Multistage-cascaded compression type heat pump set under large temperature difference

A compression heat pump, large temperature difference technology, applied in compressors, compressors with multiple evaporators, compressors with multiple condensers, etc., can solve the problem of reduced system performance coefficient and reduced energy utilization efficiency , evaporating pressure reduction and other problems, to achieve the effect of improving the comprehensive energy utilization efficiency and economy of the system, increasing the cooling capacity and system energy efficiency, and reducing the irreversible heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

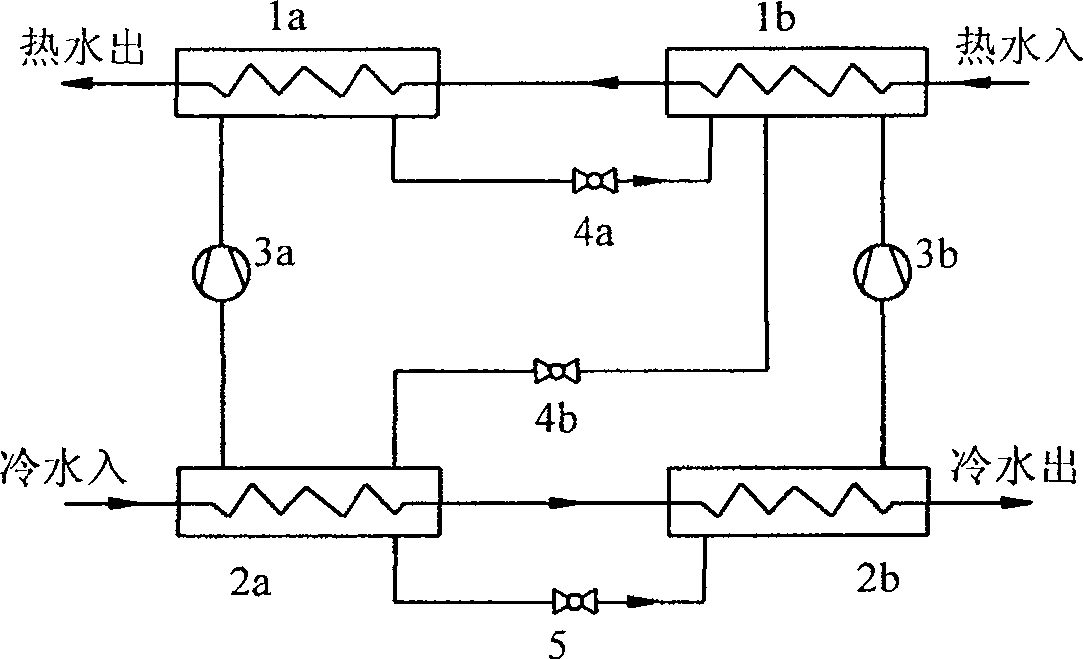

[0016] Example 1: Two-stage series-connected large temperature difference compression heat pump unit

[0017] Such as figure 1 As shown, the heat pump unit has a first-stage evaporator 2a, a first-stage compressor 3a, a first-stage condenser 1a, a first-stage condenser outlet refrigerant throttle device 4a, a first-stage evaporator outlet refrigerant section Flow device 5a, second-stage evaporator 2b, second-stage compressor 3b, second-stage condenser 1b, second-stage condenser outlet refrigerant throttling device 4b. Wherein, the pressure of the first-stage condenser 1a is greater than the pressure of the second-stage condenser 1b, the pressure of the second-stage condenser 1b is greater than the pressure of the first-stage evaporator 2a, and the pressure of the first-stage evaporator 2a is greater than the pressure of the second-stage evaporator 2b. The superheated or saturated refrigerant vapor from the first-stage evaporator 2a is compressed by the first-stage compressor ...

Embodiment 2

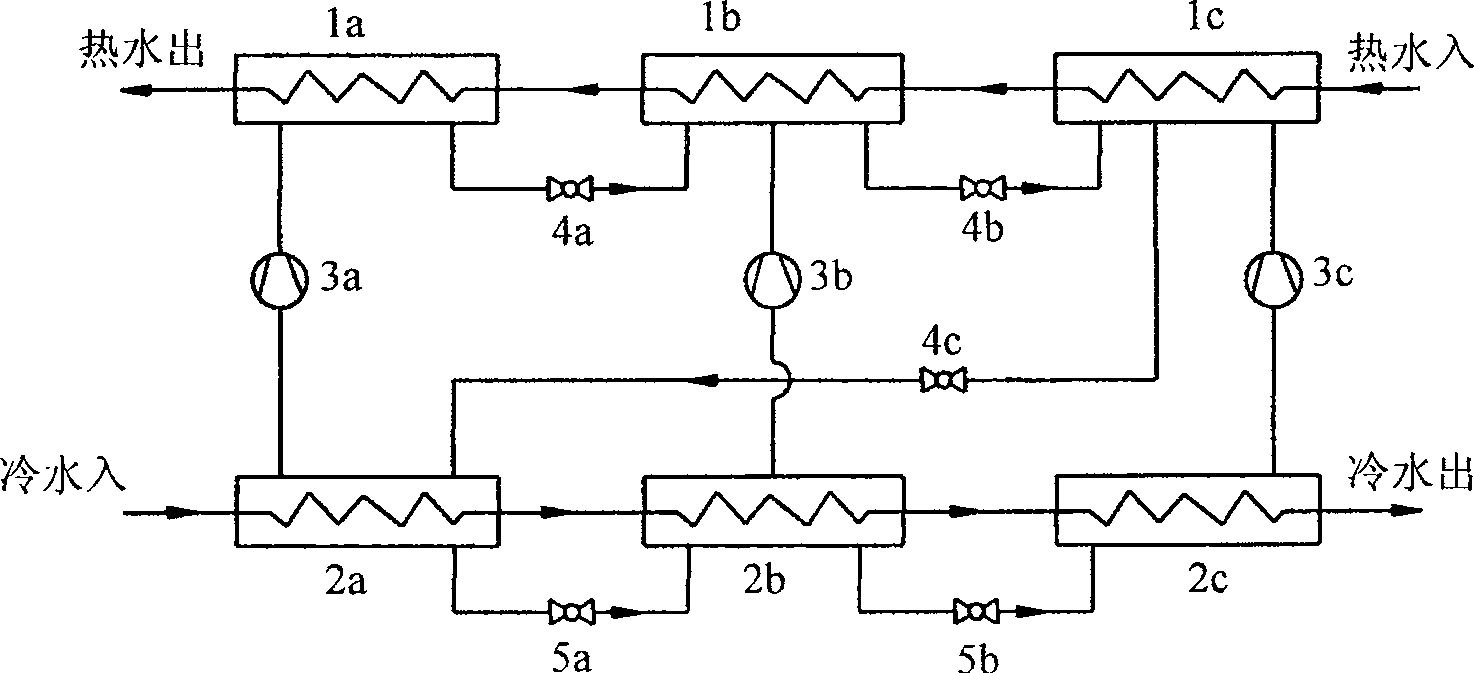

[0018] Example 2: Three-stage series-connected large temperature difference compression heat pump unit

[0019] Such as figure 2As shown, the heat pump unit has a first-stage evaporator 2a, a first-stage compressor 3a, a first-stage condenser 1a, a first-stage condenser outlet refrigerant throttle device 4a, a first-stage evaporator outlet refrigerant section Flow device 5a and second-stage evaporator 2b, second-stage compressor 3b, second-stage condenser 1b, second-stage condenser outlet refrigerant throttling device 4b, second-stage evaporator outlet refrigerant throttling device 5b And the third-stage evaporator 2c, the third-stage compressor 3c, the third-stage condenser 1c, and the third-stage condenser outlet refrigerant throttling device 4c. Wherein, the pressure of the first-stage condenser 1a is greater than the pressure of the second-stage condenser 1b, the pressure of the second-stage condenser 1b is greater than the pressure of the third-stage evaporator 1c, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com