Alpha crystal form nano alumina porous ceramic with high apparent porosity and preparation method thereof

A technology of nano-alumina and porous ceramics, which is applied in the field of nano-porous materials, can solve the problems of lower mechanical properties of products at high temperature, low decomposition temperature or combustion temperature, and a large amount of ash left by combustibles. The effect of small scale and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh γ-Al 2 o 3 1.5 g of powder, without any further treatment, was filled into a graphite mold with an inner diameter of 12 mm.

[0028] (2) Place the filled graphite mold in a spark plasma sintering furnace, vacuum sinter at 1100°C under an axial load pressure of 100MPa, and hold for 3 minutes to obtain alumina porous ceramics.

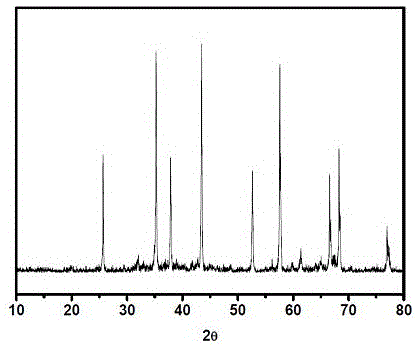

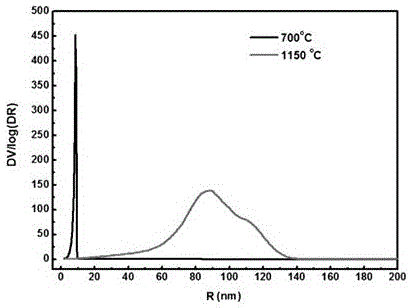

[0029] Carrying out X-ray diffraction analysis test to the obtained sintered product shows that ( figure 1 ), γ-Al 2 o 3 The powder is completely transformed into α-Al at 1100°C 2 o 3 . Mercury porosimetry was used to characterize the pores of the sintered body obtained by sintering at 1100°C and sintering at 700°C under the same conditions. The results showed that: γ-Al 2 o 3 The pore diameter of the powder accumulation is enlarged after the phase transformation is completed, and the pore diameter of the alumina porous ceramic obtained by sintering at 1100°C is 40-130nm ( figure 2 ), and the open porosity is 98.5%. The sinter...

Embodiment 2

[0031] (1) Weigh γ-Al 2 o 3 1.5 g of powder, without any further treatment, was filled into a graphite mold with an inner diameter of 12 mm.

[0032] (2) Place the filled graphite mold in a spark plasma sintering furnace, vacuum sinter at 1250°C under an axial load pressure of 100MPa, and hold for 3 minutes to obtain alumina porous ceramics.

[0033] Mercury porosimetry was used to characterize the pores of the sintered body. The results showed that the open porosity of the prepared alumina porous ceramics was 96.8%, and the pore diameter of the porous ceramics was 50-120nm. The porosity of the prepared alumina porous ceramics was measured to be 38% by drainage method. The strength test shows that the prepared alumina porous ceramics has a flexural strength of 185MPa. The observation results of the sintered products by scanning electron microscopy showed that ( Figure 4 ): α-Al 2 o 3 The average grain size of the alumina is 80-150nm. Even at 1250°C and 100MPa pressure, ...

Embodiment 3

[0035] (1) Weigh γ-Al 2 o 3 1.5 g of powder, without any further treatment, was filled into a graphite mold with an inner diameter of 12 mm.

[0036] (2) Place the filled graphite mold in a spark plasma sintering furnace, vacuum sinter at 1100°C under an axial load pressure of 30MPa, and hold for 3 minutes to obtain alumina porous ceramics.

[0037] Mercury intrusion porosity was used to characterize the pores of the sintered body. The results showed that the open porosity of the prepared alumina porous ceramics was 98.7%, and the pore diameter of the porous ceramics was 20-140nm. The sintered product was observed by scanning electron microscope, and the results showed that the worm-like α-Al was formed in the sintered body. 2 o 3 Pore framework, α-Al 2 o 3 The average grain size is 30~120nm. The porosity of the prepared alumina porous ceramics was measured to be 62% by drainage method. The strength test shows that the prepared alumina porous ceramics has a flexural str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com