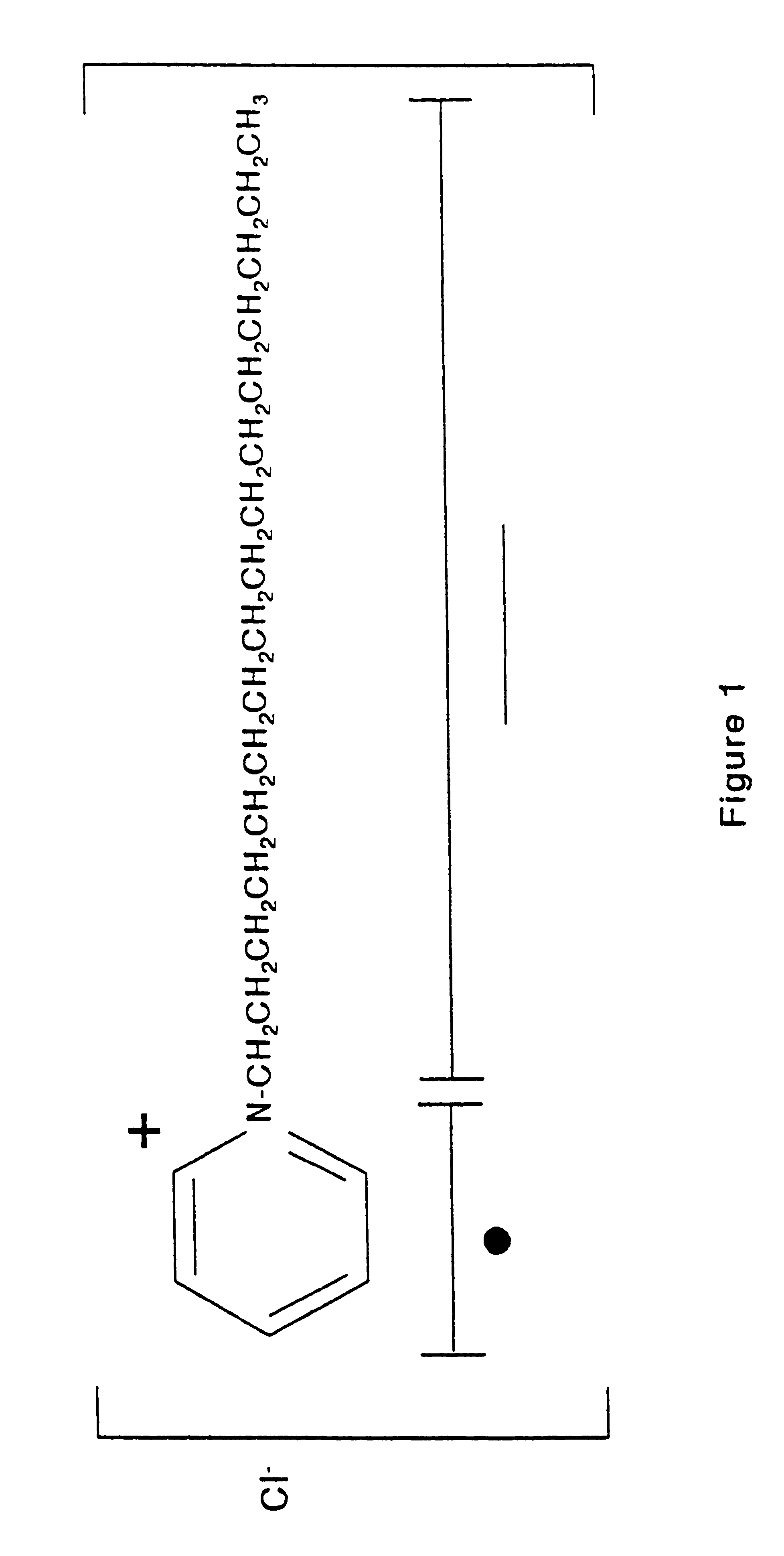

Prolongation of chemical activity of flavorants and therapeutics with cetyl pyridinium chloride

InactiveUS6207192B1Good effectShorten application timePowder deliverySolution deliveryCoated surfaceFlavor

Cetyl pyridinium chloride and other amphiphilic substances may be mixed with flavorants or therapeutics in accompaniment with such as bulking agents or sweeteners in order to prolong their duration of action at the site of attachment, which is a mucin coated surface for the purpose of providing the consumer with a more efficacious product.It is the concept of delayed dispensing that is the invention, the product being dispensed is only an illustration of the best mode.

Owner:CALFEE HALTER & GRISWOLD

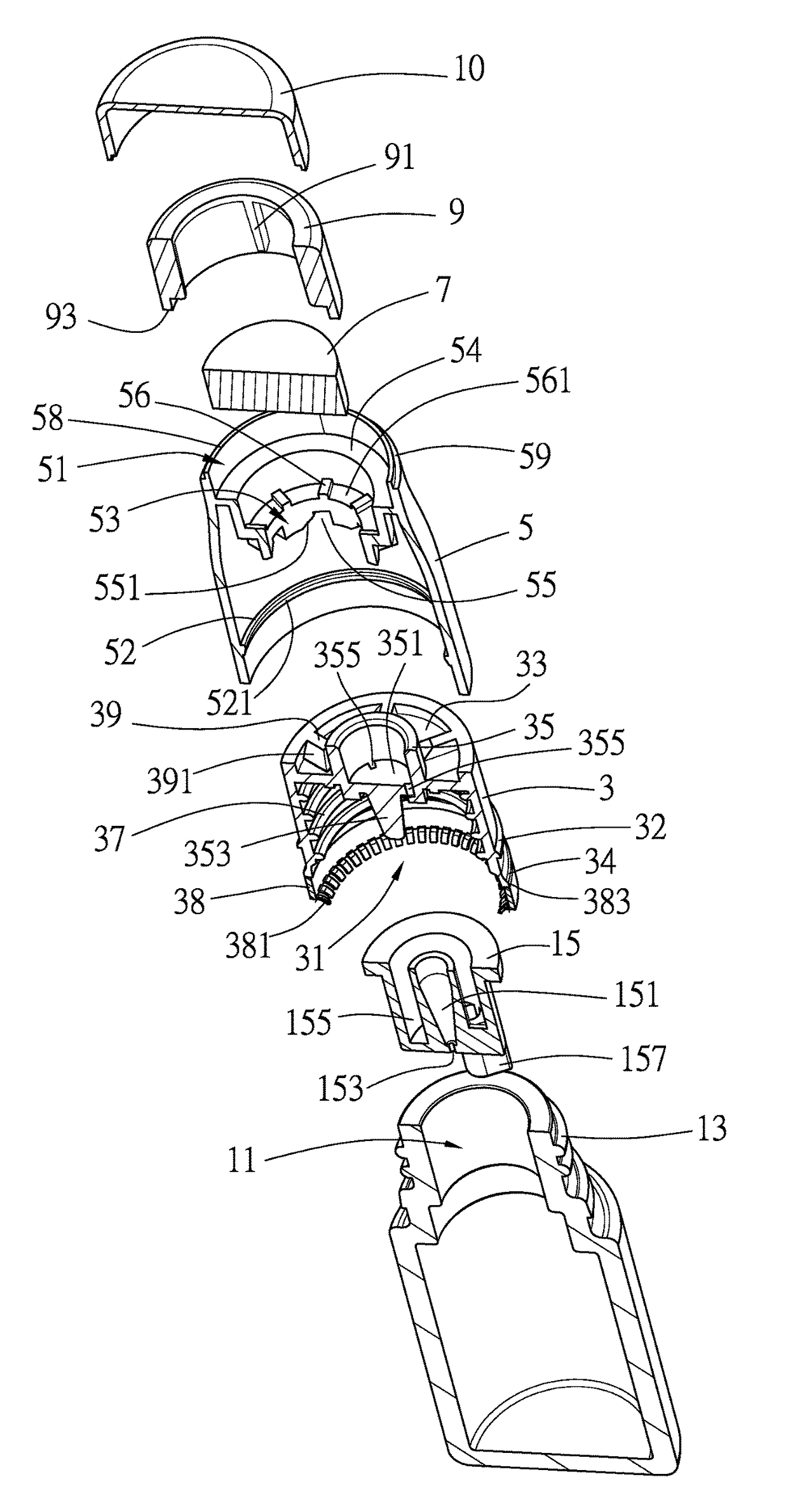

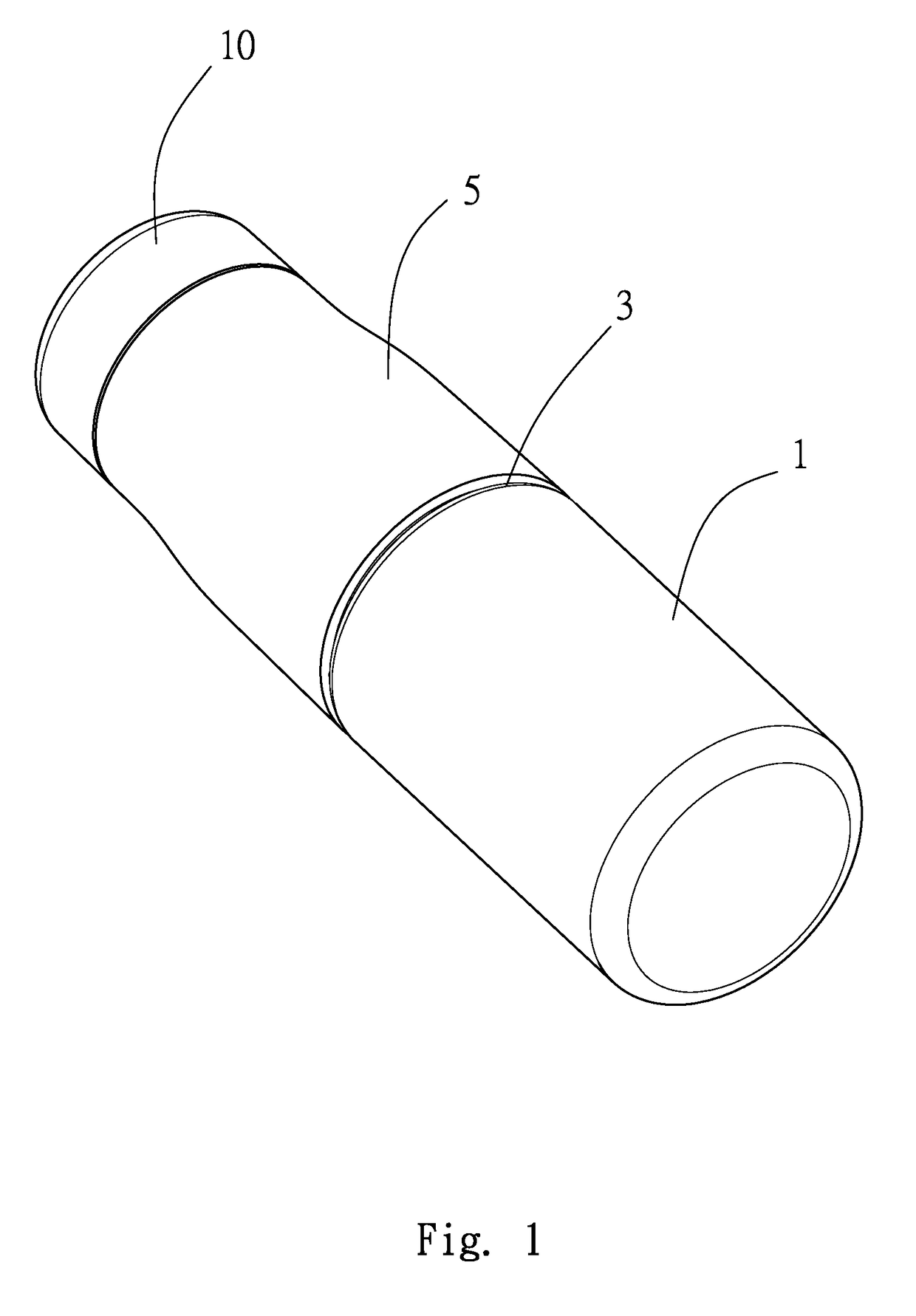

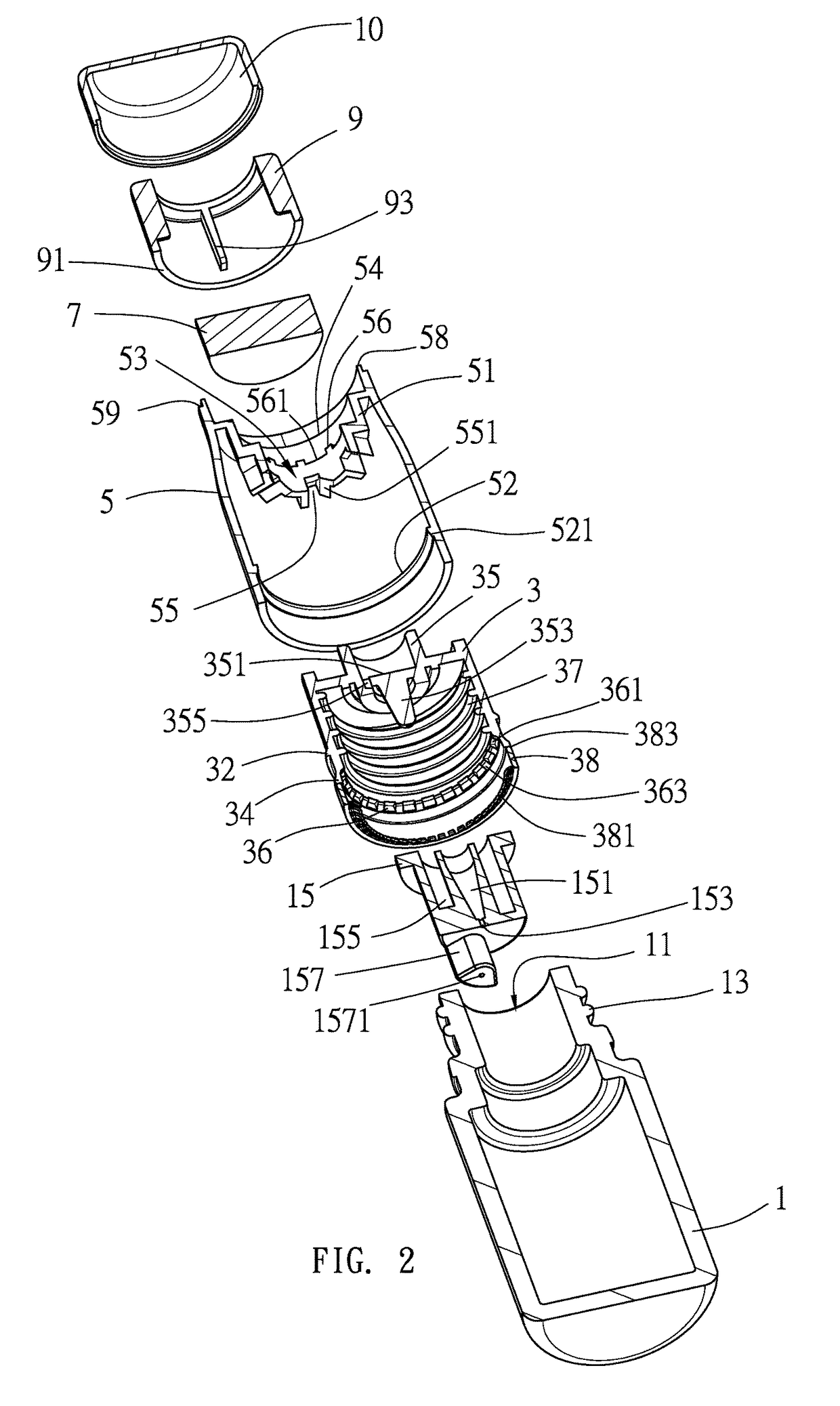

Liquid perfume diffuser

A liquid perfume diffuser includes a perfume bottle holding a liquid perfume, an inner cap threaded onto the perfume bottle, a rotary cover rotatably capped on the inner cap for pressing and rotating by the user to move the inner cap relative to the perfume bottle between a close position and an open position, so that when the perfume is opened, the liquid perfume can then be absorbed by a liquid-absorbing material in the rotary cap, enabling the pleasant smell of the liquid perfume to be slowly and naturally released into the outside open air through a capillary effect.

Owner:HSIAO MING JEN

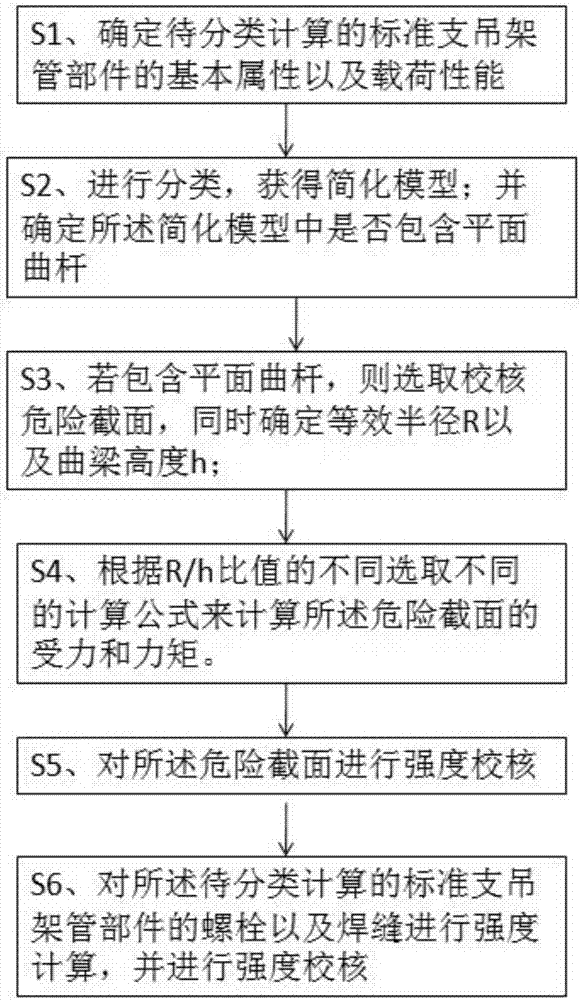

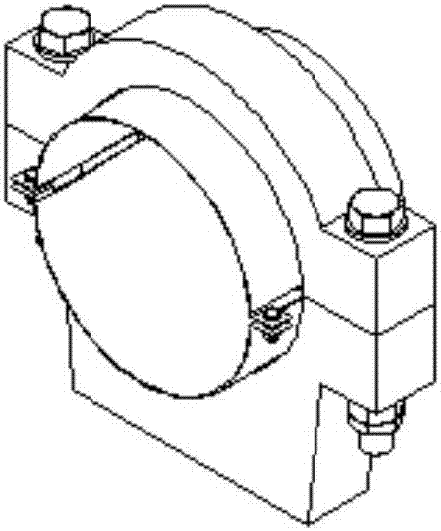

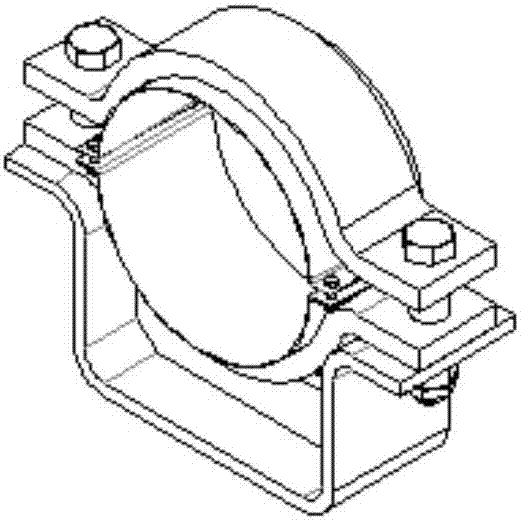

Classification and calculation method and apparatus for standard suspension pipe components of nuclear power plant process pipeline

ActiveCN107122529AShorten application timeQuick checkGeometric CADDesign optimisation/simulationReduced modelEngineering

The present invention discloses a classification and calculation method and apparatus for standard suspension pipe components of a nuclear power plant process pipeline. The method comprises: determining the basic attribute and the load performance of the to-be-classified and calculated standard suspension pipe components, classifying the to-be-classified and calculated standard suspension pipe components, and obtaining a simplified model; determining whether the to-be-classified and calculated standard suspension pipe component contains a plane curved rod; and if the plane curved rod is contained, selecting to check a dangerous cross-section, and according to the difference of the R / h ratio of the dangerous cross-section, selecting different formulas to calculate the force and the torque of the dangerous cross-section, and finally carrying out strength check. According to the technical scheme of the present invention, for the shortcoming of the long check cycle in strength calculation by using the existing bracket finite element method, manual check on the bracket strength of the standard suspension pipe components in batch is realized, fast check effects can be exerted on modifying the key section size, the similar type or corresponding pipe clip structure design can be further carried out, and the allowable load can be determined, so that the unnecessary repetitive finite element modeling calculation process is avoided, work efficiency is improved and the construction application time is reduced.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +2

Method, sensor module, and system for transferring data

InactiveUS20130321167A1Significant energy savingShorten application timeElectric signal transmission systemsRecording measured valuesEngineeringReal-time computing

In a method for transmitting a data element from a sensor module that produces sensor data to an application unit, the data element is stored in a ring buffer in the sensor module, and a corresponding item of event information is produced in an evaluation circuit from the sensor data, the data element including the sensor data and the item of event information, the data element being transmitted from the ring buffer to the application unit upon request by the application unit.

Owner:ROBERT BOSCH GMBH

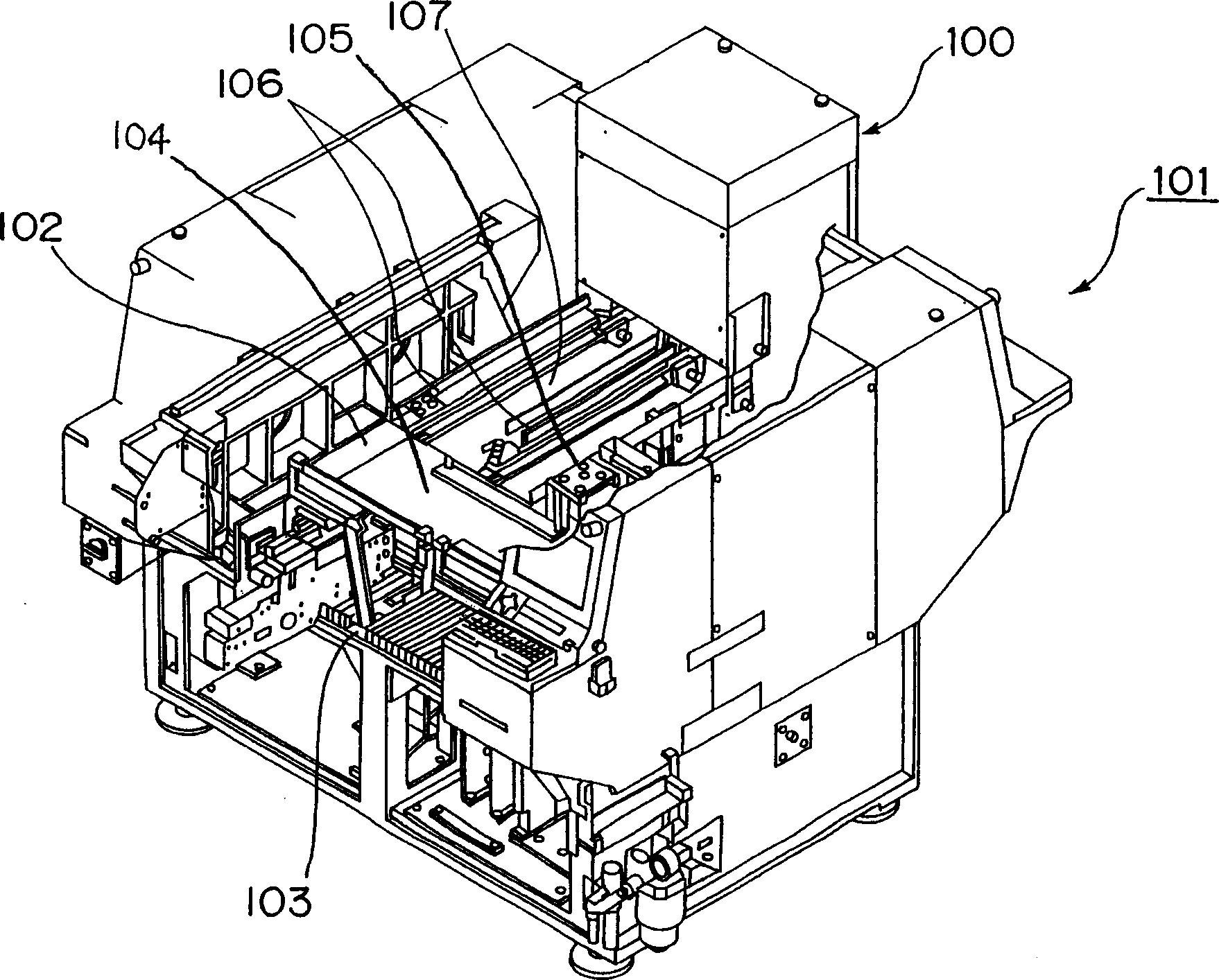

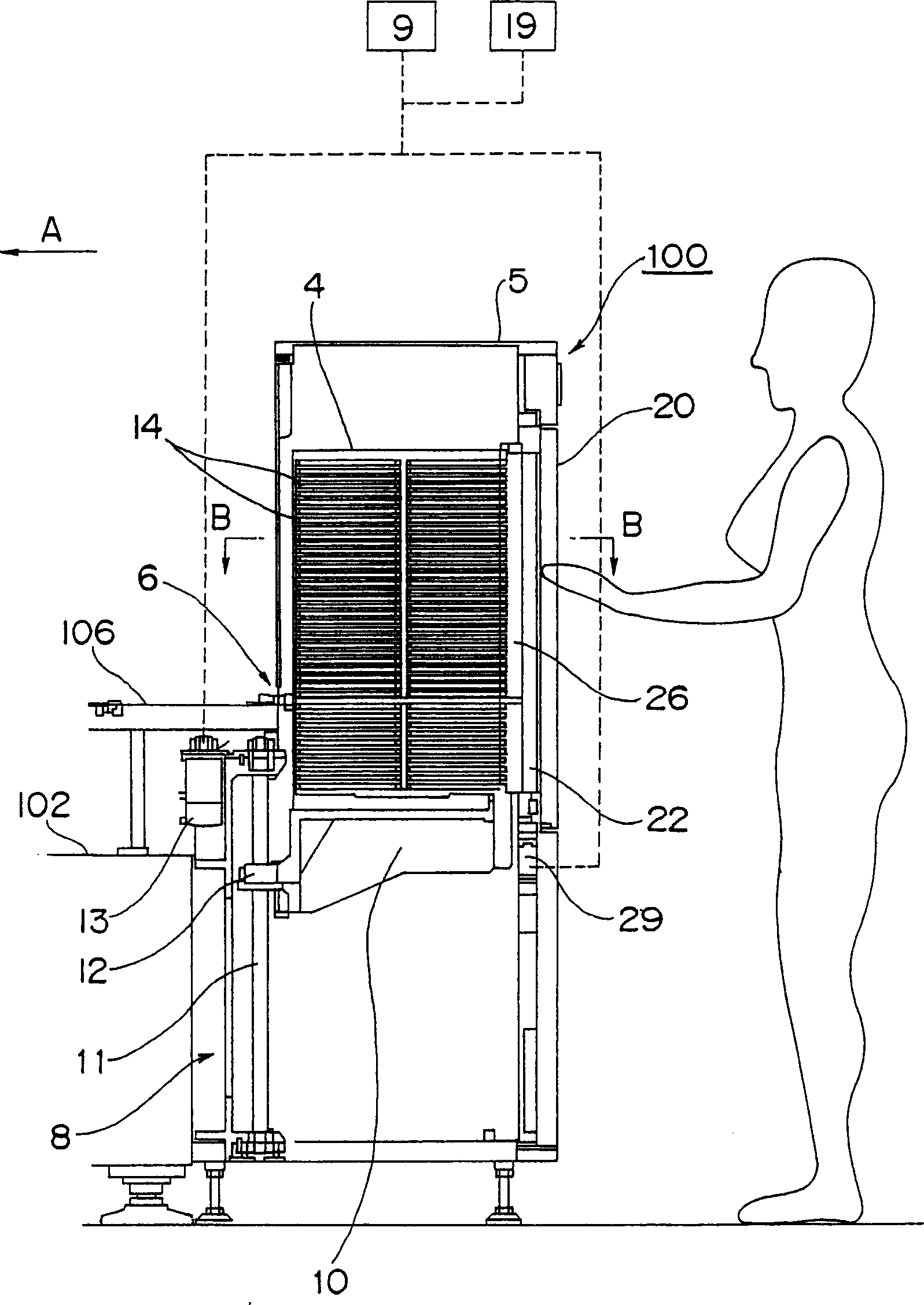

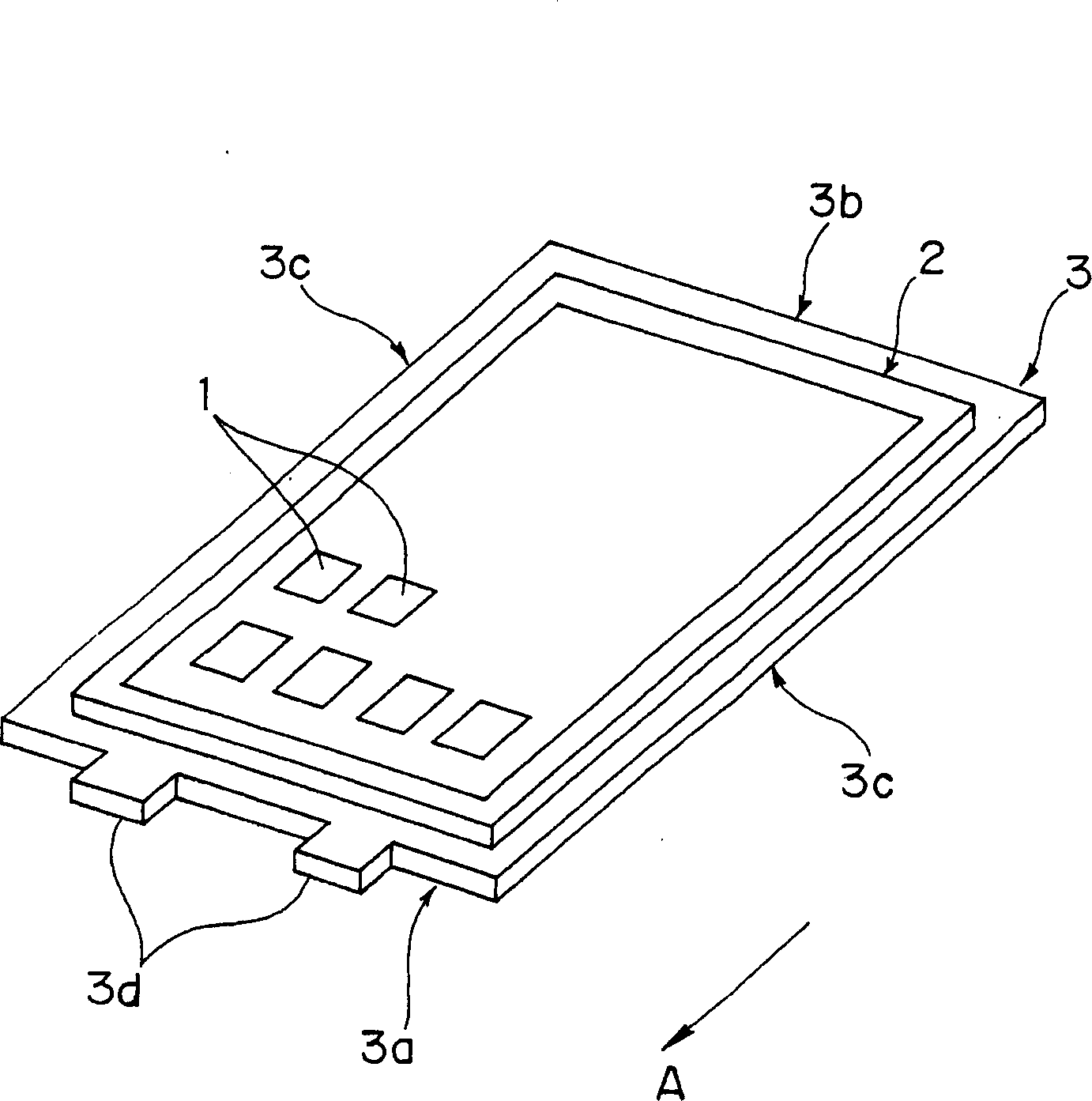

Electronic component feeder and electronic component feeding method

InactiveCN1788532AReliable interferenceDetect support postureElectrical componentsElectronic componentPallet

The invention provides a forward side adjuster (18) for adjusting the support position of a pallet loaded in a bin (4) on the forward side in the pallet feeding direction (A); an adjustment member (24), movable in said direction, for adjusting the support position of the pallet adjusted by the forward side adjustment member on the rearward side in said direction; and a horizontal attitude adjustment member (26), which can Provided between the pallets for adjusting the supporting posture of the pallets so as to maintain a substantially horizontal supporting posture of the pallets supported by the pair of supports with the arrangement.

Owner:PANASONIC CORP

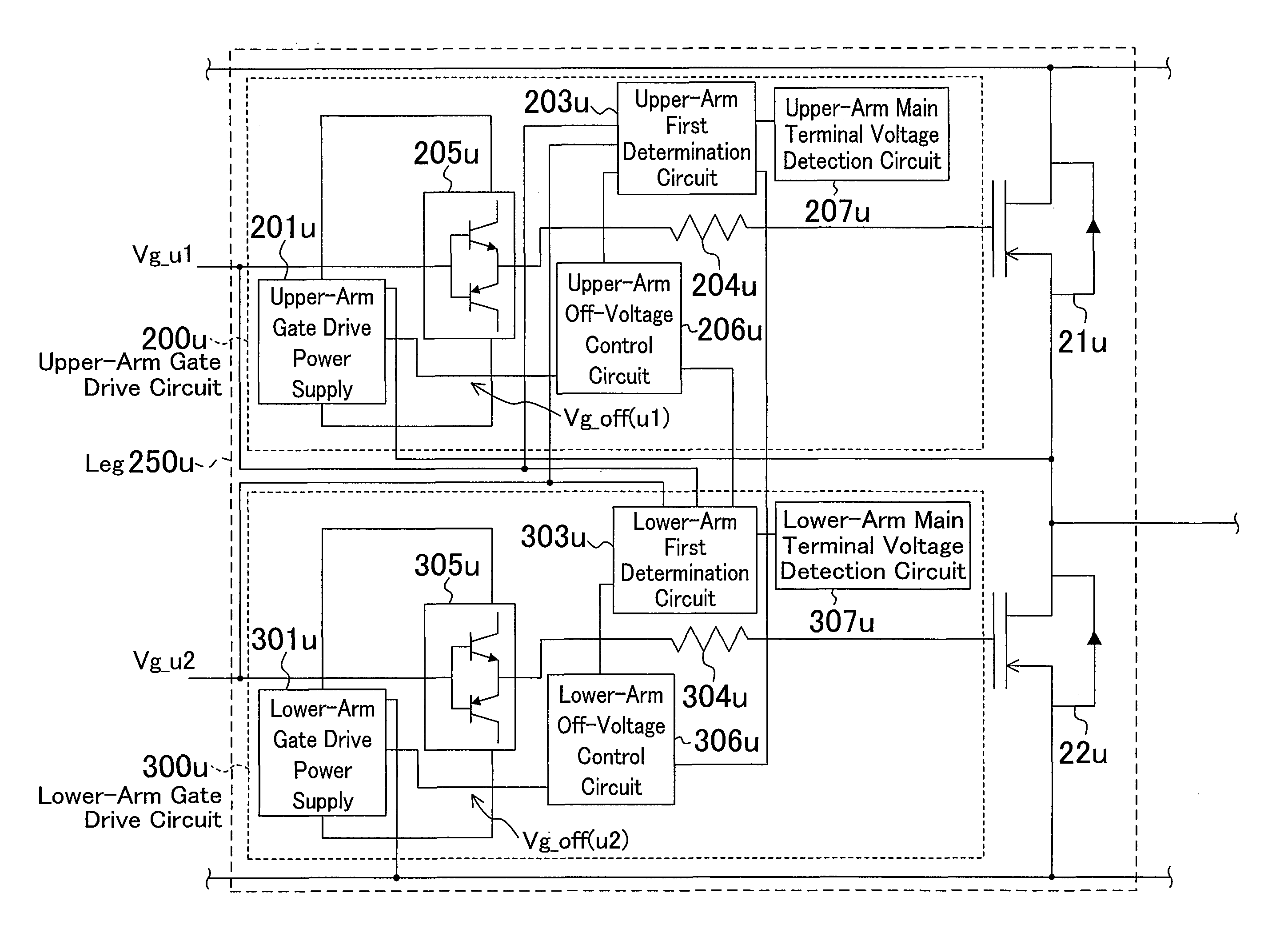

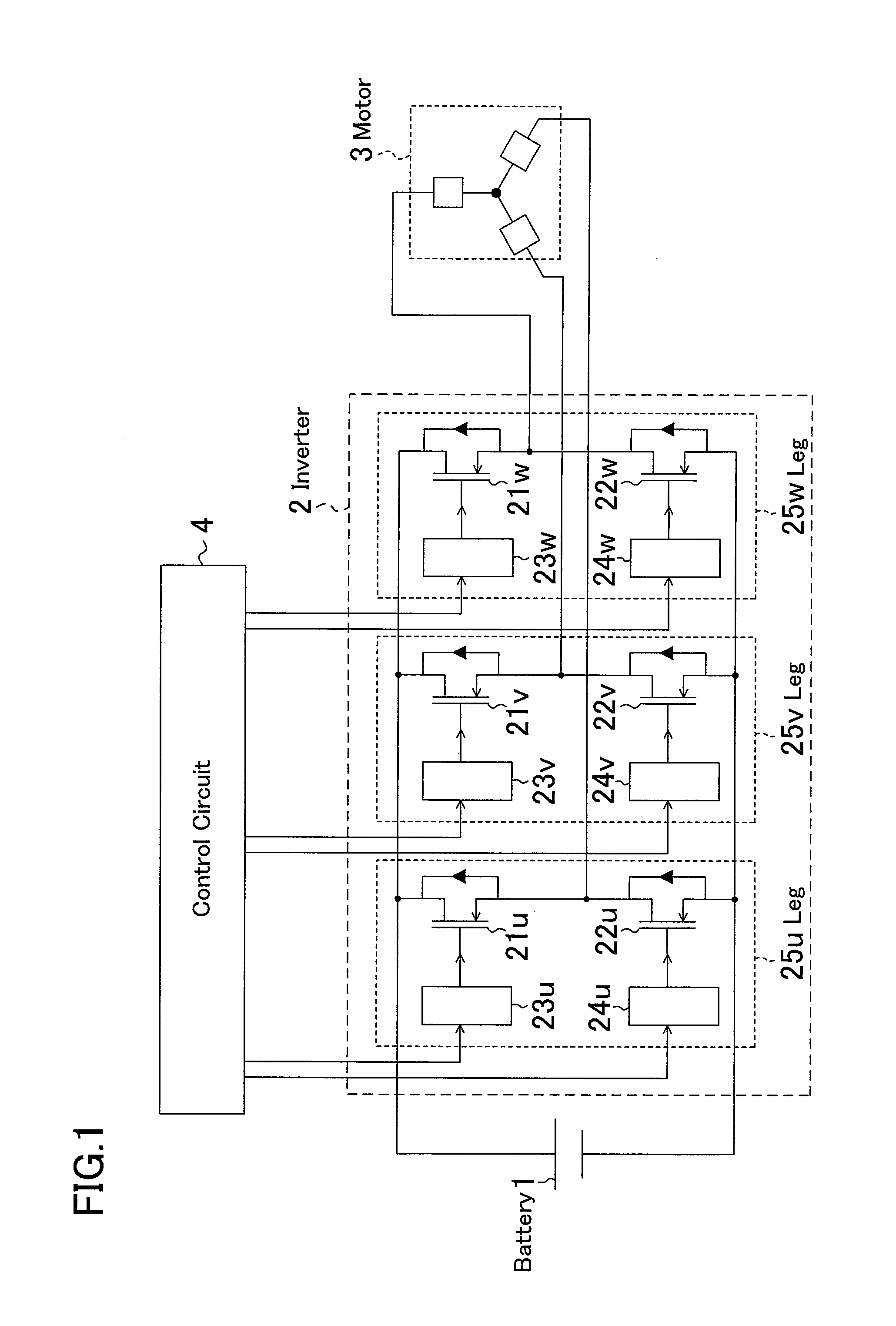

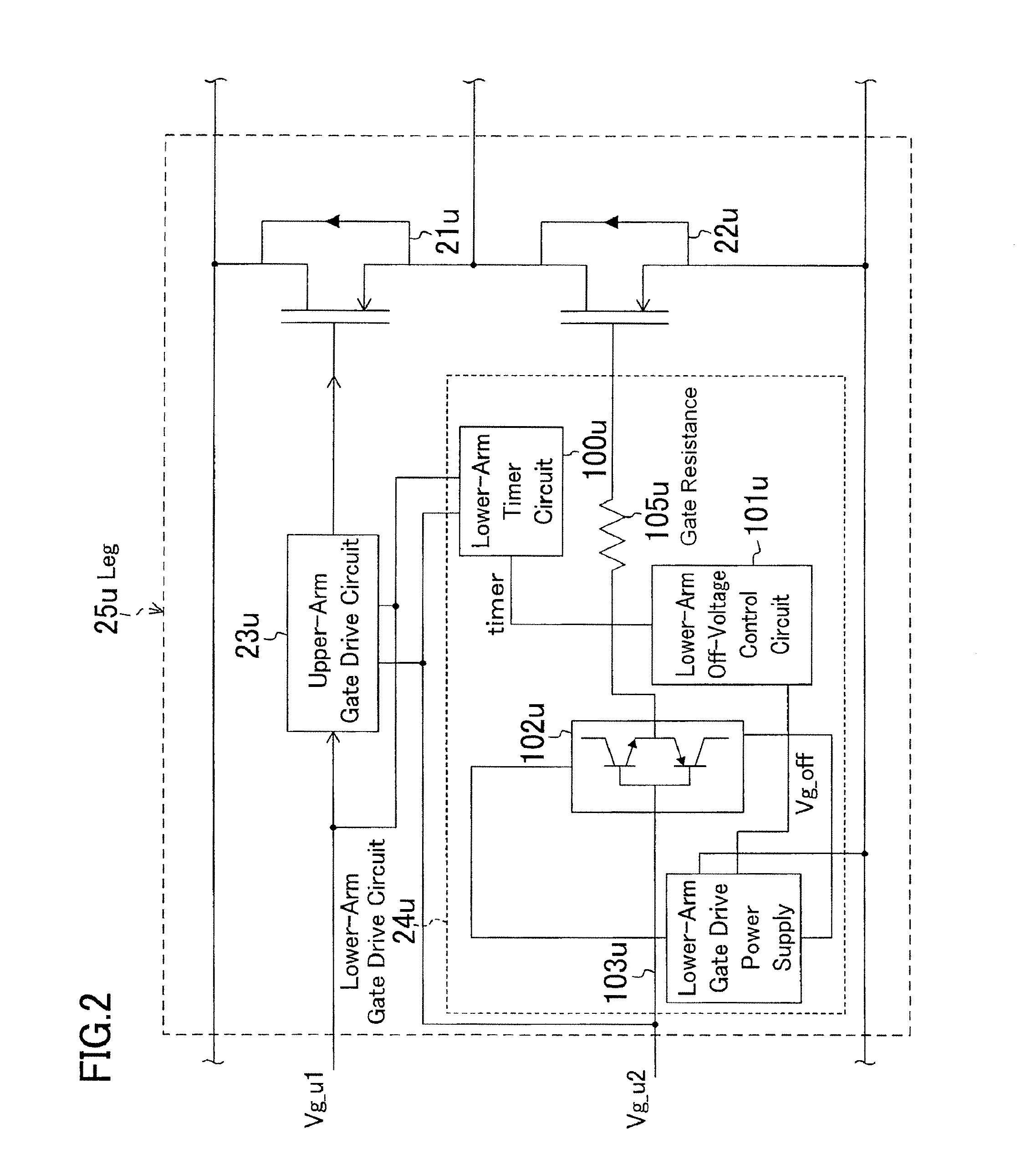

Power conversion circuit having off-voltage control circuit

ActiveUS8363440B2Shorten application timeImprove reliabilityMotor/generator/converter stoppersAC motor controlEngineeringVoltage control

In a power conversion circuit operating with high frequency, an off-voltage control circuit 101u of a lower-arm gate drive circuit 24u controls the output voltage of a gate drive power supply 103u to change the output voltage to a voltage lower than a predetermined off voltage during a time period from termination of turn-off operation of a lower arm 22u until start of turn-on operation of an upper arm 21u, and thereafter return the output voltage to the predetermined off voltage immediately after termination of the turn-on operation of the upper arm 21u. With this control, short-circuiting through the upper and lower arms occurring due to a high voltage change dv / dt can be avoided, and the life of a switching element constituting the power conversion circuit improves, increasing the reliability of the power conversion circuit.

Owner:PANASONIC CORP

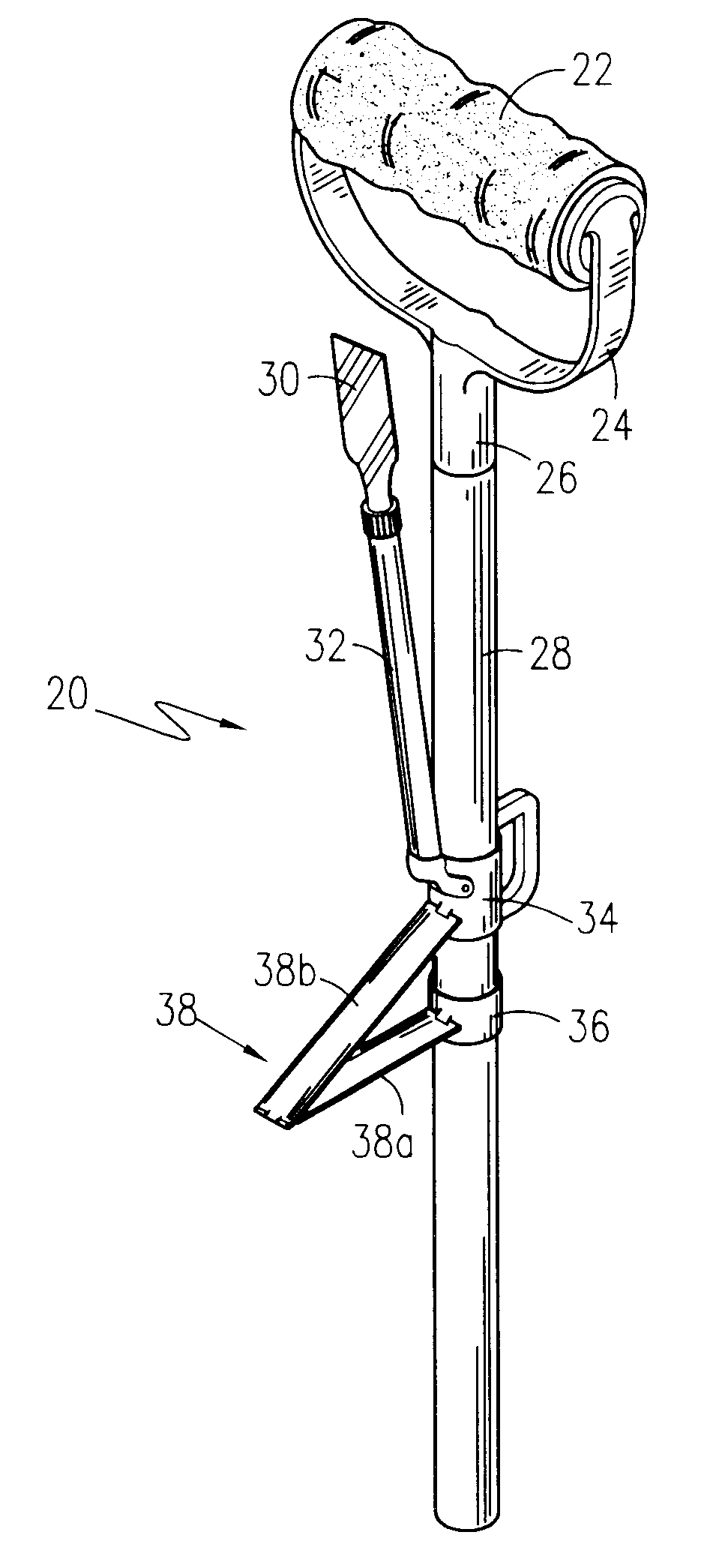

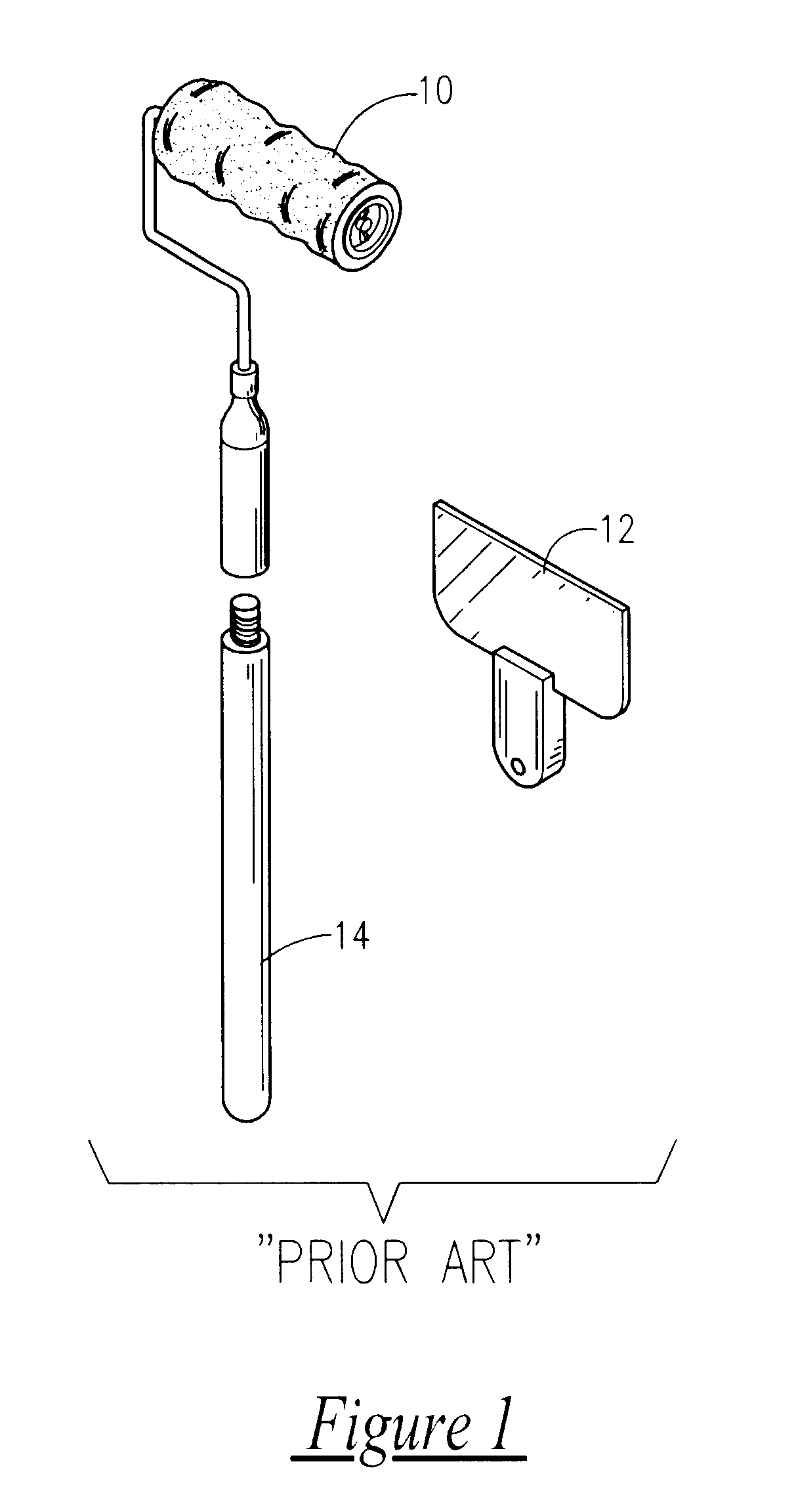

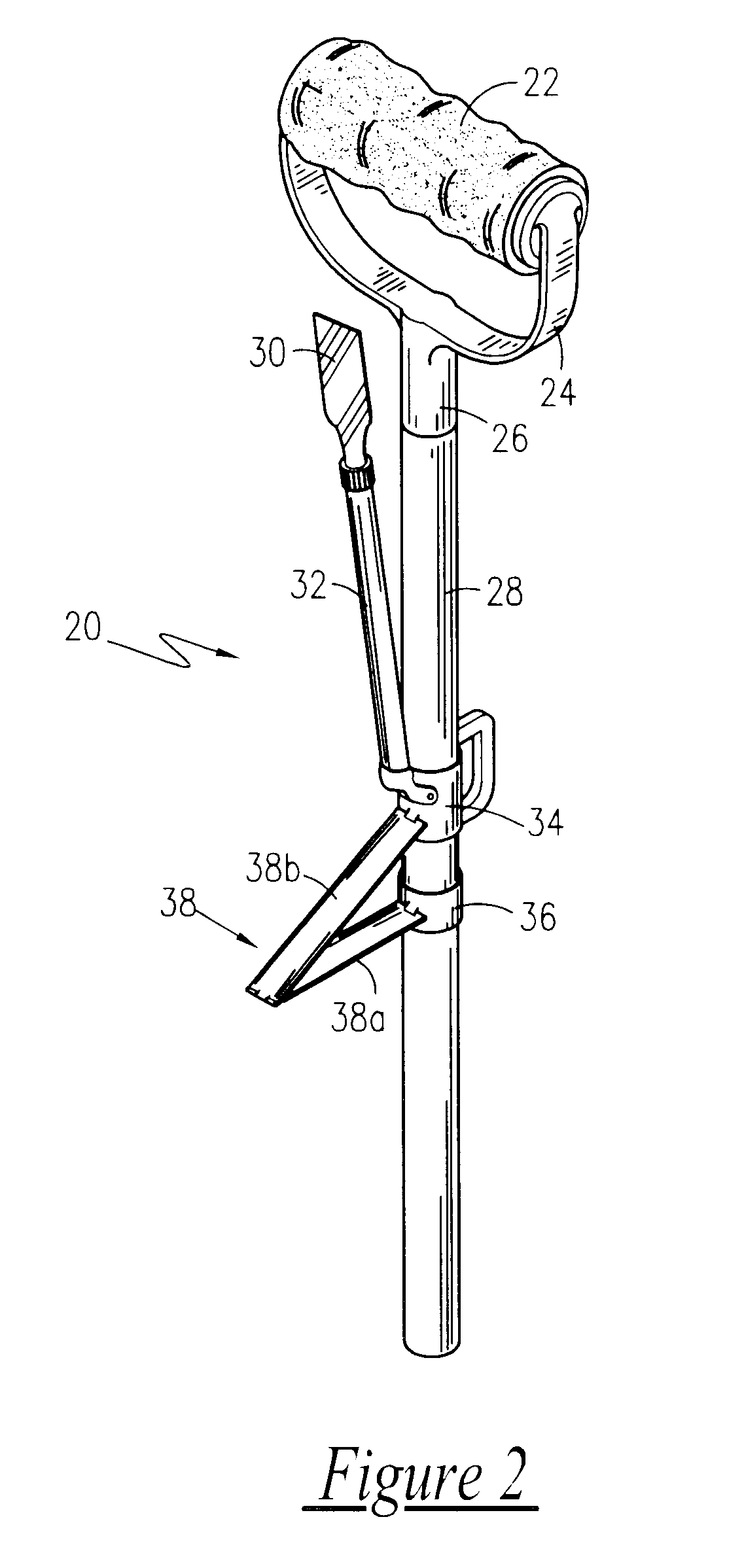

Extendable interior ceiling finishing tool

InactiveUS6688367B1Shorten application timeHigh quality finishLiquid surface applicatorsKitchenware cleanersKnife bladesBiomedical engineering

An apparatus is provide that aids in the finishing of ceilings. The tool provides for the rolling on of cement or other similar finishes and then an integral knife blade smoothes over the finished surface. Such an invention prevents the user from using multiple tools, and from using stilts to reach the ceiling surface.

Owner:RUPOSKY GEORGE A +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com