Preparation method for sponge material with adsorption, separation, filtering and purification function

A technology of filtration purification and adsorption separation, which is applied in chemical instruments and methods, filtration treatment, adsorption water/sewage treatment, etc., to achieve the effects of energy saving, simple preparation process and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

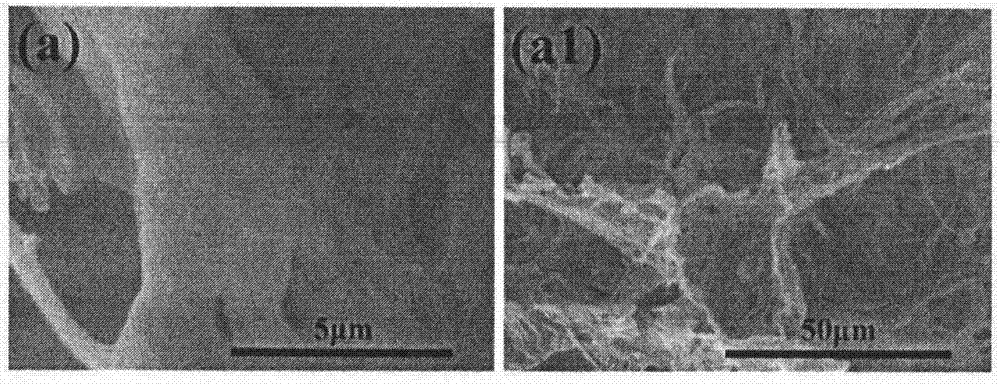

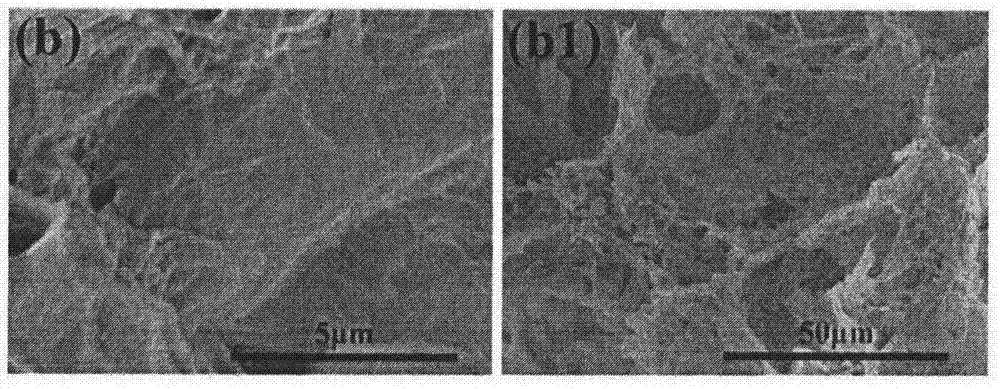

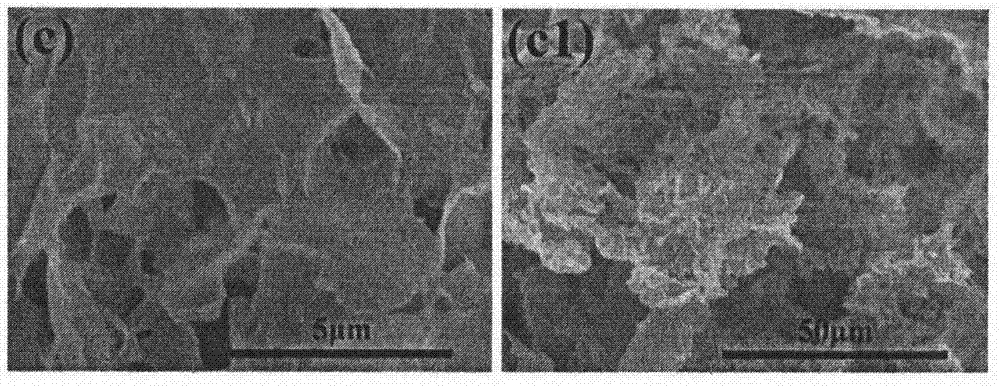

Image

Examples

Embodiment 1

[0031] (1) Preparation of polyvinyl alcohol solution: weigh 6g of 2699-type PVA particles, dissolve in 54g of water in a boiling water bath, and fully stir for 60min until the solution is transparent;

[0032] (2) Preparation of precursor: Weigh 0.8g of graphene oxide powder, add to the above dissolved PVA solution, add 10g of soluble starch, and stir well at room temperature. The temperature of the system was raised to 50°C, and 10 g of sulfuric acid aqueous solution with a mass fraction of 50% and 12 g of formaldehyde were respectively added, and stirred for 5 min;

[0033] (3) Curing and molding of the composite sponge: pour the obtained sol into a mold, and place it in a 60°C oven for curing for 3 hours;

[0034] (4) Cleaning and drying of the composite sponge: take it out from the mold, rinse it with a large amount of clear water, and dry it in a freeze dryer to obtain the adsorption sponge material.

Embodiment 2

[0036] Adjust the amount of graphene oxide powder in the step (2) of embodiment 1 to 0.4g, and the rest are the same as in embodiment 1 to obtain the adsorption sponge material.

Embodiment 3

[0038] Adjust the amount of graphene oxide powder in step (2) of embodiment 1 to 1.2g, and the rest are the same as in embodiment 1 to obtain the adsorption sponge material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com