High-acid-resistant alkali-free aluminoborosilicate glass suitable for floating process, and preparation method and applications thereof

A borosilicate glass, float process technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of insufficient environmental protection components, achieve high strain point, high acid resistance, high elastic modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing high acid-resistant alkali-free aluminoborosilicate glass suitable for a float production process, comprising the following steps:

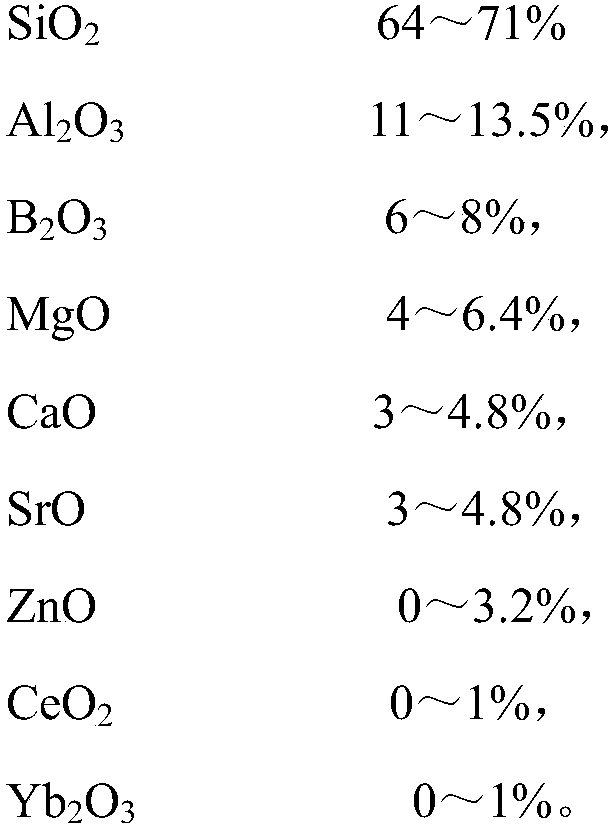

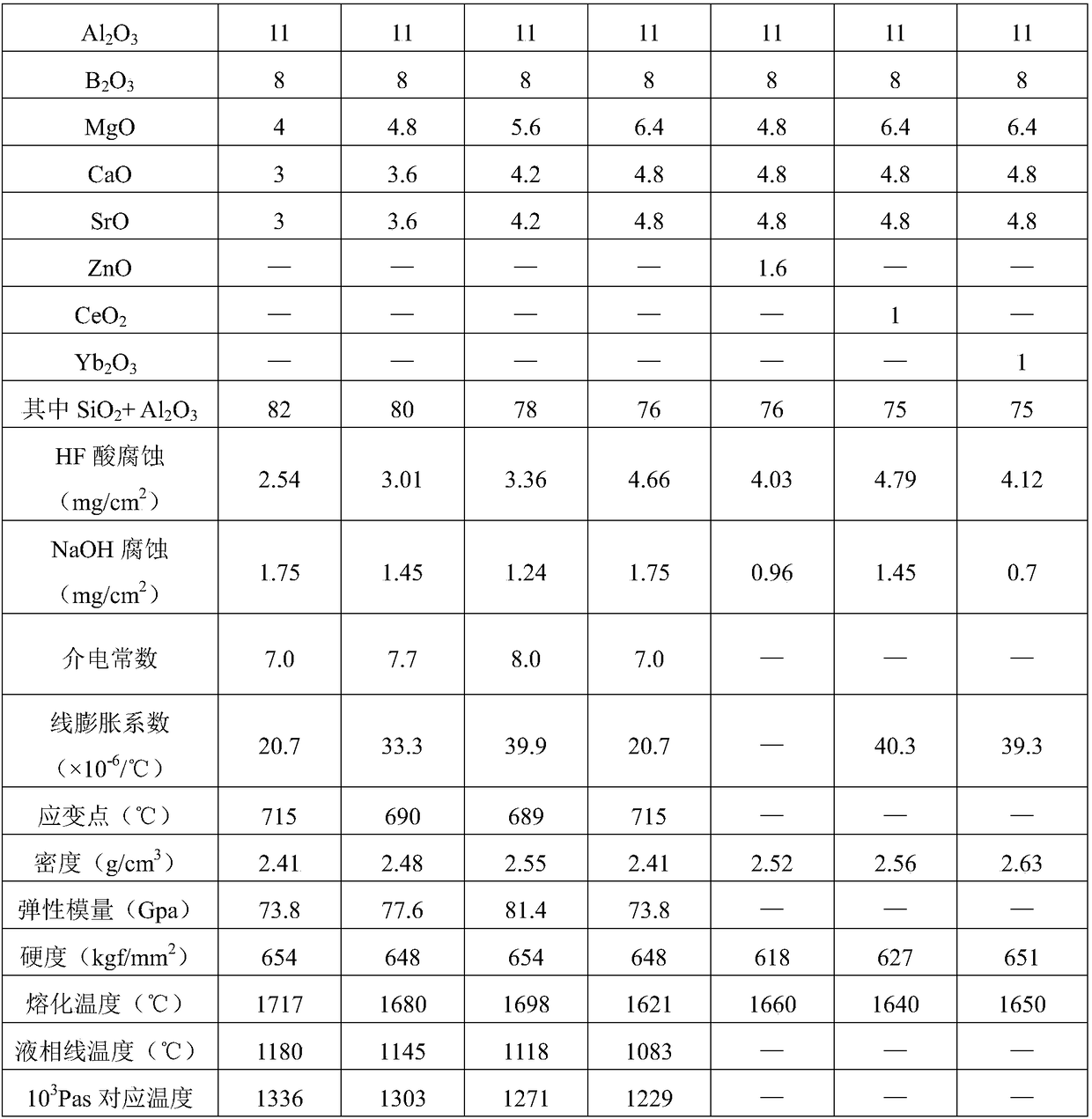

[0033] 1) Selection of raw materials: according to the mole fraction of each component in the glass: 64-71% SiO 2 , 11~13.5% Al 2 o 3 , 6~8%B 2 o 3 , 4~6.4% MgO, 3~4.8% CaO, 3~4.8% SrO, 0~3.2% ZnO, 0~1% CeO 2 ,0~1%Yb 2 o 3 Choose ingredients. And the sum of the mole percentages of each oxide satisfies 100%. Of which SiO 2 、Al 2 o 3 , B 2 o 3 , MgO, CaO, SrO, ZnO, CeO 2 , Yb 2 o 3 They are introduced by quartz sand, alumina, boric acid, light magnesium oxide, calcium carbonate, strontium carbonate, zinc oxide, cerium oxide, and ytterbium oxide.

[0034] 2) Glass preparation process: Calculate the required amount of each raw material in the batch according to the designed components, weigh it with an analytical balance, then put all the raw materials in the mixing bottle and mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com