Au/SnS2 nitrogen dioxide gas sensor and preparation process and application thereof

A gas sensor, nitrogen dioxide technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of restricting the wide application of sensors, long response recovery time, etc., and achieve low power consumption, fast heating response, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Au / SnS 2 Nitrogen dioxide gas sensor, including a gas-sensing material and a heating substrate, the gas-sensing material is spin-coated on the surface of the heating substrate, and the coating thickness is 100 μm; the composition of the gas-sensing material is gold simple substance nanoparticles and SnS 2 Nanocomposites formed from nanosheets. Au / SnS 2 Nanocomposites were prepared by a two-step solvothermal-deposition method; SnS 2 The size of the nanosheet is 600nm; the size of the gold simple nanoparticle is 10nm. The preparation process comprises the following steps:

[0033] Step 1: Using a mixture of 36.4mL of acidic buffer solution with pH=3 and 9.12mL of absolute ethanol as a solvent, 379.04mg of SnCl 2 2H 2 O was added to the mixture, stirred magnetically until it was completely dissolved, and the solution was colorless and transparent; then added 2084.81mg Na 2 S 2 o 3 ·5H 2 O and 270.76mg of sulfur powder, magnetically stirred for 40min and then poure...

Embodiment 2

[0037] Au / SnS 2 Nitrogen dioxide gas sensor, including a gas-sensing material and a heating substrate, the gas-sensing material is spin-coated on the surface of the heating substrate, and the coating thickness is 50 μm; the gas-sensing material is Au / SnS prepared by doping 0.1% gold simple substance nanoparticles 2 nanocomposites. Au / SnS 2 Nanocomposites were prepared by a two-step solvothermal-deposition method; SnS 2 The size of the nanosheet is 200nm; the size of the gold simple nanoparticle is 5nm. The preparation process comprises the following steps:

[0038] Step 1: Using a mixture of 31.6mL of acidic buffer solution with pH=3 and 8.33mL of absolute ethanol as a solvent, 371.67mg of SnCl 2 2H 2 O was added to the mixture, stirred magnetically until it was completely dissolved, and the solution was colorless and transparent; then added 2066.67mg Na 2 S 2 o 3 ·5H 2 O and 266.67mg of sulfur powder were stirred by magnetic force for 30min and then poured into the r...

Embodiment 3

[0042] The difference between this example and Example 2 is that 2 mL of chloroauric acid, 2 mL of L-lysine, and 0.2 mL of sodium citrate are added in step 2, and the rest of the steps and parameters are the same as in Example 2. According to this embodiment, Au / SnS doped with 0.5% gold single substance nanoparticles can be prepared 2 Nitrogen dioxide gas sensor.

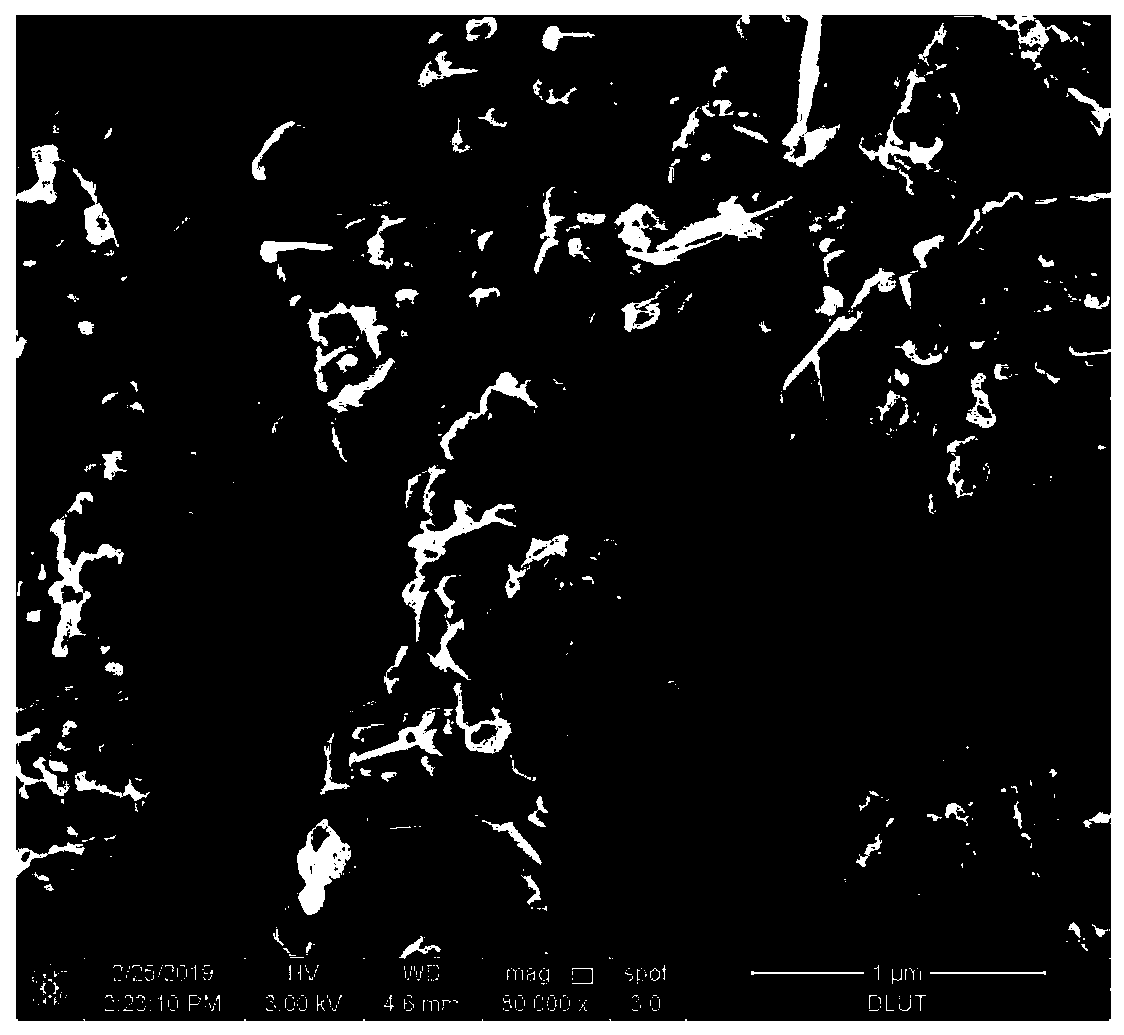

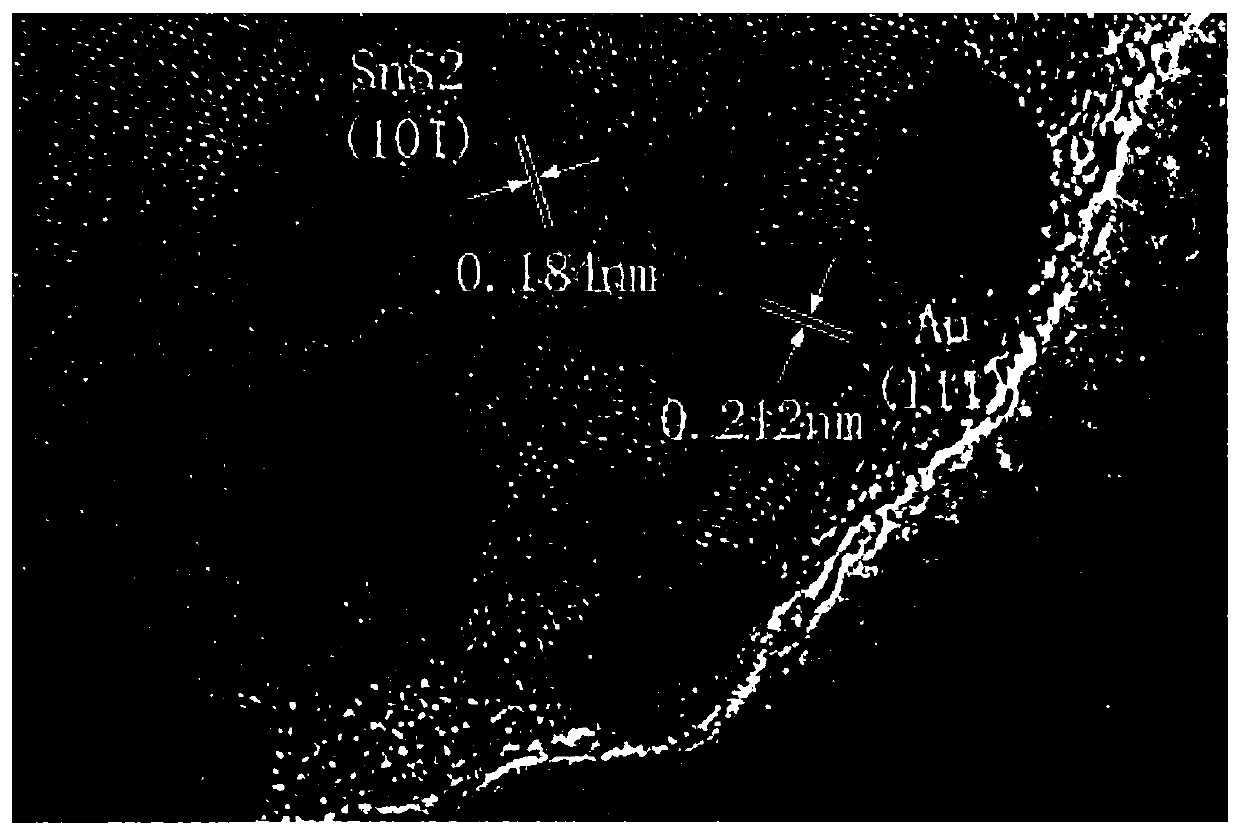

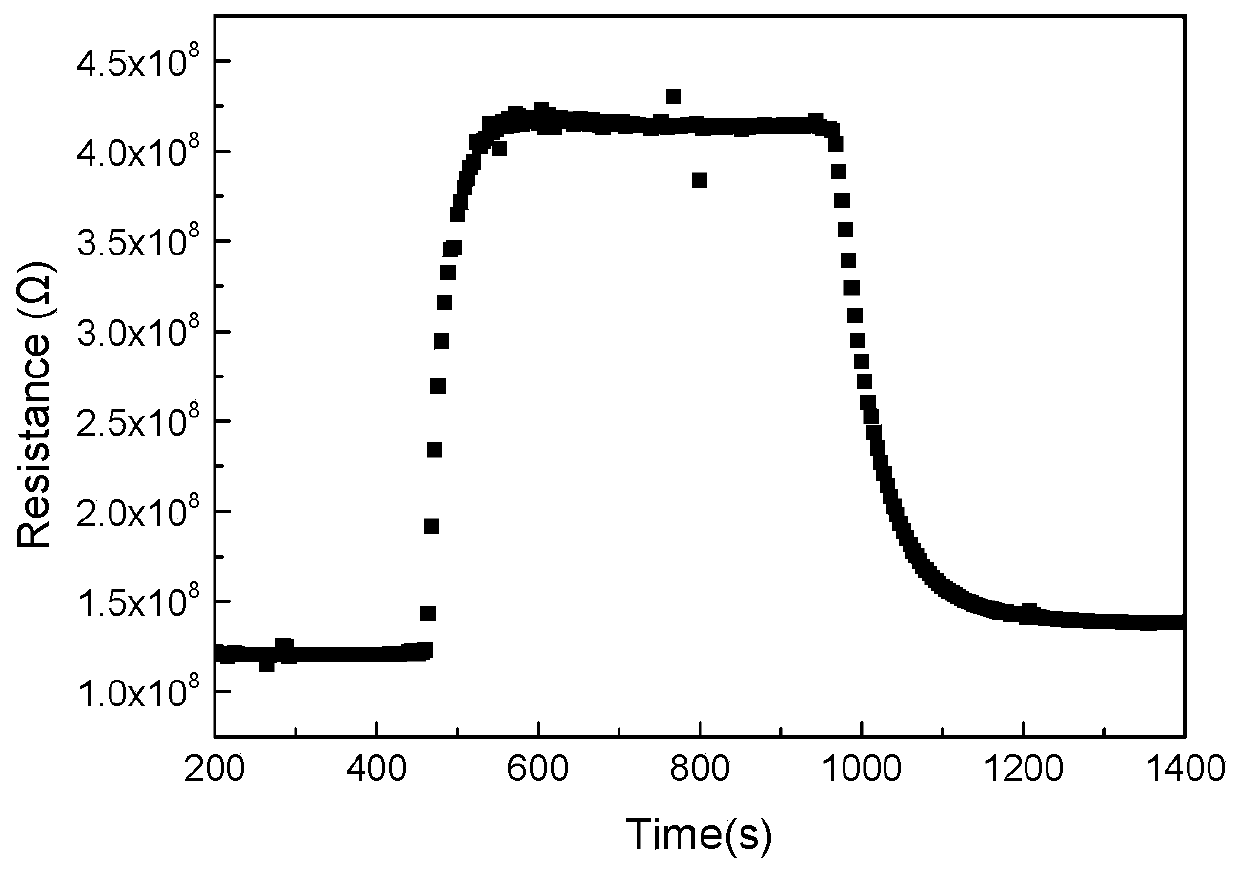

[0043] figure 1 The Au / SnS prepared in this example is given 2 Field emission electron microscope scanning image of the nanocomposite microstructure; figure 2 The Au / SnS prepared in this example is given 2 The field emission electron microscope scanning EDS image of the microstructure of the nanocomposite material shows that the prepared nanocomposite material contains three elements: Au, Sn and S; image 3 The Au / SnS prepared in this example is given 2 The HTEM image of the microstructure of the nanocomposite further illustrates that the nanocomposite is composed of simple gold nanoparticles and SnS 2 Compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com