Gelatinization sintering treatment method of waste incineration fly ash and waste treatment method

A waste incineration fly ash and sintering treatment technology, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems that cannot be popularized and used in a large scale, low resource utilization rate, and high cost, so as to facilitate large-scale engineering application, The effect of high resource utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

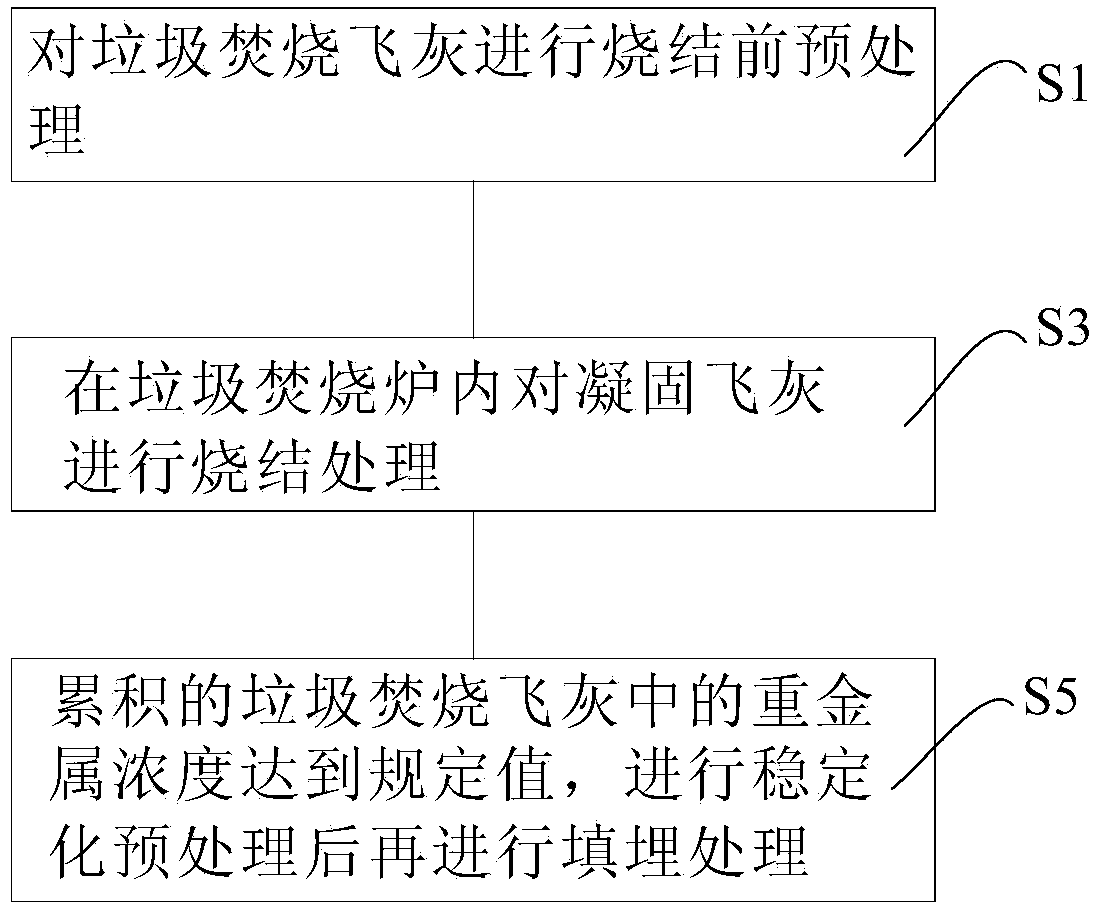

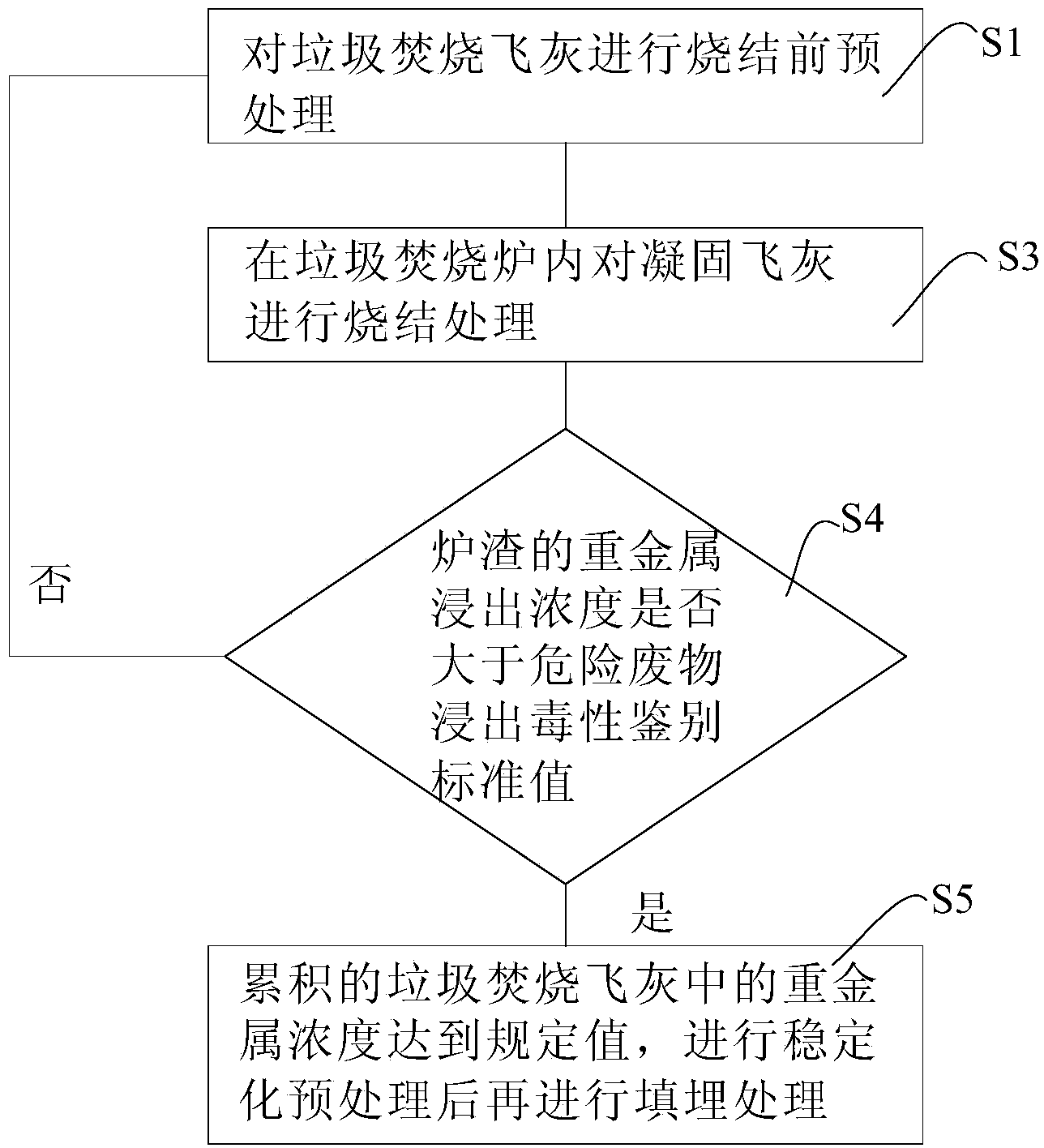

[0020] Please refer to figure 1 , the gelation and sintering treatment method of waste incineration fly ash provided by the embodiment of the present invention, it comprises the following steps:

[0021] S1, pretreatment of waste incineration fly ash before sintering.

[0022] Waste incineration fly ash is produced by the incineration of domestic waste through the waste incineration system, which includes fly ash and reaction products. The waste incineration system includes an incinerator, a waste heat boiler, a flue gas purification device and a bag filter device connected in sequence. The incinerator includes a fire grate for incinerating domestic waste and a hearth arranged on the upper part of the fire grate. Domestic waste is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com