Silane-terminated MS resin and preparation method thereof

A silane-terminated and resin technology, applied in adhesives and other directions, can solve the problems of difficult compounding, high cohesive strength, slow curing speed, etc., and achieve excellent operability and practicability, excellent weather resistance and durability, The effect of reducing filler moisture requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

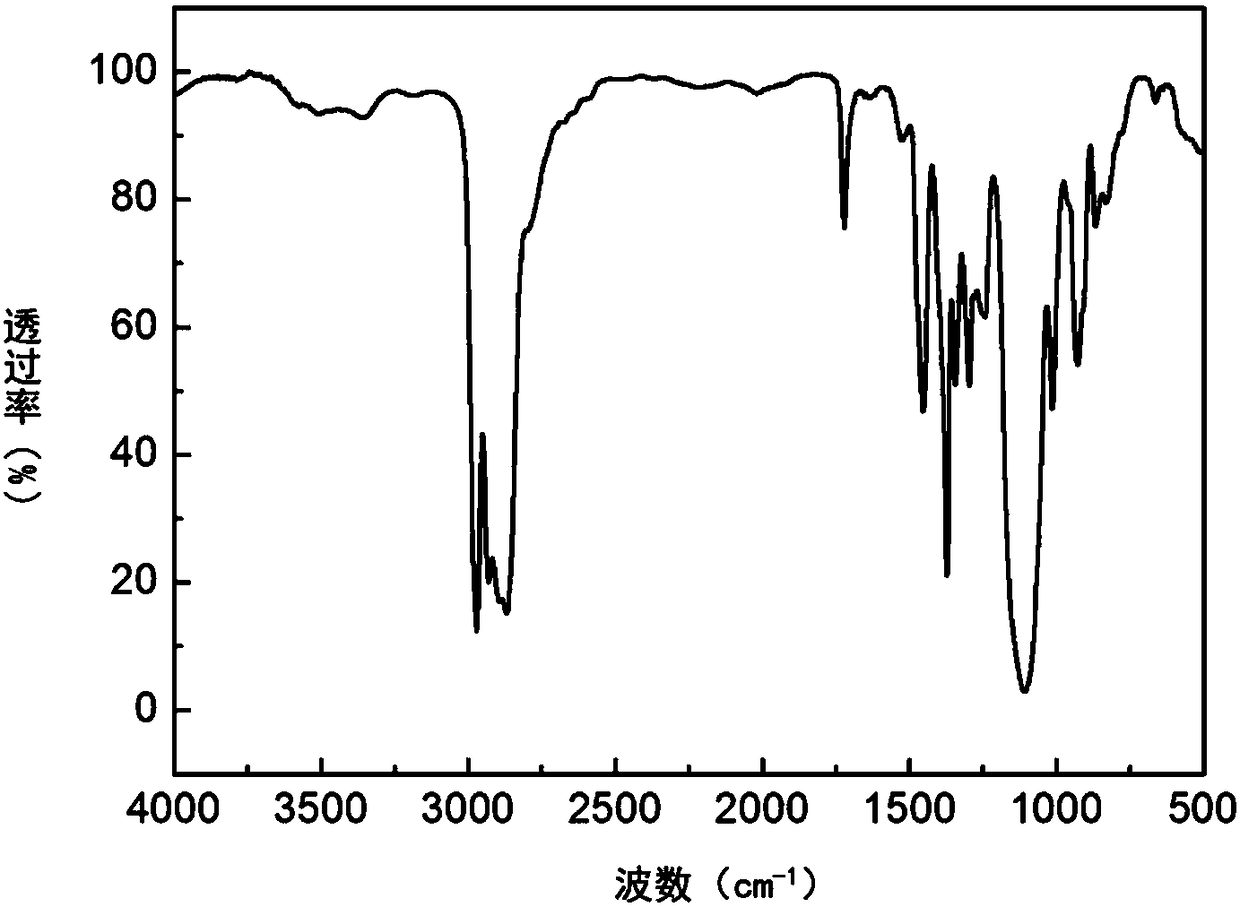

Embodiment 1

[0022] The first step: put 100kg of hydroxyl-terminated polyether after pre-water removal treatment into the reaction kettle, add 0.002kg of hydrogen-containing double head and 2*10 -6 kg of platinum catalyst, heated up to 30°C for 6 hours under the protection of nitrogen to obtain prepolymer 1. The second step: continue to add 0.008 kg of vinyltrimethoxysilane into the reaction kettle, and continue to react for 6 hours under the condition of maintaining the temperature at 90° C. to obtain the MS resin of the present invention. The infrared spectrum of the MS resin is as figure 1 shown.

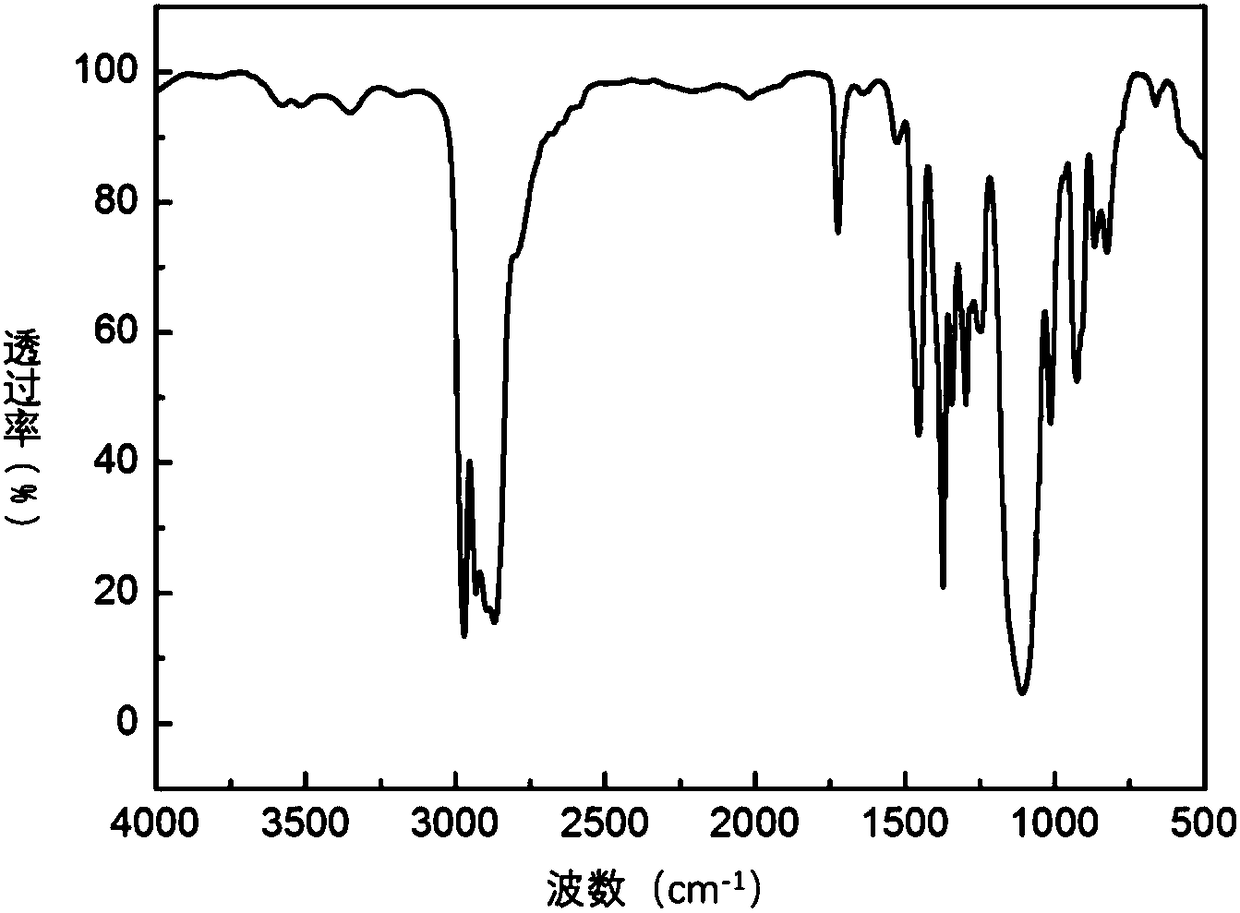

Embodiment 2

[0024] Step 1: Put 100kg of hydroxyl-terminated polyether after pre-dewatering treatment in the reactor, add 0.02kg of hydrogen-containing silicone oil with a hydrogen content of 0.5% (Foshan Huagu Silicone Co., Ltd.) and 2*10- 6kg of platinum catalyst was heated to 90°C for 4 hours under nitrogen protection to obtain prepolymer 1. The second step: continue to add 0.008 kg of γ-methacryloxypropyl trimethoxysilane into the reaction kettle, and continue to react for 6 hours under the condition of maintaining the temperature at 90° C. to obtain the MS resin of the present invention. The infrared spectrum of the MS resin is as figure 2 shown.

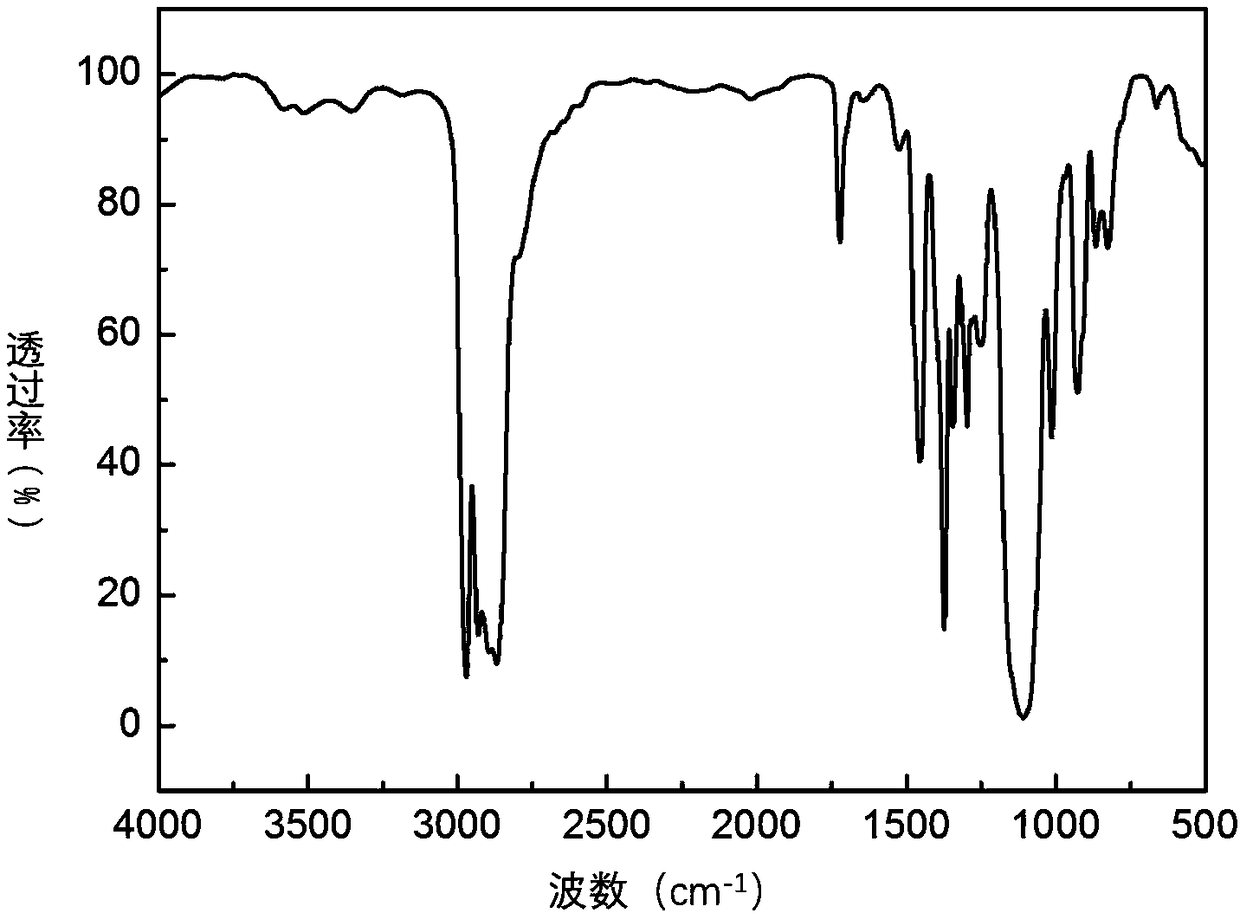

Embodiment 3

[0026] The first step: put 100kg of hydroxyl-terminated polyether after pre-water removal treatment into the reaction kettle, add 0.2kg of hydrogen-containing silicone oil with a hydrogen content of 0.5% (Foshan Huagu Silicone Co., Ltd.), under nitrogen protection The temperature was raised to 100°C for 6 hours to obtain prepolymer 1. The second step: continue to add 0.02kg γ-methacryloxypropyl trimethoxysilane and 0.03kg γ-methacryloxypropylmethyldimethoxysilane to the reactor, and keep the temperature at 110°C After continuing to react for 4h under the condition, the MS resin of the present invention was obtained. The infrared spectrum of the MS resin is as image 3 shown.

[0027] The MS resins prepared in Examples 1-3 have the performance parameters shown in Table 1 below.

[0028] Table 1

[0029] Example

Molecular weight Mn

Molecular weight distribution PDI

Viscosity cp

Exposure to air for 10 days

1

14800

1.31

10000~15000

n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com