Silane modified polyether and preparation method thereof

A technology of silane-modified polyether and polyether, which is applied in the field of sealants, can solve the problems of cumbersome self-synthesis process and difficulty in obtaining it, and achieve the effect of simple and controllable reaction conditions and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

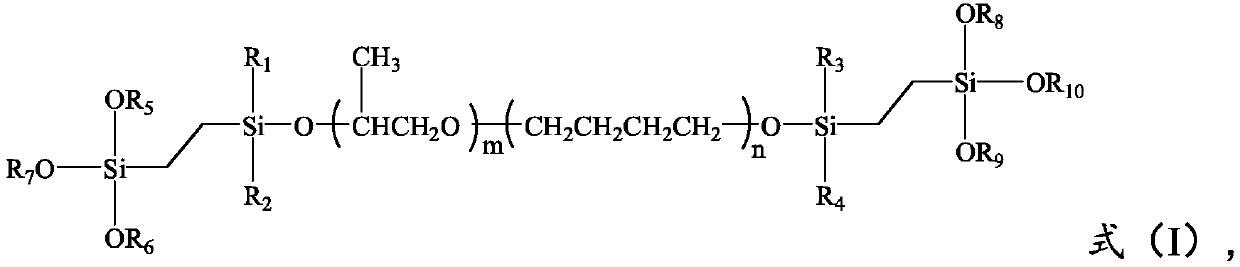

[0066] The present invention also provides a preparation method of silane polyether, comprising:

[0067] The polyether intermediate with formula (II) structure is reacted with hydrosilane to obtain the silane-modified polyether of formula (I) structure;

[0068]

[0069] where the R 1 , R 2 , R 3 and R 4 One or more independently selected from C1-C10 alkyl groups, C6-C30 phenyl groups and C2-C15 hydrocarbon groups containing functional groups;

[0070] The R 5 , R 6 , R 7 , R 8 , R 9 and R 10 One or more independently selected from C1-C10 alkyl groups and C1-C10 alkoxy groups;

[0071] The m is an integer of 68-520;

[0072] Said n is an integer of 0-18.

[0073] According to the present invention, the present invention reacts the polyether intermediate having the structure of formula (II) with hydrogen-containing silane to obtain the silane-modified polyether of formula (I); wherein, the hydrogen-containing silane is trimethoxy hydrogen-containing One or more...

Embodiment 1

[0083] Add 100 parts of hydroxyl-terminated polyether (m=85, n=0) with a molecular weight of 4948 Daltons into the reaction vessel, and after heating up to 80°C, slowly add 5 parts of tetramethyldivinyldisilazane dropwise into the above solution, and after reacting for 3 hours, vacuumize to remove excess tetramethyldivinyldisilazane to obtain a polyether intermediate;

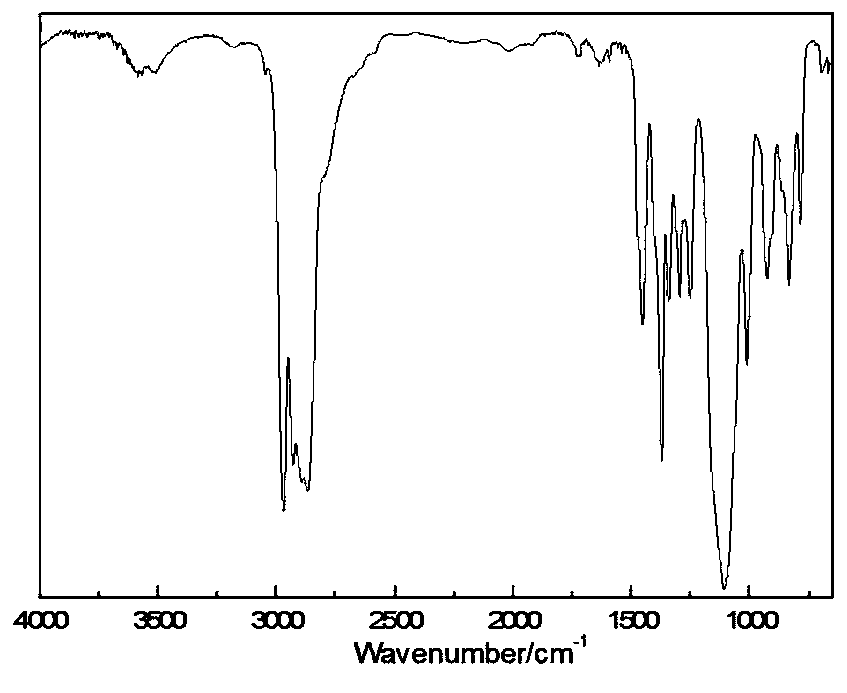

[0084] Structural identification is carried out to the obtained intermediate, and the results are shown in figure 1 , figure 1 The infrared spectrogram of the polyether intermediate obtained for the embodiment 1 of the present application;

[0085] Add 11 parts of triethoxyhydrogen-containing silane to the polyether intermediate and stir evenly, raise the temperature to 80°C, add 5 mg / kg Speier catalyst, and react for 2 hours to obtain a silane-modified polyether product with a viscosity of 3760 cp at 25°C.

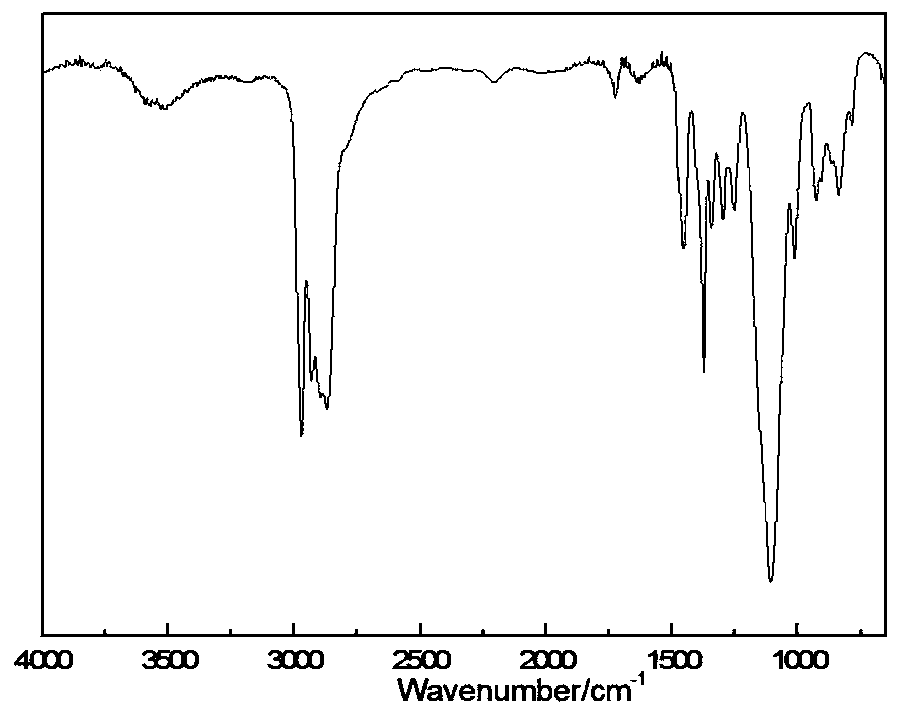

[0086] Structural identification of the obtained silane-modified polyether was carried out, the resul...

Embodiment 2

[0088] Add 100 parts of hydroxyl-terminated polyether (m=148, n=0) with a molecular weight of 8602 Daltons into the reaction vessel. Disilazane was slowly added dropwise to the above solution, and after reacting for 5 hours, the excess dimethyl bis(trifluoropropyl) divinyl disilazane was removed by vacuuming to obtain a polyether intermediate;

[0089]Add 6 parts of methyldiethoxysilane to the polyether intermediate and stir evenly, raise the temperature to 80°C, add 5 mg / kg Speier catalyst, and react for 3 hours to obtain a silane-modified polyether product with a viscosity of 9100cp at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com