Preparation method and sealing process of explosion-proof lithium primary battery cover group and sealing glass thereof

A lithium primary battery, sealing glass technology, applied in battery cover/end cover, battery pack parts, battery box/coating, etc., can solve problems such as improper operation, rupture, internal diaphragm shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044]The preparation method of the sealing glass of the explosion-proof lithium primary battery cover group is characterized in that it comprises the following steps:

[0045] 1), select raw materials according to the following molar percentages:

[0046] SiO 2 : 40%~60%,

[0047] B 2 o 3 : 10%~30%,

[0048] al 2 o 3 : 0%~5%,

[0049] BaO: 5% to 15%,

[0050] Na 2 O: 5% to 10%,

[0051] K 2 O: 0% to 5%,

[0052] MgO: 0% to 5%,

[0053] CaO: 0% to 5%,

[0054] TiO 2 : 0%~5%,

[0055] ZrO 2 : 0%~5%,

[0056] ZnO: 0% to 5%,

[0057] Among them, various oxides should include various salts and acid-base compounds;

[0058] 2) Prepare the above-mentioned raw materials and place them in an ultra-high-speed disperser for mixing and dispersing, so that various raw materials can be mixed and dispersed evenly;

[0059] 3) Put the uniformly mixed materials in the crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperat...

Embodiment 1

[0074] 1), a sealing glass material for explosion-proof lithium primary battery cover group, prepared from the following raw materials in terms of molar mass ratio: SiO 2 : 40%, B 2 o 3 : 30%, Al 2 o 3 : 1%, BaO: 10%, Na 2 O: 9%, K 2 O: 3%, MgO: 2%, CaO: 2%, TiO 2 : 1%, ZrO 2 : 1%, ZnO: 1%.

[0075] 2) Prepare the above-mentioned raw materials and place them in an ultra-high-speed disperser for mixing and dispersing, so that various raw materials can be mixed and dispersed evenly;

[0076] 3) Put the uniformly mixed materials in the crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperature to 300-600°C at a rate of 8-10°C / min in an air atmosphere, and at 300-600°C Keep warm for 30-60 minutes to promote the decomposition of various salts and acid-base compounds, then raise the temperature to 1500-1700°C at a rate of 8-10°C / min, and keep warm at 1500-1700°C for 1-2 hours; stir several times during the period , make the...

Embodiment 2

[0085] 1), a sealing glass material for explosion-proof lithium primary battery cover group, prepared from the following raw materials in terms of molar mass ratio: SiO 2 : 45%, B 2 o 3 : 25%, Al 2 o 3 : 1%, BaO: 10%, Na 2 O: 9%, K 2 O: 3%, MgO: 2%, CaO: 2%, TiO 2 : 1%, ZrO 2 : 1%, ZnO: 1%.

[0086] 2) Prepare the above-mentioned raw materials and place them in an ultra-high-speed disperser for mixing and dispersing, so that various raw materials can be mixed and dispersed evenly;

[0087] 3) Put the uniformly mixed materials in the crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperature to 300-600°C at a rate of 8-10°C / min in an air atmosphere, and at 300-600°C Keep warm for 30-60 minutes to promote the decomposition of various salts and acid-base compounds, then raise the temperature to 1500-1700°C at a rate of 8-10°C / min, and keep warm at 1500-1700°C for 1-2 hours; stir several times during the period , make the...

PUM

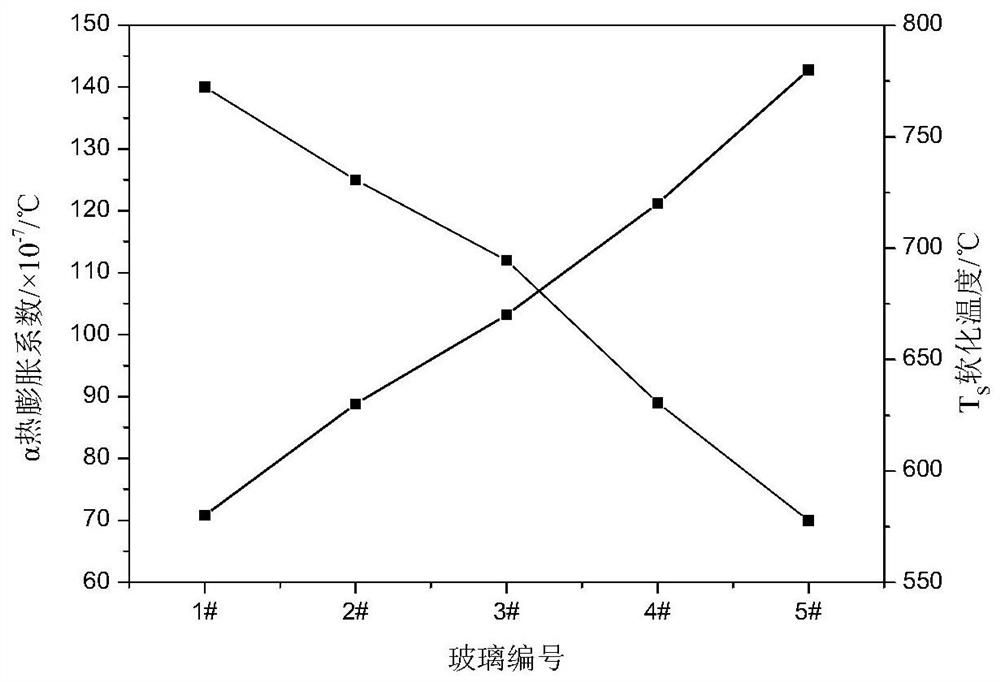

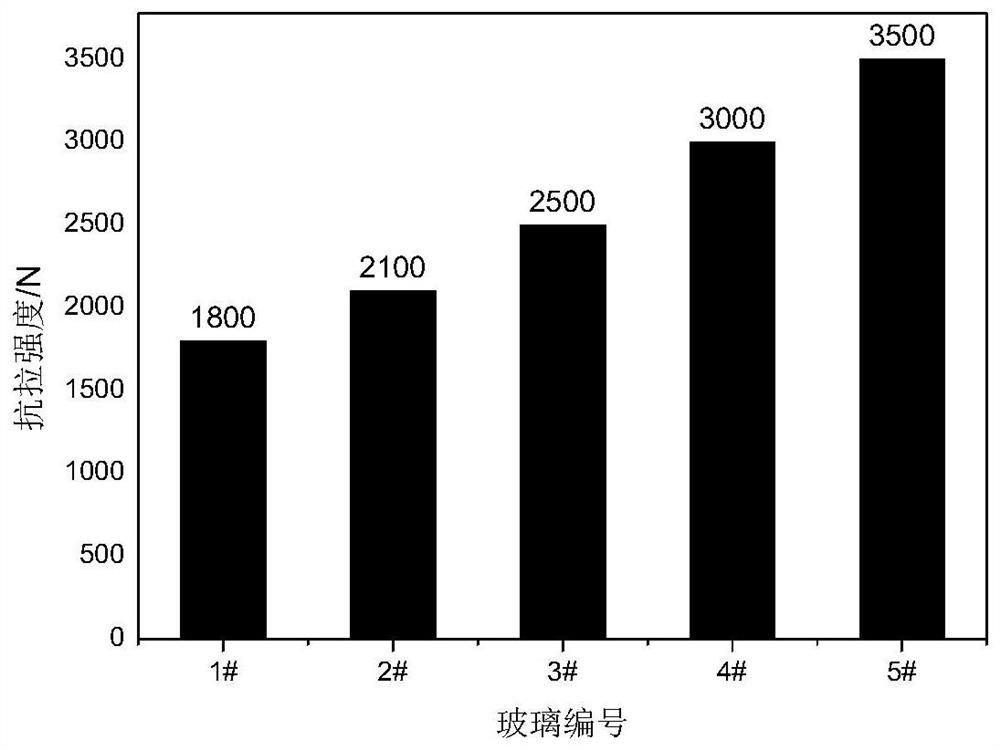

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com