Anti-skid and anti-fatigue sole

An anti-fatigue and anti-slip technology, which is applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of reduced work efficiency, easy slipping, and easy fatigue, etc., and achieve the effect of reasonable structural design, good anti-slip function, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

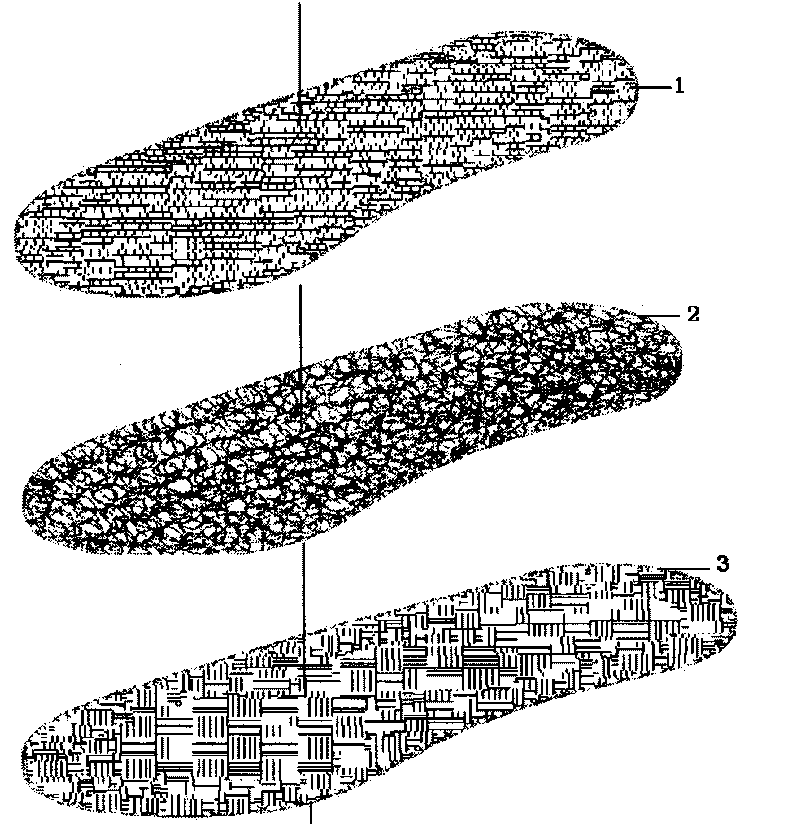

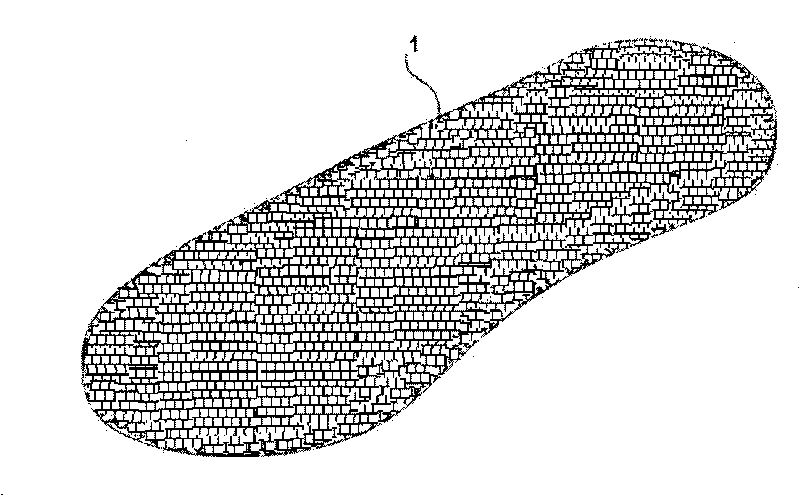

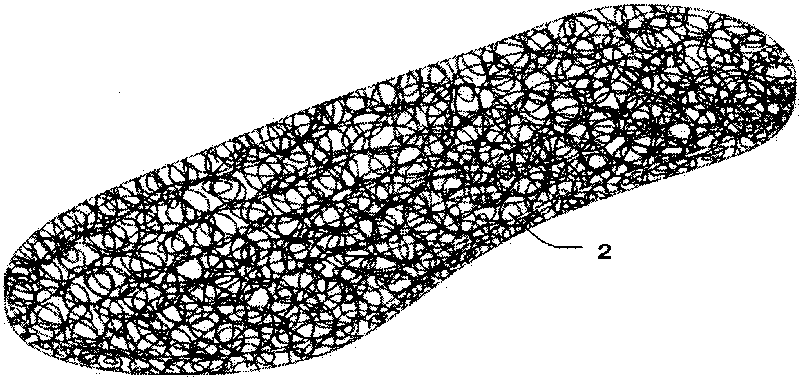

[0019] Such as Figure 1 to Figure 4 Shown, a kind of non-slip anti-fatigue sole of the present invention, it comprises sole underlayer 1, the midsole layer 2 that sticks on the undersole layer 1 and the upper sole layer 3 that sticks on the midsole layer 2, described undersole layer 1 is made of thermoplastics, the midsole 2 is made of thermoplastic loops, and the upper layer 3 of soles is made of mesh and PVC plastic coated on the mesh.

[0020] Wherein the lower layer of the sole 1 is made of thermoplastics, such as polypropylene material, which is a kind of hardness larger and has a certain degree of elasticity, can bear certain weight and pressure, and the side of the lower layer of the sole and the ground is printed with anti-slip protrusions The protrusions can be designed in different shapes, such as strip-shaped protrusions. The undersole of this structure is durable, has good wear resistance, especially good anti-slip performance, and is suitable for use in wet envir...

Embodiment 2

[0024] A kind of non-slip anti-fatigue sole of the present invention, it comprises sole underlayer 1, the midsole layer 2 that sticks on the sole underlayer 1 and the sole upper layer 3 that sticks on the sole middle layer 2, and described sole underlayer 1 is heat Made of plastic plastics, the midsole 2 is made of thermoplastic wire loops, and the upper sole 3 is made of mesh and PVC plastic coated on the mesh.

[0025] Wherein the lower layer of the sole 1 is made of polyamide material, the lower layer of the sole is a kind of hardness bigger and has certain elasticity, can bear certain weight and pressure, and the side that the lower layer of the sole contacts with the ground is printed with non-slip protrusions, said The bulges can be designed in different shapes, such as diamond-shaped bulges. The lower layer of the sole of this structure is durable, has good wear resistance, especially good anti-slip performance, and is suitable for use in wet and watery environments.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com