Mayenite-structure fluorescent powder for white light emitting of LED

A phosphor and mayenite technology, applied in the field of rare earth luminescent materials, can solve the problems of phosphor lack of red band, low color rendering index, complex control circuit, etc., to overcome the difference in light color decay speed and color reabsorption, Simple preparation process and long fluorescence lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

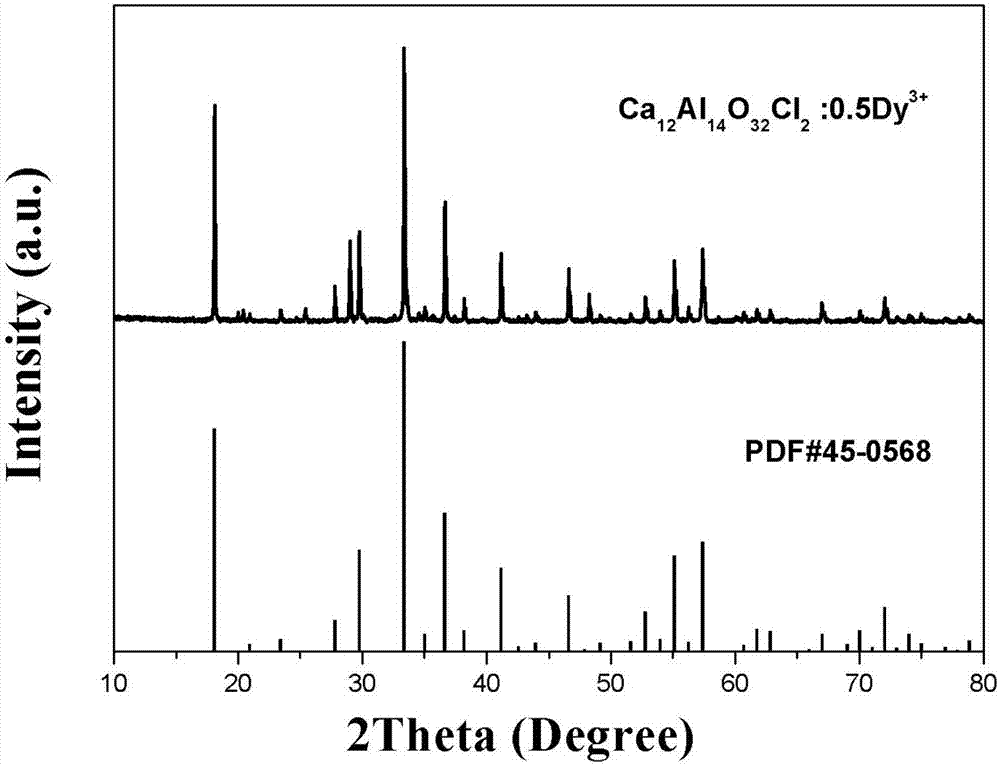

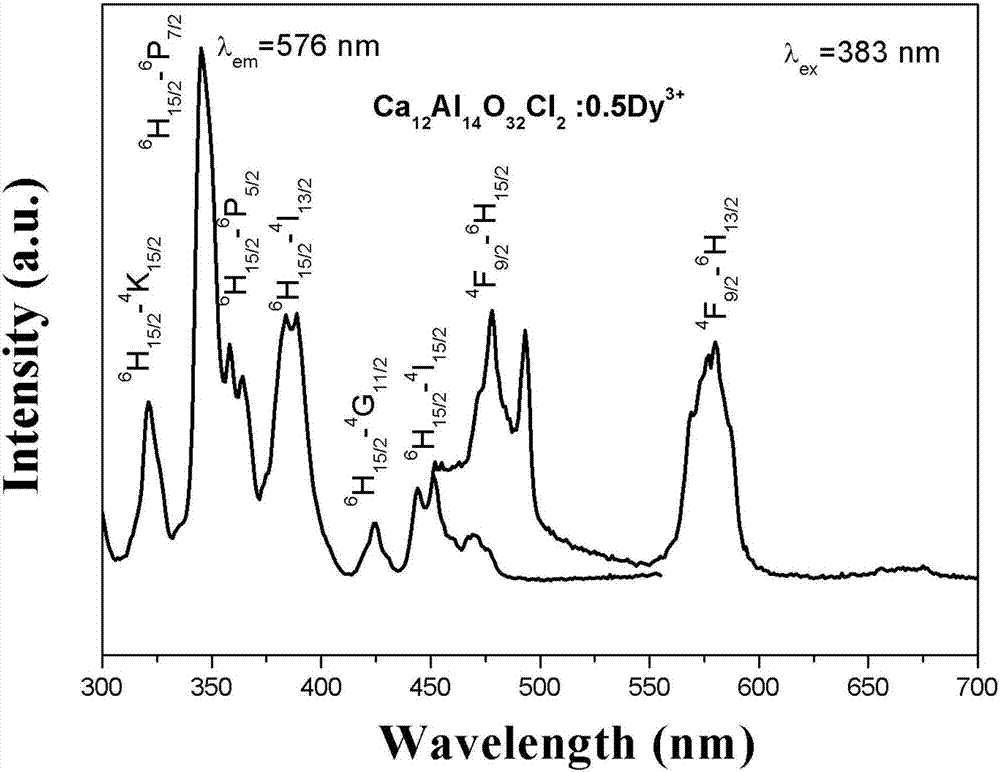

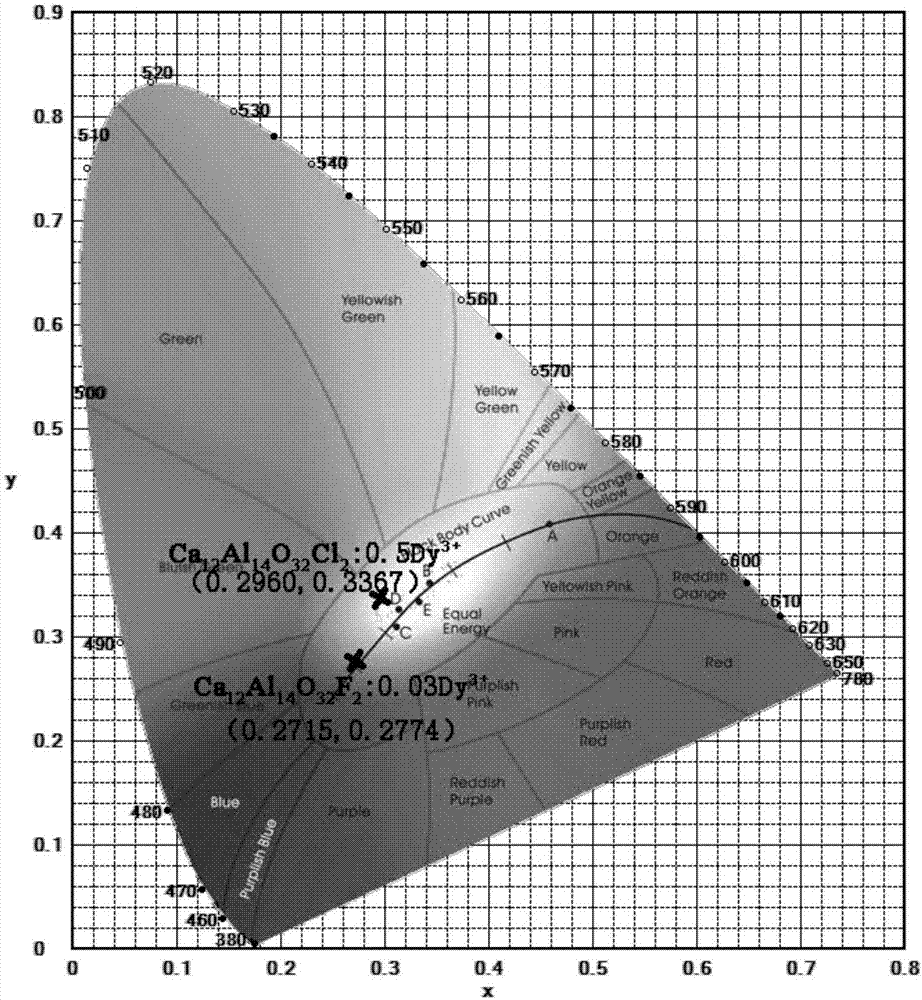

[0031] The present embodiment LED uses the mayenite structure fluorescent powder that white light emits, and the chemical structural formula of this fluorescent powder is as follows: Ca 12 Al 14 o 32 Cl 2 :0.5Dy 3+ .

[0032] The preparation method is: weigh CaO (analytical pure) 1.2338g, Al 2 o 3 (Analytical pure) 1.4274g, CaCl 2 (Analytical pure) 0.2220g, Dy 2 o 3 (99.99%) 0.1850 g. The above-mentioned raw materials are uniformly mixed and put into a mortar for thorough grinding, then put into a corundum crucible, and then high-temperature solid-phase synthesis is carried out under an air atmosphere. In this embodiment, the calcination temperature is set at 1200° C., and the calcination time is 15 hours. After the muffle furnace is cooled to room temperature, the sample is taken out and fully ground to obtain a mayenite structure phosphor sample for LED white light emission. The chemical structural formula of the phosphor is Ca 12 Al 14 o 32 Cl 2 :0.5Dy 3+ . ...

Embodiment 2

[0036] The present embodiment LED uses the mayenite structure fluorescent powder that white light emits, and the chemical structural formula of this fluorescent powder is as follows: Ca 12 Al 14 o 32 f 2 :0.03Dy 3+ .

[0037] The preparation method is: weigh CaO (analytical pure) 1.2338g, Al 2 o 3 (Analytical pure) 1.4274g, CaF 2 (Analytical pure) 0.1562g, Dy 2 o 3 (99.99%) 0.0111 g. The above-mentioned raw materials are uniformly mixed and fully ground, then put into a corundum crucible, and then high-temperature solid-phase synthesis is carried out under an air atmosphere. In this embodiment, the calcination temperature is set at 1200° C., and the time is 15 hours. After the muffle furnace is cooled to room temperature, the sample is taken out and fully ground to obtain the sample Ca 12 Al 14 o 32 f 2 :0.03Dy 3+ .

[0038] Test the phase structure of the sample with D8Advance X-ray diffractometer, by this sample and Ca 12 Al 14 o 32 f 2 Comparison of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com