A method and device for continuous casting of metals

An equipment and metal technology, applied in the field of equipment for continuous metal casting, can solve the problems of uneven thickness of slag, slag subsidence, and unbalanced flow rate of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

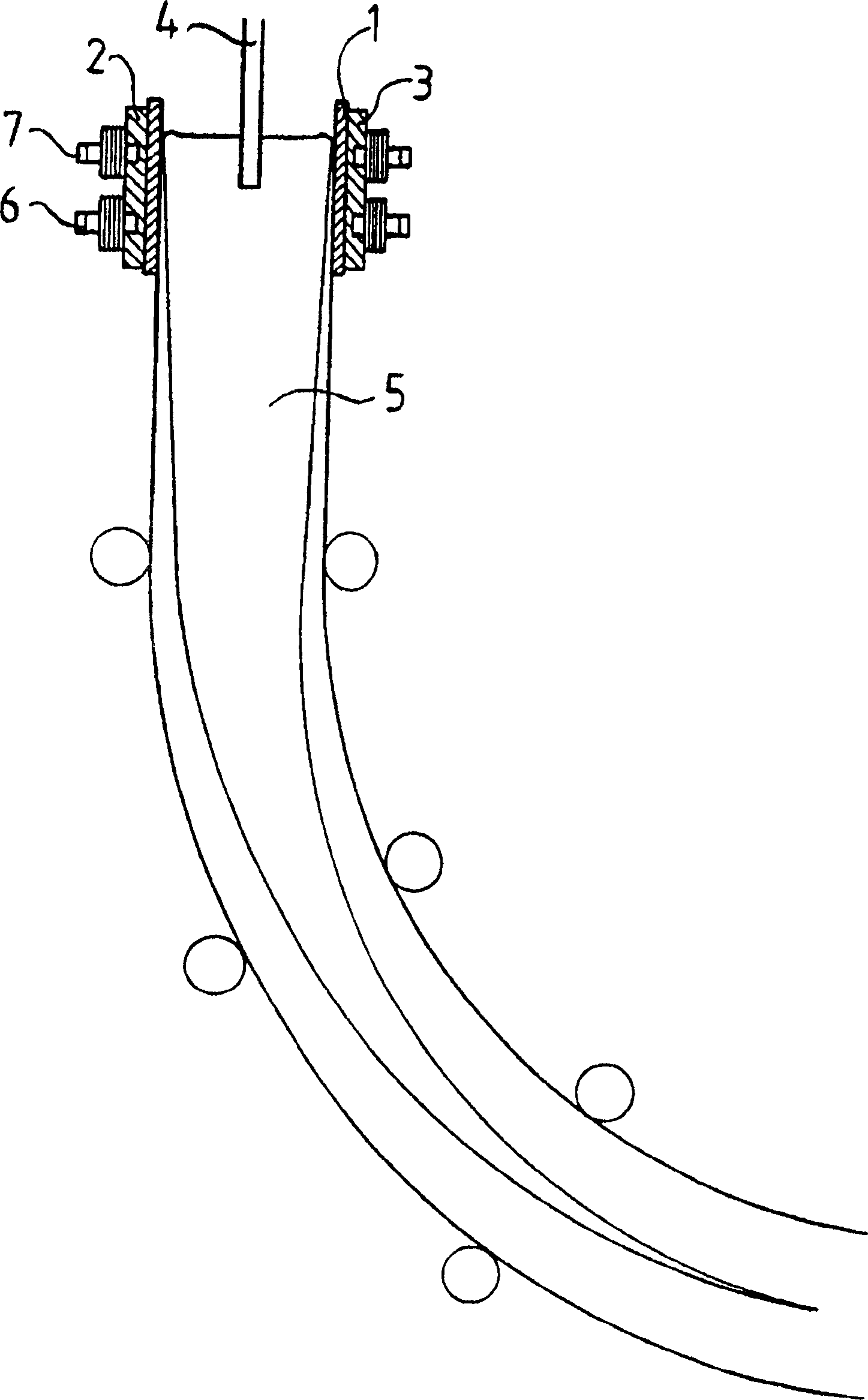

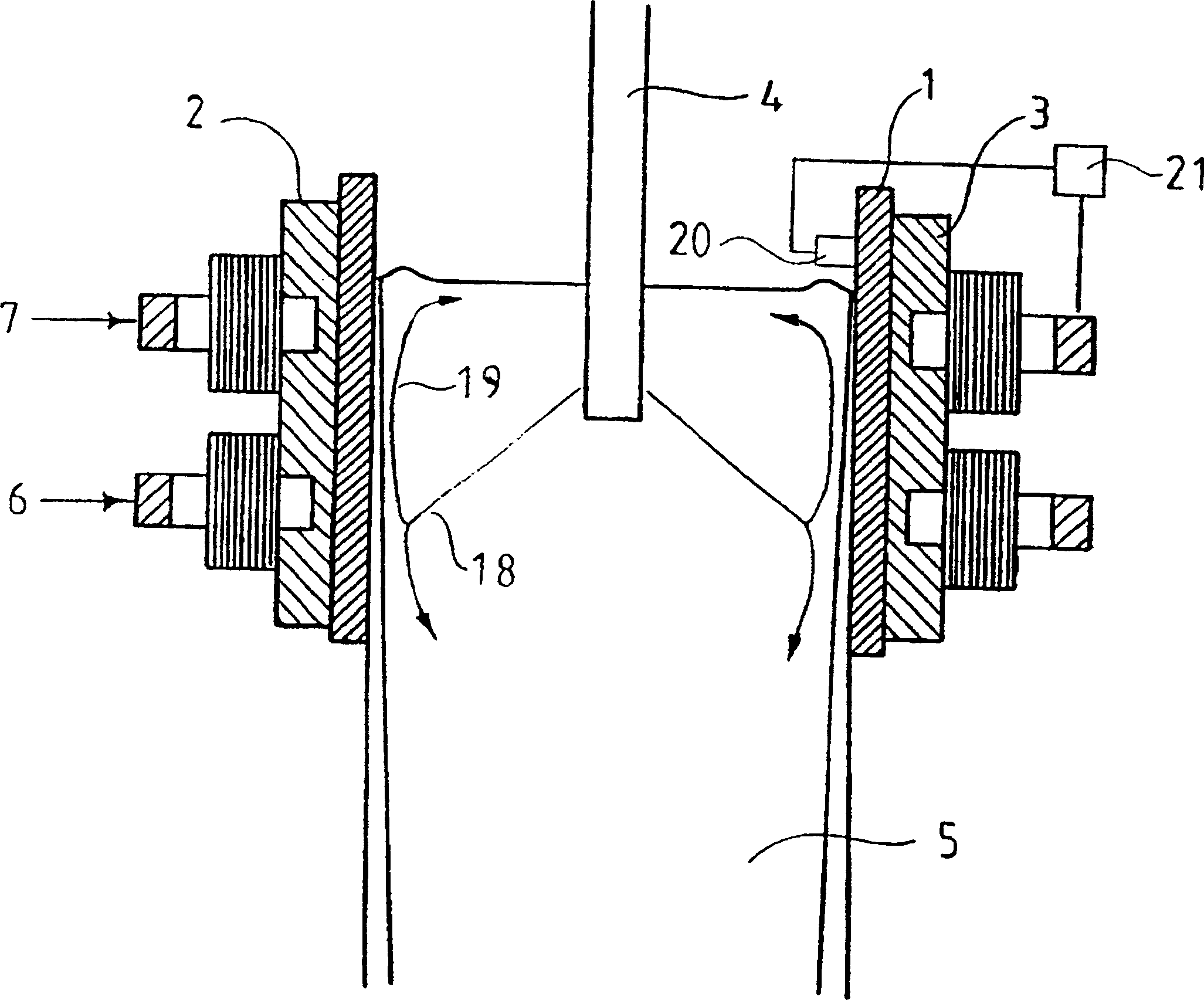

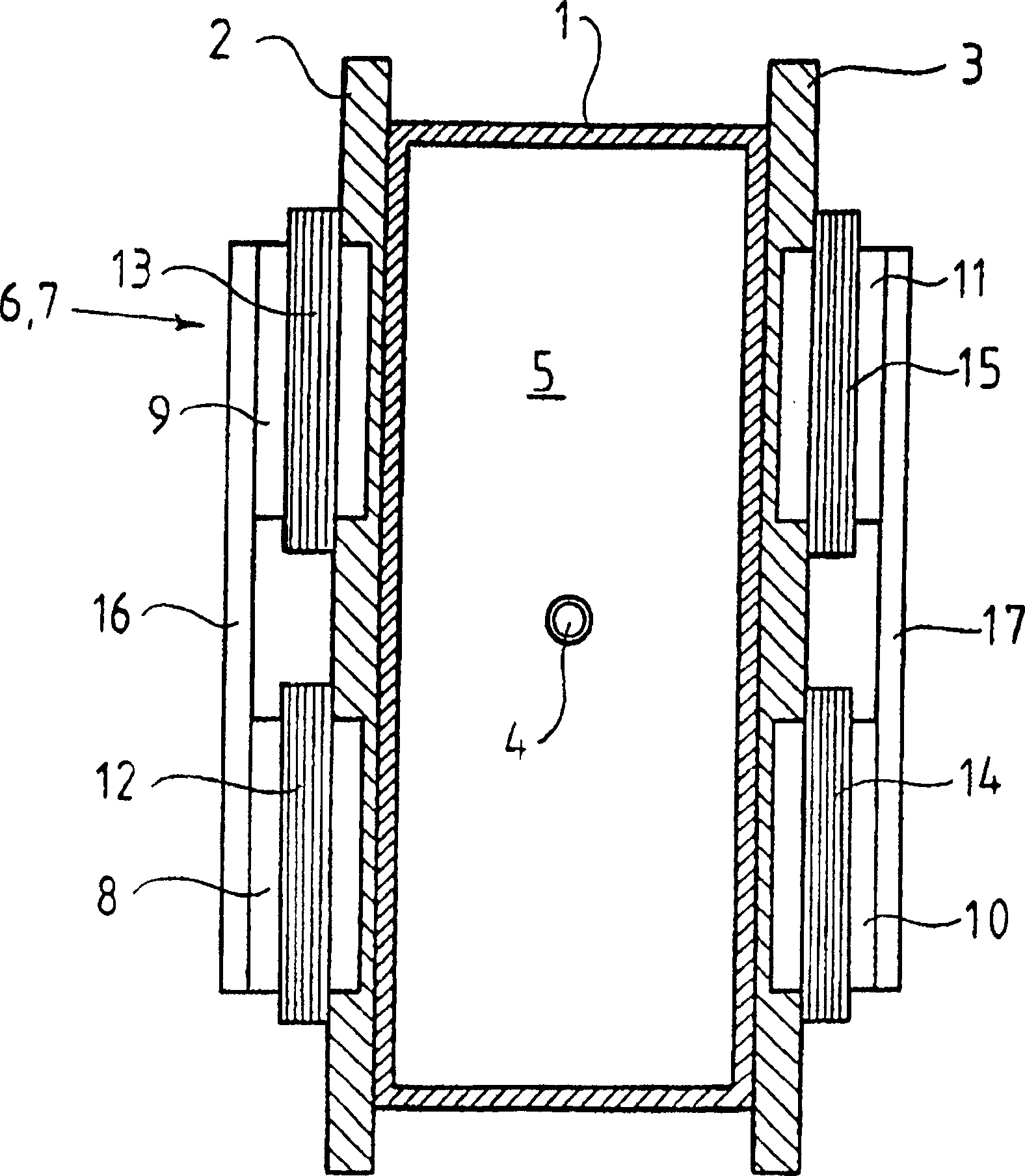

[0033] Figure 1-3 An apparatus for continuously pouring metal, such as steel, is shown. The apparatus includes a crystallizer defining a cylinder formed by four opposing walls. The crystallizer is preferably made of a copper alloy or other alloy with suitable thermal conductivity and thermal resistance. On the outside of at least two opposing walls of the crystallizer 1 are arranged elements 2 , 3 for cooling the walls. The cooling elements 2, 3 may comprise any type of support frame through which cooling channels for conveying a cooling medium, such as water, may be arranged. The channels may be arranged in such a way that the cooling medium flows directly towards the outer surface of the wall to cool the wall.

[0034] The device also comprises an element 4, a so-called "submerged nozzle (SEN)", by means of which a liquid metal can be fed from a container (not shown) to the within the space. During pouring, the crystallizer 1 is filled with metal. The metal is mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com