Waterproof and anti-fatigue shoes

An anti-fatigue and vamp technology, applied in the direction of footwear, soles, clothing, etc., can solve the problems of shortened service life, no anti-fatigue, easy to damage shoes, etc., achieve good flexibility and elasticity, easy to wear and take off, The effect of environmental protection of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

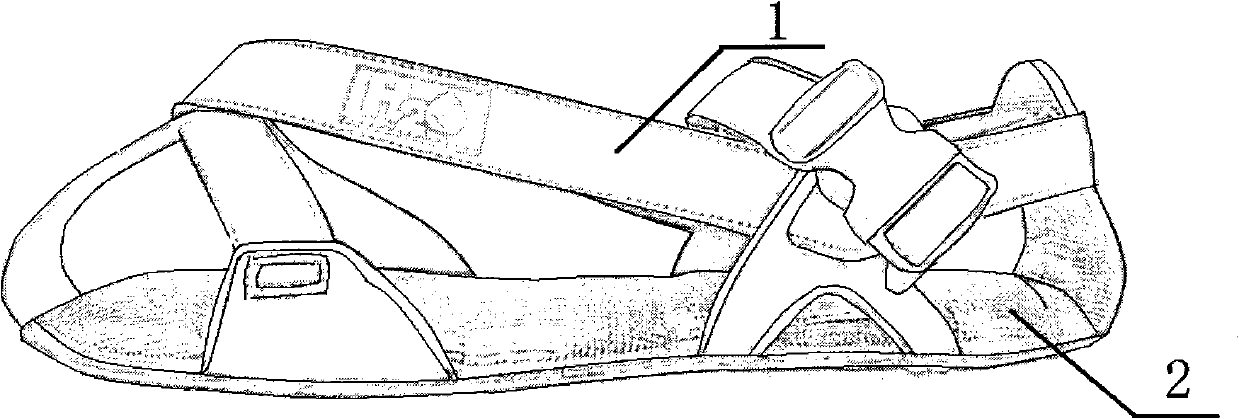

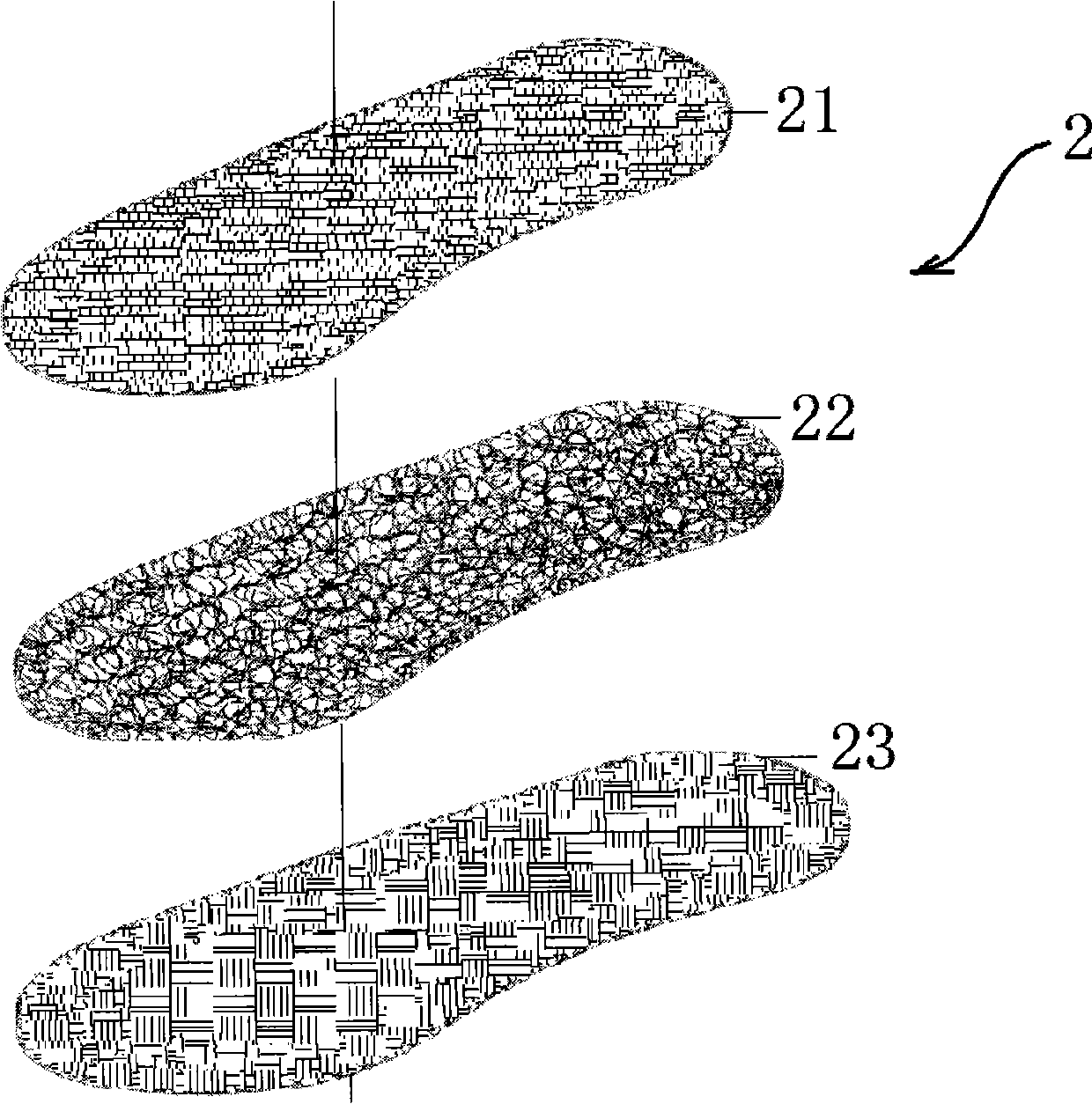

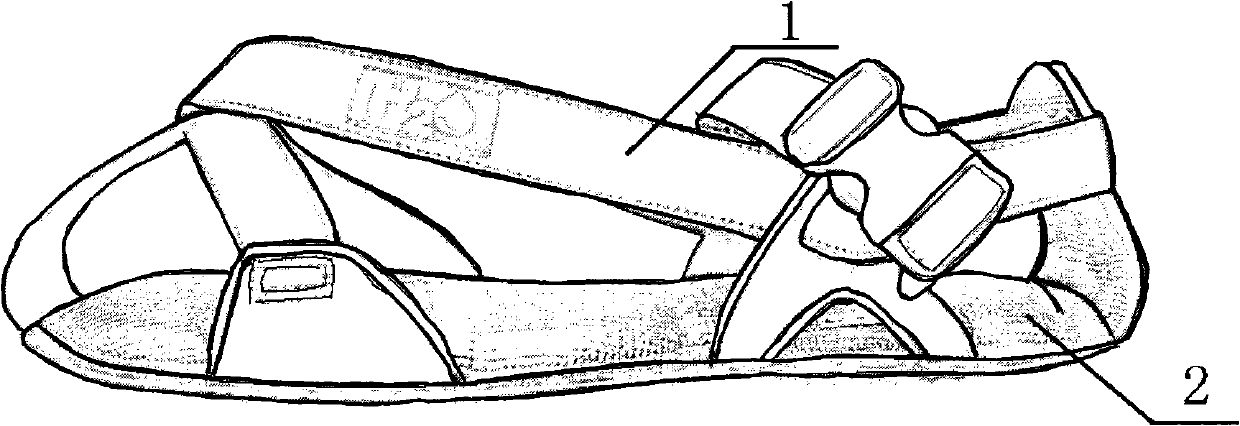

[0023] Such as figure 1 and figure 2 As shown, a kind of waterproof anti-fatigue shoe described in the present embodiment comprises a vamp 1 and a sole 2; the sole 2 includes: an upper sole 21, a midsole 22 and an undersole 23; the upper sole 21 and the undersole 23 The midsole 22 is sealed and wrapped to form a sole 2 with waterproof function. The upper layer 21 of the sole adopts a sandwich net coated with a thermoplastic elastomer to form an upper layer of the sole with a waterproof function; the middle layer 22 of the sole is composed of a thread loop of thermoplastic elastomer; the lower layer 23 of the sole is made of a thermoplastic elastomer The thickness of the middle layer 21 of the sole is 1.5mm, the thickness of the middle layer 22 of the sole is 8mm; the thickness of the lower layer 23 of the sole is 3.5mm; its thermoplastic elastomer is PVC in the present embodiment.

Embodiment 2

[0025] A waterproof anti-fatigue shoe described in this embodiment can be worn on the outside of other shoes. The waterproof anti-fatigue shoe described in this embodiment includes a vamp 1 and a sole 2; the sole 2 includes: an upper sole 21 and a middle sole 22 and the undersole 23; the upper sole 21 and the undersole 23 seal and wrap the midsole 22 to form a sole 2 with waterproof function. The upper layer 21 of the sole adopts a sandwich net coated with a thermoplastic elastomer; the middle layer 22 of the sole adopts a thread loop of a thermoplastic elastomer to form; the lower layer 23 of the sole adopts a thermoplastic elastomer to make: the middle layer 21 of the sole has a thickness of 2.5mm. The thickness of the middle layer 22 of the sole is 16mm; the thickness of the lower layer 23 of the sole is 5mm; The thermoplastic elastomer in this embodiment is EVA.

Embodiment 3

[0027] A waterproof anti-fatigue shoe described in this embodiment can be worn on the outside of other shoes. The waterproof anti-fatigue shoe described in this embodiment includes a vamp 1 and a sole 2; the sole 2 includes: an upper sole 21 and a middle sole 22 and the undersole 23; the upper sole 21 and the undersole 23 seal and wrap the midsole 22 to form a sole 2 with waterproof function. The upper layer 21 of the sole adopts a sandwich net coated with a thermoplastic elastomer; the middle layer 22 of the sole adopts a thread loop of a thermoplastic elastomer to form; the lower layer 23 of the sole adopts a thermoplastic elastomer to make: the middle layer 21 of the sole has a thickness of 1mm; the thickness of the middle layer 22 of the sole is 9mm; the thickness of the lower layer 23 of the sole is 4mm; the lower layer of the sole is provided with triangular anti-slip structural lines, and the height of the anti-slip lines is 2mm. In this embodiment, the thermoplastic el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com