Sulfur-containing malodorous gas adsorbent and preparation method thereof

A technology of malodorous gas and adsorbent, which is applied in the field of sulfur-containing malodorous gas adsorbent and its preparation, can solve the problems of unsuitable industrial production, fine particle size of molecular sieve, and difficult treatment of waste liquid, etc., and achieves easy operation, low cost, and no pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] After fully mixing 200g type A molecular sieve, 60g aluminum sol, 50g kaolin and 100g water, knead the lumpy mud, solidify the lumpy mud at room temperature for 2 hours, and then extrude the mud into strips with a vacuum extrusion molding machine , then dried at 105°C for 1.5h, and calcined at 550°C for 3 hours to make adsorbent PZ-1.

Embodiment 2

[0024] After mixing 200g type A molecular sieve with 60g silica sol, 50g kaolin and 100g water, knead the lumpy mud, solidify the lumpy mud at room temperature for 2 hours, and then extrude the mud into strips with a vacuum extrusion molding machine. Then it was dried at 105°C for 1.5h and calcined at 550°C for 3 hours to make adsorbent PZ-2.

Embodiment 3

[0026] After mixing 200g shape-selective molecular sieve, 60g squash powder, 50g kaolin and 100g water, knead the lumpy mud, solidify the lumpy mud at room temperature for 2 hours, and then extrude the mud into strips with a vacuum extrusion molding machine shape, then dried at 105°C for 1.5h, and calcined at 550°C for 3 hours to make adsorbent PZ-3.

[0027] Adsorbent Physical Properties

[0028] Bulk density: 0.66-0.75g / cm3

[0029] Appearance: white strip

[0030] Specific table: 270-350m2 / g

[0031] Compressive strength: 120-160N / cm

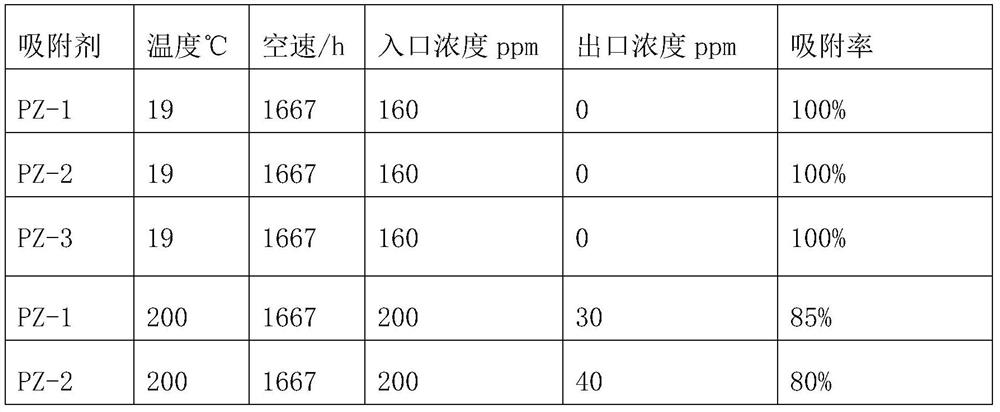

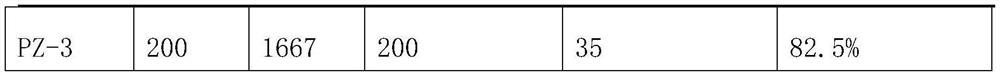

[0032] Put 30ml of the adsorbent prepared above into the evaluation device for evaluation, and the adsorption effect is compared as follows:

[0033]

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com