Ferric ion reduction method

A ferric iron and ion technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as low conversion rate, and achieve low operating conditions, simple reduction process, and simple and easy preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

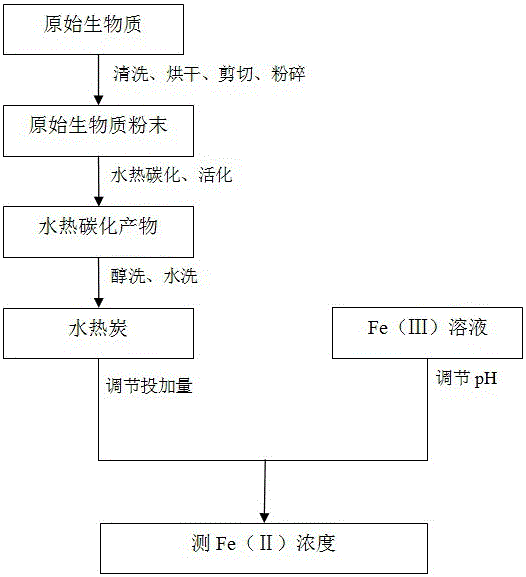

[0030] In this example, see figure 1 and figure 2 , ferric ion reduction method, comprises the following steps:

[0031] a. Raw material preparation: Wash the collected raw biomass with distilled water, air-dry it, and then dry it in a blast drying box at 105°C, then pulverize it with a pulverizer, and sieve it to obtain Carbon biomass dry powder;

[0032] b. Preparation of hydrothermal biochar: Weigh 10g of the carbon-containing biomass dry powder sieved in the above step a, mix it with 50ml of distilled water and place it in a high-pressure reactor, and pass nitrogen at a rate of 100ml / min for 10 minutes to remove oxygen After sealing, control the hydrothermal temperature in the autoclave to 240°C. After heating the reactants in the autoclave for 4 hours, take out the hydrothermal carbonization product from the autoclave, let it cool at room temperature, and then carbonize the hydrothermal The product was repeatedly washed with absolute ethanol and distilled water until ...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, especially in that:

[0039] In the present embodiment, the ferric ion reduction method comprises the following steps:

[0040] a. raw material preparation: same as embodiment one;

[0041] b. Preparation of hydrothermal biochar: same as Example 1;

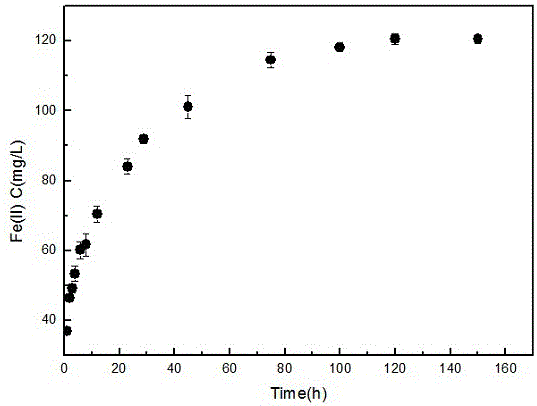

[0042] c. Reduction process: Weigh the hydrothermal biochar powder prepared in the above step b, and add Fe with a concentration of 100 mg / L and pH=2±0.1 to the hydrothermal biochar powder at a dosage of 1 g / L. 3+ In the solution, the reduction reaction was carried out for 120h, and Fe was obtained after the reduction reaction 2+ solution, get the solution after the reaction of the present embodiment that detects required amount and carry out rapid filtration, adopt o-phenanthroline spectrophotometry to measure its Fe 3+ and Fe 2+ Concentration, by comparing and calculating the test results, the Fe of the present embodiment 3+ The reduction rate is 100%, see imag...

Embodiment 3

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In the present embodiment, the ferric ion reduction method comprises the following steps:

[0046] a. raw material preparation: same as embodiment one;

[0047] b. Preparation of hydrothermal biochar: same as Example 1;

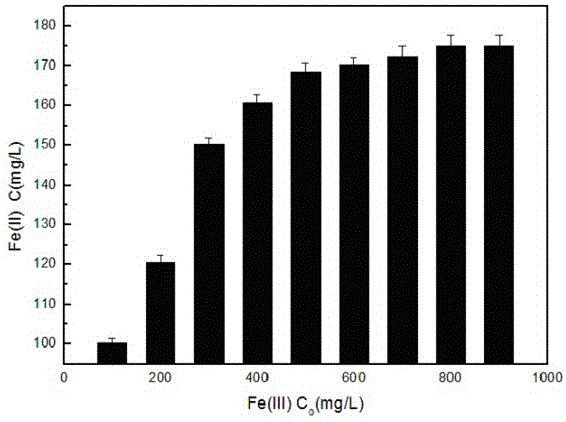

[0048] c. Reduction process: Weigh the hydrothermal biochar powder prepared in the above step b, and add Fe with a concentration of 300 mg / L and pH=2±0.1 to the hydrothermal biochar powder at a dosage of 1 g / L. 3+ In the solution, the reduction reaction was carried out for 120h, and Fe was obtained after the reduction reaction 2+ solution, get the solution after the reaction of the present embodiment that detects required amount and carry out rapid filtration, adopt o-phenanthroline spectrophotometry to measure its Fe 3+ and Fe 2+ Concentration, by comparing and calculating the test results, the Fe of the present embodiment 3+ 50% reduction, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com