Soil nitrification inhibitor slow-release body containing sodium carboxymethyl cellulose and preparation method thereof

A technology of sodium carboxymethyl cellulose and nitrification inhibitor, which is applied in the field of soil nitrification inhibitor slow-release body and its preparation, can solve the problem of limiting the application range and application effect of DMPP, uniform and effective distribution of difficult product components, and spray drying equipment. High requirements are required to achieve good denitrification performance, good embedding capacity, and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

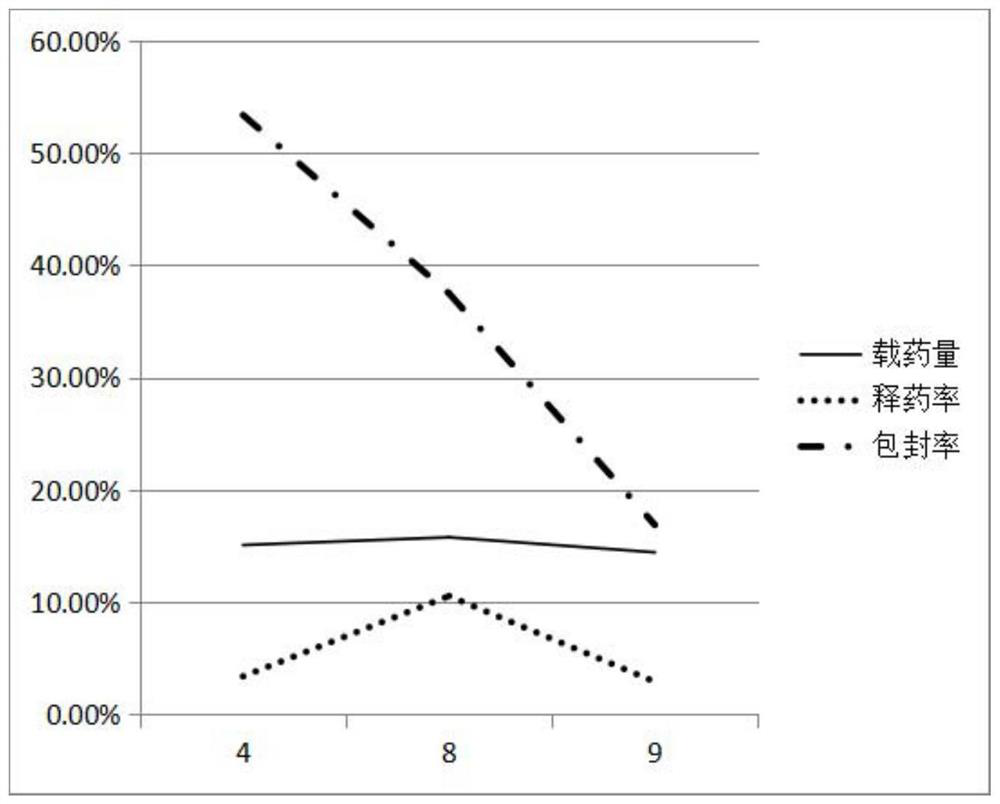

Examples

Embodiment 1

[0029] A soil nitrification inhibitor slow-release body containing sodium carboxymethylcellulose, comprising 0.5g of polyvinyl alcohol, 0.375g of sodium carboxymethylcellulose, and 1.125g of dimethyl phosphate, by mass percentage, polyethylene Alcohol accounts for 20 parts, sodium carboxymethylcellulose accounts for 15 parts, and dimethyl methylphosphonate accounts for 45 parts.

[0030] The preparation method of the soil nitrification inhibitor sustained-release body containing sodium carboxymethyl cellulose comprises the following steps:

[0031] (1) Prepare polyvinyl alcohol solution; weigh 0.5g of polyvinyl alcohol in a beaker, add 100ml of deionized water, put it in a water bath, stir at 80°C to 100°C until completely dissolved; then place it at room temperature, Stir continuously with a magnetic stirrer, set aside;

[0032] (2) Prepare slow-release body solution; weigh 0.375g of sodium carboxymethylcellulose and 1.125g of dimethyl methylphosphonate in a beaker, add 15ml...

Embodiment 2

[0036] A soil nitrification inhibitor slow-release body containing sodium carboxymethyl cellulose, comprising 0.625 g of polyvinyl alcohol, 0.5 g of sodium carboxymethyl cellulose, and 1.375 g of dimethyl phosphate, by mass percentage, polyethylene Alcohol accounts for 25 parts, sodium carboxymethylcellulose accounts for 20 parts, and dimethyl methylphosphonate accounts for 55 parts.

[0037] The preparation method of the soil nitrification inhibitor sustained-release body containing sodium carboxymethyl cellulose comprises the following steps:

[0038] (1) Prepare polyvinyl alcohol solution; weigh 0.625g of polyvinyl alcohol in a beaker, add 100ml of deionized water, put it in a water bath, stir at 80°C to 100°C until completely dissolved; then place it at room temperature, Stir continuously with a magnetic stirrer, set aside;

[0039] (2) Prepare the sustained-release body solution; weigh 0.5 g of sodium carboxymethyl cellulose and 1.375 g of dimethyl methylphosphonate in a...

Embodiment 3

[0043] A soil nitrification inhibitor slow-release body containing sodium carboxymethyl cellulose, comprising 1.0 g of polyvinyl alcohol, 0.625 g of sodium carboxymethyl cellulose, and 1.5 g of dimethyl phosphate, by mass percentage, polyethylene Alcohol accounts for 40 parts, sodium carboxymethylcellulose accounts for 25 parts, and dimethyl methylphosphonate accounts for 60 parts.

[0044] The preparation method of the soil nitrification inhibitor sustained-release body containing sodium carboxymethyl cellulose comprises the following steps:

[0045] (1) Prepare polyvinyl alcohol solution; weigh 1.0g of polyvinyl alcohol into a beaker, add 100ml of deionized water, put it in a water bath, stir at 80°C to 100°C until completely dissolved; then place it at room temperature, Stir continuously with a magnetic stirrer, set aside;

[0046] (2) Prepare the sustained-release body solution; weigh 0.625g of sodium carboxymethylcellulose and 1.5g of dimethyl methylphosphonate in a beak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com