Amphoteric gel polymer electrolyte with good performance and preparation and application thereof

An amphoteric gel, good performance technology, applied in the field of understanding of ion transport in amphoteric gel polymer electrolytes, can solve problems such as difficulty in preparing new performance zwitterionic gel electrolytes, and achieve easy promotion, high conductivity, and low The effect of interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Experimental part

[0045] Material

[0046] Acrylic acid (AA) and azobisisobutylamidine hydrochloride (AIBA) were purchased from Aladdin. Acryloyloxyethyltrimethylammonium chloride (DAC) was purchased from Bailingwei Technology Co., Ltd. Carbon black was purchased from Alfa Aesar. Lithium chloride (LiCl), polyvinyl alcohol type 1799 (PVA), activated carbon, polyvinylidene fluoride (PVDF), and N-methylpyrrolidone were purchased from McLean. Nickel was purchased from MTI Corporation.

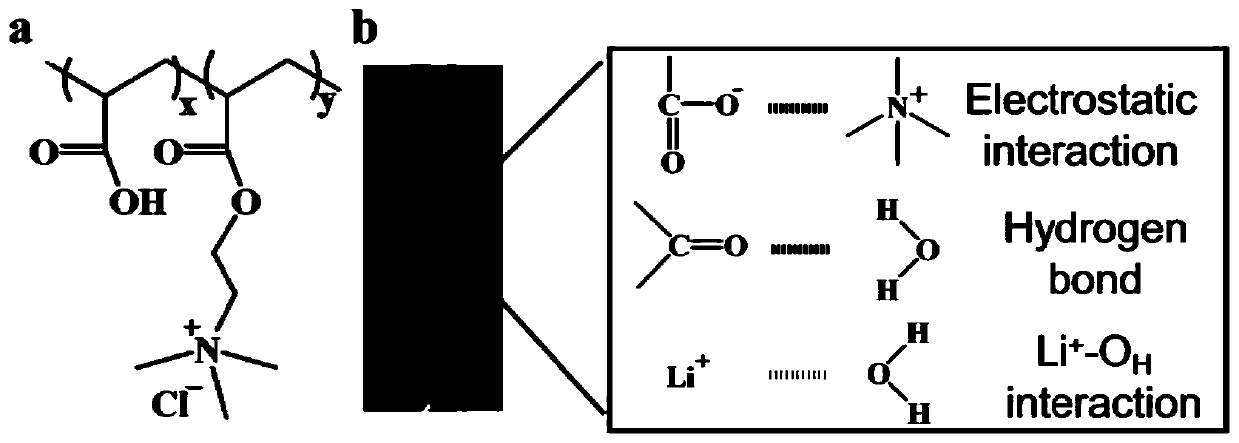

[0047] Preparation of P(AA-DAC) Electrolyte

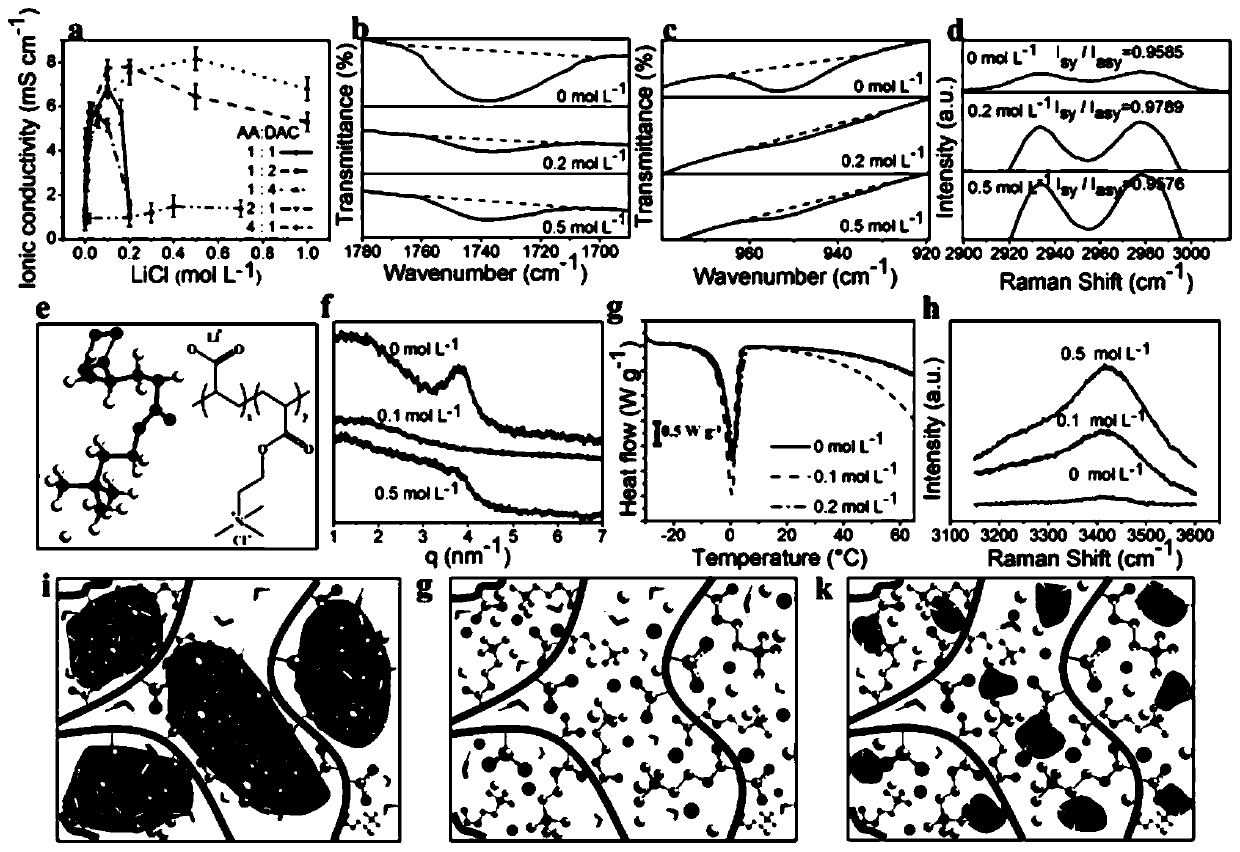

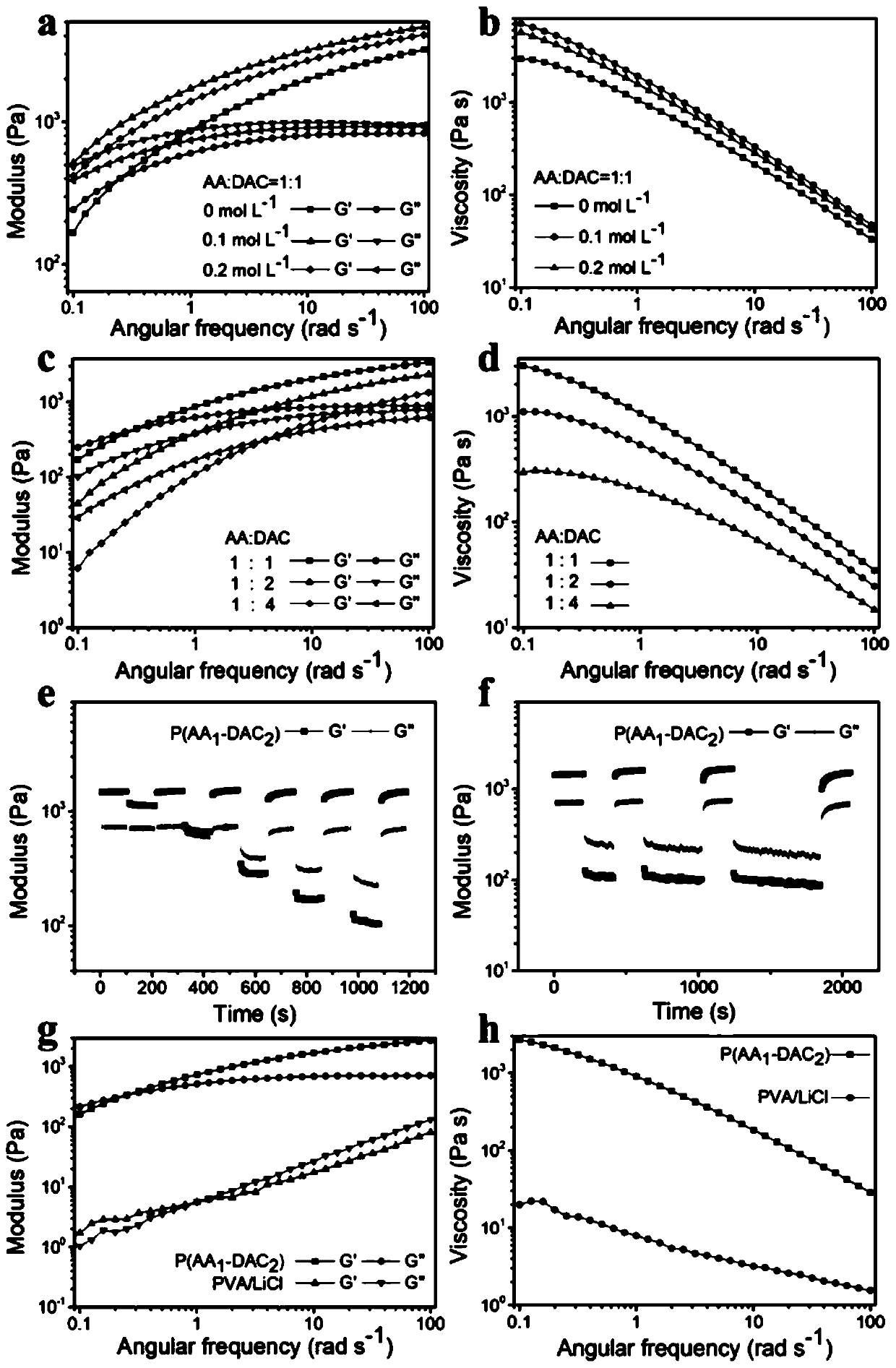

[0048] The P(AA-DAC) electrolyte is a foam prepared by radical polymerization of AA and DAC monomers. AA, DAC and distilled water (12mL) with a total mass of 4g were added to 20ml glass bottles respectively, and the molar ratios of the two monomers were controlled at 1:1, 1:2, 1:4, 2:1 and 4: 1. Different concentrations of LiCl were added to the mixed solution. After the mixed solution was stirred in an ice bath for 1.5 hours, 0.04 g of...

Embodiment 2

[0098] DFT calculation part:

[0099] The binding energy Eb of ion and AA, DAC segment is determined by the formula:

[0100] E. b 1=E(LiCl)-E(Cl - )-E(Li + );E b 2=E(AA+Li + )-E(AA)-E(Li + );

[0101] E. b 3=E(AA+DAC)-E(AA)-E(DAC); E b 4=E(AA+Cl - )-E(AA)-E(Cl - )

[0102] Among them, Eb1-4 are the binding energies of two fragments in the polymer and four cases of two ions, respectively. E(LiCl) is the energy of LiCl, and E(AA+DAC) is the total energy of the two stages. E(AA+Li+)E(AA+Cl-) is the total energy of the segmented ions in the polymer. E(Cl-)E(Li+)E(AA)E(DAC) are the energies of the two ions and the two segments, respectively.

[0103] Structural formula such as Figure 12

[0104] Cartesian Coordination for the optimized structures of DAC-COO

[0105] E(DAC-COO)=-493.6089x10 3 Kcal / mol

[0106]

[0107] Charge scheme of DAC-COO

[0108]

[0109] Structural formula such as Figure 13

[0110] Cartesian Coordination for the optimized stru...

Embodiment 3

[0124] The preparation of the P (AA-DAC) electrolyte, the method for assembling the supercapacitor, and the subsequent detection method are the same as in Example 1, except that the LiPF 6 Instead of LiCl, the test results show that: in 0.5mol L -1 Li PF 6 concentration, P(AA 1 -DAC 2 ) and P(AA 1 -DAC 4 ) conductivity reaches ~6.9mS cm -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com