Patents

Literature

32results about How to "Adjust mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sticky high-mechanical-strength nano hybrid hydrogel and preparation method thereof

InactiveCN105111341AHigh mechanical strengthOvercome the disadvantage of low mechanical strengthPolyvinyl alcoholCyclodextrin

The invention discloses a sticky high-mechanical-strength nano hybrid hydrogel and a preparation method thereof. The sticky hydrogel is obtained by polymerizing an acrylamide or N-alkyl substituted acrylamide derivative in aqueous dispersion of an inorganic nano crosslinking agent namely of laponite, polyvinyl alcohol and cyclodextrin, has high mechanical strength and stickiness and can adhere to surfaces of skins, metals, glasses and ceramics. The preparation method of the sticky hydrogel comprises the following steps: dispersing the inorganic nano crosslinking agent namely laponite and a monomer into water, and stirring to obtain uniform and transparent dispersion; adding polyvinyl alcohol into a reaction mixed solution, and stirring uniformly; then adding the cyclodextrin into the reaction mixed solution, and stirring uniformly; adding an initiating agent at last; and filling a mold with the reaction solution, sealing the mold, and putting the mold into an environment of 20-25 DEG C for reaction for 12-48 hours to obtain the sticky high-mechanical-strength nano hybrid hydrogel, wherein the tensile strength of the hydrogel is more than or equal to 100kPa, and the adhesive strength is more than or equal to 10kPa.

Owner:SOUTH CHINA UNIV OF TECH

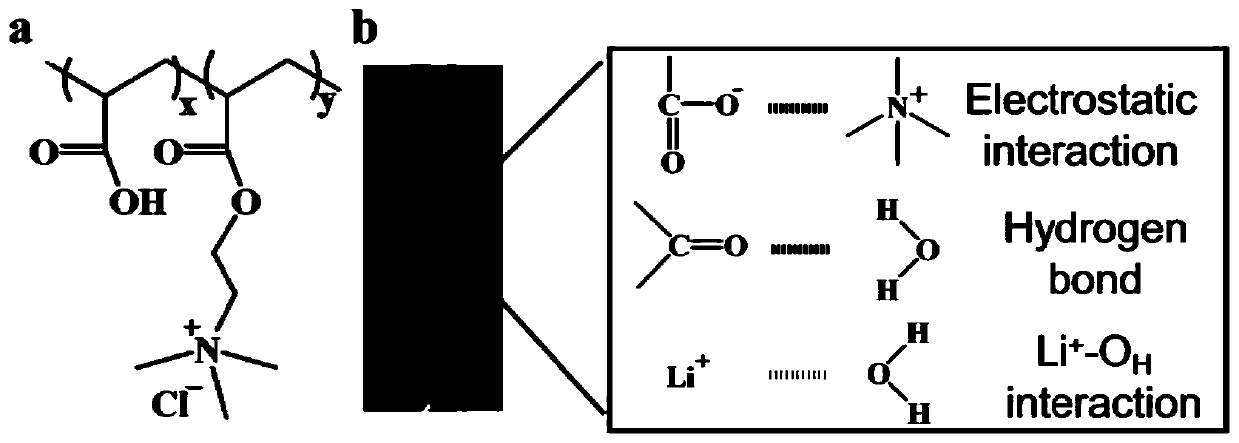

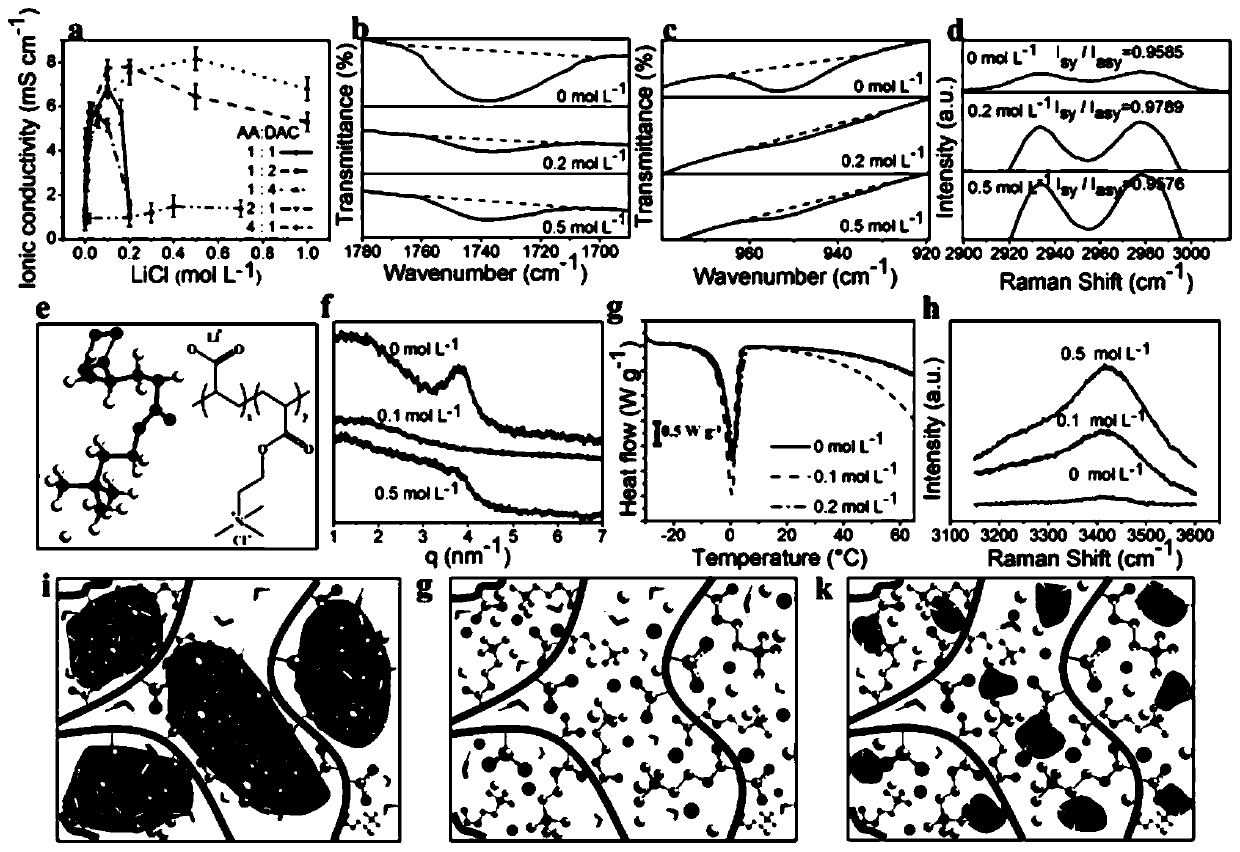

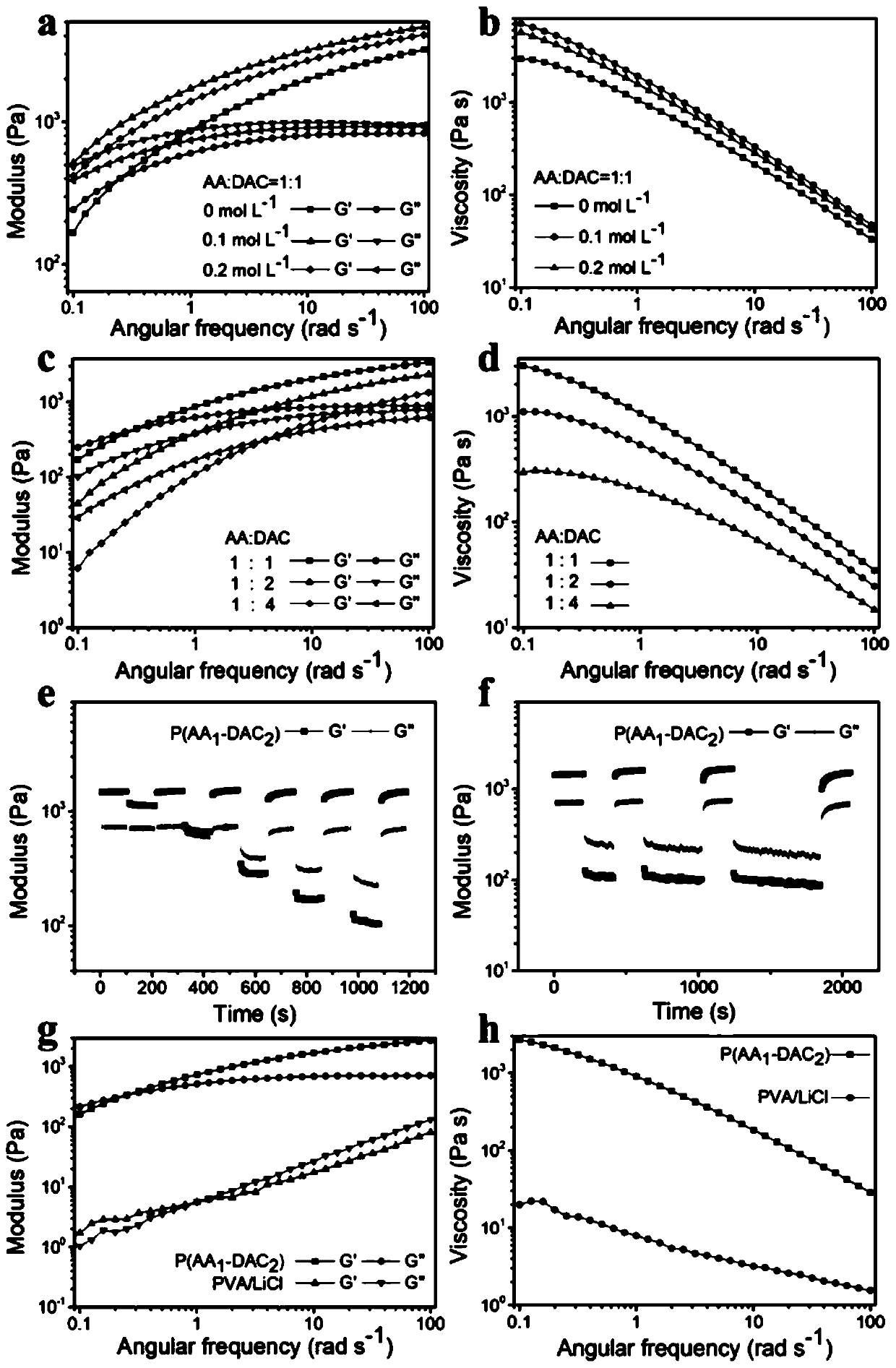

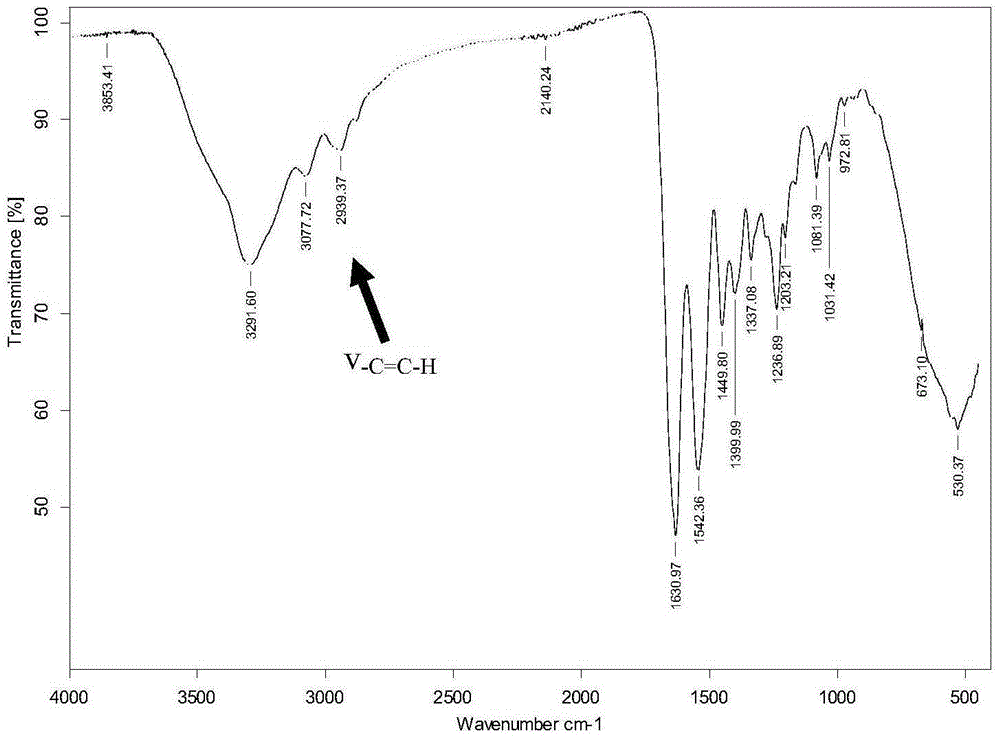

Amphoteric gel polymer electrolyte with good performance and preparation and application thereof

ActiveCN109935476AInhibit migrationReduce interface resistanceHybrid capacitor electrolytesHybrid/EDL manufactureCapacitancePolymer science

The invention relates to an amphoteric gel polymer electrolyte with good performance and preparation and application thereof. A series of zwitterionic gel electrolytes are prepared in the invention. An amphoteric gel electrolyte with high mechanical strength and a conductivity of 8.2 mScm-1 can be prepared by controlling the ratio of monomers and the concentration of lithium salt. The interfacialresistance between an electrode and the electrolyte is greatly reduced by immersing an AC electrode into a monomer solution for in-situ polymerization. The AC electrode with the in-situ polymerized electrolyte has a large area capacitance of 297mF cm-2 at a current density of 0.8 mA cm-2 and can remain 70% after 7000 cyclic tests. Remarkably, the combined solid capacitor not only have an area energy density up to 6.6 mWh cm-2 and a power density up to 2.4 W cm-2, but also have a good self-healing property. The work of the invention provides a new idea for the field of gel electrolytes, and obtains a zwitterionic gel electrolyte having great application potential in energy storage equipment.

Owner:QILU UNIV OF TECH

Photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and preparation method thereof

ActiveCN105294955AHigh affinityGood formabilityArtificial cell constructsSkeletal/connective tissue cellsHardnessPhoto curing

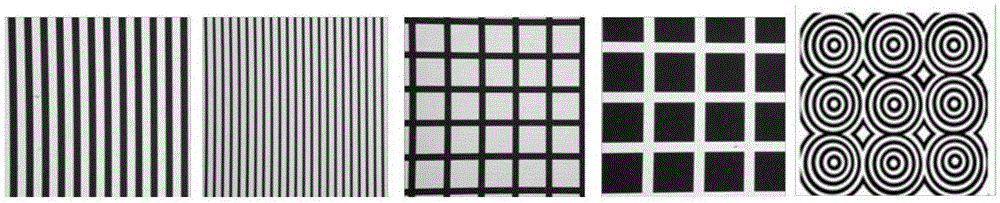

The invention belongs to the field of biomedical materials, and particularly relates to photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and a preparation method thereof. The photo-curing hydrogel is prepared by taking modified high-polymer materials with the photo-curing performance as raw materials and are divided into multiple different areas by straight-stripe-shaped or net-stripe-shaped or annular-stripe-shaped micro-pattern structures, the hardness of the photo-curing hydrogel in the same area is same, the hardness of the photo-curing hydrogel in the different areas is same or different, and the overall photo-curing hydrogel at least has two kinds of the hardness. According to the photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and the preparation method thereof, on one hand, the elasticity moduli of all the areas of the photo-curing hydrogel are different by controlling the ultraviolet radiation curing degree; on the other hand, all the areas with the different elasticity moduli present the micro-pattern structures on the photo-curing hydrogel, selective adhesion, proliferation and differentiation of cells on the photo-curing hydrogel can be achieved by combining the elasticity moduli with the micro-pattern structures, and therefore controllable cell sorting or stem cell area-selecting differentiation can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

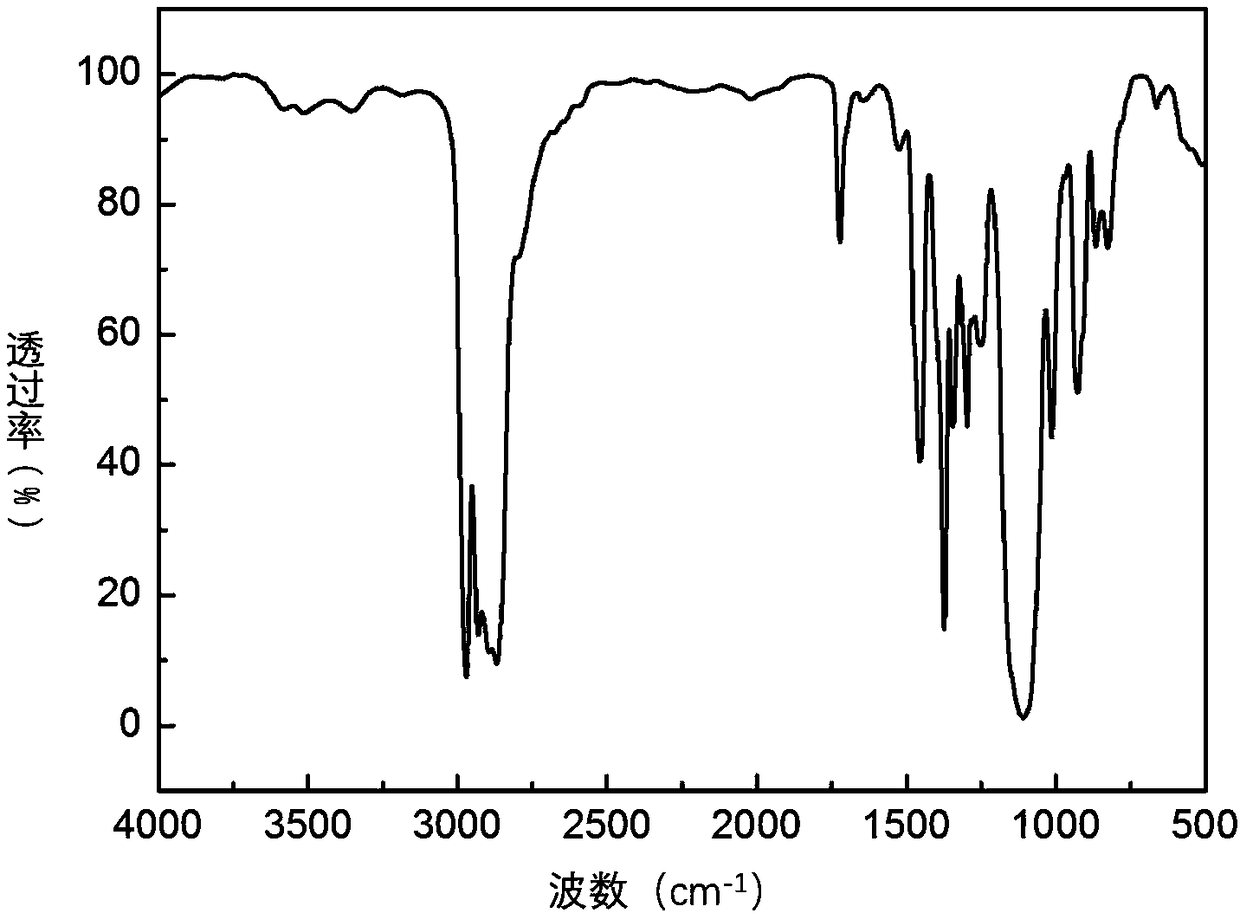

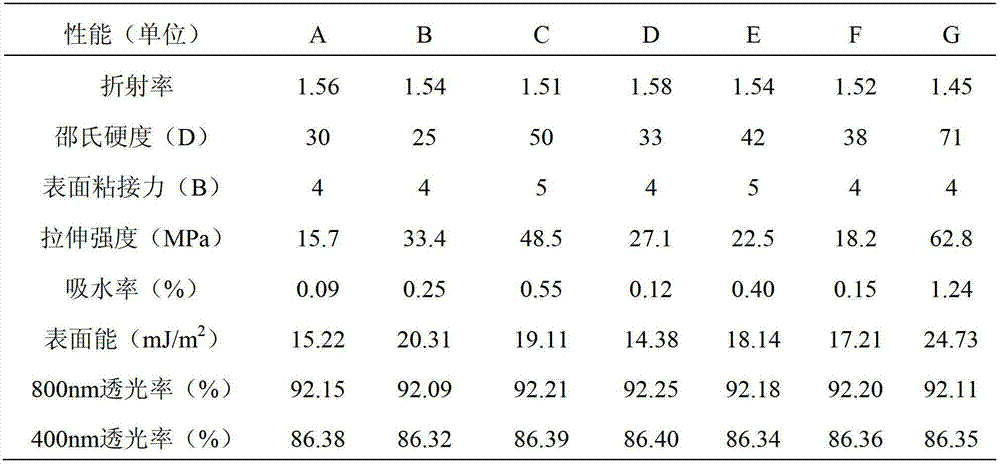

Method for preparing organosilicone hybrid resin and power type encapsulating material for light-emitting diodes (LED) thereof and application

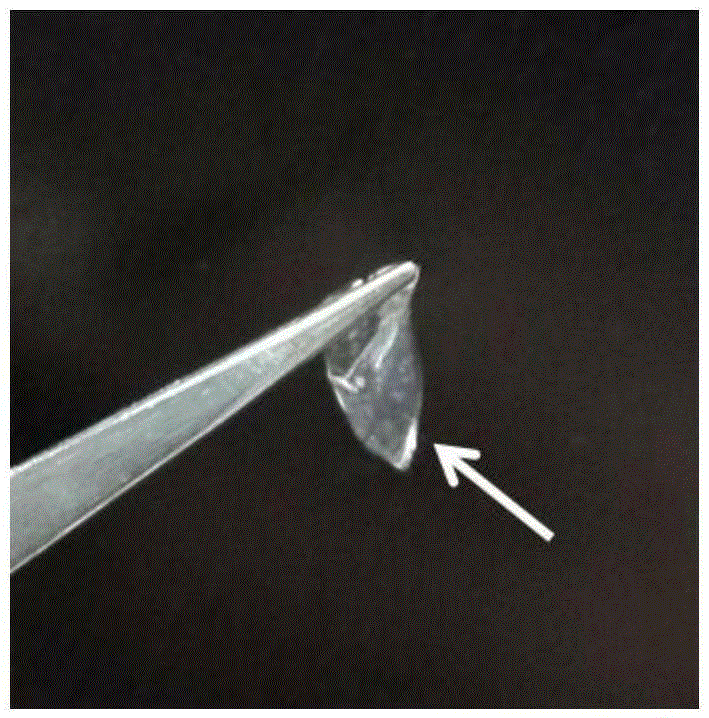

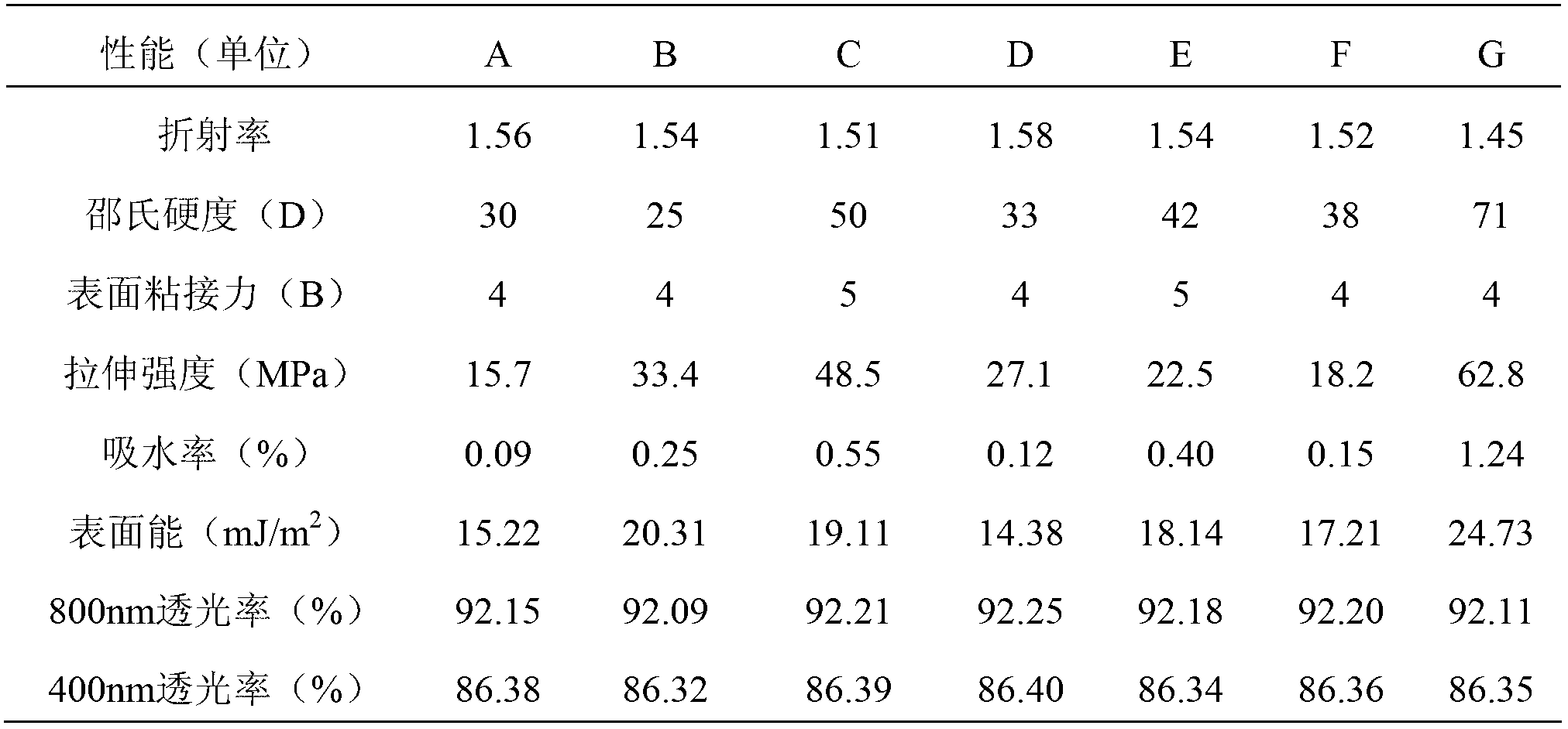

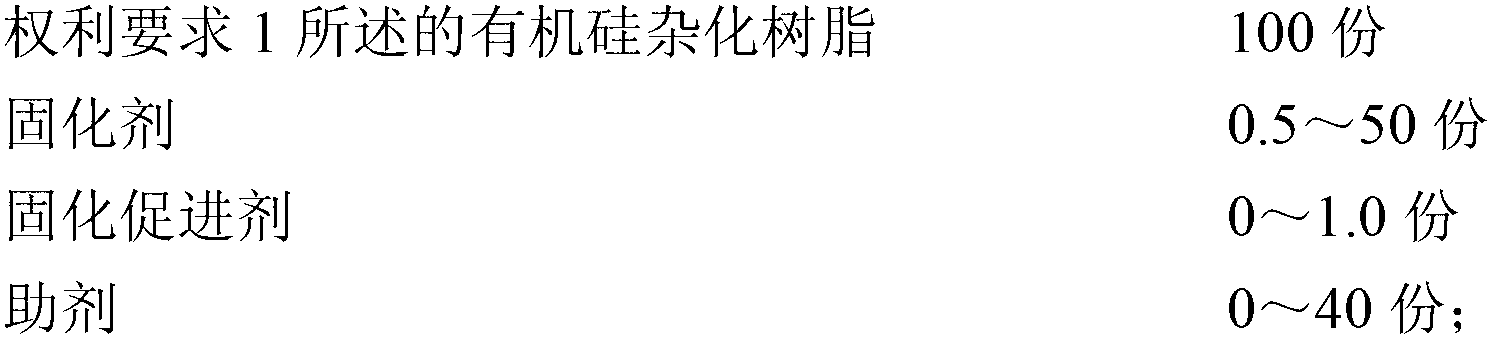

ActiveCN102702532AEasy to prepareRaw materials are environmentally friendlyPlastic/resin/waxes insulatorsCoatingsEpoxyAdhesive

The invention discloses a method for preparing organosilicone hybrid resin and a power type encapsulating material for light-emitting diodes (LED) thereof and application. According to the method, the organosilicone hybrid resin containing three functional groups of an epoxy group, a fluorin group and a phenyl group is prepared by a cohydrolysis condensation method, and the content of each group in the resin is optimized by controlling the ratios of fluoro alkyl silicane, epoxy alkyl silicane and phenyl silicane, so that the resin is applied to the power type encapsulating material for the LEDs. The prepared encapsulating material has the advantages of epoxy resin and organosilicone, has high performance of high light transmittance and refractive index, low hygroscopicity, high mechanical property and ageing-resistant performance and the like, and the problems of low light output rate, short service life and the like of the LEDs due to dropping caused by low bonding strength and poor mechanical property of the ordinary organosilicone material for encapsulating LEDs are solved. The method for preparing the organosilicone hybrid resin and the power type encapsulating material for the LEDs is simple, and raw materials are readily available and environment-friendly; and the organosilicone hybrid resin can also be used as the raw materials to be applied to processing and preparation of optical lens materials, photovoltaic conversion materials, integrated circuit encapsulating materials, insulating materials, coating materials, adhesives and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Near-infrared-light-responsive intelligent aquagel bionic arm and preparation method thereof

ActiveCN105111388AHigh mechanical strengthOvercome the disadvantage of low mechanical strengthProsthesisSmart hydrogelsEngineering

The invention discloses a near-infrared-light-responsive intelligent aquagel bionic arm and a preparation method thereof. The aquagel bionic arm is formed by connecting three aquagels with different functions by in-situ free-radical polymerization, wherein the three aquagels are respectively a I-extension section, a II-contraction section and a III-grabbing section. The aquagel bionic arm can capture the target object under the action of viscosity or magnetism. The intelligent aquagel bionic arm can implement the bionic actions of extension, object capturing and retrieval under the irradiation of near-infrared light. The preparation method comprises the following steps: respectively dispersing the three aquagel components in water, adding an initiator, adding the three aquagels into a mold according to the sequence of I-II-III or III-II-I, sealing, and reacting in a 10-25-DEG C environment for 12-48 hours to obtain the near-infrared-light-responsive intelligent aquagel bionic arm.

Owner:SOUTH CHINA UNIV OF TECH

Porous active artificial bone and preparation method thereof

The invention relates to a porous active artificial bone. In the porous active artificial bone, a calcium phosphate-based biological ceramic material is used as a matrix, and the porous active artificial bone comprises small pores, dense parts and directional pore channels and chelates with diphosphonate. A preparation method of the porous active artificial bone comprises the steps of preparing calcium phosphate precursor powder, compression molding a ceramic blank by using a pore-foaming agent, polyester fiber and the precursor powder, high temperature sintering into a calcium phosphate-based ceramic sintered body and forming the dense parts, the small pores distributed alternately; and immersing calcium phosphate-based ceramic sintered body in a diphosphonate solution to chelate with the diphosphonate so as to obtain the drug-loaded porous active artificial bone. The artificial bone provided by the invention has longitudinal directional pores and a porous structure suitable for osteoblast migration, propagation and growth metabolism, can slowly release small molecular drugs capable of promoting the growth of the osteoblast and inhibiting osteoclast, and is particularly suitable for the fields of treating bone defects of osteoporosis patients, dental restoration, and the like.

Owner:SHENZHEN LANDO BIOMATERIALS

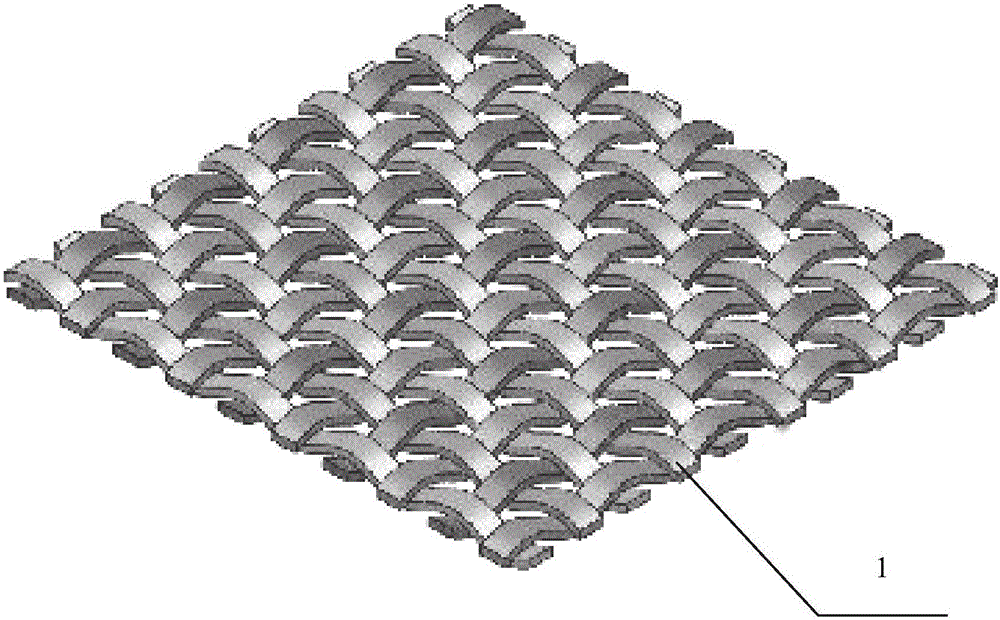

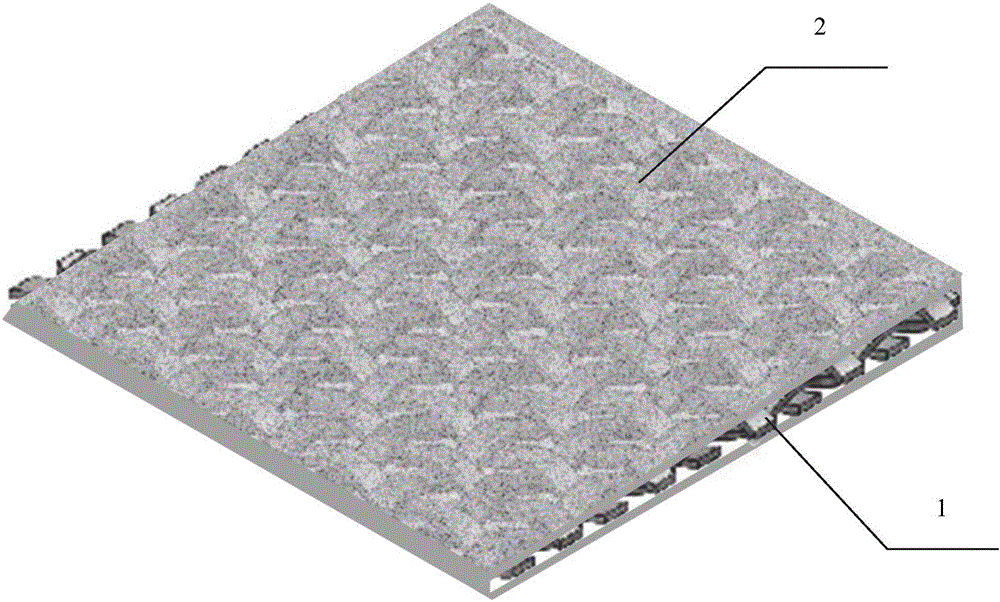

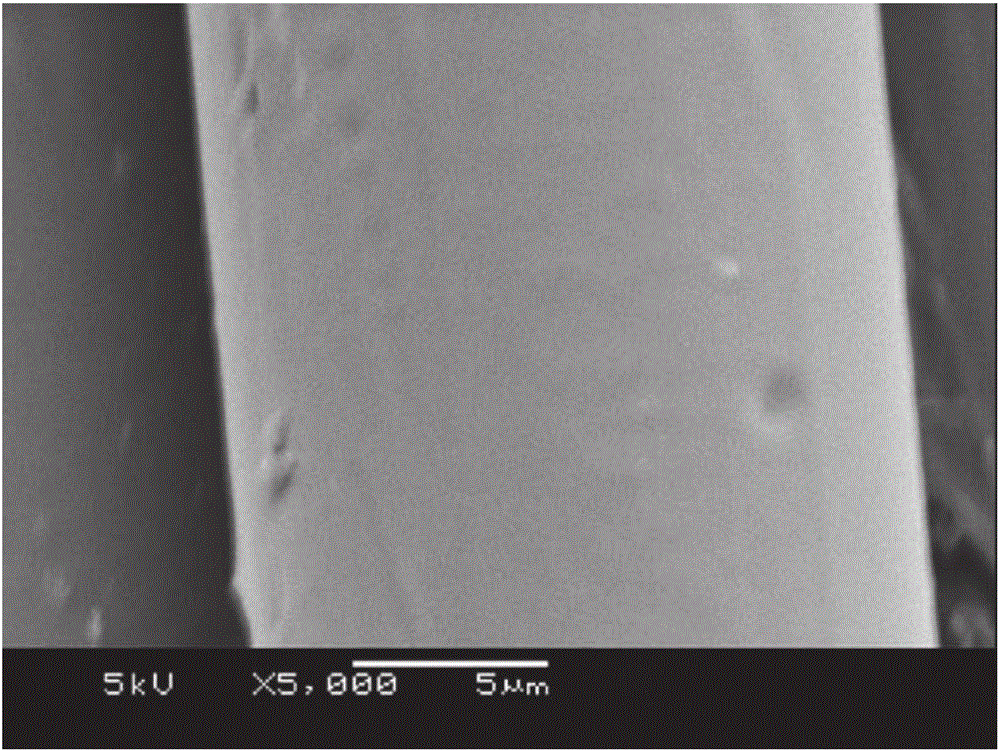

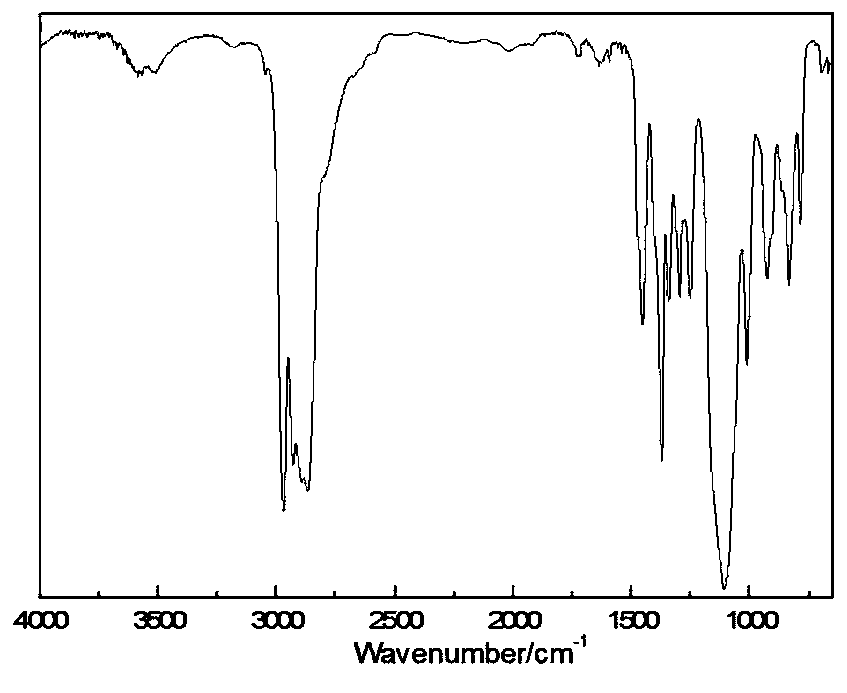

Composite type artificial dura mater and preparation method

The invention relates to a composite type artificial dura mater, comprising two hydrogel layers and a woven layer, wherein the woven layer is arranged between the two hydrogel layers, the woven layer is a degradable polymer material, and cell growth factors are contained in the hydrogel layers. The composite type artificial dura mater disclosed by the invention has the following beneficial effects: (1) the artificial dura mater is made from the degradable polymer material and biological protein which are easily available, and has good biocompatibility; (2) atmospheric pressure plasma jet treatment increases the fiber surface area of the woven layer, decreases a contact angle of a material surface, and improves water transmissibility, degradation speed and cellular affinity; (3) regulation on physical characteristics of the artificial dura mater, such as malleability, toughness, mechanical strength and the like can be realized by regulating a weaving method; and 4) the composite type artificial dura mater is favorable for wound repair, and silver ions enable artificial skin to have good antibacterial performance, so that toxic and side effects on a human body due to the use of a chemical antibacterial medicine are avoided, and storage life of the artificial skin is prolonged.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

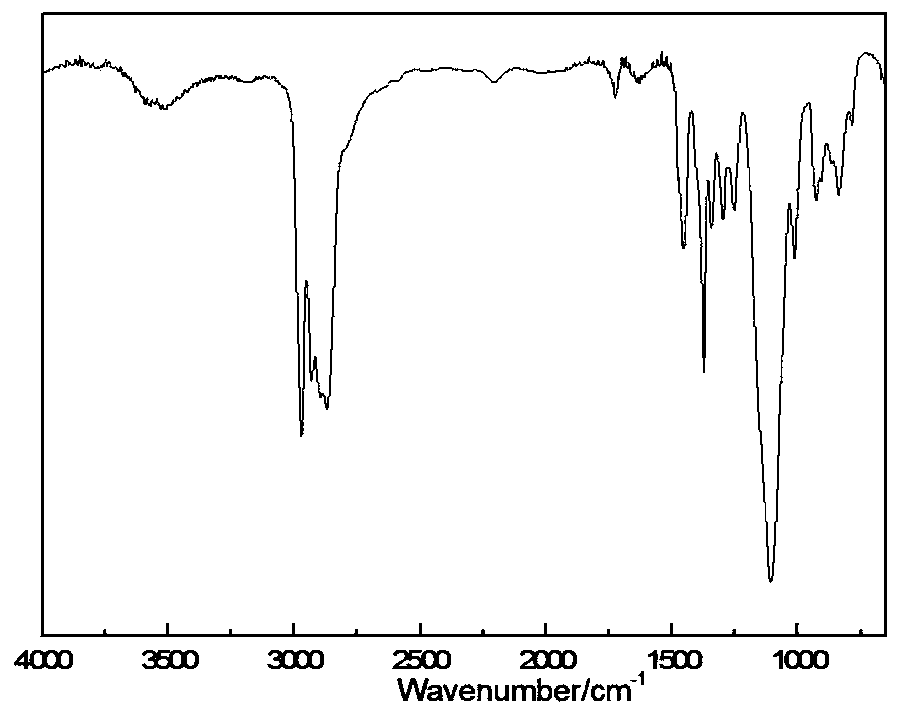

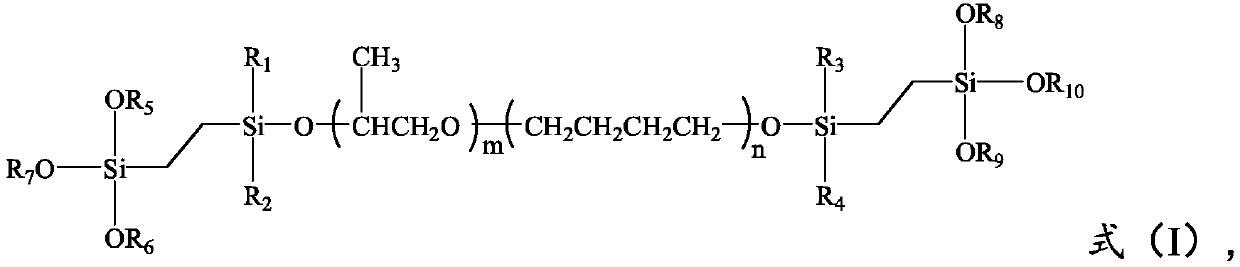

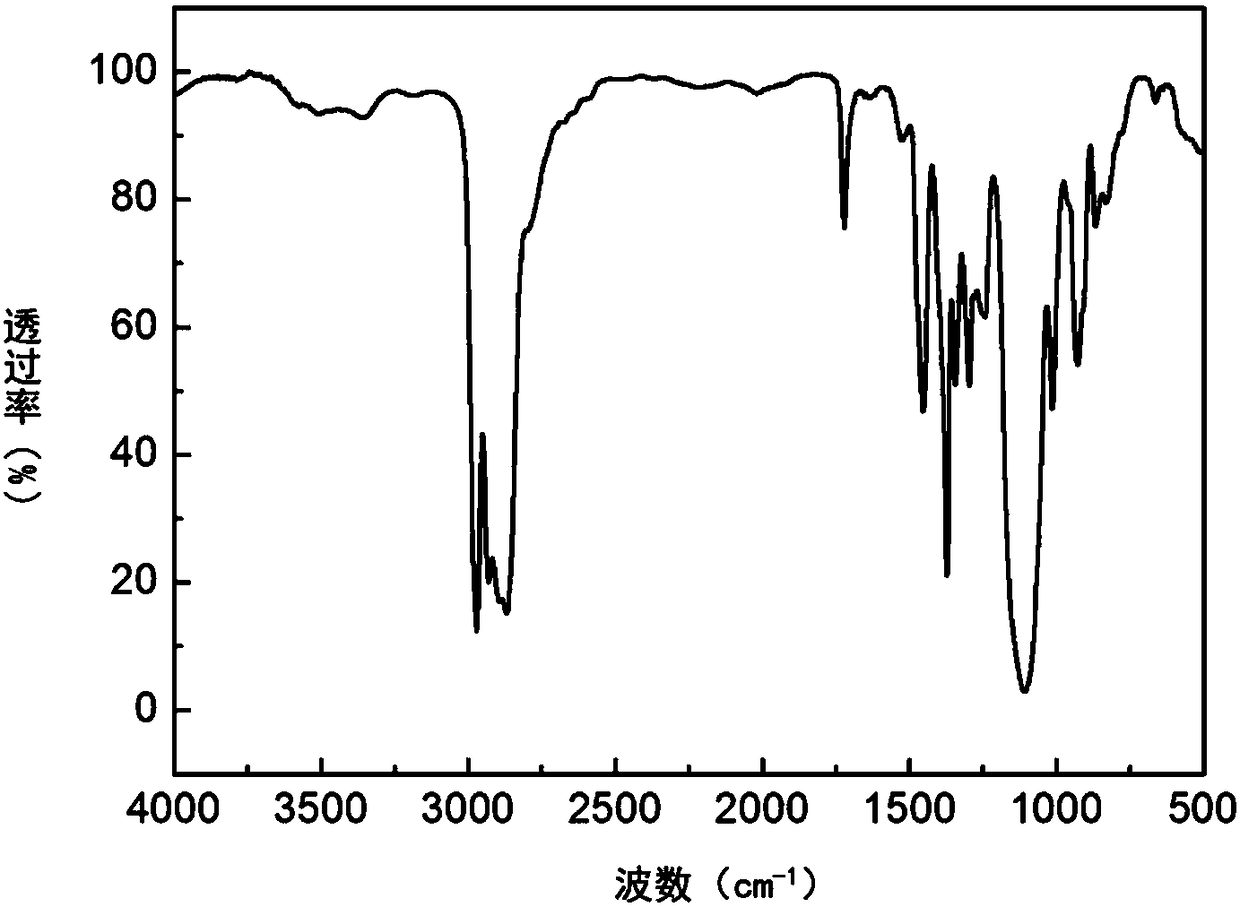

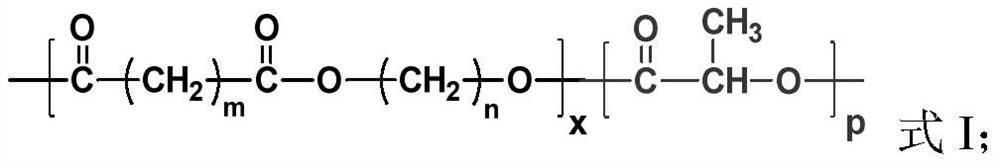

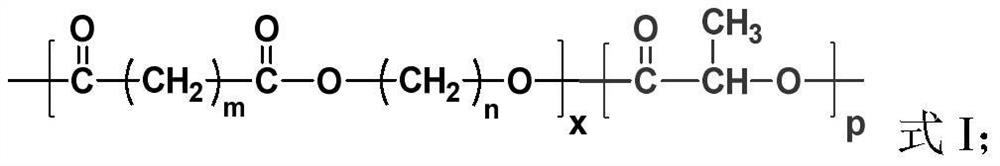

Silane modified polyether and preparation method thereof

ActiveCN110117357AAdjust mechanical strengthAdjust the cure rateNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveSilanes

The invention provides a silane modified polyether and a preparation method thereof. According to the silane modified polyether with the structure shown in a formula (I), the polyether is prepared byselecting specific raw materials and adjusting the molecular weight of the polyether and the type of a silane end capping agent, the adjustment of the mechanical strength and curing rate of an MS polymer can be achieved, MS adhesives with a series of strengths and curing speeds are obtained when the polyether is used in formulas, the synthesis of a polyether intermediate in the method does not need to use a catalyst, the reaction conditions are simple and controllable, a toxic reagent allyl chloride / allyl bromide is not used, chain extension is not needed (a chain extender methylene halide cannot be used), an organotin catalyst used in silane modified polyurethane is also avoided, no salt by-products are produced, the silane modified polyether is safe, environmentally friendly and free ofpollution, and the preparation method is an environment-friendly and energy-saving method for synthesizing the polyether.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Self-driving dopamine gel driver, preparation method and driving manner thereof

ActiveCN107163185ATo overcome the defect that the shape memory cycle must obtain a temporary shape through external forceEasy to prepareEngineeringDopamine

The invention discloses a self-driving dopamine gel driver, a preparation method and a driving manner thereof. The dopamine gel driver is prepared in the manner of copolymerizing dopamine methacrylamide and acrylamide monomers into a gel, soaking the gel in a Fe3+ solution for treating and then acquiring a fixed temporary shape in an alkaline solution. The dopamine gel driver can realize the driving function of automatically changing the shape of the hydrogel in the solution according to the method of changing the pH value of the solution.

Owner:SOUTH CHINA UNIV OF TECH

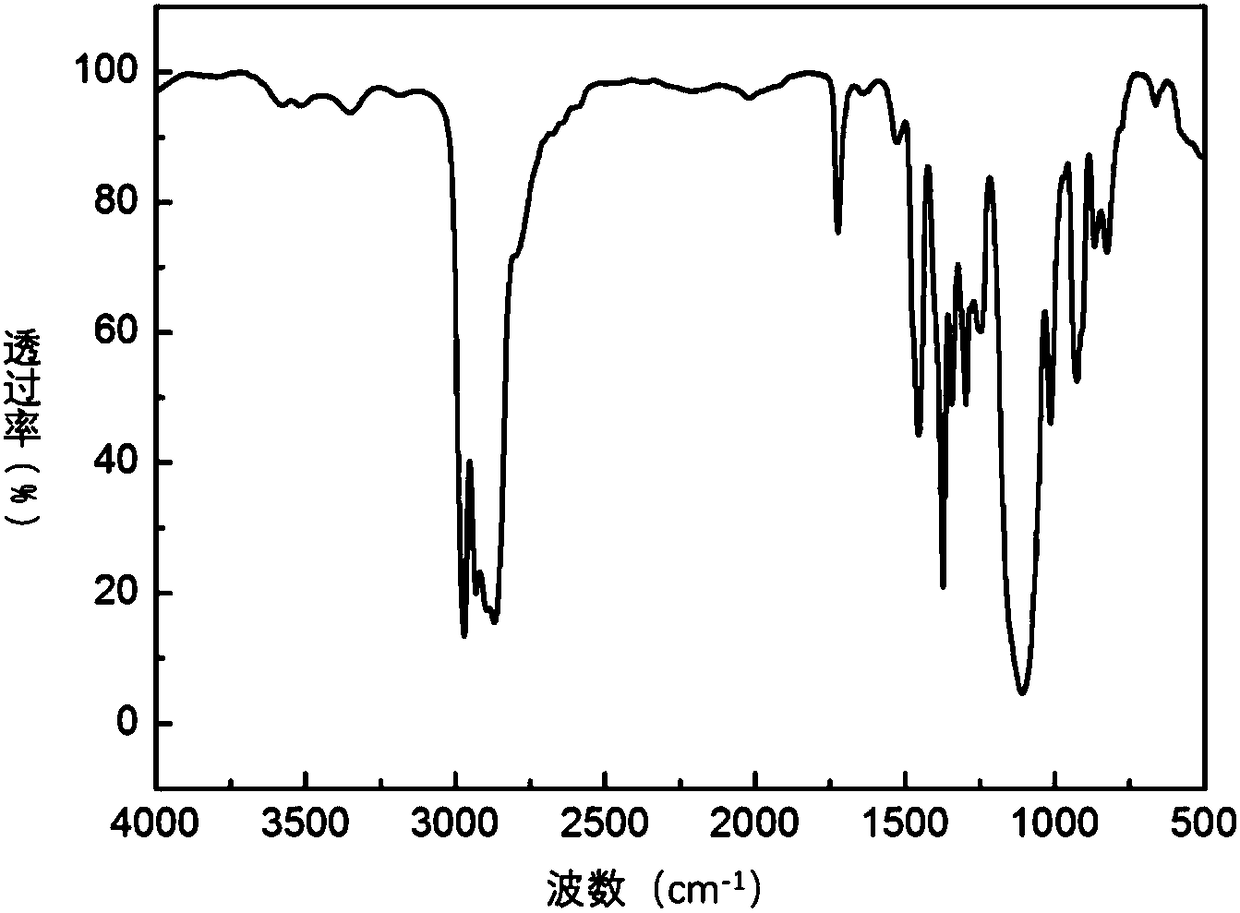

Silane-terminated MS resin and preparation method thereof

The invention discloses a silane-terminated MS resin and a preparation method thereof. The silane-terminated MS resin is characterized in that the silane-terminated MS resin is ethyoxyl- or methoxyl-terminated; the preparation method comprises the following steps of (1) adding 100 weight parts of hydroxyl terminated polyether, which is subjected to pre-dehydration treatment, into a reaction still,adding hydrogen-containing double-terminating head or terminal hydrogen-containing silicone oil, further adding a platinum catalyst, raising the temperature to 30 to 100 DEG C under the protection ofnitrogen, reacting for 6 to 10h to obtain a prepolymer I; (2) continuously adding 0.005 to 0.1 weight part of vinyl silane terminating agent, maintaining the temperature to be 90 to 110 DEG C and continuously reacting for 4 to 6h to obtain the MS resin. According to the preparation method, provided by the invention, no organotin catalyst is used in a synthesizing process, MS resins with differentmolecular weights, different viscosities and terminated by different silanes can be synthesized by the method, and the MS resin prepared by the method is good in curing speed and difficult to coagulate.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

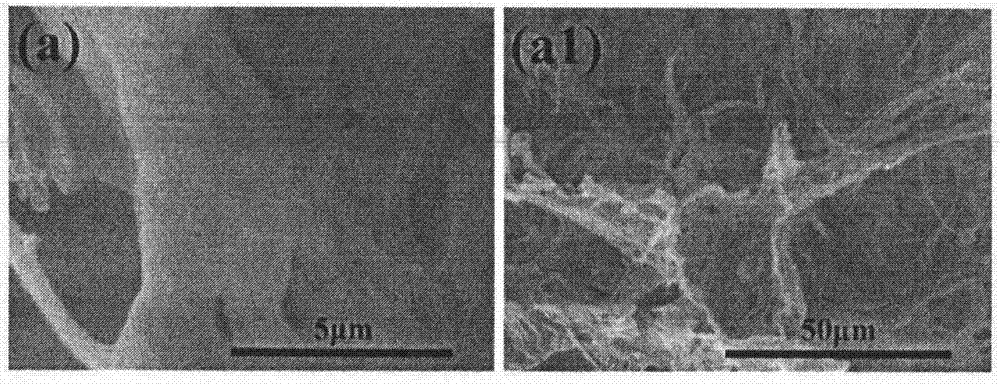

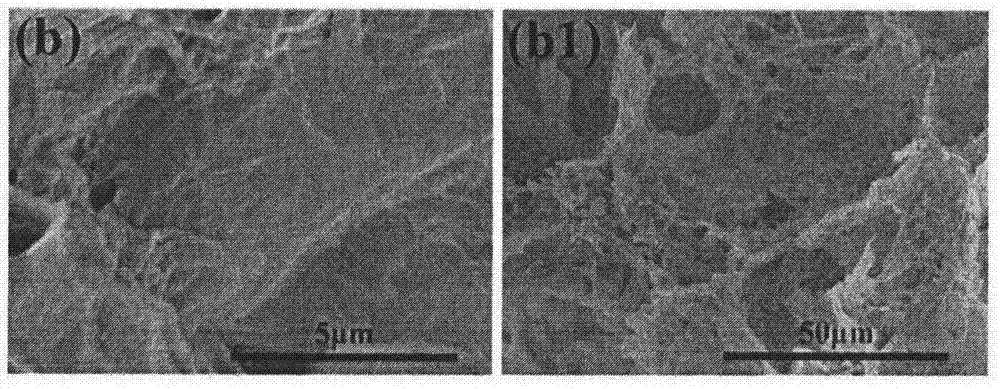

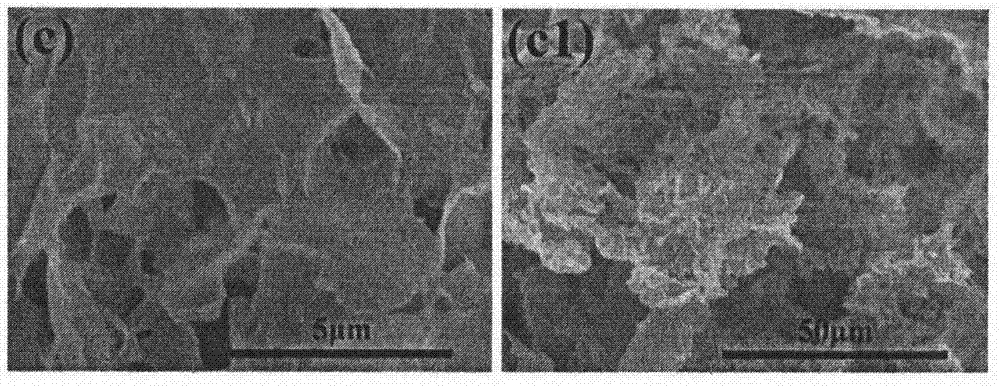

Preparation method for sponge material with adsorption, separation, filtering and purification function

InactiveCN107987310AEasy to prepareLow costWater contaminantsTreatment involving filtrationCross-linkWater filter

The invention provides a preparation method for a sponge material with an adsorption, separation, filtering and purification function for chemical substances including organic dyes, heavy metal ions and the like in water. The preparation method comprises the following steps: (1) accurately weighting polyvinyl alcohol, and dissolving the polyvinyl alcohol into deionized water at a certain mass ratio, and evenly stirring; (2) adding graphene oxide, a foaming agent, a cross-linking agent and a catalyst into polyvinyl alcohol solution, and stirring for certain time after one reagent is added to evenly disperse the reagent; (3) transferring a precursor into a die, and heating and solidifying for forming; (4) cleaning a formed compound sponge with water for multiple times, and drying to obtain the dried sponge material. The preparation method has the advantages of simple process, low cost and wide applicable range. The obtained sponge material is porous, hydrophilic and resistant to solvent,has a high adsorption rate and high removal efficiency for the organic dyes and heavy metal ions, and does not need additional energy consumption, and the sponge material can be desorbed, cleaned andutilized after pollutants are adsorbed and is suitable for industrial wastewater processing and household water filters.

Owner:TIANJIN POLYTECHNIC UNIV

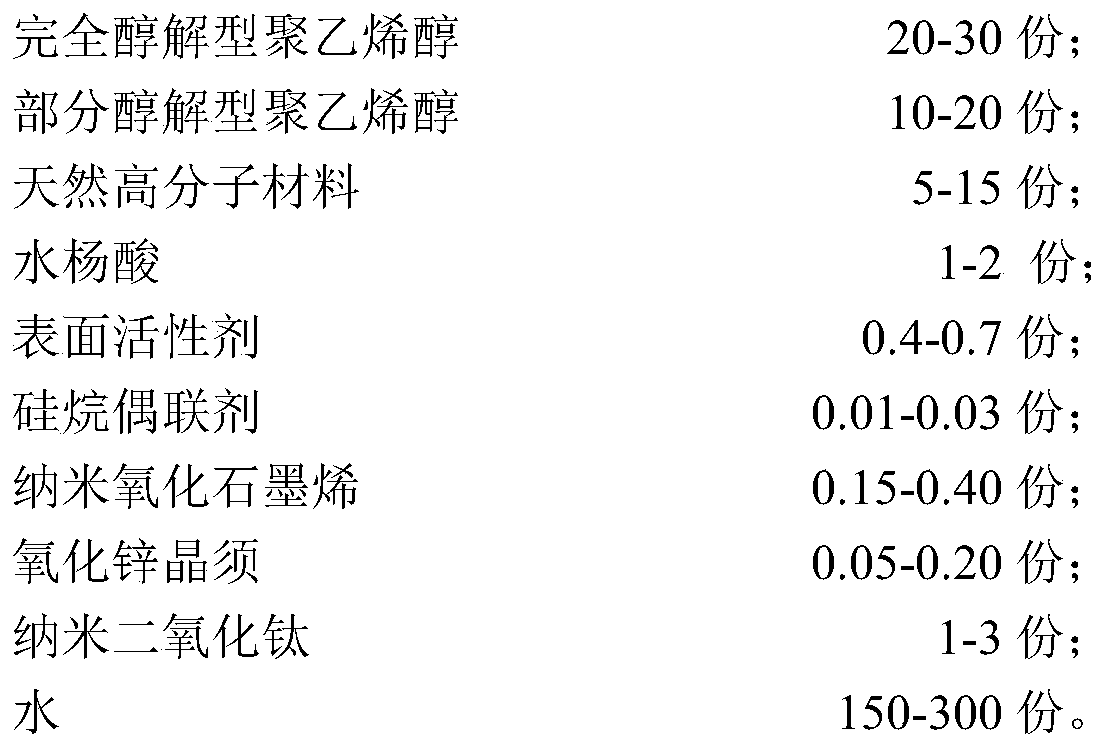

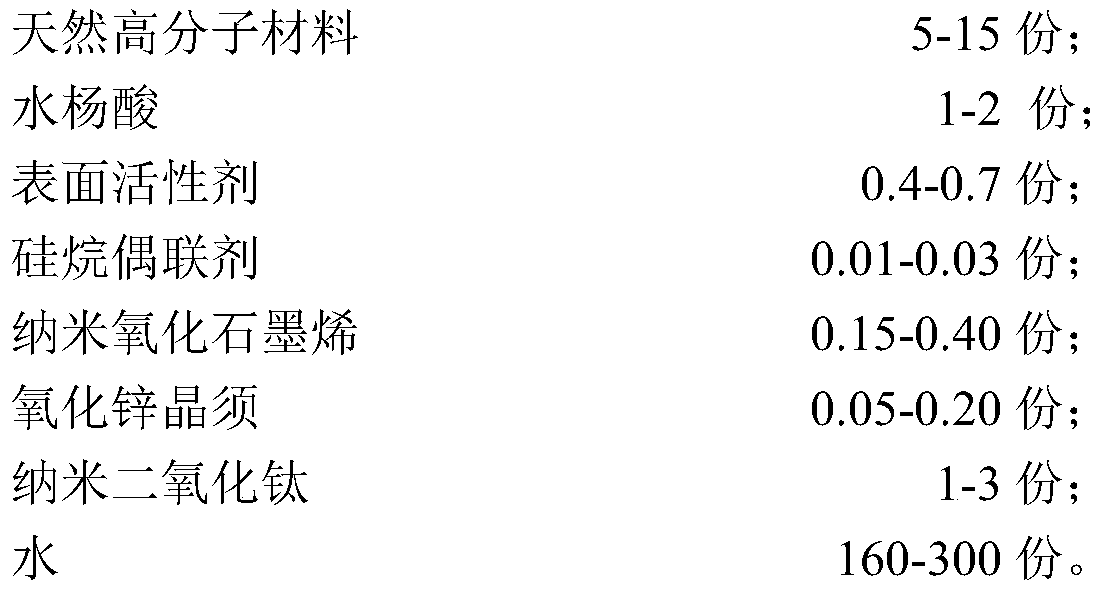

Composite hydrogel, composite hydrogel film and preparation method and application thereof

PendingCN109824916AImprove antibacterial propertiesPlay a bactericidal effectAntifouling/underwater paintsFibre treatmentPolymer scienceSalicylic acid

The invention relates to the field of high polymer materials, in particular to a composite hydrogel, a composite hydrogel film and a preparation method and application thereof. The composite hydrogelis mainly prepared from complete alcoholysis type polyvinyl alcohol, partial alcoholysis type polyvinyl alcohol, a natural polymer material, salicylic acid, a surfactant, a silane coupling agent, nanographene oxide, zinc oxide whiskers, nano titanium dioxide, water and the like. A water-soluble polymer base material is adopted, water serves as a solvent, the natural polymer material is added, harmful chemical substances or stimulating substances are avoided, and environmental friendliness and safety are realized; by adoption of salicylic acid, nano titanium dioxide and zinc oxide whiskers asan antibacterial agent and an anti-ultraviolet agent, great escherichia coli antibacterial effects are achieved, and ultraviolet harms are effectively reduced; the composite hydrogel film is excellentin mechanical performance and available for antibacterial and ultraviolet protection application, such as touch screen sterilization, textile material bacterium resisting, ultraviolet prevention andthe like.

Owner:HUNAN INSTITUTE OF ENGINEERING

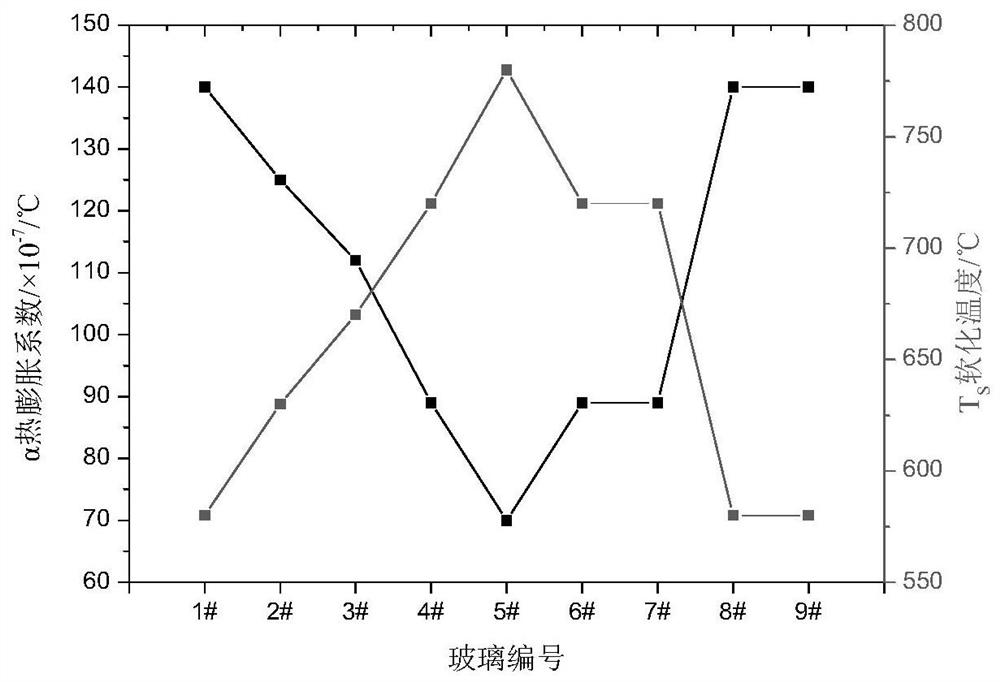

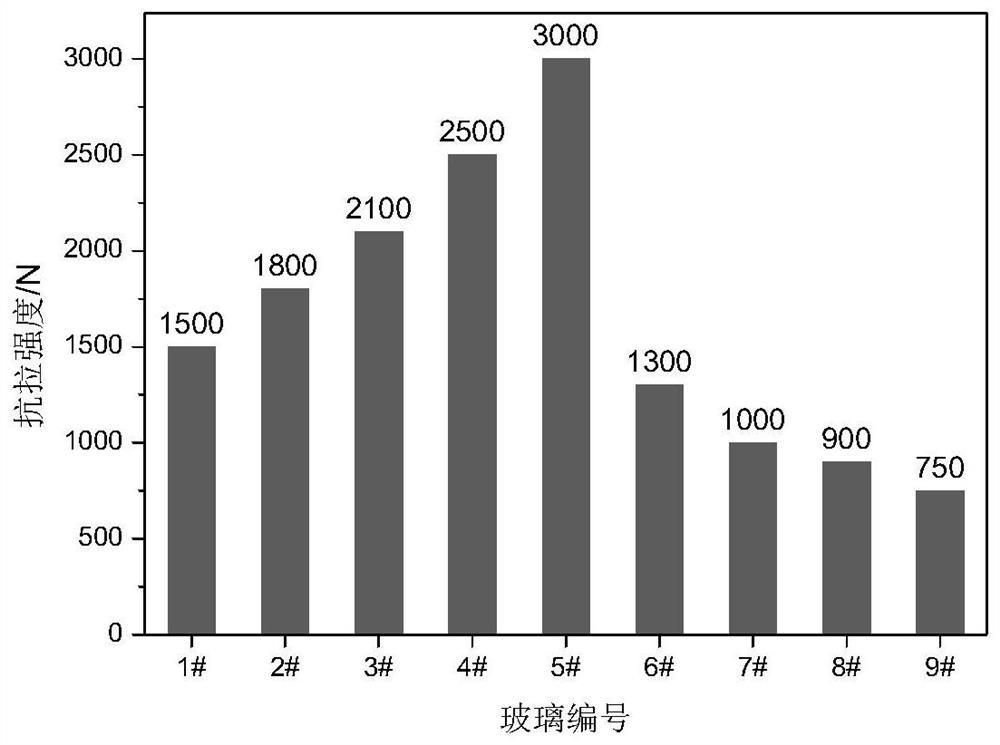

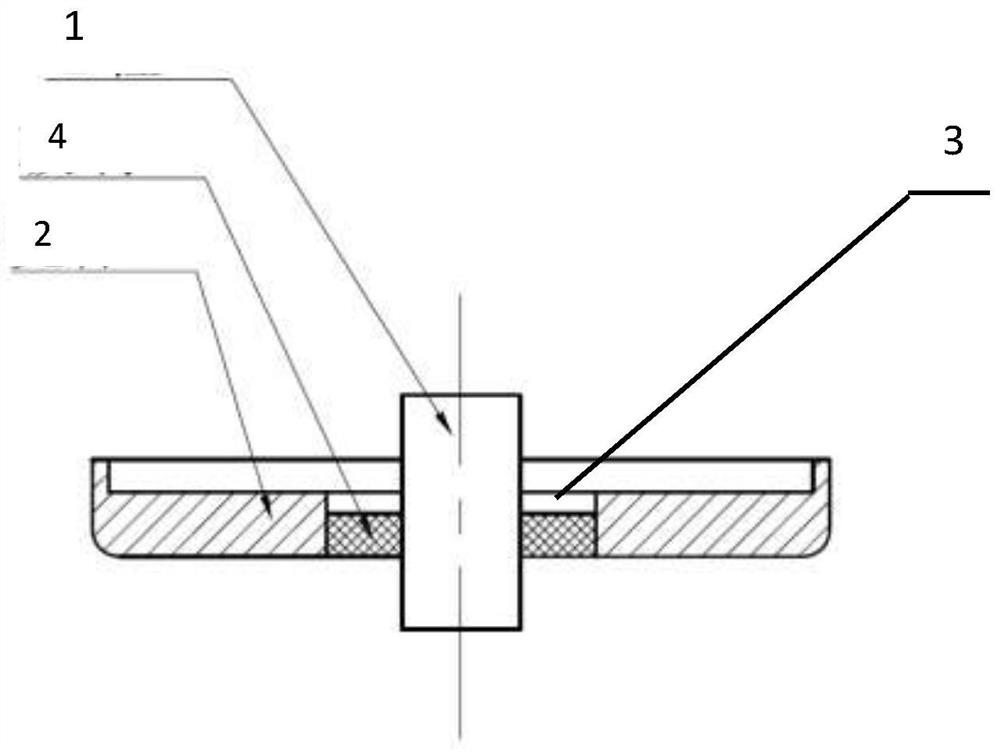

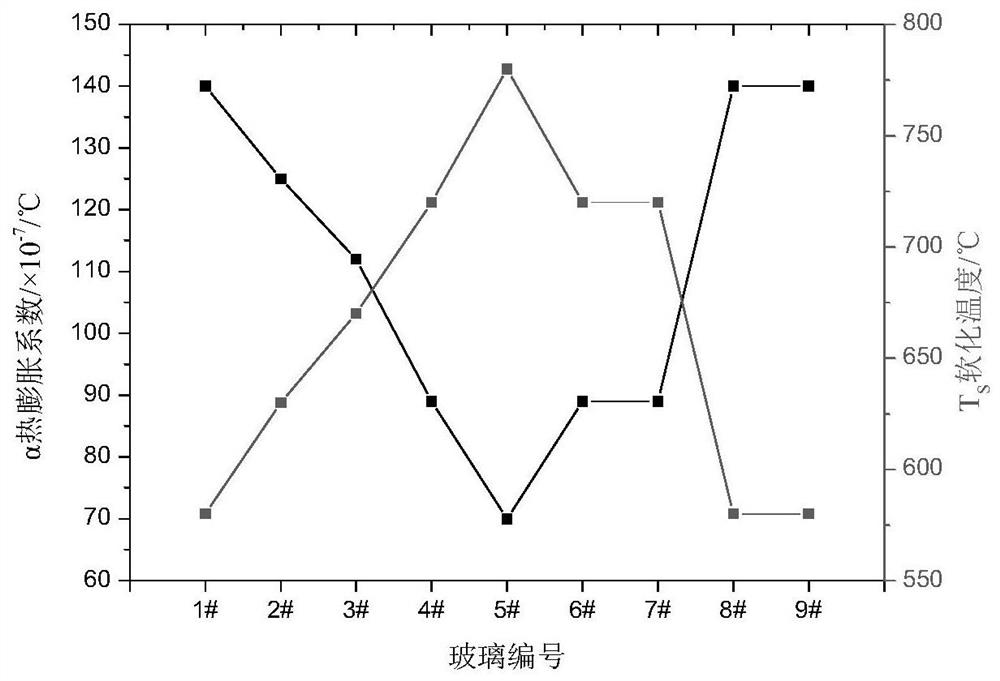

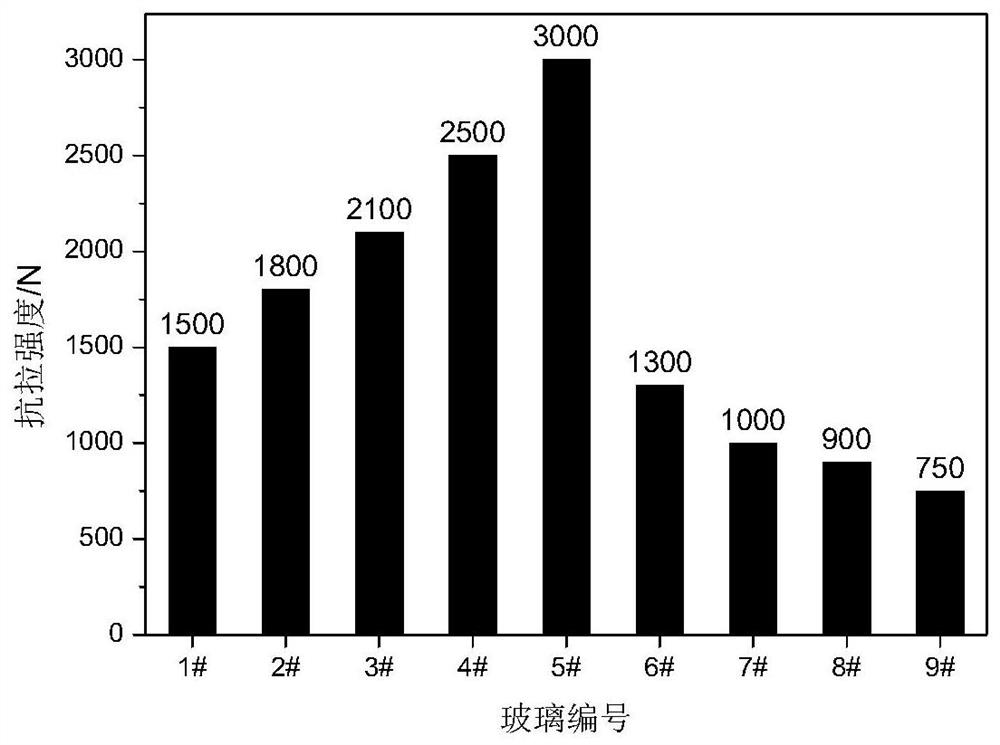

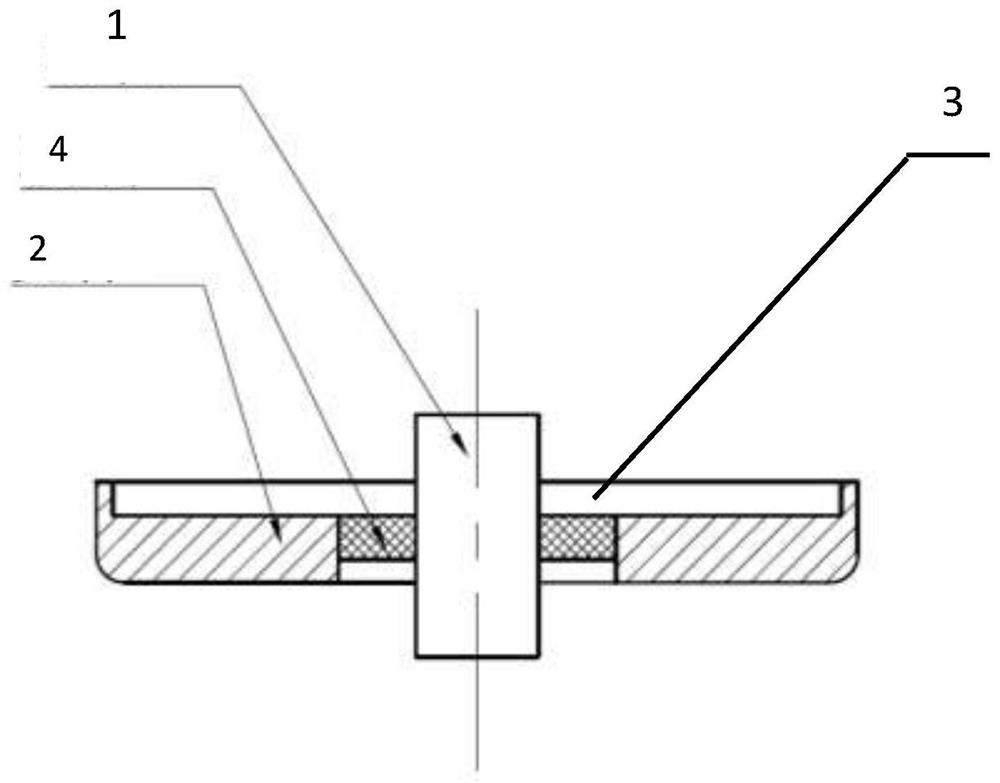

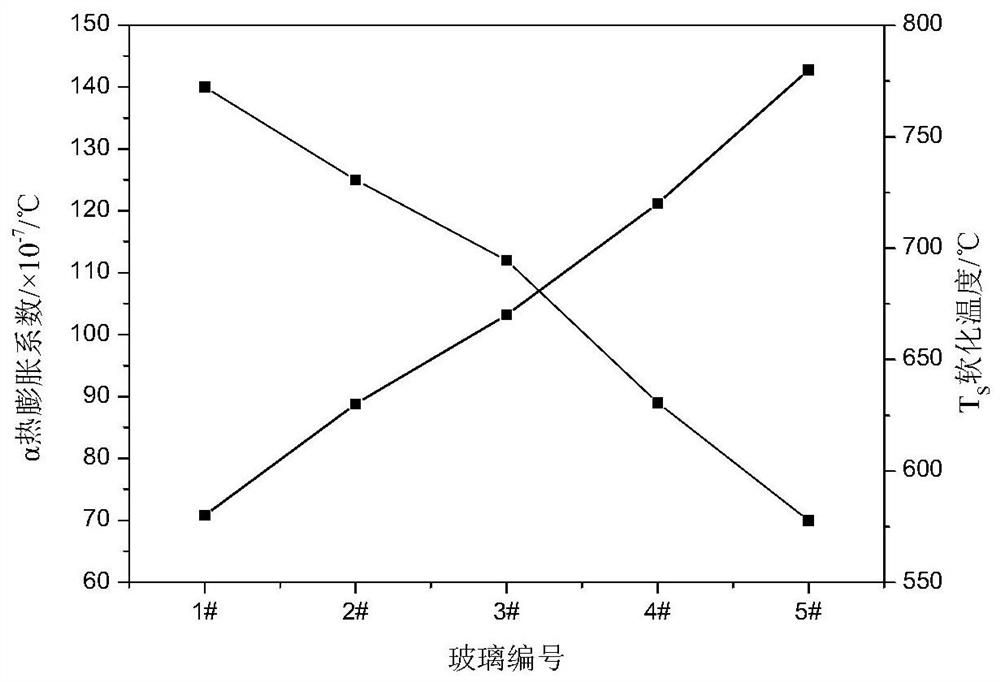

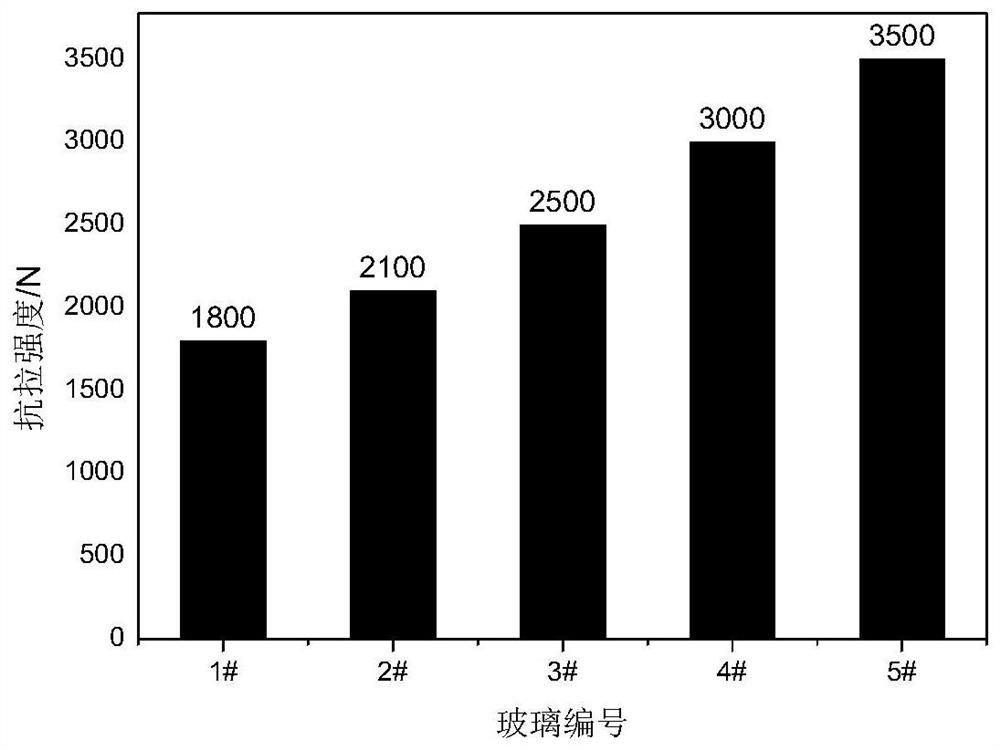

Preparation method and sealing process of explosion-proof primary lithium battery cover group and sealing glass

PendingCN112694257AControl the compressive strengthAdjust the coefficient of thermal expansionCell sealing materialsThermal dilatationElectrolytic agent

The invention discloses a preparation method and a sealing process of an explosion-proof primary lithium battery cover group and sealing glass. A glass material which is resistant to electrolyte corrosion, excellent in electrochemical performance, controllable in mechanical strength and used for sealing the primary lithium battery cover group is provided, and the compressive strength of the glass is controlled by designing glass components and the sealing thickness. The explosion-proof principle is that when the internal pressure of the battery is greater than the designed pressure in the use process, namely the pressure of the battery is overloaded, the pressure-bearing strength of the glass material is just reached, so that the glass is cracked, the internal pressure of the battery is slowly released, and the battery does not have dangerous situations such as violent explosion. The shell is made of stainless steel series and carbon steel series, the stainless steel series comprises 304L, 316L and the like, and the core column is made of series iron-nickel alloys such as alloys 4J28, 4J50, 4J52 and the like. A SiO2-B2O3-BaO-Na2O3 glass system is selected as a main body, and various metal oxides are added to adjust the thermal expansion coefficient, the glass softening temperature, the chemical stability and the mechanical properties of the glass.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

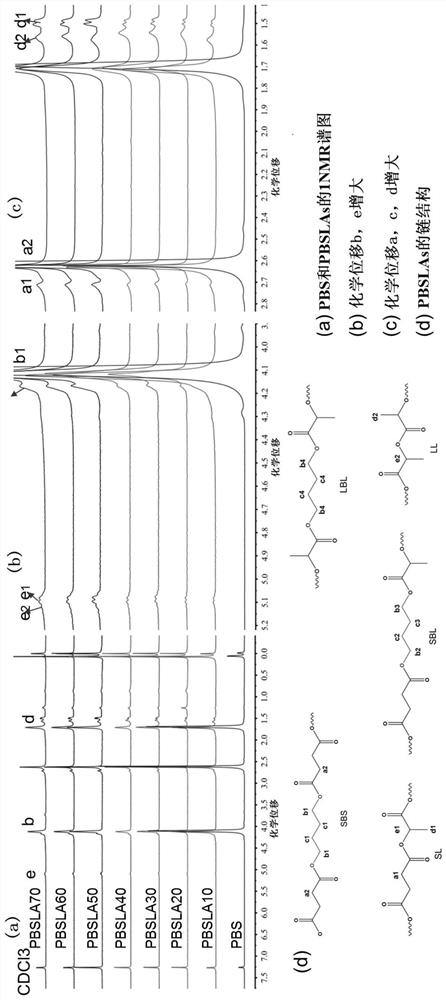

Degradable copolyester as well as preparation method and application thereof

ActiveCN113307957AImprove mechanical propertiesPromote degradationBio-packagingPolymer scienceCopolyester

The invention discloses a degradable copolyester which is a random copolymer or a double-block copolymer composed of difficult-to-hydrolyze polyester fragments and easy-to-hydrolyze fragments or sites, wherein the number-average molecular weight of the copolyester is 30000 g / moL to 500000 g / moL; and the easy-to-hydrolyze fragments or sites are selected from polylactic acid with different chain segment lengths. The copolyester is high in molecular weight, free of environment-unfriendly chain extenders, good in mechanical strength and toughness, resistant to heat and good in processability, and can be independently used as plastic. In various natural environments such as water, soil, compost and the like, the copolyester can be completely degraded in the natural environments to form environment-pollution-free carbon dioxide and water. The invention also discloses a preparation method and application of the degradable copolyester.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

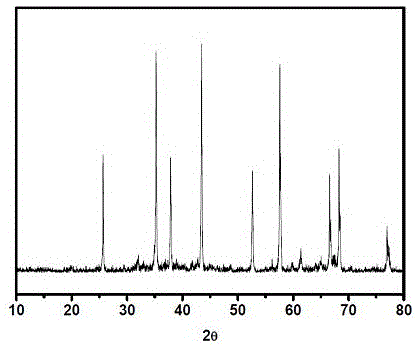

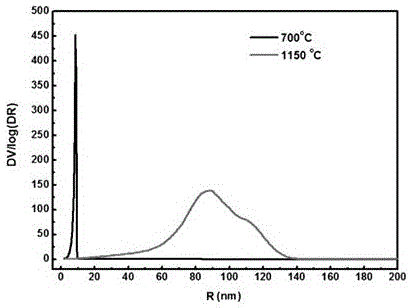

Alpha crystal form nano alumina porous ceramic with high apparent porosity and preparation method thereof

The invention discloses an alpha crystal form nano alumina porous ceramic with a high apparent porosity and a preparation method thereof, and belongs to the field of nano porous materials. The preparation method comprises the following steps: filling gamma-Al2O3 powder into a graphite mould, placing the mould into a discharging plasma sintering furnace, loading an axial load pressure of 30 to 100 MPa, sintering the powder in vacuum at a temperature of 1100 to 1250 DEG C, maintaining the temperature for 3 to 5 minutes; or placing a gamma-Al2O3 blank in a conventional air furnace, sintering the blank under zero pressure at a temperature of 1350 to 1450 DEG C, and maintaining the temperature for 30 to 120 minutes to obtain the alpha crystal form nano alumina porous ceramic with a high apparent porosity; wherein the average particle size of the porous ceramic is smaller than 160 nm, and the apparent porosity is more than 95%. The provided preparation method has the advantages of low cost and good repeatability. The porous structure is formed without any sintering aid or pore forming agent. The prepared alumina porous ceramic has the advantages of evenly-distributed pores, small pore diameter, high apparent porosity (more than 95%), and excellent mechanical properties.

Owner:HUBEI UNIV OF TECH

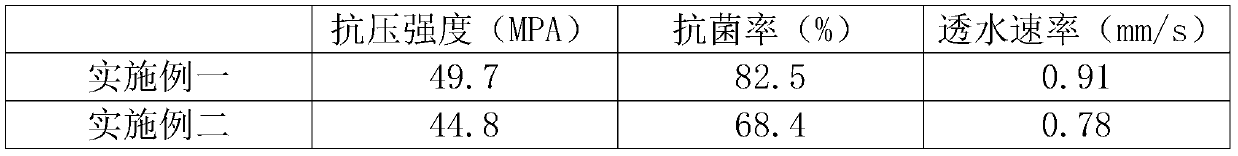

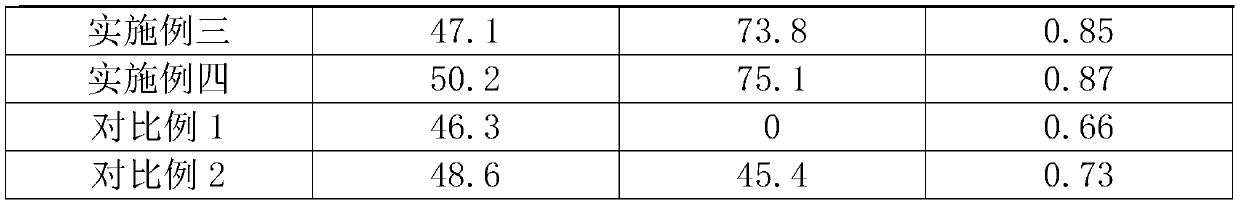

High-strength antibacterial environment-friendly water-permeable brick and preparation method thereof

InactiveCN110156488AEasy to makeGood compressive strengthCeramic materials productionCeramicwareActivated carbonCorrosion

The invention discloses a high-strength antibacterial environment-friendly water-permeable brick and a preparation method thereof. The water-permeable brick comprises the following components in partsby weight: 80-100 parts of polymer fiber porous concrete, 40-60 parts of building waste residues, 10-20 parts of hollow microbeads, 3-9 parts of nano titanium dioxide, 2-6 parts of nano silicon dioxide, 3-10 parts of nano tourmaline, 2-4 parts of modified activated carbon, 1-3 parts of modified graphene oxide, 2-8 parts of zirconia fibers and 2-6 parts of an antibacterial agent. According to thehigh-strength antibacterial environment-friendly water-permeable brick disclosed by the invention, an antibacterial agent taking carboxymethyl chitosan as a main component is added, so that the water-permeable brick has a balanced sterilization effect, damage to the environmental is small, and the lasting time of the sterilization effect is long. The water-permeable brick is simple in preparationmethod, has the advantages of excellent compressive strength, wear resistance and corrosion resistance and high strength, is not easily damaged, and has the advantages of adsorbing pollutants in waterand inhibiting and resisting bacteria. Environmental protection performance is good, and popularization and use are convenient.

Owner:柳州柳晶环保科技有限公司

Preparation method and application of gel polymer electrolyte for high-performance all-solid-state supercapacitor

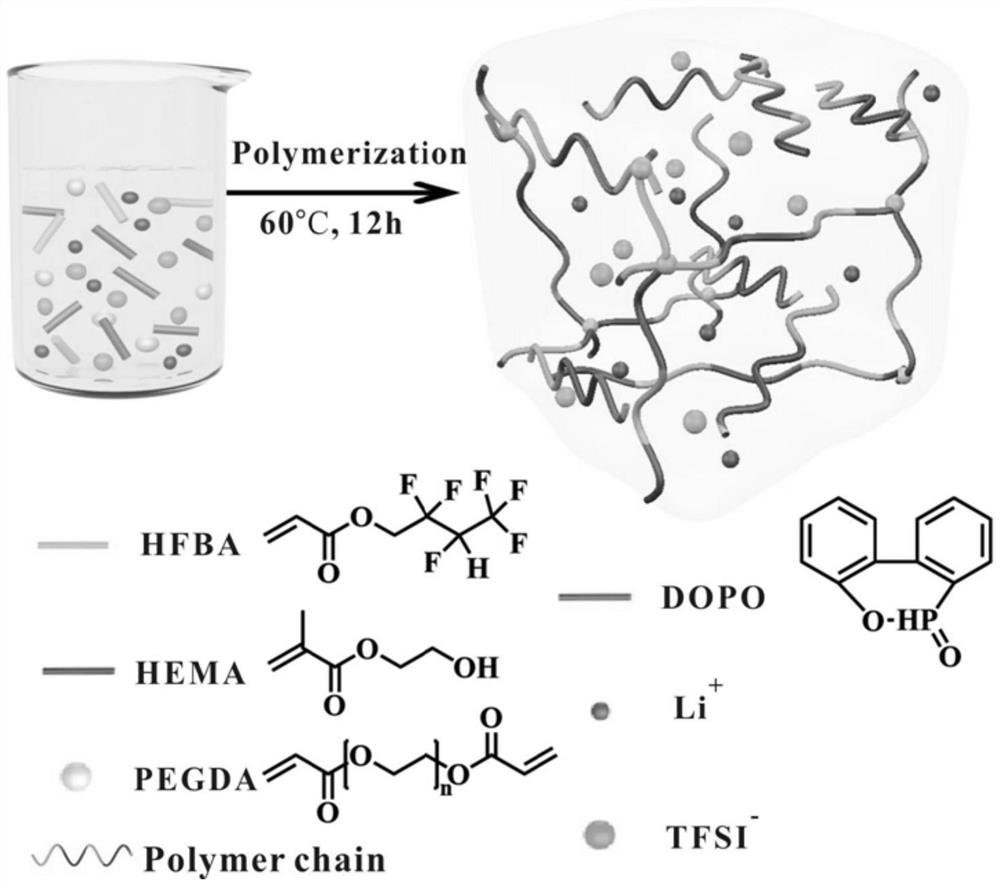

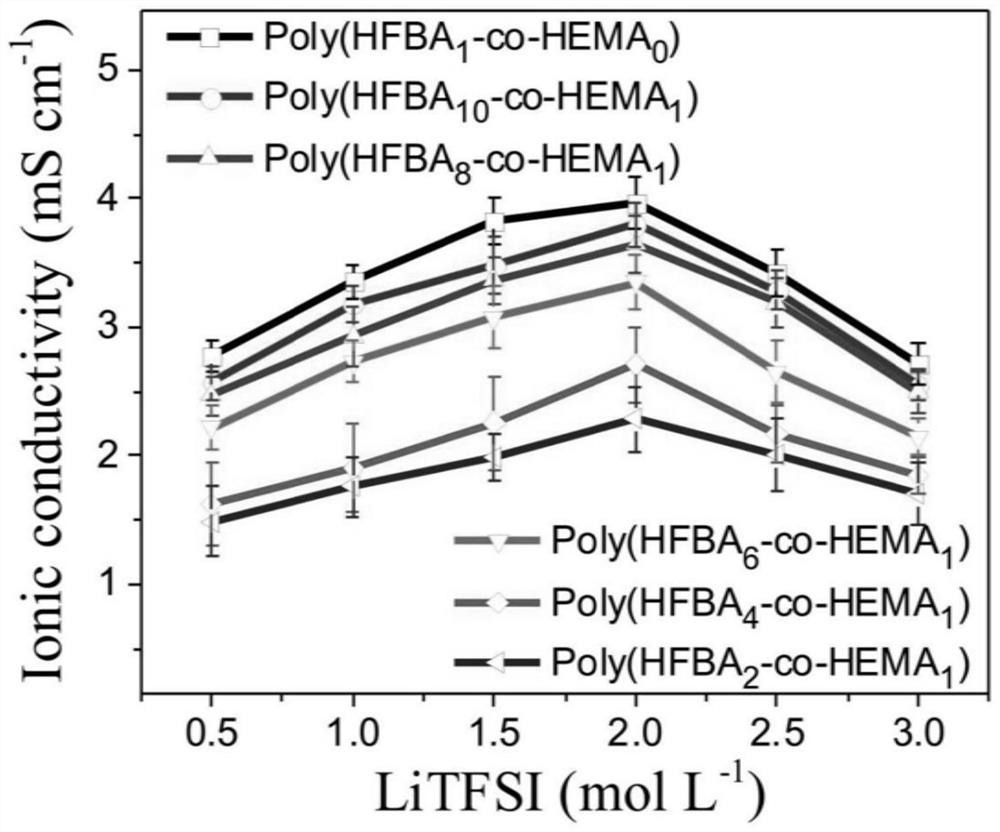

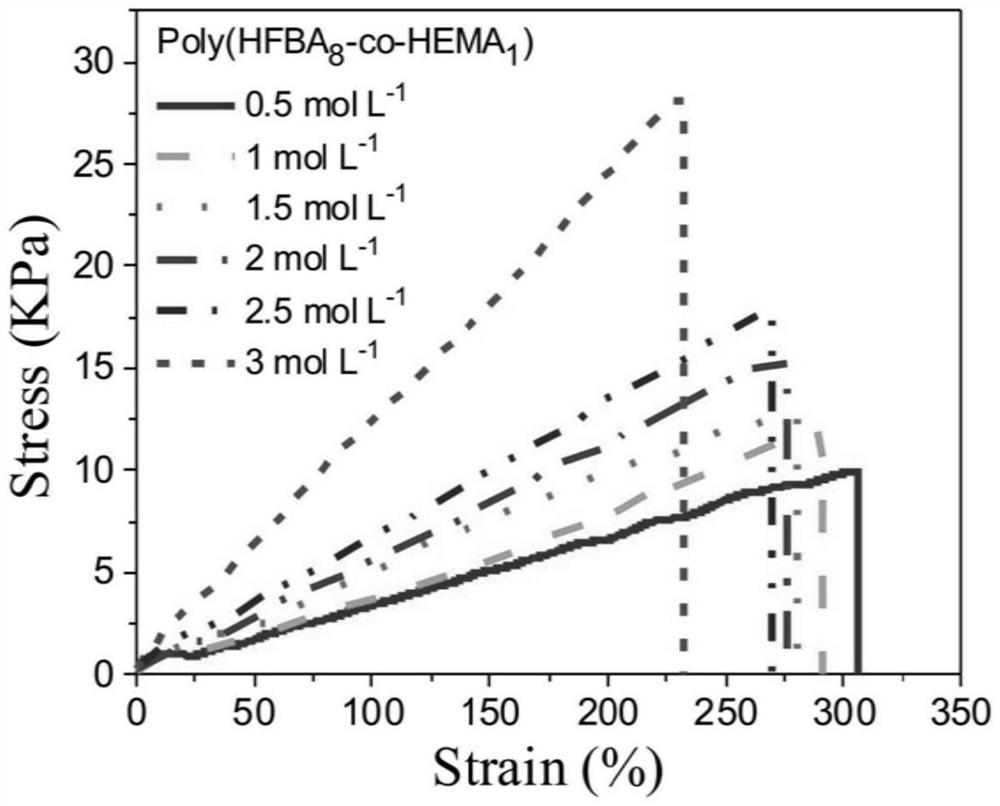

ActiveCN113035585AImprove conductivityImprove flame retardant performanceHybrid capacitor electrolytesPolymer science(Hydroxyethyl)methacrylate

The invention belongs to the field of energy storage, and relates to a preparation method and application of a gel polymer electrolyte of a high-performance all-solid-state supercapacitor. The preparation method comprises the following steps: adding hexafluorobutyl acrylate (HFBA) and hydroxyethyl methylacrylate (HEMA) into a solvent, adding a flame retardant, polyethylene glycol diacrylate (PEGDA) and lithium bis (trifluoromethanesulfonyl) imide (LiTFSI), adding an initiator, and polymerizing at 50-80 DEG C for 10-14 hours to prepare the flame-retardant gel polymer electrolyte. According to the invention, the gel electrolyte has good ionic conductivity of 4 mS cm<-1> and good flame retardant capacity at 20 DEG C, and the mechanical strength of the gel electrolyte is adjusted within the range of the maximum stress of 28 KPa and the maximum strain of 305%; the gel-based SC has good resistance to low temperatures and can operate normally in a temperature range of -20 DEG C to 60 DEG C; and the multiple advantages of the gel electrolyte expand the application of the gel electrolyte in ion conductors and energy storage equipment, and overcome the defects that the traditional liquid electrolyte is easy to volatilize, inflammable, easy to leak and the like.

Owner:QILU UNIV OF TECH

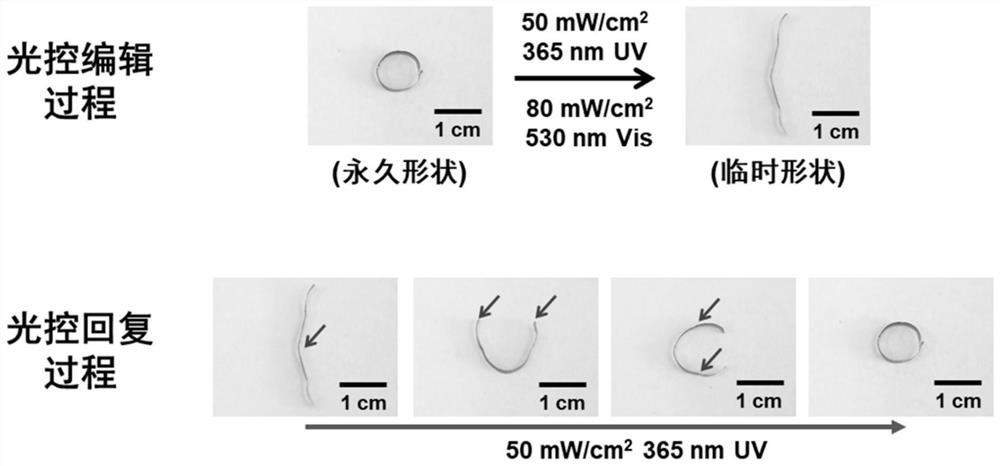

Hydrogen bond-containing linear azobenzene polymer as well as preparation method and application thereof

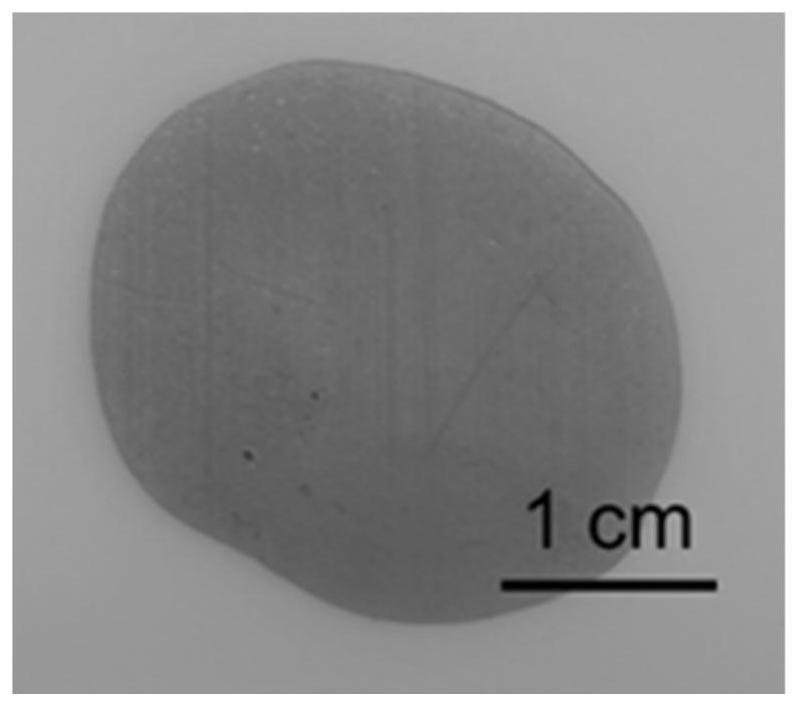

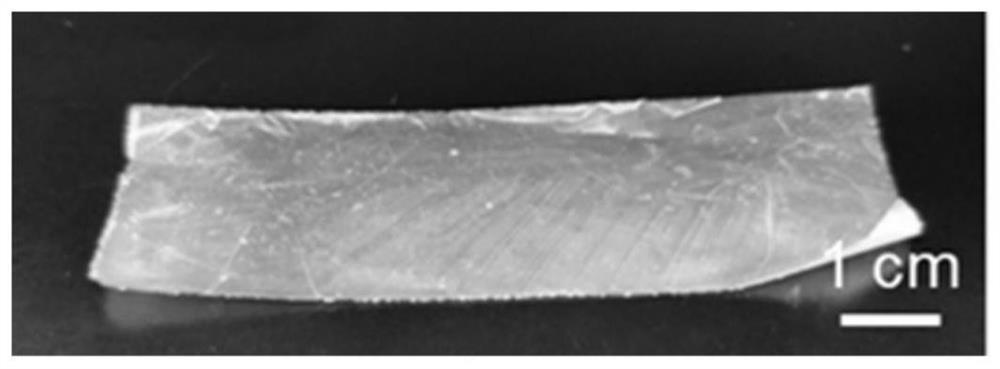

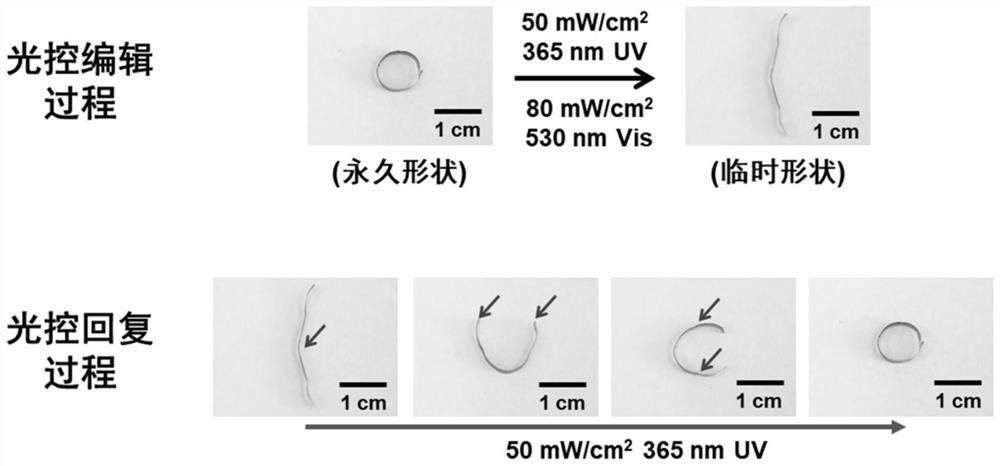

ActiveCN111875765AThe synthesis steps are simpleUnlimited molding size and shapeLiquid crystal compositionsPhenyl groupPolymer chemistry

The invention belongs to the technical field of polymer materials and relates to a hydrogen bond-containing linear azobenzene polymer as well as a preparation method and application thereof. The molecular chain of the polymer is of a linear structure, azobenzene elements are located on a main chain of the polymer, and hydrogen bonds provided by urethane bonds exist between the molecular chains forphysical crosslinking. Compared with the prior art, the hydrogen bond-containing linear azobenzene polymer provided by the invention is simple in synthesis steps, can be processed by a melting and solution method, is not limited in molding size and shape, and can be recycled after being processed and molded. After processing and molding, through pre-editing or non-editing, the shape of the polymer can be changed under the illumination of a specific wavelength. In addition, the polymer can greatly regulate and control the mechanical and photoresponse deformability of the polymer by regulatingand controlling spacer groups on two sides of azobenzene and the structure of diisocyanate.

Owner:FUDAN UNIV

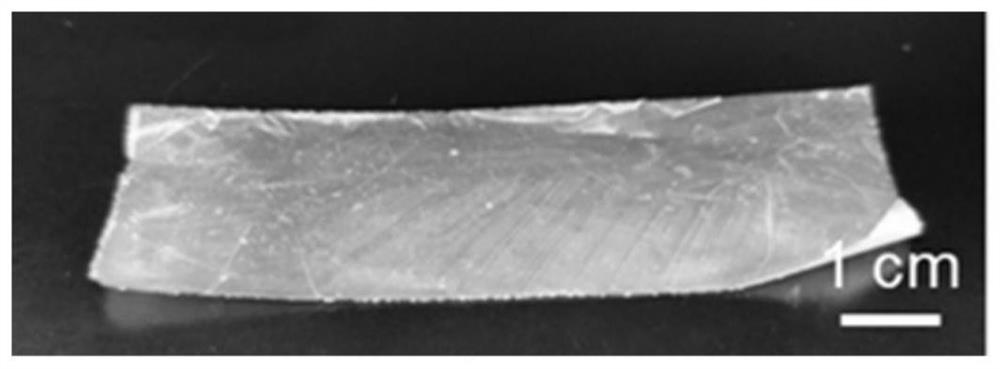

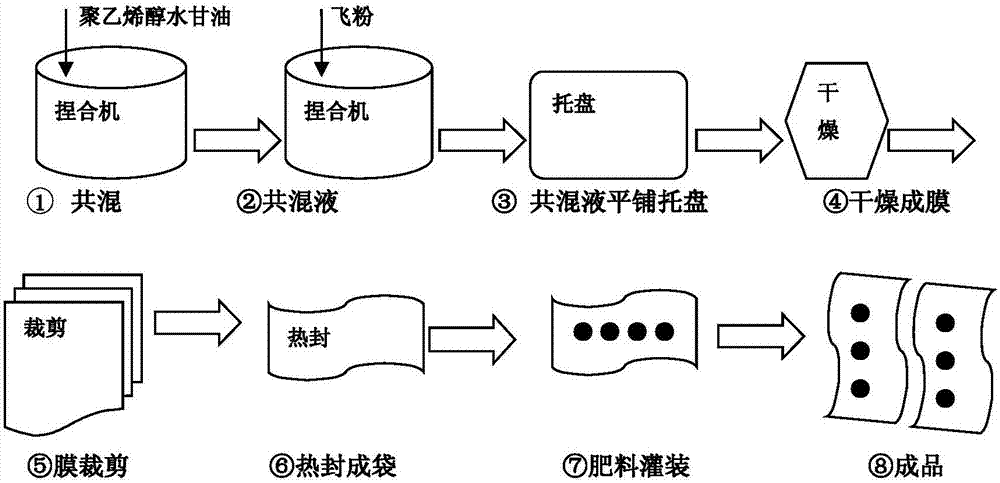

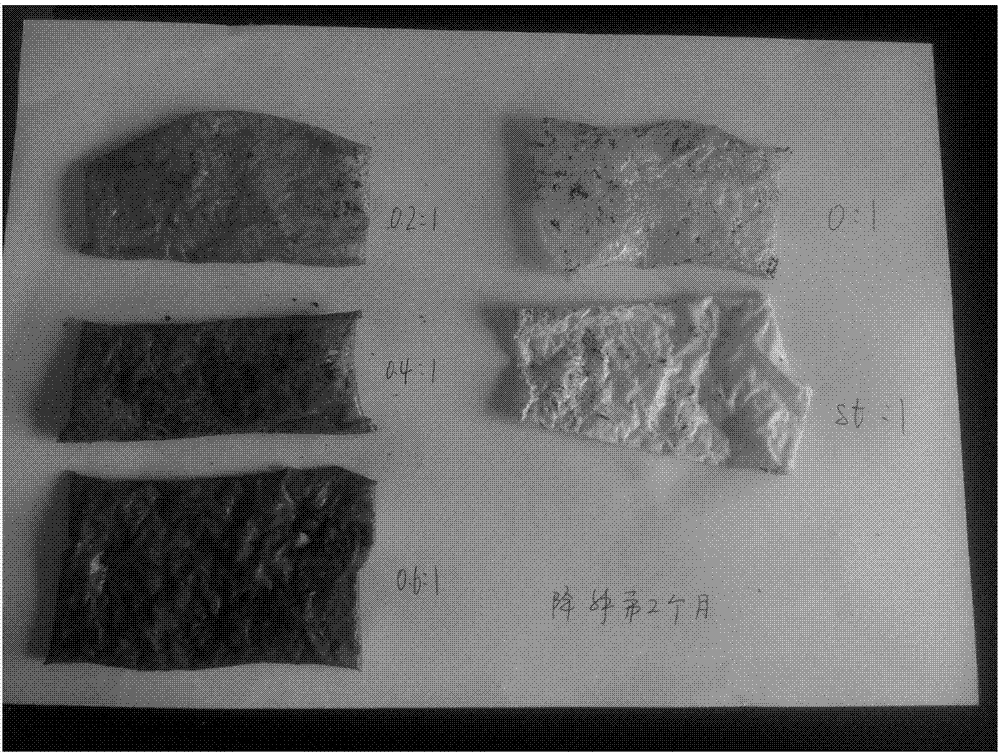

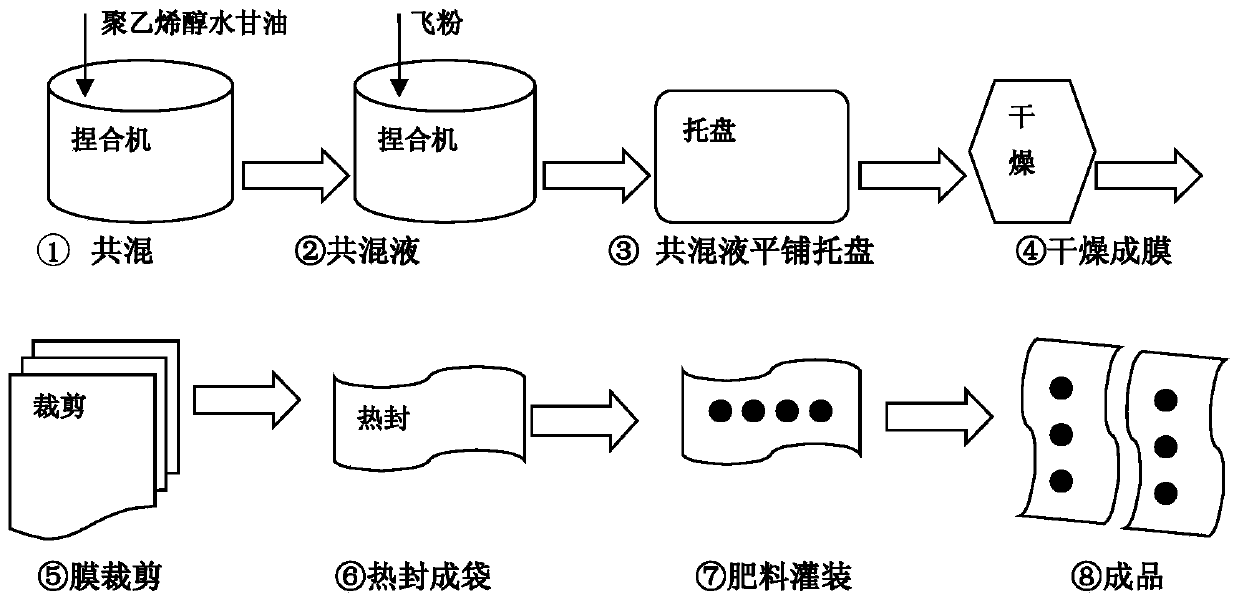

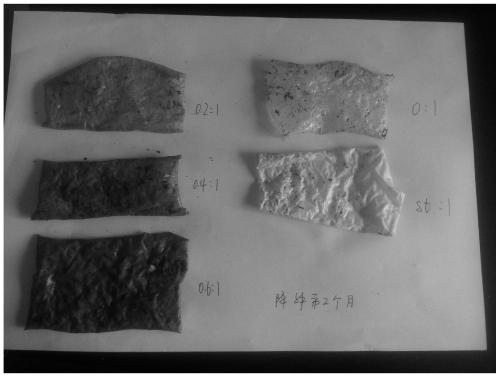

Preparation method of konjac flying powder-coated fertilizer

InactiveCN106957504ANo heat lossGood compatibilityFlat articlesAmmonium salt fertilisersPolyvinyl alcoholForced-air

The invention belongs to the technical field of fertilizer preparation and discloses a preparation method of a konjac flying powder-coated fertilizer. The method is characterized by comprising the following steps: (1) selecting raw materials according to the ratio of konjac flying powder to polyvinyl alcohol to water to glycerinum of (3-12)g:15g:300g:9g; (2) pouring the selected polyvinyl alcohol, water and glycerinum into a kneading machine; (3) adding the konjac flying powder to obtain a mixture; (4) extruding the mixture obtained in the step (3) through a screw of the kneading machine, containing the mixture in a polyethylene tray, immediately carrying out curtain coating until the solution is uniformly paved on the tray; (5) carrying out forced air drying on the tray containing the mixture obtained in the step (4) at 50-80 DEG C for 2-3h and forming a film from the mixture in the tray; (6) removing a film to obtain the film which is 0.12-0.2mm in thickness; (7) carrying out film cutting and sealing to prepare a coated fertilizer bag; and (8) carrying out fertilizer filling and sealing to obtain the required konjac flying powder-coated fertilizer. According to the method, the problem of shortage of a deep process technology of the konjac flying powder can be solved, and a factory technology is provided for production of the konjac flying powder-coated fertilizer.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI +1

A near-infrared light-responsive smart hydrogel bionic arm and its preparation method

ActiveCN105111388BHigh mechanical strengthOvercome the disadvantage of low mechanical strengthProsthesisSmart hydrogelsEngineering

The invention discloses a near-infrared light-responsive intelligent hydrogel bionic arm and a preparation method thereof. The hydrogel bionic arm is formed by connecting three sections of hydrogel with different functions through in-situ free radical polymerization. The hydrogels are respectively: I-extending segment, II-contracting segment and III-grabbing segment, the hydrogel bionic arm can capture the target object through viscosity or magnetism; the intelligent hydrogel bionic arm can The bionic actions of elongation, object capture, and retrieval are realized under irradiation; the preparation method of the near-infrared light-responsive smart hydrogel bionic arm is as follows: the components of the above three sections of hydrogel are respectively dispersed in water, and the trigger Agents, according to the order of I‑II‑III or III‑II‑I, were added to the mold and sealed, and placed in an environment of 10~25 oC to react for 12‑48 hours to obtain a near-infrared light-responsive smart hydrogel bionic arm .

Owner:SOUTH CHINA UNIV OF TECH

A spontaneously driven dopamine gel driver and its preparation method and driving method

The invention discloses a self-driving dopamine gel driver, a preparation method and a driving manner thereof. The dopamine gel driver is prepared in the manner of copolymerizing dopamine methacrylamide and acrylamide monomers into a gel, soaking the gel in a Fe3+ solution for treating and then acquiring a fixed temporary shape in an alkaline solution. The dopamine gel driver can realize the driving function of automatically changing the shape of the hydrogel in the solution according to the method of changing the pH value of the solution.

Owner:SOUTH CHINA UNIV OF TECH

A kind of linear azobenzene polymer containing hydrogen bond and its preparation method and application

ActiveCN111875765BSimplify complex reaction stepsThe synthesis steps are simpleLiquid crystal compositionsPolymer scienceBackbone chain

The invention belongs to the technical field of polymer materials, and relates to a linear azobenzene polymer containing hydrogen bonds and a preparation method and application thereof. The polymer molecular chain has a linear structure, the azophenyl element is located in the polymer main chain, and there is a hydrogen bond physical cross-linking provided by the urethane bond between the molecular chains. Compared with the prior art, the hydrogen bond-containing linear azobenzene polymer proposed by the present invention has simple synthesis steps, can be processed by melting and solution methods, and has unlimited molding size and shape, and can be recycled and reused after processing and molding. . Pre-edited or unedited after molding, polymers change shape when exposed to specific wavelengths of light. In addition, this polymer can greatly control its mechanical and light-responsive deformability by adjusting the spacers on both sides of the azobenzene and the structure of the diisocyanate.

Owner:FUDAN UNIV

Method for preparing organosilicone hybrid resin and power type encapsulating material for light-emitting diodes (LED) thereof and application

ActiveCN102702532BEasy to prepareRaw materials are environmentally friendlyPlastic/resin/waxes insulatorsCoatingsEpoxyOptical transmittance

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

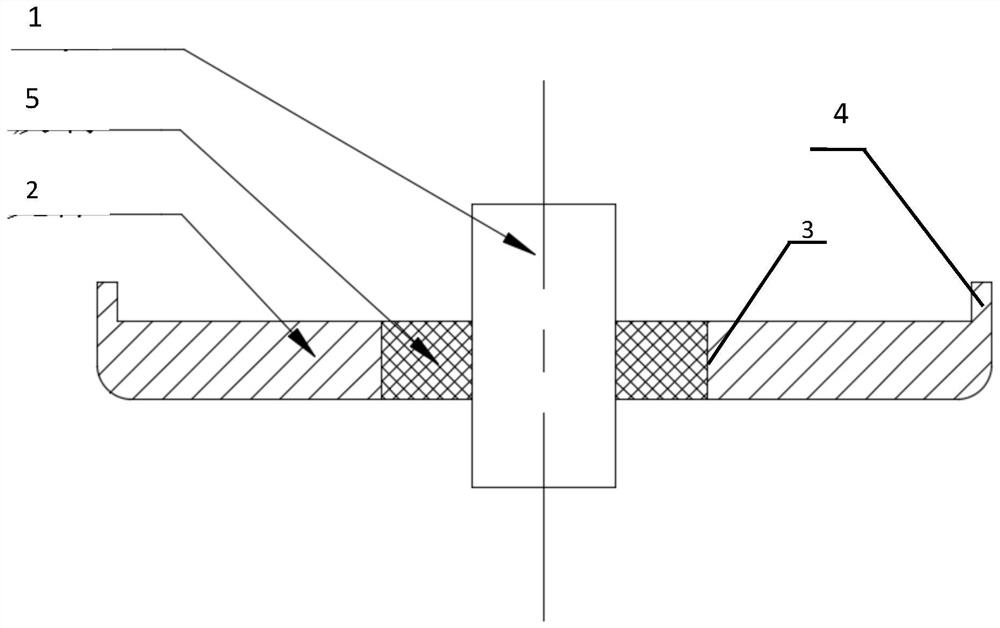

Explosion-proof lithium battery cover assembly sealing structure and preparation method thereof and sealing process

PendingCN112707643AIncrease capacityControllable mechanical strengthGlass furnace apparatusCell lids/coversElectrolytic agentPhysical chemistry

The invention belongs to the field of sealing glass and preparation thereof, and particularly relates to an explosion-proof lithium battery cover assembly sealing structure and a preparation method thereof and a sealing process. The preparation method of the explosion-proof lithium battery cover group sealing glass material comprises the following step of: (1) selecting the following raw materials in percentage by mole: 40%-60% of SiO2, 10%-30% of B2O3, 0%-5% of Al2O3, 5%-15% of BaO, 5%-10% of Na2O, 0%-5% of K2O, 0%-5% of MgO, 0%-5% of CaO, 0%-5% of TiO2, 0%-5% of ZnO2 and 0%-5% of ZnO, wherein the various oxides should comprise various salts and acid-base compounds thereof. The invention discloses an explosion-proof lithium battery cover assembly sealing glass material and a structural design thereof for improving battery capacity, provides a preparation method of the explosion-proof lithium battery cover group sealing glass material and a sealing process, and provides a glass material which is resistant to electrolyte corrosion, excellent in electrochemical performance, controllable in mechanical strength and used for sealing a primary lithium battery cover assembly.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

A kind of preparation method of konjac flying powder coated fertilizer

InactiveCN106957504BNo heat lossGood compatibilityFlat articlesAmmonium salt fertilisersPolyvinyl alcoholForced-air

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI +1

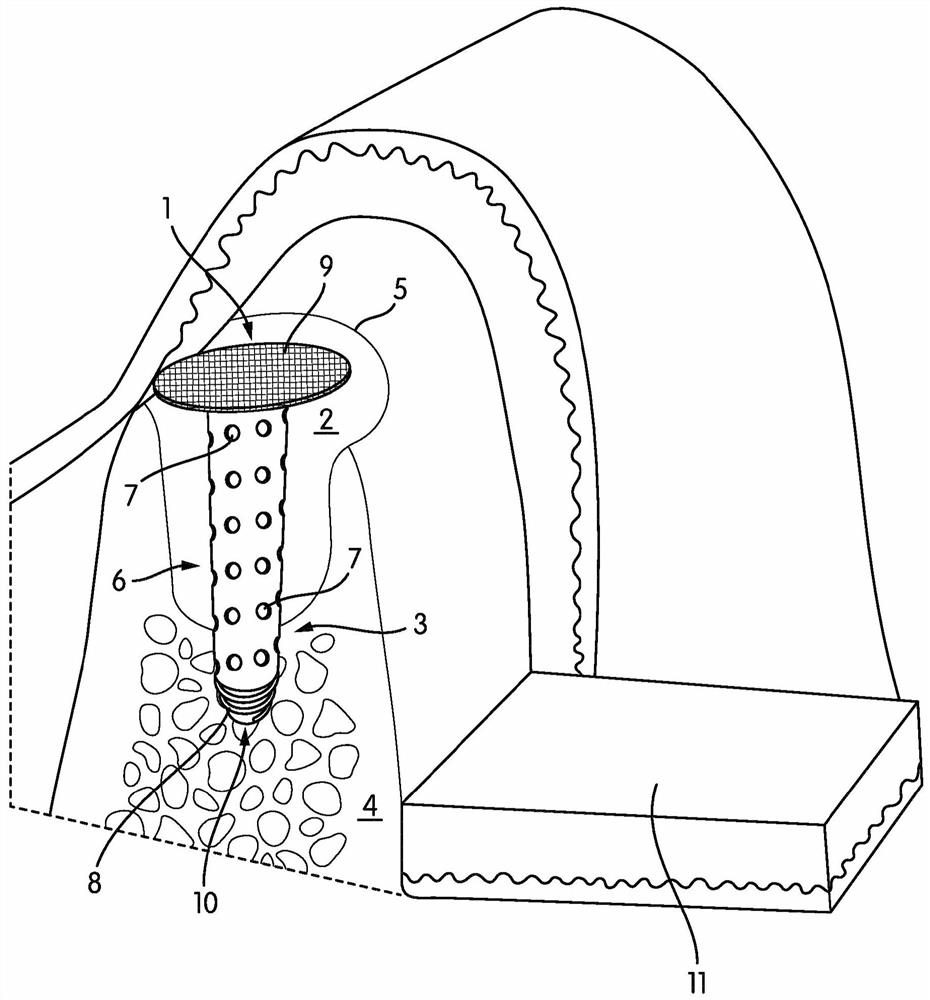

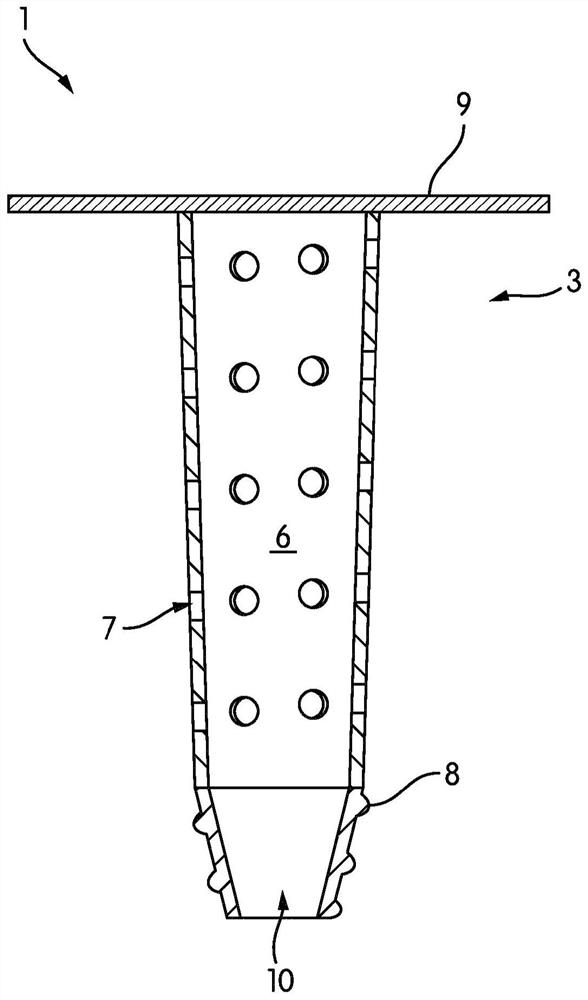

Dental device for ridge preservation and promotion of jaw bone regeneration in an extraction site

ActiveCN113473943APromote regenerationEliminates the need for removal surgeryDental implantsPeptide/protein ingredientsExtraction siteJaw bone

Owner:DENTSPLY SIRONA INC +1

Preparation method and sealing process of explosion-proof lithium primary battery cover group and sealing glass thereof

PendingCN112551905AAdjust the coefficient of thermal expansionAdjust softening temperatureCell lids/coversCell sealing materialsElectrolytic agentElectrical battery

The invention discloses an explosion-proof primary lithium battery cover group sealing glass material and a preparation method and a packaging process thereof, and provides a glass material which is resistant to electrolyte corrosion, excellent in electrochemical performance and controllable in mechanical strength and is used for sealing a primary lithium battery cover group. The explosion-proof principle is that when the internal pressure of the battery is greater than the designed pressure in the use process, namely the pressure of the battery is overloaded, the pressure-bearing strength ofthe glass material is just reached, so that the glass is cracked, the internal pressure of the battery is slowly released, and the battery does not have dangerous situations such as violent explosion.The explosion-proof primary lithium battery cover group comprises a core column and a shell, a sealing hole is formed in the shell, the core column is inserted into the sealing hole and penetrates through the sealing hole, a circle of convex edge is arranged at the edge of the upper surface of the shell, and the shell and the core column are sealed through sealing glass to obtain the explosion-proof primary lithium battery cover group.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

A double-layer hydrogel bionic hand and its preparation method

ActiveCN106142786BSticky enoughIncrease stickinessSynthetic resin layered productsEngineeringALLYL SUCROSE

The invention discloses a double-layer hydrogel bionic hand and a preparation method thereof. The double-layer hydrogel bionic hand is formed by bonding a layer of polyacrylic acid hydrogel with pH responsiveness and viscidity and a layer of Fe<3+> cross-linked polyacrylic acid hydrogel through the viscous effect; the double-layer hydrogel bionic hand can be similar to a human hand to achieve bionic actions of hand closing and opening through a method of changing the pH values and ionic strengths of solutions in the solutions with the different pH values, and the effects of grabbing and releasing objects are achieved.

Owner:SOUTH CHINA UNIV OF TECH

A high-performance aluminum alloy for power transmission and transformation equipment and its preparation method

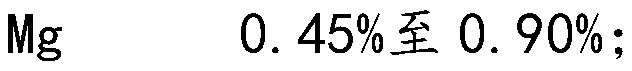

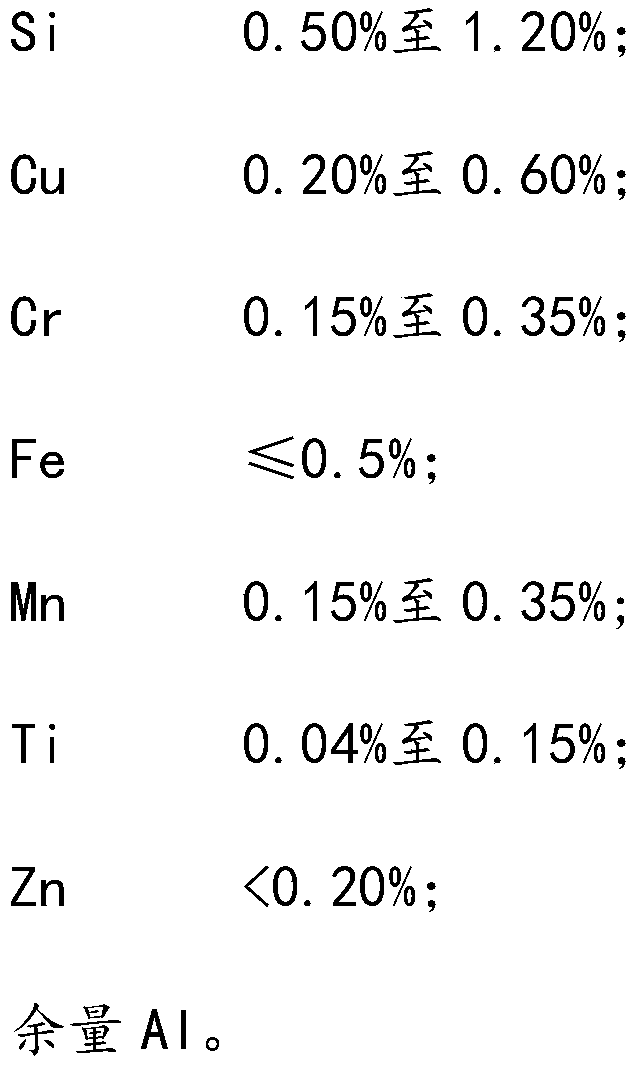

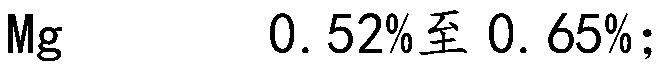

The invention discloses a high-performance aluminum alloy for power transmission and transformation equipment. The high-performance aluminum alloy for the power transmission and transformation equipment comprises the following components of, by mass, 0.45%-0.90% of Mg, 0.50%-1.20% of Si, 0.20%-0.60% of Cu, 0.15%-0.35% of Cr, less than or equal to 0.5% of Fe, 0.15%-0.35% of Mn, 0.04%-0.15% of Ti, less than 0.20% of Zn, and the balance Al; the invention further discloses a preparation method of the aluminum alloy, the preparation method comprises the following steps that A, a cast ingot is cast;B, the cast ingot is homogenized; C, a rolling process is carried out, heat machining is conducted on the cast ingot to form a pre-machined workpiece; D, solid solution heat treatment is conducted onthe workpiece; E, quenching is conducted; and F, artificial aging is conducted to obtain a finished product. The alloy and the method further have the characteristics of being high in elongation while high in strength at the same time.

Owner:精美铝业有限公司

Porous active artificial bone and preparation method thereof

The invention relates to a porous active artificial bone. In the porous active artificial bone, a calcium phosphate-based biological ceramic material is used as a matrix, and the porous active artificial bone comprises small pores, dense parts and directional pore channels and chelates with diphosphonate. A preparation method of the porous active artificial bone comprises the steps of preparing calcium phosphate precursor powder, compression molding a ceramic blank by using a pore-foaming agent, polyester fiber and the precursor powder, high temperature sintering into a calcium phosphate-based ceramic sintered body and forming the dense parts, the small pores distributed alternately; and immersing calcium phosphate-based ceramic sintered body in a diphosphonate solution to chelate with the diphosphonate so as to obtain the drug-loaded porous active artificial bone. The artificial bone provided by the invention has longitudinal directional pores and a porous structure suitable for osteoblast migration, propagation and growth metabolism, can slowly release small molecular drugs capable of promoting the growth of the osteoblast and inhibiting osteoclast, and is particularly suitable for the fields of treating bone defects of osteoporosis patients, dental restoration, and the like.

Owner:SHENZHEN LANDO BIOMATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com