Organosilicone hybrid and organosilicone composite paint and preparations thereof

A composite coating and organosilicon technology, applied in the coating and other directions, can solve the problems of complex preparation, long surface drying time, high cost of high temperature resistant coatings, and achieve the effects of simple preparation process, simple preparation method and environmental protection of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Take 50g of methyltriethoxysilane, 50g of dimethyldiethoxysilane, 10g of distilled water, and 0.5g of dibutyltin dilaurate and stir evenly, reflux and hydrolyze at 80°C for 8 hours, and remove the water after the reaction A reactive silicone component is obtained.

[0053] (2) Take 100g of the active silicone component obtained in step (1), 20g of γ-(methacryloyloxy)propyltrimethoxysilane, 3g of dibutyltin dilaurate, and 10g of distilled water and mix well , The organosilicon hybrid was prepared after reflux reaction at 60°C for 10 hours. The number average molecular weight obtained by gel gas chromatography was 8470.

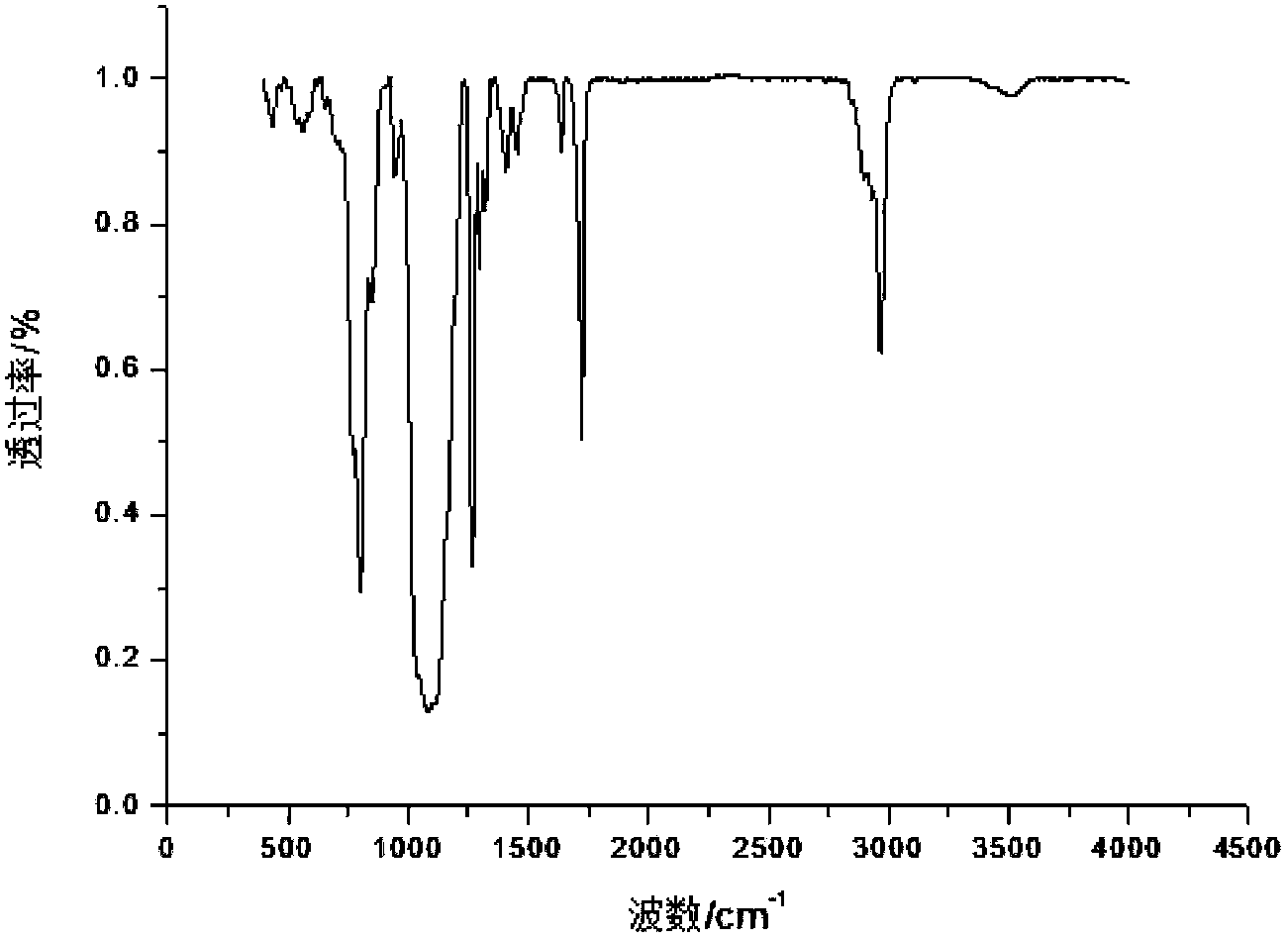

[0054] The main absorption peaks of the FT-IR spectrum of this organosilicon hybrid (such as figure 1 As shown): 800cm -1 、1270cm -1 、2970cm -1 The sharp absorption peak of Si-CH 3 vibration absorption peak, 1100cm -1 The strong and broad absorption peaks on the left and right are the absorption peaks of Si-O-Si, 1640cm -1 The absorption peak...

Embodiment 2

[0057] (1) Mix 50g of phenyltriethoxysilane, 50g of dimethyldimethoxysilane, 3g of triethylamine, 1g of distilled water and 50g of ethanol and stir evenly; then condense and reflux at 80°C After reacting for 6 hours, the water was removed to obtain the active silicone component.

[0058] (2) Mix 100g of the active silicone component obtained in step (1), 40g of vinyltriethoxysilane, 2g of dibutyltin diacetate and 20g of distilled water, and condense and reflux at 80°C The organosilicon hybrid was prepared by reacting for 8 hours.

[0059] (3) Dissolve 100g of the organosilicon hybrid obtained in step (2) into 40g of ethyl acetate, continue to add 8g of 1,6-hexanediol diacrylate, 8g of ethoxylated trimethylolpropane triacrylic acid Esters, 0.5g of isopropylthioxanthone, 0.5g of 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-propanone, 2g of tributyl phosphate, 15g Organobentonite, 35g talcum powder, 20g nano-silicon dioxide, 20g glass powder and 15g kaolin were mixed uniforml...

Embodiment 3

[0061] (1) Take 20g of ethyl orthosilicate, 40g of dimethyldiethoxysilane, 40g of phenyltrichlorosilane, 10g of distilled water and 6g of boric acid, mix them evenly, and reflux at 80°C for 8 hours. After the reaction The active silicone component is obtained after the water is drawn off.

[0062] (2) Take 100g of the active silicone component obtained in step (1), 60g of propenyltrichlorosilane, 1g of dibutyltin diacetate and 30g of distilled water, mix them evenly, and condense and reflux at 100°C for 5 hours to obtain Silicone hybrid.

[0063] (3) Dissolve 100g of the organosilicon hybrid obtained in step (2) into 60g of xylene, continue to add 20g of ethoxylated triglyceride diacrylate, 1.5g of benzoin dimethyl ether, 3g of p-phenylenediamine, 15g of organobentonite, 20g of mica powder, 25g of nano silicon dioxide, 15g of glass powder and 30g of titanium dioxide were uniformly mixed to obtain a high temperature resistant silicone composite coating C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com