Catalyst for fuel cell and preparation method thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor scalability of the preparation process, poor catalyst stability, complex preparation methods, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides a catalyst for a fuel cell, which is a nitrogen-hybridized carbon-based catalytic material containing one or more metals, which is an M-NC single-metal nitrogen-carbon catalyst, a double-metal nitrogen-carbon catalyst or A multi-metal nitrogen-carbon catalyst, wherein M is one or more of metal elements, and M includes but is not limited to one or more of platinum, ruthenium, palladium, iron, cobalt, nickel, copper, tin, iridium, gold and silver Various metal elements.

[0040] Specifically, it has a large number of pore structures, excellent gas and electron conductivity, high degree of graphitization and nitrogen content, large specific surface area, many active sites and uniform distribution, high activity, and strong stability. It also has the advantages of high catalytic activity, long service life and low overall cost, and can be used in proton exchange membrane fuel cells and direct alcohol fuel cells.

[0041] In this embodiment, FeCo-NC c...

Embodiment 2

[0043] The present invention also provides a method for preparing a catalyst for a fuel cell, comprising the following steps:

[0044] S1. Directly and fully mix the carbon source material, nitrogen source material, structure-oriented material and metal precursor material, wherein the molar ratio of each material to the metal precursor material is not limited;

[0045] S2. Preliminarily heat-treat the mixed material obtained in step S1 at 80°C to 350°C for 0.5 to 72 hours, so that the carbon source material, nitrogen source material, structure-oriented material and the metal precursor are further fully contacted and reacted , to obtain the catalyst precursor material;

[0046] S3. Grinding the catalyst precursor material obtained in step S2 into a powder catalyst precursor material by means of ball milling or disc milling, the speed of ball milling or disc milling is 50-1000 rpm, and the time is 0.1-10 hours;

[0047] S4. The powder catalyst precursor material obtained in ste...

experiment example 1

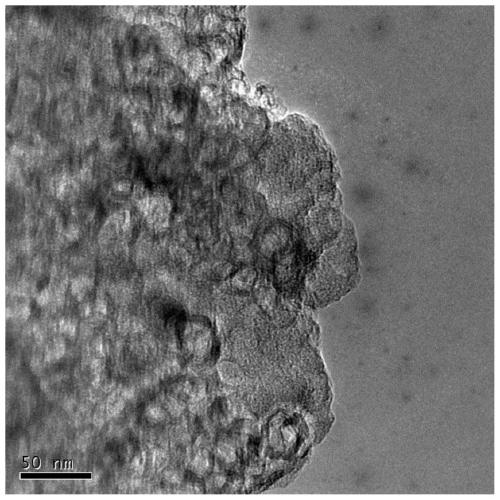

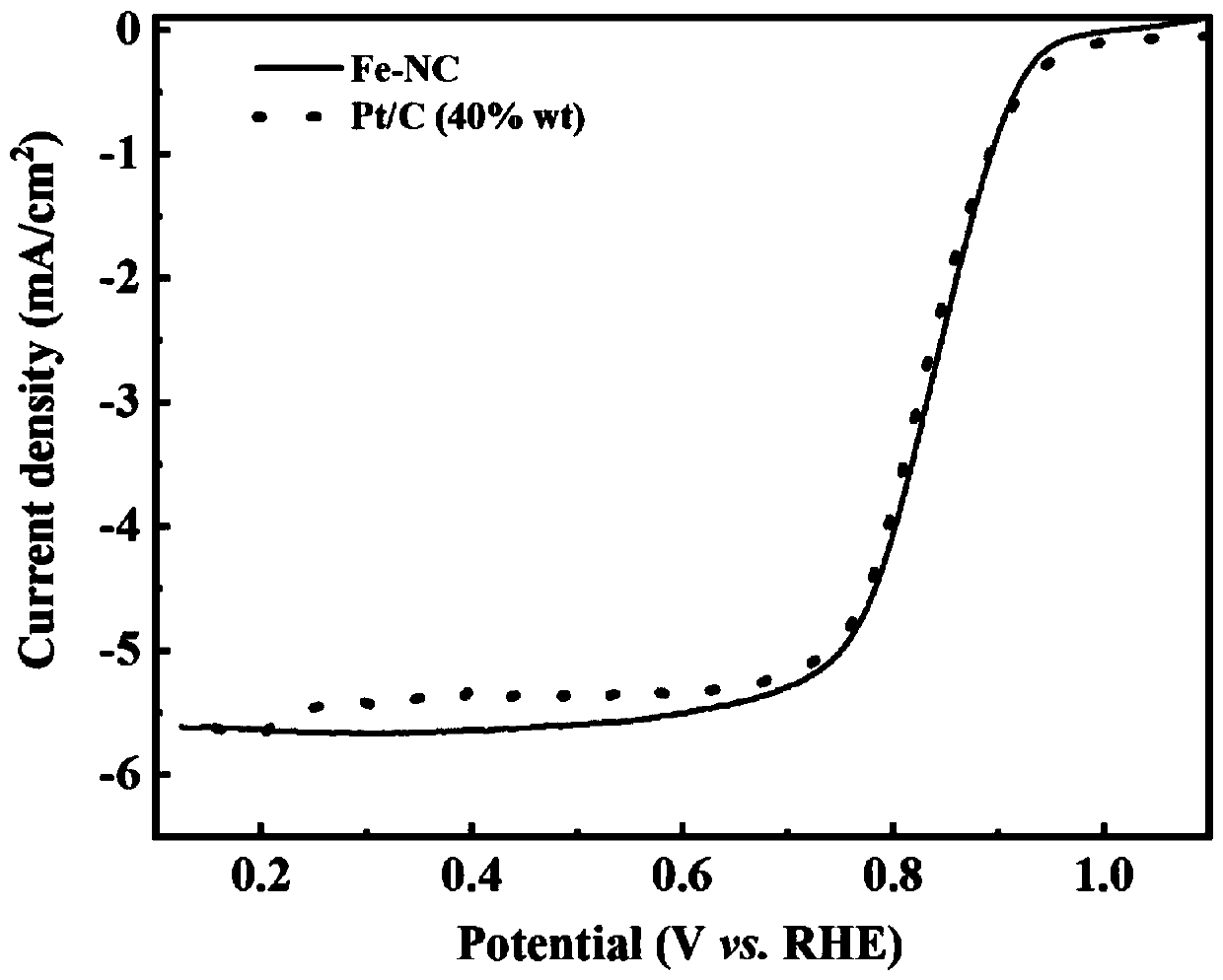

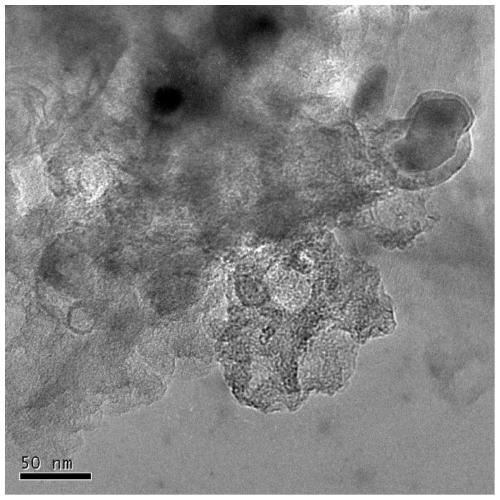

[0059] Take 4 mmoles of ferrous oxalate, 7.8 mmoles of zinc oxide, and 20.8 mmoles of 2-methylimidazole in a ball milling tank, and transfer the resulting powder to a high-temperature reaction kettle after ball milling at 200 rpm for 2 hours. After 24 hours of reaction, the catalyst precursor material was obtained. Thereafter, the obtained catalyst precursor material was ball milled again at 400 rpm for 3 hours to form a powder. The obtained catalyst precursor powder was transferred to a tube furnace, and the temperature was raised to 950 °C at a heating rate of 10 °C / min under an ammonia atmosphere and kept for reaction for 3 hours to obtain the Fe-NC catalyst material. like figure 1 Shown is the transmission electron microscope image of the obtained Fe-NC catalyst material, as figure 2 Shown is the half-cell polarization curve of the obtained Fe-NC catalyst material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com