Multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling temperature

A low-temperature evaporation and concentration system technology, which is applied in the fields of industrial technology, energy and environmental protection, can solve the problems of reducing the available heat for heating materials, affecting steam, and reducing system energy efficiency, so as to reduce the possibility of adhesion or coking and ensure vacuum pressure , The effect of improving the energy efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present application are described in detail below in conjunction with specific embodiments.

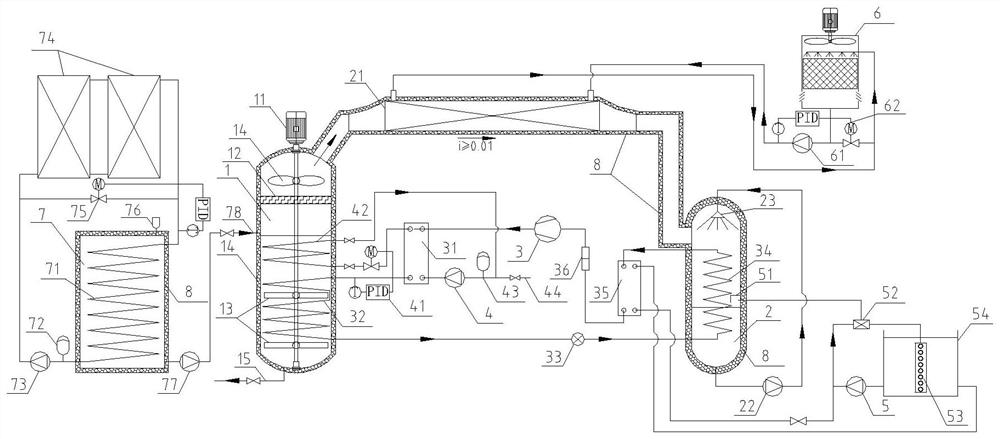

[0050] According to the present invention, the multi-energy cascade heat pump low-temperature evaporation and concentration system capable of precise temperature control includes a heating tank, a steam cooling and condensation system, a heat pump circulation system, a vacuum pumping and recondensation system, a water circulation temperature adjustment system, a heat dissipation system, and a material pretreatment system. thermal system, where,

[0051] A stirring motor is arranged above the outside of the heating tank, a fan blade, a defoaming device, and a stirring blade are arranged inside the heating tank, and a concentrated material liquid outlet pipe is arranged at the bottom, and the stirring motor provides the power for the stirring blade and the fan blade to rotate, and the heating The tank is provided with an insulation layer;

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com