Preparation method of konjac flying powder-coated fertilizer

A konjac fly powder and coating technology, applied in ammonium salt fertilizer, nitrogen fertilizer, fertilization device and other directions, can solve the problems of low utilization rate of fertilizer, irreversibility, waste of resources, etc., and achieve high coating rate, high compatibility, The effect of precise control of the amount of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Comparison of mechanical properties of fly powder and polyvinyl alcohol blend film, starch and polyvinyl alcohol blend film

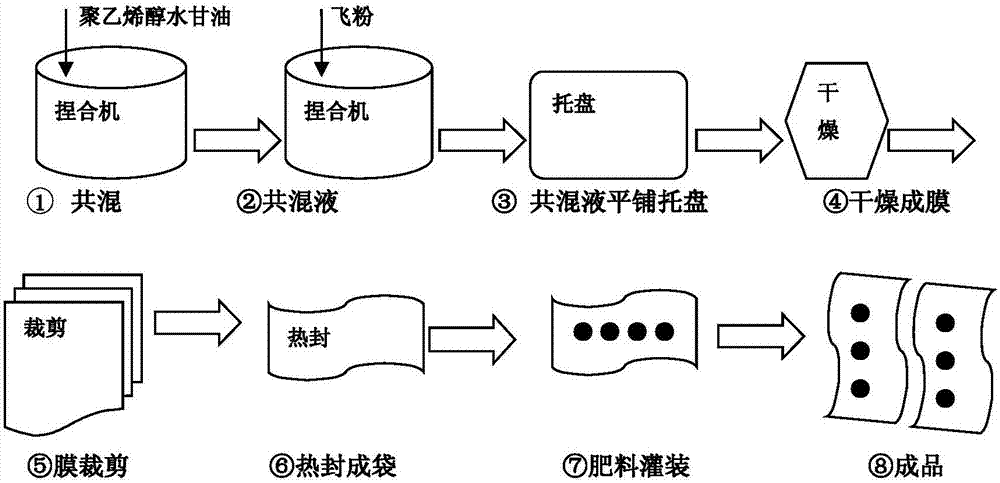

[0039] Such as figure 1 Shown, a kind of preparation method of konjac coated fertilizer comprises the steps:

[0040] 1) Take 3 parts of konjac flying powder, which are 3 grams, 6 grams and 9 grams respectively. 5 parts of polyvinyl alcohol, 15 grams each. 5 parts of water, each 300 milliliters (ie 300g). 5 parts of glycerin, 9 grams each. Starch 1 part, quality is 6 grams. The samples to be prepared are listed in Table 1 below.

[0041] The distribution ratio and performance of each sample group in table 1

[0042]

[0043] 2) Pour 1 part of polyvinyl alcohol, 1 part of water and 1 part of glycerin (that is, No. 1 in Table 1) selected in step 1) into a beaker. The water bath condition of the beaker is 95°C, and the heating time is 180 minutes;

[0044] 3) After step 2) is completed, pour the first portion of konjac flying po...

Embodiment 2

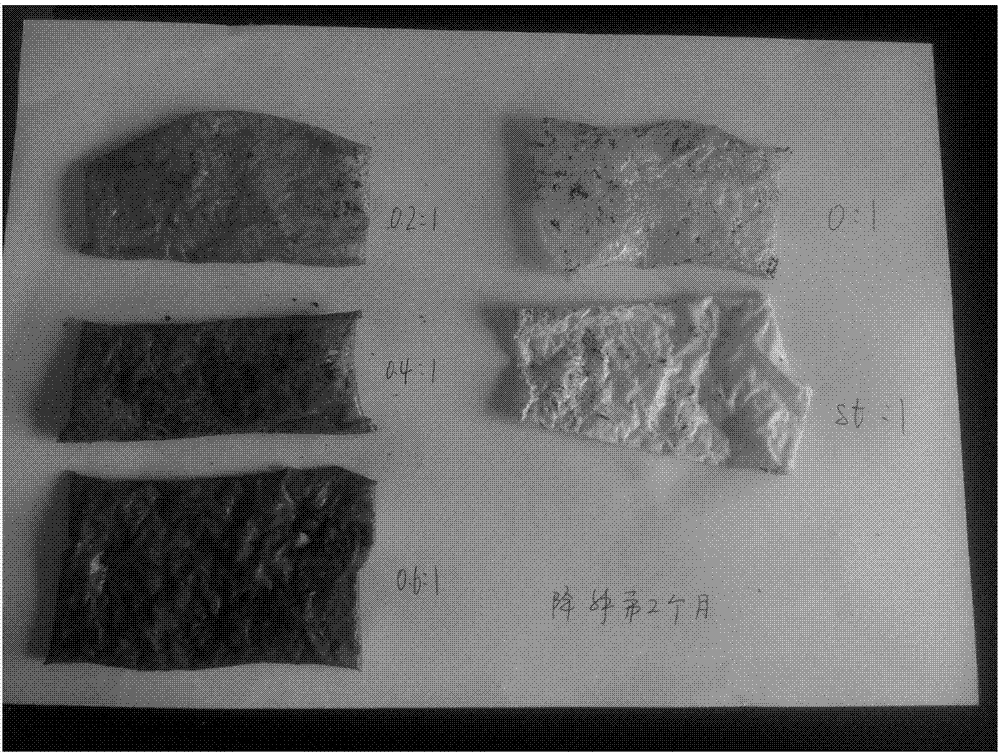

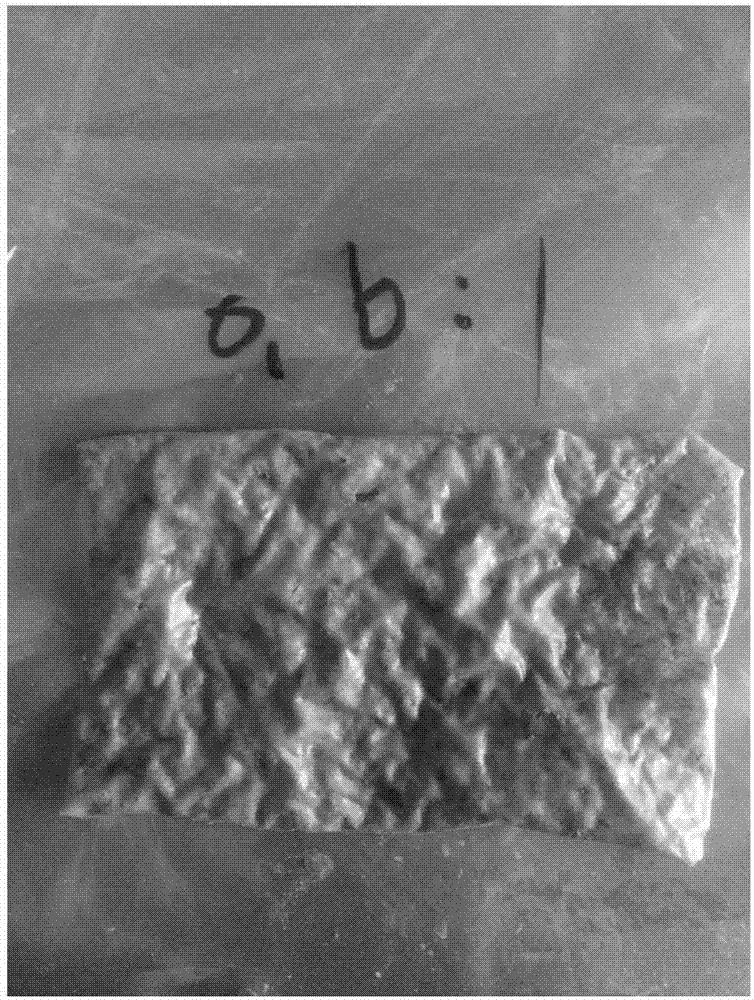

[0054] Example 2: Comparison of film degradation properties of fly powder-polyvinyl alcohol blends and starch blends

[0055] Film was prepared according to the formula in Table 1, and the method was the same as step 1)-step 5) in Example 1. Cut into 8.5*5.5cm, cut 12 pieces for each recipe, and bury it in yellow loam soil to degrade naturally for 12 months. The soil depth is 10cm. Take out one piece of each formula sample regularly every month, take pictures of mildew and damage, and observe the microstructure of scanning electron microscope. See the results of taking photos in the second month figure 2 , image 3 , Figure 4 and scan results of some samples such as Figure 7 , Figure 8 , Figure 9 . figure 2 , image 3 , Figure 4 The degradation performance of fly powder and polyvinyl alcohol blend film is obviously higher than that of starch and polyvinyl alcohol blend film and polyvinyl alcohol film. Figure 7 , Figure 8 , Figure 9 It shows that the fly ...

Embodiment 3

[0058] Example 3: Comparison of slow-release performance of fly powder-polyvinyl alcohol blend and starch blend coated fertilizer

[0059] Film was prepared according to the formula in Table 1, and the method was the same as step 1)-step 5) of Example 1. Uncover the film, and cut each film diagonally into 2 pieces. Then fold it diagonally, seal one side with a sealing machine, pour 5 grams of urea into it, and seal it. The coated fertilizer bag and the coated fertilizer are as follows: Figure 5-6 . The prepared coated fertilizer is put into a beaker with 100 milliliters of distilled water, and the beaker is placed in a constant temperature water bath at a temperature of 25°C. The fertilizer in the coated fertilizer is slowly released into the distilled water in the beaker, and the release period is 28 days. On the 24th, 4th, 8th, 12th, 16th, 20th, 24th, and 28th days of release, take 10 ml of the sustained-release solution from the beaker and immediately add 10 ml of distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com