Electronic component feeder and electronic component feeding method

A technology for supplying electronic components and components, applied in the direction of electrical components, electrical components, etc., can solve problems such as unfavorable lifting, inability to perform component installation, and large lifting of the component supply plate 552

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0138] A first embodiment of the present invention will be described in detail below with reference to the drawings.

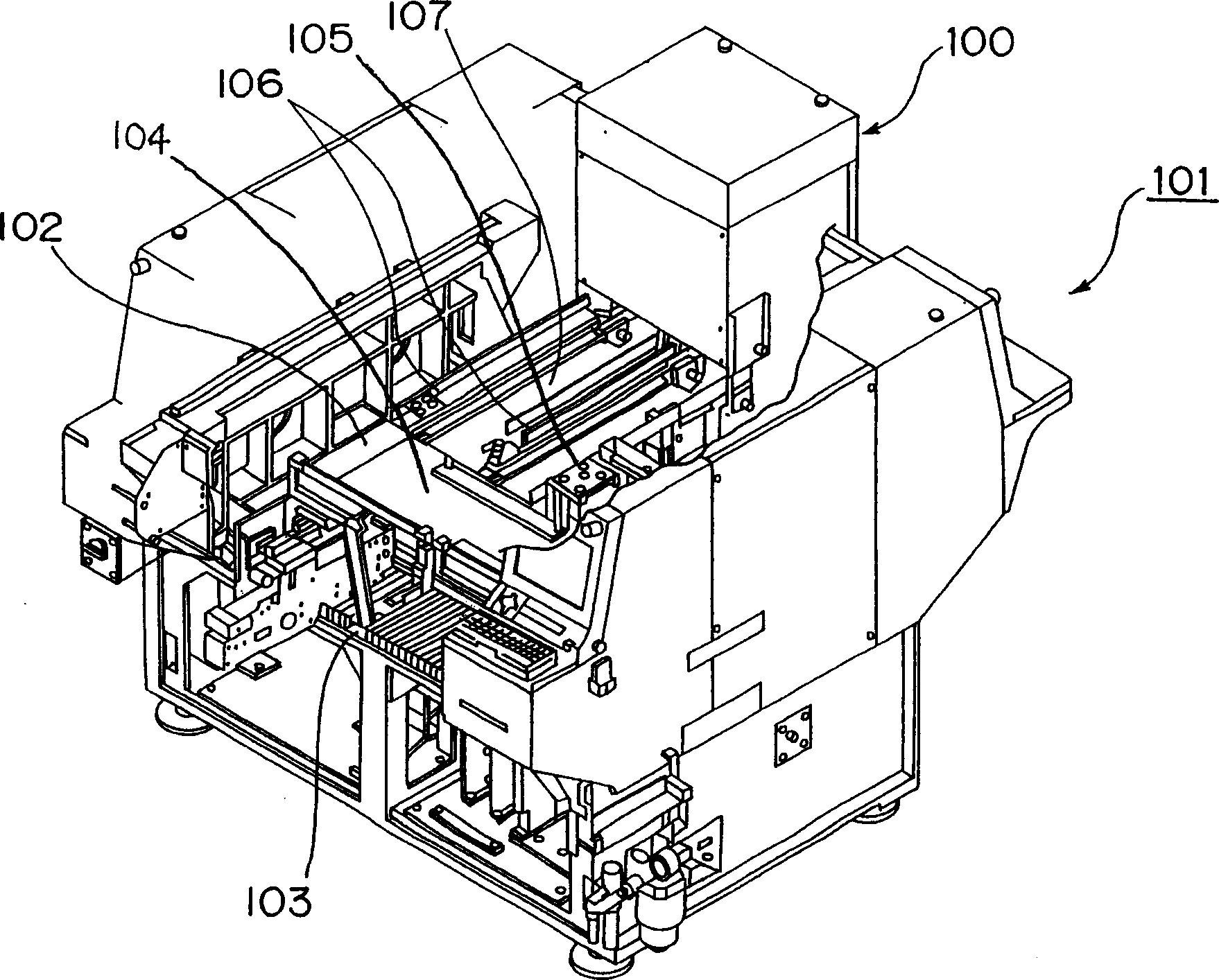

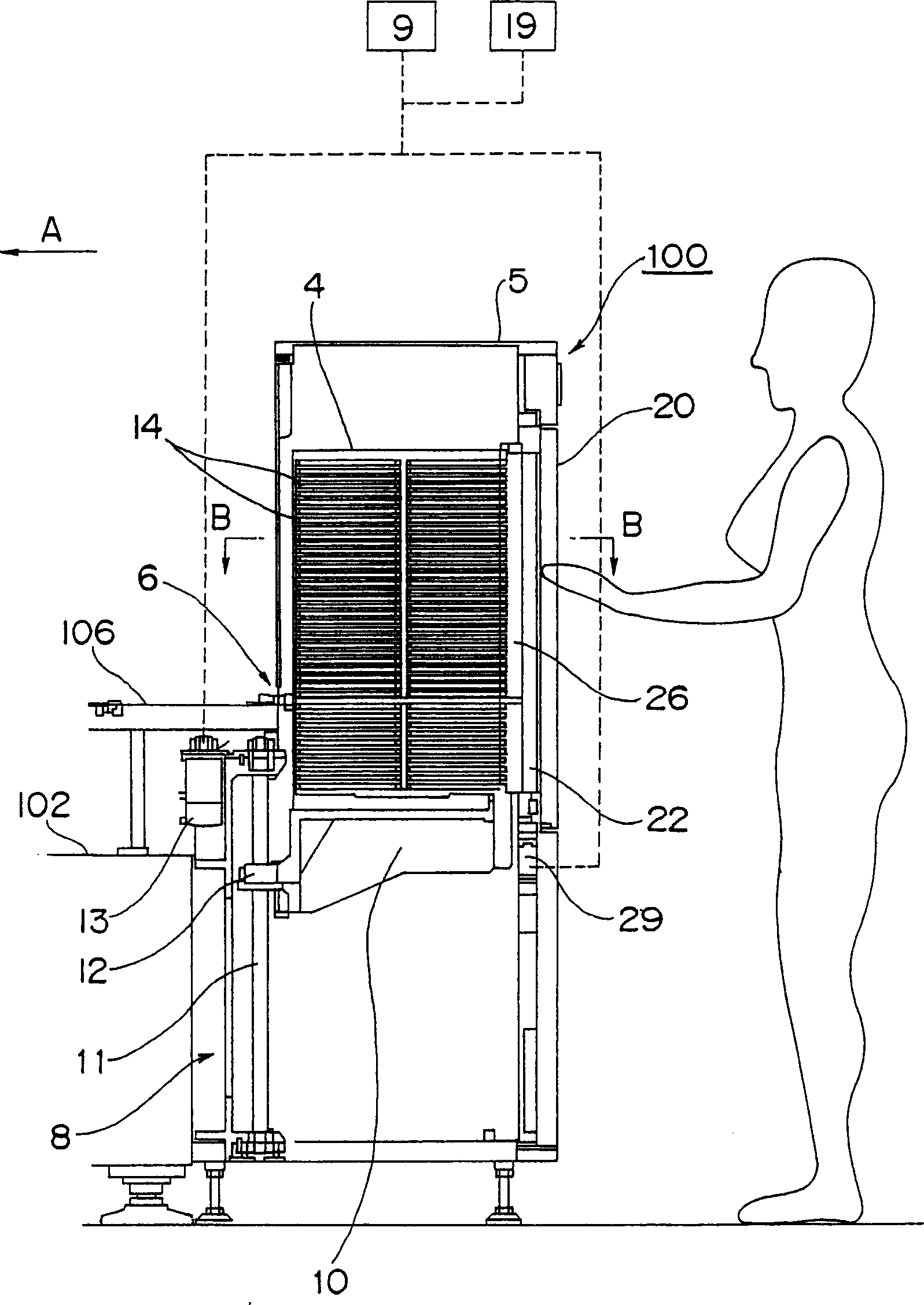

[0139] figure 1 An external perspective view (partially shown transparently) of the electronic component mounting apparatus 101 provided with the electronic component feeder 100 according to the first embodiment of the present invention is shown.

[0140] Such as figure 1 As shown in , an electronic component mounting apparatus 101 that performs component mounting to mount a plurality of supplied electronic devices on a circuit board is provided with an electronic component feeder 100 (which may be referred to as a tray component feeder) for supplyable A plurality of electronic components arranged in a line are accommodated on removable trays on the illustrated rearward side of the machine base 102 of the electronic component mounting apparatus 101; a tape-carried component feeder is also provided 103 , for supplying a plurality of tape-carried electronic ...

no. 2 example

[0195] The present invention is not limited to the above-described embodiments, but allows various other implementations. For example, it will be described below with respect to the second embodiment of the present invention that stable and efficient implementation can be performed by modifying the method for fixing a component supply tray on a pallet in an example of a pallet in the electronic component feeder 100 of the first embodiment. An electronic component feeder with a tray plate structure that prevents electronic components from jumping out of the component supply tray, etc. or an electronic component feeder with another structure.

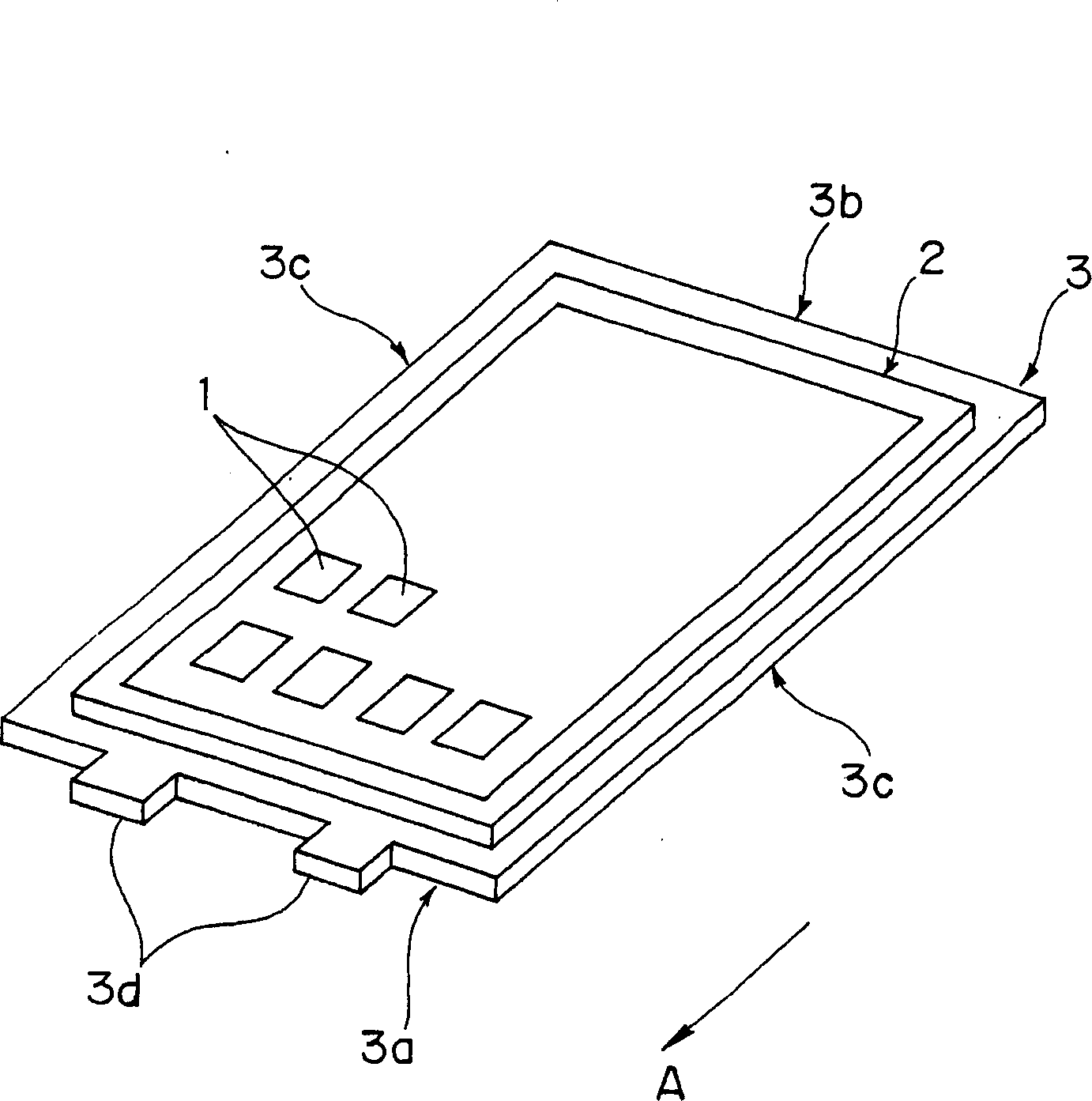

[0196] 13A shows a plan view of a tray plate 503 of an example of a placement section in which a component supply tray (also an example of a tray) handled in an electronic component feeder according to a second embodiment of the present invention is placed, and Figure 13B Its side view is shown. also, Figure 14A A plan view showing a ...

example

[0225] first, Figure 17 A schematic sectional view of, for example, the X-axis fixing rod 524 according to the first modified example of the second embodiment of the present invention is shown. Such as Figure 17 As shown in , the X-axis fixing bar 524 is provided with a horizontal direction fixing surface 524a serving as an example of a first direction fixing portion and also serving as an example of a first direction fixing surface for passing the The end portion 502a of the tray 502 contacts the placement position of the component supply tray 502 fixed in the direction along the surface of the tray placement surface 504, and a vertical direction fixing spring (an example of a pusher) 524c serves as an example of a second direction fixing portion, Also serves as a second direction fixing surface for fixing placement of the component supply tray 502 in a direction perpendicular to the tray placement surface 504 by contact with the upper portion of the end portion 502a of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com