Method for producing molten iron through powdery iron ore suspension state direct reducing-electric arc furnace smelting

An electric arc furnace smelting and iron ore technology, applied in the field of metallurgy, can solve the problem of high foreign dependence of iron ore resources, and achieve the effects of high heat utilization efficiency, energy saving and no heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

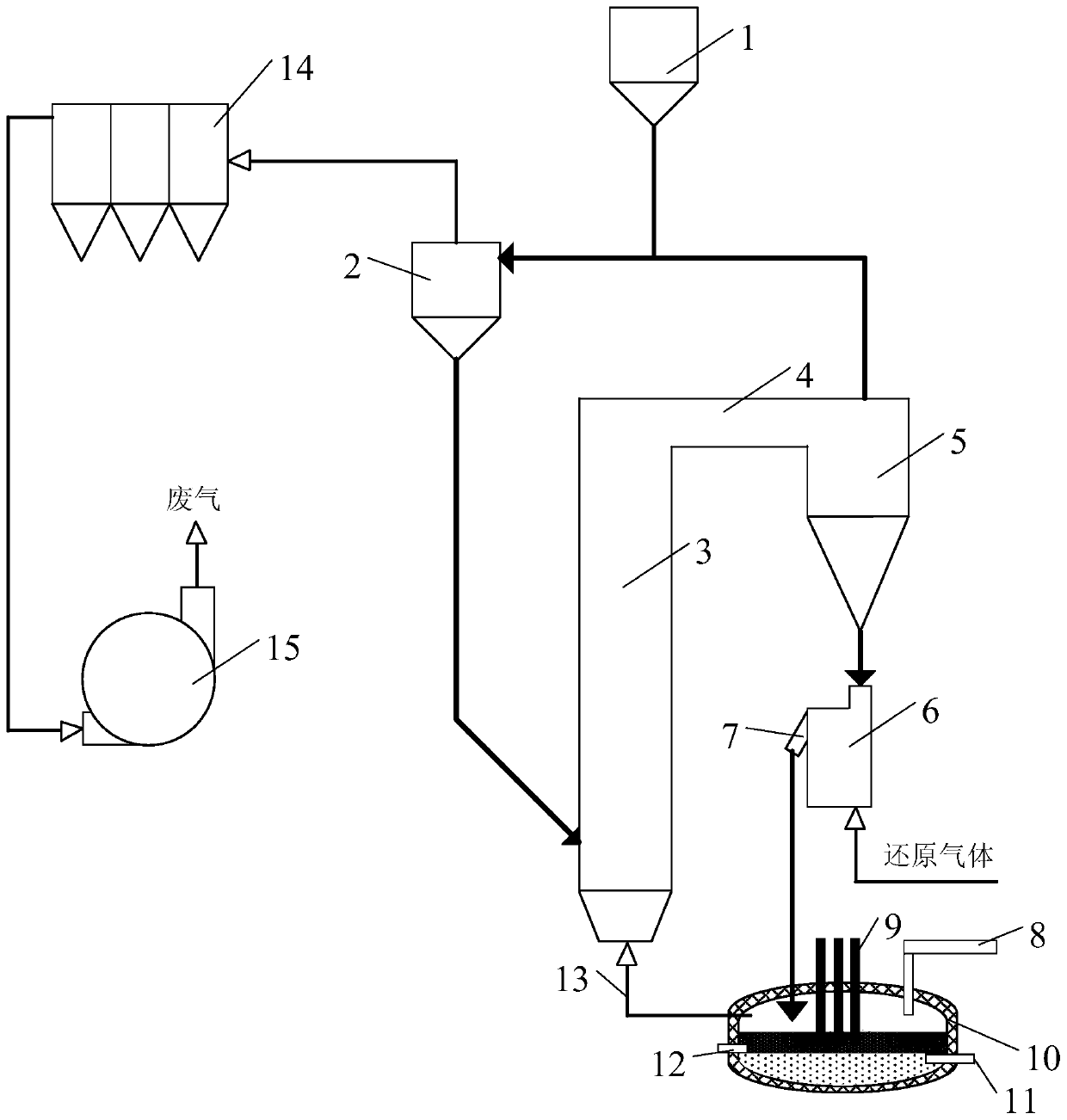

[0035] A certain powdery iron ore contains TFe 55.88%, FeO 0.30%, SiO 2 3.01%, Al 2 o 3 7.28%, CaO 0.10%, MgO 10.2%, P 0.08%, S 0.03%, the particle size of -0.074mm accounts for 40% of the total weight;

[0036]The powdered iron ore is transported to the first-stage cyclone separator through the silo, and the first-stage solid material is separated and enters the lower part of the suspension heating furnace; the air outlet of the first-stage cyclone separator is connected with the air inlet of the dust collector, and the dust collector The gas outlet of the suspension heating furnace is connected with the induced draft fan; the bottom of the suspension heating furnace is connected with the high temperature flue gas outlet of the electric arc furnace. Level solid material heating;

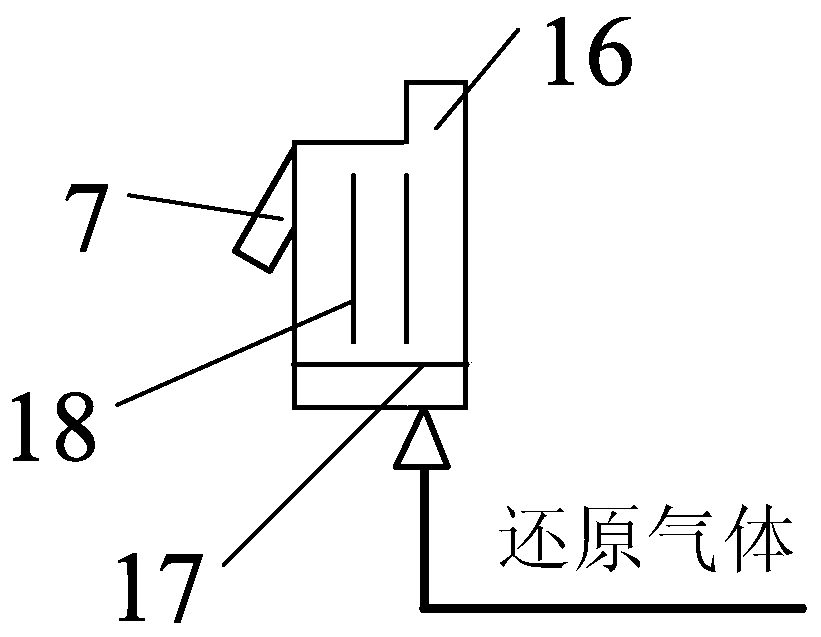

[0037] The gas outlet of the secondary cyclone separator is connected with the feed port of the primary cyclone separator, and the discharge port of the secondary cyclone separator is connected...

Embodiment 2

[0047] A powdered iron ore containing TFe 56.58%, FeO 0.13%, SiO 2 7.81%, Al 2 o 3 3.02%, CaO 0.10%, MgO 0.11%, P 0.08%, S 0.04%, the particle size of -0.074mm accounts for 50% of the total weight;

[0048] Method is with embodiment 1, and difference is:

[0049] (1) The flux is calcium oxide, and the amount of flux added is to control the basicity of the slag layer at 1.50;

[0050] (2) The temperature of the high-temperature flue gas is 1040°C, and the temperature when the primary solid material enters the secondary cyclone separator after heating is 810°C; the volume flow rate of the high-temperature flue gas in the suspension heating furnace and the mass flow rate of the primary solid material Scale is 0.1m 3 / kg; the ratio of the volume flow rate of the reducing gas in the reduction reactor to the mass flow rate of the secondary solid material is 0.06m 3 / kg, the residence time of the secondary solid material in the reduction reactor is 40min, and the temperature o...

Embodiment 3

[0056] A certain powdery iron ore contains TFe 61.92%, FeO 12.06%, SiO 2 3.53%, Al 2 o 3 7.81%, CaO 0.10%, MgO 0.16%, P 0.09%, S 0.02%, the particle size of -0.074mm accounts for 80% of the total weight;

[0057] Method is with embodiment 1, and difference is:

[0058] (1) The flux is an equal mass mixture of limestone and calcium oxide, and the amount of flux added is at 2.00 to control the alkalinity of the slag layer;

[0059] (2) The temperature of the high-temperature flue gas is 1130°C, and the temperature when the primary solid material enters the secondary cyclone separator after heating is 910°C; the volume flow rate of the high-temperature flue gas in the suspension heating furnace and the mass flow rate of the primary solid material Scale is 0.2m 3 / kg; the ratio of the volume flow rate of the reducing gas in the reduction reactor to the mass flow rate of the secondary solid material is 0.08m 3 / kg, the residence time of the secondary solid material in the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com